Worm Ring

We are main supplier of this product.

Wire Straightening and Cutting Machine

We are offering Wire Straightening Machine

TMT BAR FORGING MACHINE

We are main supplier of this product.

Tie Rod Thread Rolling Machine

1 piece (MOQ)

Specification: model No.: Imc-25 max. Pitch Can Be Rolled (in Mm): 2.5 max. Dia Can Be Rolled in Feed (in Mm): 25 max. Dia Can Be Through Feed (in Mm): 16 max. Rolling Length in Feed (in Mm): 80 max. Rolling Length Through Feed: Indefinite max. Outer Dia Thread Rolls (in Mm): 150 spindle Dia (bore Dia) (in Mm): 54 max. Rolling Force: 8 Tons power for Roll Spindles: 3 H.p. 1400 Rpm power for Hydraulic Pump: 2 H.p. power for Coolant Pump: 0.1 H.p. model No.: Imc-40 max. Pitch Can Be Rolled (in Mm): 3.5 max. Dia Can Be Rolled in Feed (in Mm): 40 max. Dia Can Be Through Feed (in Mm): 28 max. Rolling Length in Feed (in Mm): 150 max. Rolling Length Through Feed: Indefinite max. Outer Dia Thread Rolls (in Mm): 180 spindle Dia (bore Dia) (in Mm): 54 max. Rolling Force: 13 Tons power for Roll Spindles: 5 H.p. 1400 Rpm power for Hydraulic Pump: 3 H.p. power for Coolant Pump: 0.1 H.p. model No.: Imc-50 max. Pitch Can Be Rolled (in Mm): 4.0 max. Dia Can Be Rolled in Feed (in Mm): 50 max. Dia Can Be Through Feed (in Mm): 35 max. Rolling Length in Feed (in Mm): 150 max. Rolling Length Through Feed: Indefinite max. Outer Dia Thread Rolls (in Mm): 200 spindle Dia (bore Dia) (in Mm): 69.85 max. Rolling Force: 15 Tons power for Roll Spindles: 7.5 H.p. 1400 Rpm power for Hydraulic Pump: 5 H.p. power for Coolant Pump: 0.1 H.p. model No.: Imc-80 max. Pitch Can Be Rolled (in Mm): 5.0 max. Dia Can Be Rolled in Feed (in Mm): 80 max. Dia Can Be Through Feed (in Mm): 40 max. Rolling Length in Feed (in Mm): 150 max. Rolling Length Through Feed: Indefinite max. Outer Dia Thread Rolls (in Mm): 220 spindle Dia (bore Dia) (in Mm): 69.85 max. Rolling Force: 24 Tons power for Roll Spindles: 10 H.p. 1440 Rpm power for Hydraulic Pump: 5 H.p. power for Coolant Pump: 0.1 H.p. model No.: Imc-100 max. Pitch Can Be Rolled (in Mm): 5.5 max. Dia Can Be Rolled in Feed (in Mm): 100 max. Dia Can Be Through Feed (in Mm): 50 max. Rolling Length in Feed (in Mm): 150 max. Rolling Length Through Feed: Indefinite max. Outer Dia Thread Rolls (in Mm): 220 spindle Dia (bore Dia) (in Mm): 69.85 max. Rolling Force: 30 Tons power for Roll Spindles: 12.5 H.p. 1440 Rpm power for Hydraulic Pump: 5 H.p. power for Coolant Pump: 0.1 H.p. model No.: Imc-120 max. Pitch Can Be Rolled (in Mm): 8 max. Dia Can Be Rolled in Feed (in Mm): 125 max. Dia Can Be Through Feed (in Mm): 70 max. Rolling Length in Feed (in Mm): 150 max. Rolling Length Through Feed: Indefinite max. Outer Dia Thread Rolls (in Mm): 220 spindle Dia (bore Dia) (in Mm): 69.85 max. Rolling Force: 40 Tons power for Roll Spindles: 15 H.p. 1400 Rpm power for Hydraulic Pump: 7.5 H.p. power for Coolant Pump: 0.1 H.p.

