TMT BAR FORGING MACHINE

220 tons 40MM capacity, Hydraulic TMT Bar Forging Machine to be comprising of 01 No's of Double Stroke Double Acting Hydraulic Cylinders of which one is the Hydraulic Clamping Cylinders & other is the Forging Cylinder, One no's of Forging Block with 01 nos Holder & 3 nos of Die Sets along with Punch & 03 nos of 7.5 H.P. Dual type (High Pressure & Low-Pressure Power Pack Unit.

Country of Origin : India

Type : Forging Machine

Brand Name : IMC

Certification : ISO 9001:2008 Certified

Color : Blue

Pressure : Low Pressure, High Pressure

...more

Threading Taps

IMC Threading taps are specially designed tools used to cut the female portion of a mating pair of metal fasteners. A Threading Tap removes material from a pre-drilled or punched hole. The result produces threads within the drilled hole. The cutting edges at the front of a tap remove material from the workpiece. The chips are stored in the flutes, or pushed forward in front of the tap, or drawn up along the flutes, removing the chips and cutting fluids from the hole. A chamfer is a tapered portion at the front end of the tap. Both the chamfered portion and the first full thread beyond the chamfer produce the finished thread of the part. Industrial Machinery Corporation manufactured Threading Taps as per industry standards and stands high on parameters of quality and durability. Threading is divided into two types, internal and external. Internal threading is done by using a tool called a TAP in a hole drilled to a specific diameter for the thread size and pitch you want to cut. External threads, such as bolts and studs, are made by using a tool called a DIE, which is applied to a specific diameter of the rod for the size and pitch of the threads you want to cut. Taps and dies are tools used to create screw threads, which is called threading. Many are cutting tools; others are forming tools. A Threading Tap is used to cut or form the female portion of the mating pair (e.g., a nut). A die is used to cut or form the male portion of the mating pair (e.g., a bolt). The process of cutting or forming threads using a tap is called tapping, whereas the process using a die is called threading. Both tools can be used to clean up a thread, which is called chasing. A Threading Tap cuts a thread on the inside surface of a hole, creating a female surface that functions like a nut. Machine Tapping The internal Threading Machine is used a tool tap for internal threading. Machine tapping is faster, and generally more accurate because human error is eliminated. Although in general machine tapping is more accurate, tapping operations have traditionally been very tricky to execute due to frequent tap breakage and inconsistent quality of tapping. The Threading Taps are offered by Industrial Machinery Corporation. Different types of Threading Taps can be used for internal threads such as BSW, NPT, UNF, METRIC, UNC, ACME, BSF Threads, etc. Industrial Machinery Corporation will also offer the benefit of customization

Country of Origin : India

Certification : ISO 9001:2008 Certified

Condition : New

Brand Name : IMC

...more

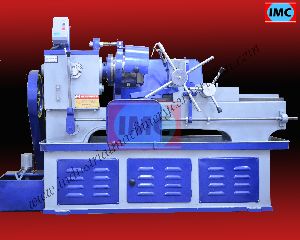

Thread Rolling Machine Flat Die Type

Available with us is this precisely designed Flat Die Thread Rolling Machine, which is reckoned for reliable performance and durable life. Designed for a flawless performance, our Flat Die Thread Rolling Machine is ideal for the production of large and small batches of all kinds of threads that can be cold formed. Robust structure, easy operation and low maintenance are some of the words that best describe our Flat Die Thread Rolling Machine. Further, the clients can obtain the Flat Die Thread Rolling Machine in customized specifications, as per their requirements. Specialty : Easy to operate Sturdy construction Possesses advanced features Ensures long lasting performance

...more

Thread Rolling Machine

Industrial Machinery Corporation are engaged in manufacturing and offering Thread Rolling Machine used for producing screws, bolts and tools. Thread rolling is a cold-forming operation only for external screws threads in a blank. The blank is pressed by thread rolling dies which are attached to the machine. The threads were formed by the pressing progress.

Country of Origin : India

Type : Thread Rolling Machine

Color : Light Green

Condition : New

Automatic Grade : Semi Automatic, Manual, Fully Automatic, Automatic

Brand Name : IMC

...more

TAP AND TOOL GRINDER MACHINE

Industrial Machinery Corporation has uniquely positioned itself as a dependable firm, engaged in manufacturing and supplying a commendable array of Resharpening machines. These Tools and Taps Resharpening Machines are manufactured using excellent quality raw materials and the latest technology by our skilled professionals. In order to ensure quality, this Tap and Tool Grinder Machine is stringently tested on various parameters by our experts. Apart from this, remarkable quality and durability increase the demand for our offered range in the market. No injuries during the re-sharpening process and saving time from re-sharpening taps and tools. The Tap and Tool Grinder Machine is used for re-sharpen the taps and tools. Taps, like all other cutting tools, become dull through use. Dull taps can produce either oversize or undersized holes. They may chip, produce poor threads, or break in extreme cases. This Tap and Tool Grinder Machine is used for dull or bad tools re-sharpening outside and saving the cost of hiring a skilled worker for re-sharpening taps and tools. This Tap and Tool Grinder Machine will be saving you cost and time. Smaller sizes of taps are generally reconditioned by grinding the chamfer portion only, while larger taps may also require flute grinding. Taper pipe taps must be sharpened by grinding the flutes and spiral-pointed taps must be reground in the angular portion of the flute as well as on the chamfer. Flute grinding or spiral point grinding should also be done on a tap reconditioning machine or on a cutter grinder. Flute grinding wheels should be shaped with a diamond dresser of the appropriate type to produce a rake face or hook face as required. Both chamfers and flutes should be ground carefully so as not to burn the cutting edges of the tap, careful grinding will also produce a smooth finish on the tap. Wheels of K or L hardness and 60-grain or finer should be used. Tap and Tool Grinder Machine Features: Conventional design Grinding fast and with high accuracy. Optimum performance Simple to set up. Easy to operate. Long service life

Country of Origin : India

Certification : ISO 9001:2008 Certified

Condition : New

...more

Steel TMT Chaser Rebar Threading Machine

Specifications We have a wide range of semi-automatic Steel TMT Chaser Rebar Threading Machine which is used for site projects and it does outside threading on TMT bars. Steel TMT Chaser Rebar Threading Machine threads the standard EN8-D TMT bar. The threading is done after the Rebar TMT bar forging process. Threading Machine is used for High Production. Industrial Machinery Corporation has been offering a High-Speed Steel TMT Chaser Rebar Threading Machine. This Rebar Threading Machine is made from high-density alloys. This machine is manufactured by our experts using excellent quality components and cutting-edge technology. This Threading Machine is used for saving time and effort. List of threads that can be cut using TMT Rebar Threading Machine: Metric, BSP, BSPT, NPT, UNF, UNC, BSW, Acme Threads, B.S.F. This Threading Machine has features like robust construction, high performance, and durability. Steel TMT Chaser Rebar Threading Machine needs less maintenance and works for long hours. This Machine tool's cost is very cheap. We have gained all the vital mastery and specialized know-how to make the best Rebar Threading Machine arriving in the market. We assemble our Rebar Threading Machine with all the customizations as said by the customer preceding the beginning of production. If you need to buy the TMT rebar threading machine. Industrial Machinery Corporation is a great choice, as they not only offer a vast range, but also the assurance that each machine that is sent out of their unit is a piece of excellence. Our TMT Rebar Threading Machines are running in various countries like Abu Dhabi, Algeria, Australia, Bangladesh, Bhutan, Canada, Central America, Colombia, Germany, Ghana, Jordan, Kuwait, Lebanon, Malaysia, Maldives, Mexico, Myanmar, Nepal, Peru, Philippines, Qatar, Saudi Arabia, South Australia, Sri Lanka, