Manual Multi Spindle Drilling Machine

Get Price Quote

We are staffed with professionals and under their guidance; we keep a close check on the products and ensure that the range is as per the exact customers' requirements. We are a notable name in the domain offering the best in class and quality Manual Multi Spindle Drilling Machine.

Itco Drilling machine

Get Price Quote

5 Piece (MOQ)

Best Deals from Heavy Duty Drill

Drilling Machine

Get Price Quote

We offer the best quality Drilling Machine. The company is a reliable and respected Supplier of Drilling Machine.

cnc drill machine

Get Price Quote

Heavy Duty Pillar Type Drilling Machine

Get Price Quote

Heavy Duty Pillar Type Drilling Machine, manufacturer, exporter & Supplier by us, is precision engineered and gives cutting edge performance. Fabricated using top grade raw materials, Heavy Duty Pillar Type Drilling Machine, that we provide, is robustly constructed and gives lifelong hassle free performance. Heavy Duty Pillar Type Drilling Machine is suitable for various industrial applications.

AUTOMATIC REBAR COUPLER DRILLING AND CUTTING MACHINE

Get Price Quote

AUTOMATIC REBAR COUPLER DRILLING AND CUTTING MACHINE The Automatic Rebar Coupler Drilling and Cutting Machine is used to drilling and cutting the rebar coupler according to the desired length required. The drilling and cutting of the rebar couplers are normally in 2~3 minutes. This Rebar Coupler Drilling and Cutting Machine is used for high speed coupler making process. Automatic Rebar Coupler Drilling and Cutting Machine they are building is made up the best quality raw material, using the best and latest technology and the most advanced machine just to make this machine work for long years without any symptoms of the system crash or malfunction. Owing to the unstoppable qualities of our hydraulic surface grinder machine-like being best in accuracy, durability, efficiency, compatibility, reliability, handiness and extremely low maintenance cost we have become a very well-known company in the field of industrial machine manufacturing.

Pillar Type Drilling Machine

1,000 Per Set

10 Set(s) (MOQ)

Radial & Pillar Drilling Machine

Get Price Quote

Manifature of all type of Heavy Duty & Hignh Precision Radial & Pillar Drilling Machine.

Hydraulic Drilling Machine

60,000 - 65,000 Per Piece

CNC Drilling & Tapping Machine

Get Price Quote

The company shares glorious credentials with the eminent Suppliers of CNC Drilling and Tapping Machine and offers the best deals. Consider our name, if seeking for high quality products that are prepared using the best grade material and modern technology. Our associates procure it from the reliable names after complete quality satisfaction. Applications: Drilling, Chamfering, Reaming, Hole Milling Spot Facing, Burnishing, Countersinking, Counter boring, For Steel or harden materials. For aluminum or soft material.Features : Rigid construction, Drilling cycle (Rapid forward-feed-dwell-rapid return) Spindle drive through timing belt and inter changeable pulley sets. Hydraulic spindle feed, infinitely variable spindle speed. Wood packing cycle for deep hole drilling. Standard Accessories Hydraulic Hydraulic System (whichever is applicable duly interfaced with the mother machine. Comprehensive electrical control panels/operating pendant with all safety elements and logic controller for automation duly wired to the basic machine. Reputed make main motor duly assembled in the machine with all drive elements. Operational and maintenance manual. Standard Accessories CNC Single axis controller Coolant Pump & Assembly Clamp Tray Lamp Manual Lubrication Optional Accessories Variable frequency Drive for main spindle infinite speed variation Wood -peaking cycle for deep hole drilling. Multi-Spindle drill heads with guide bar arrangement, & movable jig plate. Component Hydraulic clamping fixture as per application. Tool Holders suitable for application. Coolant system -complete with necessary splash guards etc. Flexible Lighting arrangement. Machine cladding. Centralized lubrication system Anti Vibration Pads. Optional Accessories CNC Two Axis interpolation Table Servo Control Rotary Table Hydraulic Operated Power chuck with Rotary Table

Manual Multi Spindle Drilling Machine

Get Price Quote

Due to our secure and hassle-free payment procedures, clients stay satisfied with us. We undertake both online and offline payment processing methods including cash and bank transfers. Purchasers can rest secure; our entire range is premium, as they are wholesaled by us after subjecting them to a string of quality control tests. Features : User-friendly Precision engineered QC verified High productivity

Center Drills

Get Price Quote

We are offering centre drills, committed to quality, we bring forth a wide range of centre drills . These centre drills are made of sturdy and corrosion resistant metals that also ensure durability. Centre drills are deep hole drilling tools, perfect to be used in latest machining centers like hmc & vmc. Keeping in mind diverse demands of the clients, we offer centre drills in different size and specifications as well.