...more

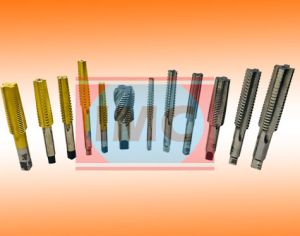

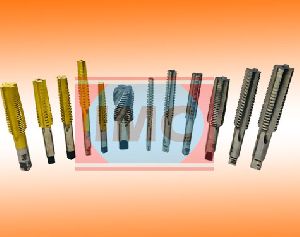

THREADING TOOLS TAPS, THREAD TAPS, THREADING TAP

IMC Threading taps are especially designed tools used to cut the female portion of a mating pair of metal fasteners. A Threading Tap removes material from a pre-drilled or punched hole. The result produces threads within the drilled hole. The cutting edges at the front of a tap remove material from the workpiece. The chips are stored in the flutes, or pushed forward in front of the tap, or are drawn up along the flutes, removing the chips and cutting fluids from the hole. A chamfer is a tapered portion at the front end of the tap. Both the chamfered portion and the first full thread beyond the chamfer produce the finished thread of the part. Industrial Machinery Corporation manufactured Threading Taps as per industry standards and stands high on parameters of quality and durability. Threading is divided into two types, internal and external. Internal threading is done by using a tool called a TAP in a hole drilled to a specific diameter for the thread size and pitch you want to cut. External threads, such as for bolts and studs, are made by using a tool called a DIE, which is applied to a specific diameter of rod for the size and pitch of the threads you want to cut. Taps and dies are tools used to create screw threads, which is called threading. Many are cutting tools; others are forming tools. A Threading Tap is used to cut or form the female portion of the mating pair (e.g., a nut). A die is used to cut or form the male portion of the mating pair (e.g., a bolt). The process of cutting or forming threads using a tap is called tapping, whereas the process using a die is called threading. Both tools can be used to clean up a thread, which is called chasing. A Threading Tap cuts a thread on the inside surface of a hole, creating a female surface which functions like a nut. Machine Tapping Internal Threading Machine is used tool tap for internal threading. Machine tapping is faster, and generally more accurate because human error is eliminated. Although in general machine tapping is more accurate, tapping operations have traditionally been very tricky to execute due to frequent tap breakage and inconsistent quality of tapping. The Threading Taps offered by Industrial Machinery Corporation. Different types of Threading Taps can be used for internal threads such as BSW, NPT, UNF, METRIC, UNC, ACME, BSF Threads etc. Industrial Machinery Corporation will also offer the benefit of customization.

Brand Name : IMC

...more

Threading Taps

Material : SS

Brand Name : IMC

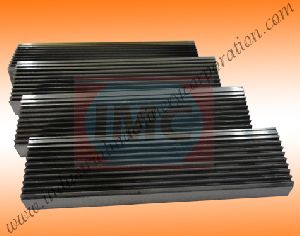

Threading Tangential Chaser

We manufacture Threading Tangential Chaser from metallurgical standard proven imported high grade Steel. These Threading Tangential Chasers enable manufacturing of natural and fine threads. These Landis Tangential Chasers are available in various lengths ranging from 1� to 6�depending on the size of the die head. BSP, BSPT, NPT, UNF, UNC, BSW threads can be excellently cut on our Tangential Chaser. The Threading Tangential Chaser is processed with heat treatment in the Automatic Imported Heat Treatment Plant and Imported Testing equipment. We are rated among the leading Thread Cutting Chaser Manufacturers in Punjab. Types Of Threading Tangential Chaser Thread cutting chaser Pipe threading chaser Bolt threading chaser Rod threading chaser Note : IMC Chasers are interchangeable. If one PC of a chaser set is damaged & is beyond use then, same no. of PC of the other chaser set lying in stock may be used and there will be no difference in threading performance. The damaged set can be replaced without the necessity of replacing entire set.

...more

Threading Machines

Threading Machine is use to threading the external end of rod, bar, bolt, pipe, tmt rebar, steel bar, pvc pipe etc.

...more

threading machine spare parts

We are main supplier of this product.

Threading Machine

1 Set(s) (MOQ)

Range of IMC Threading Machines and Die Heads. 1/4" to 1" Capacity 3/8" to 1.1/2" Capacity 1/2" to 2.1/2" Capacity 1" to 4" Capacity 2.1/2" to 6" Capacity 4" to 8" Capacity Specifications: Model No.: 1/4" to 1" saddle Movement: 10" spindle Speed Range: 60-90 number of Spindle Speed: 2 threading Capacity: 1/4" to 1" production per Hour: 60-80 h.p. Required: 3 H.p. lead Screw: Optional weight (kg) Aprox.: 500 Model No.: 3/8" to 1.1/2" saddle Movement: 10" spindle Speed Range: 60-90 number of Spindle Speed: 2 threading Capacity: 3/8" to 1.1/2" production per Hour: 60-80 h.p. Required: 3 H.p. lead Screw: Optional weight (kg) Aprox.: 550 Model No.: 1/2" to 2.1/2" saddle Movement: 12" -16" spindle Speed Range: 60-90 number of Spindle Speed: 2 threading Capacity: 1/2" to 2.1/2" production per Hour: 70-90 h.p. Required: 7.5 H.p. lead Screw: Optional weight (kg) Aprox.: 990 Model No.: 1" to 4" saddle Movement: 10" - 12" spindle Speed Range: 40-75-115 number of Spindle Speed: 3 threading Capacity: 1" to 4" production per Hour: 35-40 h.p. Required: 12.5 H.p. lead Screw: Provided weight (kg) Aprox.: 1600 Model No.: 2.1/2" to 6" saddle Movement: 10" - 12" spindle Speed Range: 25-50 number of Spindle Speed: 2 threading Capacity: 2.1/2" to 6" production per Hour: 20-25 h.p. Required: 15 H.p. lead Screw: Provided weight (kg) Aprox.: 1900 Model No.: 4" to 8" saddle Movement: 10"-12" spindle Speed Range: 25-50 number of Spindle Speed: 2 threading Capacity: 4" to 8" production per Hour: 15-20 h.p. Required: 20 H.p. lead Screw: Provided weight (kg) Aprox.: 2500

