hss gt threading tap

Get Price Quote

General Specification: Thread - TPI or Pitch: 1/8 in - 27 NPT, 1/4 in - 18 NPT, 3/8 in - 18 NPT, 1/2 in - 14 NPT, 3/4 in - 14 NPT, 1 in - 11 1/2 NPT Material: Carbon Steel, HSS Includes: Wooden Case, Taps, Dies Type: Tap & Die Special Taps: Your tapping requirement may be unique for various reasons, but one common requirement in all applications is successful tapping. Some examples of why your application may be special. Material characteristic such as swarf type, elasticity, strength and hardness. depth of hole thread size pitch thread form reach holding There are essentially four qualities in successfully designing and manufacturing a tap. Theoretical knowledge and practical experience are intrinsic in this process. Size form geometry texture or finish. Base material, its heat treatment, and final surface coating are significant factors; but they would be irrelevant without the correct geometry. Tap geometry involves a combination of features tailored to all the above... thread and flute cutting angles, flute pattern, cutting force reduction features. The culmination of these geometrical features is the knowledge we refer to. Our knowledge combined with processes and equipment, allow consideration of all these variables.

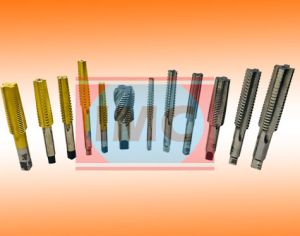

HSS Threading Taps

Get Price Quote

We offer superior quality HSS Threading Taps that are commonly used in various industries. To match the different needs of the clients, we provide HSS Ground Thread Taps in various sizes. High durability, excellent performance and low maintenance are some of the salient features of our High Speed Steel Thread Taps. We stand in the midst of major HSS G.T. threading taps Suppliers in India. Technical Specifications : Available from 1/8" to 8" (BSW, BSF, UNC, UNF) Available from 1/8" to 6" (BSP, BSPT, NPS, NPT, NPTF, NPSF) Available from 3 mm to 205 mm (metric threads) in Fine Pitch and Coarse Pitch. Fine Pitch Taps are in set of 2 Pcs and Coarse Pitch Taps are in set of 3 Pcs. Also available in British Standard Conduit and British Standard Brass Whitworth forms

Best Deals from HSS Tap

Tap Die Set

200 Per Set

50 Piece (MOQ)

HSS Tap Set

200 Per Set

Hss tap set use for internal threading available in m-2. m-35 or m42 grade also available in fine pitch bsp bspt npt and other special sizes as per coustmer requairment

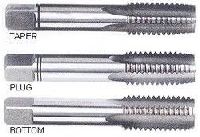

Fluted Tap

Get Price Quote

hese standard style taps have straight flutes of a number specified as either standard or optional. Hand taps are for general purpose applications such as production tapping or hand tapping operations. Taper, plug and bottoming styles provide versatility in tough materials, blind and through holes.

THREADING TOOLS TAPS, THREAD TAPS, THREADING TAP

Get Price Quote

IMC Threading taps are especially designed tools used to cut the female portion of a mating pair of metal fasteners. A Threading Tap removes material from a pre-drilled or punched hole. The result produces threads within the drilled hole. The cutting edges at the front of a tap remove material from the workpiece. The chips are stored in the flutes, or pushed forward in front of the tap, or are drawn up along the flutes, removing the chips and cutting fluids from the hole. A chamfer is a tapered portion at the front end of the tap. Both the chamfered portion and the first full thread beyond the chamfer produce the finished thread of the part. Industrial Machinery Corporation manufactured Threading Taps as per industry standards and stands high on parameters of quality and durability. Threading is divided into two types, internal and external. Internal threading is done by using a tool called a TAP in a hole drilled to a specific diameter for the thread size and pitch you want to cut. External threads, such as for bolts and studs, are made by using a tool called a DIE, which is applied to a specific diameter of rod for the size and pitch of the threads you want to cut. Taps and dies are tools used to create screw threads, which is called threading. Many are cutting tools; others are forming tools. A Threading Tap is used to cut or form the female portion of the mating pair (e.g., a nut). A die is used to cut or form the male portion of the mating pair (e.g., a bolt). The process of cutting or forming threads using a tap is called tapping, whereas the process using a die is called threading. Both tools can be used to clean up a thread, which is called chasing. A Threading Tap cuts a thread on the inside surface of a hole, creating a female surface which functions like a nut. Machine Tapping Internal Threading Machine is used tool tap for internal threading. Machine tapping is faster, and generally more accurate because human error is eliminated. Although in general machine tapping is more accurate, tapping operations have traditionally been very tricky to execute due to frequent tap breakage and inconsistent quality of tapping. The Threading Taps offered by Industrial Machinery Corporation. Different types of Threading Taps can be used for internal threads such as BSW, NPT, UNF, METRIC, UNC, ACME, BSF Threads etc. Industrial Machinery Corporation will also offer the benefit of customization.