Hydraulic Drilling Machine

420,000 Per Piece

We have hired experienced quality auditors who stringently check the raw materials against varied quality parameters before procurement. Thus, we ensure quality products at buyer's end. We have successfully emerged as a distinguished supplier of Hydraulic Drilling Machine that is highly demanded amidst the customers. Hydraulic Drilling Machine has a smooth and polished surface with excellent dimensional precision. Price Range : 80000 to 600000 Rs./ piece

AUTOMATIC COUPLER DRILLING AND CUTTING MACHINE

Get Price Quote

The Automatic Rebar Coupler Drilling and Cutting Machine is use to drilling and cutting the rebar coupler according to the desire length required. The drilling and cutting of the rebar couplers is normally in 2~3 minutes. This Rebar Coupler Drilling and Cutting Machine is used for high speed coupler making process. Automatic Rebar Coupler Drilling and Cutting Machine they are building is made up the best quality raw material, using the best and latest technology and most advanced machine just to make this machine work for long years without any symptoms of system crash or malfunction. Owing to the unstoppable qualities of our hydraulic surface grinder machine like being best in accuracy, durability, efficiency, compatibility, reliability, handiness and extremely low maintenance cost we have became a very well-known company in the field of industrial machine manufacturing. Specifications :- Model No.IMC-ARC-25 MMIMC-ARC-32 MMIMC-ARC-40 MMIMC-ARC-50 MMIMC- ARC-60 MMIMC-ARC-70 MM Max. Capacity Round Bar 22 mm 30 mm 37 mm 47 mm 56 mm 65 mm Hexagonal 22 mm 25 mm 32 mm 47 mm 56 mm 65 mm Square 18 mm 24 mm 27 mm 36 mm 42 mm 45 mm Maximum Turning Length 40 mm 45 mm 50 mm 60 mm 70 mm 76 mm Maximum Drill 40 mm 50 mm 55 mm 60 mm 65 mm 70 mm Electric Drive Motor 2 HP 1440 RPM 3 HP 1440 RPM 3 HP 1440 RPM 5 HP 960 RPM 5 HP 960 RPM 7 HP 960 RPM

Center Drills

Get Price Quote

For accurate and precise centering operations use our Center Drills. We are reputed Manufacturer, Supplier and Exporter of Center Drills from Punjab. These Center Drills are manufactured using quality tested raw materials and cutting edge technology. We make Center Drills available in both DIN and BS standards. Customization of the Drills is also done to suit different customer requirements. Customers can purchase the Center Drills at reasonable rates.

Ralli Wolf Heavy Duty Drill

7,000 Per Piece

1 Piece (MOQ)

Vertical & Horizontal Drill Machine

150,000 Per Piece

We pali machine tools manufacture all types of multi spindle drill machines.hydrulic and penumatic . Automatic and fully automatic .

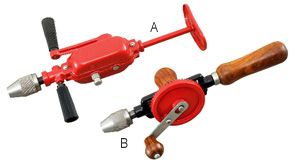

Drill Machine

Get Price Quote

Drill Machine (A) Breast Drill(Double Speed with 3 Jaw Chuck)(B) Hand DrillWith 3 Jaw ChuckAvailable Wooden, Plastic Handle

zero till drill machine

Get Price Quote

Machine enables us to sow directly after paddy harvest without prior seed bed preparation.Sowing all types of Seeds: Wheat , Maize, Soya, pulses, etc.Machine enables us to sow directly after paddy harvest without prior seed bed preparation.This saved the seeds, diesel, tractor's working time, labor and most important it gives higher crops yield.

Drilling Machine

Get Price Quote

multi spindle drill machine

150,000 Per Pieces

1 Piece (MOQ)

Semi Geared Radial Drilling Machine

Get Price Quote

We are reckoned amongst the trusted manufacturers of Semi Geared Radial Drilling Machine. These are manufactured using high grade material and are offered with drilling capacity of 40 mm, 50 mm & 60 mm.