...more

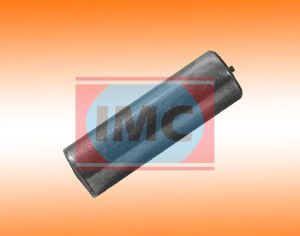

threading dies

We specialize in manufacturer and supply variety of Circular thread rolling dies as per customers specifications and requirements. Our assortment of products caters to any and all models of thread rolling machines. All our products are manufactured by us are as per international quality standard.These thread rolling Dies are used on thread rolling machine. These Thread Rolling Dies comes in set of two and three pieces manufactured from D2,D3 and M2 Material to suit any type of machine. For any specification of thread such as ISO Metric Din Whiteworhth America, Trapozodical, Acme etc.

...more

Threading Die Head

Size : 1/2\" to 1. 1/2\" 1.5/8 to 2.1/2\"

Color : Silver

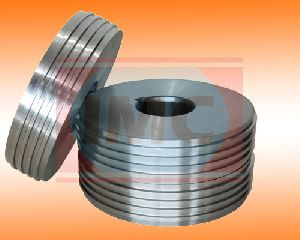

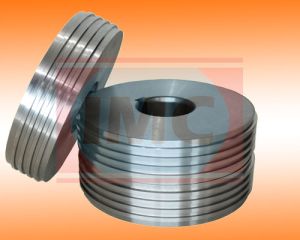

Thread Rolls

The company offers Thread Rolls in India and abroad. The Thread Rolls are manufactured by us are as per international quality standard. The Thread Rolls are used on Thread Rolling Machines. We offer Thread Rolls in set of two and three pieces that are manufactured from D2, D3, and M2 Material so that they suit any type of machine. These Thread Rolls are ideal for all types of threads such as ISO Metric Din Whiteworhth America, Trapozodical, Acme, etc. Our products come in different types like Circular Thread Rolls, etc. and we are renowned as one of the best Wholesale Thread Rolls Manufacturers in India.

Country of Origin : India

Type : Thread Rolls

Material : Metal

Application : PFD Garments

Color : Silver

Condition : New

...more

Thread Rolling Machine

Brand Name : IMC

Condition : New

Automatic Grade : Manual

...more

Thread Rolling Dies

We specialize in manufacturer and supply variety of Circular thread rolling dies as per customers specifications and requirements. Our assortment of products caters to any and all models of thread rolling machines. All our products are manufactured by us are as per international quality standard.

...more

Thread Cutting Machine

1 piece (MOQ)

Range of Imc Threading Machines and Die Heads. 1/4" to 1" Capacity 3/8" to 1.1/2" Capacity 1/2" to 2.1/2" Capacity 1" to 4" Capacity 2.1/2" to 6" Capacity 4" to 8" Capacity Specifications: Model No.: 1/4" to 1" saddle Movement: 10" spindle Speed Range: 60-90 number of Spindle Speed: 2 threading Capacity: 1/4" to 1" production per Hour: 60-80 h.p. Required: 3 H.p. lead Screw: Optional weight (kg) Aprox.: 500 Model No.: 3/8" to 1.1/2" saddle Movement: 10" spindle Speed Range: 60-90 number of Spindle Speed: 2 threading Capacity: 3/8" to 1.1/2" production per Hour: 60-80 h.p. Required: 3 H.p. lead Screw: Optional weight (kg) Aprox.: 550 Model No.: 1/2" to 2.1/2" saddle Movement: 12" -16" spindle Speed Range: 60-90 number of Spindle Speed: 2 threading Capacity: 1/2" to 2.1/2" production per Hour: 70-90 h.p. Required: 7.5 H.p. lead Screw: Optional weight (kg) Aprox.: 990 Model No.: 1" to 4" saddle Movement: 10" - 12" spindle Speed Range: 40-75-115 number of Spindle Speed: 3 threading Capacity: 1" to 4" production per Hour: 35-40 h.p. Required: 12.5 H.p. lead Screw: Provided weight (kg) Aprox.: 1600 Model No.: 2.1/2" to 6" saddle Movement: 10" - 12" spindle Speed Range: 25-50 number of Spindle Speed: 2 threading Capacity: 2.1/2" to 6" production per Hour: 20-25 h.p. Required: 15 H.p. lead Screw: Provided weight (kg) Aprox.: 1900 Model No.: 4" to 8" saddle Movement: 10"-12" spindle Speed Range: 25-50 number of Spindle Speed: 2 threading Capacity: 4" to 8" production per Hour: 15-20 h.p. Required: 20 H.p. lead Screw: Provided weight (kg) Aprox.: 2500