ACME Taps

Get Price Quote

Our company holds expertise in manufacturing, exporting and supplying precision engineered ACME Taps. Finding wide application in manufacturing valves, jacks and other mechanisms, the ACME Taps are used for producing traversing motions on machine tools. They are fabricated using high speed steel ensuring optimum wear resistance. Further, the ACME Taps are quality approved by the authorities after rigorous quality checks. We make available ACME Taps in a wide assortment of specifications at very affordable prices.

ACME Taps

Get Price Quote

Head quartered in Ludhiana, Punjab, India, we are a popular and well-established manufacturer of Acme Taps. These ground threading Acme Taps that we offer are made from high-grade, high-tensile and engineered for precision and strength. These Acme Taps are available in standard dia sizes and are widely appreciated of their performance and durability. You can procure these Acme taps at competitive market rates.

HSS Straight Fluted Taps

Get Price Quote

HSS Threading Tap

Get Price Quote

We do not have to worry about stock-out situations or meeting bulk requirements, as we have an equipped warehouse facility. It has the latest inventory control and management software and helps us maintain continuous product availability. We provide customized as well as standard packaging of the products. With the assistance of our streamlined packing system, we are able to provide damage-free products to the clients. Features : Thread - TPI or Pitch : 1/8 in - 27 NPT, 1/4 in - 18 NPT, 3/8 in - 18 NPT, 1/2 in - 14 NPT, 3/4 in - 14 NPT, 1 in - 11 1/2 NPT Material : Carbon Steel, HSS Includes : Wooden Case, Taps, Dies Type : Tap & Die Special Taps : Your tapping requirement may be unique for various reasons, but one common requirement in all applications is successful tapping. Some examples of why your application may be special. Material characteristic such as swarf type, elasticity, strength and hardness. depth of hole thread size pitch thread form reach holding. There are essentially four qualities in successfully designing and manufacturing a tap. Theoretical knowledge and practical experience are intrinsic in this process. Size form geometry texture or finish Base material, its heat treatment, and final surface coating are significant factors; but they would be irrelevant without the correct geometry. Tap geometry involves a combination of features tailored to all the above... thread and flute cutting angles, flute pattern, cutting force reduction features. The culmination of these geometrical features is the knowledge we refer to. Our knowledge combined with processes and equipment, allow consideration of all these variables.

Threading Taps

Get Price Quote

IMC Threading taps are specially designed tools used to cut the female portion of a mating pair of metal fasteners. A Threading Tap removes material from a pre-drilled or punched hole. The result produces threads within the drilled hole. The cutting edges at the front of a tap remove material from the workpiece. The chips are stored in the flutes, or pushed forward in front of the tap, or drawn up along the flutes, removing the chips and cutting fluids from the hole. A chamfer is a tapered portion at the front end of the tap. Both the chamfered portion and the first full thread beyond the chamfer produce the finished thread of the part. Industrial Machinery Corporation manufactured Threading Taps as per industry standards and stands high on parameters of quality and durability. Threading is divided into two types, internal and external. Internal threading is done by using a tool called a TAP in a hole drilled to a specific diameter for the thread size and pitch you want to cut. External threads, such as bolts and studs, are made by using a tool called a DIE, which is applied to a specific diameter of the rod for the size and pitch of the threads you want to cut. Taps and dies are tools used to create screw threads, which is called threading. Many are cutting tools; others are forming tools. A Threading Tap is used to cut or form the female portion of the mating pair (e.g., a nut). A die is used to cut or form the male portion of the mating pair (e.g., a bolt). The process of cutting or forming threads using a tap is called tapping, whereas the process using a die is called threading. Both tools can be used to clean up a thread, which is called chasing. A Threading Tap cuts a thread on the inside surface of a hole, creating a female surface that functions like a nut. Machine Tapping The internal Threading Machine is used a tool tap for internal threading. Machine tapping is faster, and generally more accurate because human error is eliminated. Although in general machine tapping is more accurate, tapping operations have traditionally been very tricky to execute due to frequent tap breakage and inconsistent quality of tapping. The Threading Taps are offered by Industrial Machinery Corporation. Different types of Threading Taps can be used for internal threads such as BSW, NPT, UNF, METRIC, UNC, ACME, BSF Threads, etc. Industrial Machinery Corporation will also offer the benefit of customization