Roto Seed Drill Machine

Get Price Quote

We offer a complete range of agricultural equipment such as Roto Seed Drill Machine, which is used for sowing wheat, maize, mustard, pea etc. This machine makes the process of sowing of cereals and crops easier. The machines are equipped with latest technology that enables them to offer superior performance. Along with these advantages the low power consumption and noiseless operation of these Roto Seed Drill Machines have facilitated us to become a distinguished Manufacturer and Supplier from Chandigarh, Punjab.

Scaffolding Inner Prop Drilling Machine

Get Price Quote

Keeping in mind the growing requirements of Scaffolding Industries, we are engaged in offering sophisticated range of Multi Spindles Drill Machines for Inner Prop. These machines are widely used for Drilling of the Components Specially in Inner Prop. Available in different capacities, these are widely appreciated by clients for high performance and low maintenance.This Machine is specially design to boost the Production at lowest labour cost with high level of accuracy in Inner Prop (Scaffolding).

All Geared Radial Drilling Machines

Get Price Quote

HIPAT” Precision Heavy Duty Radial Drilling Machines have a stremlined modern outlook and contain all the characteristics normally expected in a superiior qualillty machine.All the castings are of close-grained, heavy duty alloyed cast iron and amply ribbed to withstand stress without distortion, the shafts are of special quality steel andare having ground finish. all the bearings, shafts and gears of the main assemblies are force lubricated properly. the gears are induction hardened. The hardened and ground spindle run in a hardened and super-finished barrel, which slides an honed sleeve of the gear-box, the locking of the gear-box to arm and the radial movement is having special design to hold it rigidly during drilling operation.

Automatic Multi Spindle Drilling Machine

Get Price Quote

We ensure that the payment procedures we undertake are completely secured. Credit cards, purchase cards, PINless debit cards, bank account transfers, cash payments, etc., are some of the modes of payment that we accept. We strictly follow the packaging guidelines and we ensure that finest quality packaging material is used as packaging protects the enclosed product from physical, chemical and microbiological invasion. Details Features of the Multi-Spindle Drilling Machine Specially designed for Scaffolding pipes drilling operation. Machine will have the capacity to load 40 NB, 2000mm length pipes, for auto mode and 3000mm in semi auto mode Drilling Pitch will be 120mm Please note that our machine has 14 spindles fixed in particular pitch. They are not adjustable. If any change in, pitch and no of holes to be drilled, is required please specify in your enquiry. For Drill height adjustment-adjustable Sleeves Type Din 6327 with MT-2 Taper will be provided. (Max drill size 17.5 mm with MT2 taper shank) Machine will be equipped with automatic loading of the pipe from loading table to the V-Block for drilling. Machine will have Manual/semi-auto and Automatic Mode Selection in operation. In manual mode, individual functions of the machine can be operated manually during initial machine setup. After machine setup is completed, it can be run in Semi auto or Automatic-mode by selecting Semi auto or Auto Mode Automatic cycle sequence is as below. Positioning of the pipe. Clamping of the pipe. Slide up with rapid movement till the drill point. Coolant ON & Slide up with feed movement to drill the pipe on one side.

Drilling Cum Tapping Machine

48,000 Per Piece

Bench Drilling Machine

Get Price Quote

Pillar Drilling Machine

Get Price Quote

Our Pillar Drilling Machine can be used perfectly for drilling holes in different materials. We trade in the 13 MM Bench Type Pillar Drill which comes loaded with features that can be customized as per requirement. Our Pillar Drilling Machine can efficiently drill an extensive variety of materials. Special Features : Sturdy construction Low maintenance Corrosion resistant Affordable pricing Ideal for drilling : Metal sheets Glass Concrete Plastic Wood Rocks Heavy duty machines

CNC Drill Tap Machine

Get Price Quote

SPECIFICATION APPLICATIONS Drilling, Chamfering, Reaming, Hole Milling. Spot Facing ,Burnishing ,Countersinking, Counter boring. For Steel or harden materials. For aluminum or soft material. FEATURES Rigid construction Drilling cycle (Rapid forward-feed-dwell-rapid return). Spindle drive through timing belt and inter changeable pulley sets. Wood packing cycle for deep hole drilling.