...more

Tapping Threading Machine

We have firmly positioned ourselves as one of the distinguished Horizontal Tapping Threading Machine Suppliers, Manufacturers and Exporters based in India. Designed for a dependable performance, the Tapping Threading Machine available with us is user friendly and durable at the same time. Our Machine is suitable for inside and outside threading with taps and round split dies respectively. Largely admired for sophisticated functioning and long lasting performance, the Tapping Threading Machine Industrial Machinery Corporation India is surely the best choice to rely upon. Known For : Reliable performance Robust structure Easy operation Longer functional life Specification Model  No. 1/2" to 2.1/2" Threading length can be cut 150 MM Number of speed in gear box 5 Production per hour 80 Pcs. Electrical Motor 5 H.P. 960 RPM

Weight : 100-1000kg

Voltage : 220V

Automatic Grade : Automatic

Power : 1-3kw

Driven Type : Electric

Warranty : 1year

...more

TAP AND TOOL GRINDER MACHINE

Industrial Machinery Corporation has uniquely positioned ourselves as a dependable firm, engaged in manufacturing and supplying a commendable array of Resharpening Machine. These Tools and Taps Resharpening Machines are manufactured using excellent quality raw material and latest technology by our skilled professionals. In order to ensure quality, this Tap and Tool Grinder Machine are stringently tested on various parameters by our experts. Apart from this, remarkable quality and durability increase the demand of our offered range in the market. No injure during the re-sharpening process and saving time from re-sharpening taps and tools. Tap and Tool Grinder Machine is used for re-sharpen the taps and tools. Taps, like all other cutting tools, become dull through use. Dull taps can produce either oversize or undersize holes. They may chip, produce poor threads, or break in extreme cases. This Tap and Tool Grinder Machine is used for dull or bad tools re-sharpening outside and saving the cost of hiring the skilled worker for re-sharpening taps and tools. This Tap and Tool Grinder Machine will be saving your cost and time. Smaller sizes of taps are generally reconditioned by grinding the chamfer portion only, while larger taps may also require flute grinding. Taper pipe taps must be sharpened by grinding the flutes and spiral-pointed taps must be reground in the angular portion of the flute as well as on the chamfer. Flute grinding or spiral point grinding should also be done on a tap reconditioning machine or on a cutter grinder. Flute grinding wheels should be shaped with a diamond dresser of the appropriate type to produce a rake face or hook face as required. Both chamfers and flutes should be ground carefully so as not to burn the cutting edges of the tap, careful grinding will also produce a smooth finish on the tap. Wheels of K or L hardness and 60-grain or finer should be used. TAP AND TOOL GRINDER MACHINE FEATURES: Conventional design Grinding fast and high accuracy. Optimum performance Simple to set up.

...more

Surface Grinding Machine

SURFACE GRINDING MACHINE Industrial Machinery Corporation are Surface Grinding Machine Manufacturer , Exporters and supplier. These Hydraulic Surface Grinder Machine are made from very high quality raw material which ensures hassle free work performance at its user end. These Hydraulic Surface Grinder Machine are widely finds its applications in various industrial sectors. Standard Accessories Electric Motor Starter V-Belts Wheel Balancing Stand Optional Accessories Coolant Pump Magnet Chuck

...more

surface grinders

Straight Pin (Set of 4 Pcs)

We are main supplier of this product.

Square Bush (Set of 4 Pcs)

We are main supplier of this product.

Square Bush Ring

We are main supplier of this product.

Shank Reducing Machine

We are offering automatic bolt head trimming & shank reducing machine. the company has created a strong foothold in the field of manufacturing, exporting and supplying automatic bolt head trimming & shank reducing machine. Designed to precision, our bolt head trimming & shank reducing machine that we offer is fully automatic, user friendly and requires low maintenance. Largely appreciated for reliable performance and longer functional life, the automatic bolt head trimming & shank reducing machine is ideal for h.t. Or m.s. Bolt blanks. We provide the automatic bolt head trimming & shank reducing machine in customized specifications as per the client’s requirements. attributes : robust constructionprecision madereliable performancelow maintenance

...moreOpening Hours