Threading Taps

Get Price Quote

Threading Taps (B.S. 949)

Get Price Quote

Threading Taps British Standard (B.S. 949)BSW(Sizes - 116' to 2")BSF(Sizes - 316" to 2")UNF(Sizes - 14" to 2")UNC(Sizes - 14 to 2")

HSS Threading Tap

Get Price Quote

Thread - TPI or Pitch : 1/8 in - 27 NPT, 1/4 in - 18 NPT, 3/8 in - 18 NPT, 1/2 in - 14 NPT, 3/4 in - 14 NPT, 1 in - 11 1/2 NPT Material : Carbon Steel, HSS Includes : Wooden Case, Taps, Dies Type : Tap & Die Special Taps: Your tapping requirement may be unique for various reasons, but one common requirement in all applications is successful tapping. Some examples of why your application may be special. Material characteristic such as swarf type, elasticity, strength and hardness. depth of hole thread size pitch thread form reach holding. There are essentially four qualities in successfully designing and manufacturing a tap. Theoretical knowledge and practical experience are intrinsic in this process. Size form geometry texture or finish Base material, its heat treatment, and final surface coating are significant factors; but they would be irrelevant without the correct geometry. Tap geometry involves a combination of features tailored to all the above... thread and flute cutting angles, flute pattern, cutting force reduction features. The culmination of these geometrical features is the knowledge we refer to. Our knowledge combined with processes and equipment, allow consideration of all these variables

HSS Threading Tap

Get Price Quote

Thread - TPI or Pitch: 1/8 in - 27 NPT, 1/4 in - 18 NPT, 3/8 in - 18 NPT, 1/2 in - 14 NPT, 3/4 in - 14 NPT, 1 in - 11 1/2 NPT Material: Carbon Steel, HSS Includes: Wooden Case, Taps, Dies Type: Tap & DieSpecial Taps: Your tapping requirement may be unique for various reasons, but one common requirement in all applications is successful tapping. Some examples of why your application may be special. Material characteristic such as swarf type, elasticity, strength and hardness. depth of hole thread size pitch thread form reach holding There are essentially four qualities in successfully designing and manufacturing a tap. Theoretical knowledge and practical experience are intrinsic in this process.Size form geometry texture or finish. Base material, its heat treatment, and final surface coating are significant factors; but they would be irrelevant without the correct geometry. Tap geometry involves a combination of features tailored to all the above... thread and flute cutting angles, flute pattern, cutting force reduction features. The culmination of these geometrical features is the knowledge we refer to. Our knowledge combined with processes and equipment, allow consideration of all these variables.

H.S.S Ground Thread Taps

Get Price Quote

Stub ACME Thread Taps

Get Price Quote

stub acme thread taps come in different types. We manufacture stub acme thread taps from good quality material which suits exact requirement of the application. Stub acme thread taps have high precision accuracy and are used for tapping in any type of material like stainless steel and graded casting. stub acme thread taps are manufactured as per ansi/asme b 1.8:1988 we also manufacture multi-start stub acme thread taps. we can manufacture modified stub acme thread taps. stub acme thread taps can also be manufactured as per drawing.

Roll Forming Taps

620 Per Piece

Carbon Threading Taps

Get Price Quote

We are offering hss & carbon threading taps.

carbon steel hand taps

Get Price Quote

threading tap

Get Price Quote

Your tapping requirement may be unique for various reasons, but one common requirement in all applications is successful tapping. Some examples of why your application may be special. Material characteristic such as swarf type, elasticity, strength and hardness. depth of hole thread size pitch thread form reach holding There are essentially four qualities in successfully designing and manufacturing a tap. Theoretical knowledge and practical experience are intrinsic in this process. Size form geometry texture or finish. Base material, its heat treatment, and final surface coating are significant factors; but they would be irrelevant without the correct geometry. Tap geometry involves a combination of features tailored to all the above... thread and flute cutting angles, flute pattern, cutting force reduction features. The culmination of these geometrical features is the knowledge we refer to. Our knowledge combined with processes and equipment, allow consideration of all these variables.

Threading Taps

Get Price Quote

Made from selected high speed steel, our Threading Taps feature tools that are properly tempered and stress relieved. The Tap Blanks of Threading Taps are heat treated In-house with the help of high accuracy temperature controlling system so that optimum hardness along required toughness and wear resistance is imparted to tools. We are a remarkable entity engaged in offering superior quality assortment of Threading Tap. Our skilled professionals manufacture the entire range using world class raw material and sophisticated technology, as per international quality standards. To meet the variegated demands of the clients, we offer these products in different related specifications. In addition to this, we offer our products at a reasonable price range.

Carbon Steel Tap Cutter

Get Price Quote

HSS Nut Tap

1,500 Per Piece

12 Piece(s) (MOQ)

Tap Sets

40 - 75 Per Piece

H.S.S Threading Tap

Get Price Quote

Your tapping requirement may be unique for various reasons, but one common requirement in all applications is successful tapping. Some examples of why your application may be special. Material characteristic such as swarf type, elasticity, strength and hardness. depth of hole thread size pitch thread form reach holding There are essentially four qualities in successfully designing and manufacturing a tap. Theoretical knowledge and practical experience are intrinsic in this process.Size form geometry texture or finish. Base material, its heat treatment, and final surface coating are significant factors; but they would be irrelevant without the correct geometry. Tap geometry involves a combination of features tailored to all the above... thread and flute cutting angles, flute pattern, cutting force reduction features. The culmination of these geometrical features is the knowledge we refer to. Our knowledge combined with processes and equipment, allow consideration of all these variables.

HSS Threading Taps

Get Price Quote

Our organization assures distribution of wholesale as well as retail consignments of the goods as per the jointly decided period. We have our own storage unit wherein we keep a large stock for meeting urgent and massive requirements of the clients. Laced with modern amenities, this unit keeps the lot free from the damaging factors. Features : Thread - TPI or Pitch - 1/8 in - 27 NPT, 1/4 in - 18 NPT, 3/8 in - 18 NPT, 1/2 in - 14 NPT, 3/4 in - 14 NPT, 1 in - 11 1/2 NPT Material - Carbon Steel, HSS Includes - Wooden Case, Taps, Dies Type - Tap & Die Special Taps : Your tapping requirement may be unique for various reasons, but one common requirement in all applications is successful tapping. Some examples of why your application may be special. Material characteristic such as swarf type, elasticity, strength and hardness. depth of hole thread size pitch thread form reach holding. There are essentially four qualities in successfully designing and manufacturing a tap. Theoretical knowledge and practical experience are intrinsic in this process. Size form geometry texture or finish Base material, its heat treatment, and final surface coating are significant factors; but they would be irrelevant without the correct geometry. Tap geometry involves a combination of features tailored to all the above... thread and flute cutting angles, flute pattern, cutting force reduction features. The culmination of these geometrical features is the knowledge we refer to. Our knowledge combined with processes and equipment, allow consideration of all these variables.

HSS Threading Tap

Get Price Quote

FEATURESThread - TPI or Pitch : 1/8 in - 27 NPT, 1/4 in - 18 NPT, 3/8 in - 18 NPT, 1/2 in - 14 NPT, 3/4 in - 14 NPT, 1 in - 11 1/2 NPTMaterial : Carbon Steel, HSSIncludes : Wooden Case, Taps, DiesType : Tap & DieSpecial Taps:Your tapping requirement may be unique for various reasons, but one common requirement in all applications is successful tapping. Some examples of why your application may be special.material characteristic such as swarf type, elasticity, strength and hardness. depth of hole thread size pitch thread form reach holding.There are essentially four qualities in successfully designing and manufacturing a tap.theoretical knowledge and practical experience are intrinsic in this process.size form geometry texture or finishBase material, its heat treatment, and final surface coating are significant factors; but they would be irrelevant without the correct geometry. Tap geometry involves a combination of features tailored to all the above... thread and flute cutting angles, flute pattern, cutting force reduction features. The culmination of these geometrical features is the knowledge we refer to. Our knowledge combined with processes and equipment, allow consideration of all these variables.

Threading Taps

Get Price Quote

We are offering threading taps.

HSS Threading Taps

Get Price Quote

HSS Threading Taps, Cutting Tools, Bottom Cup, Swivel Coupler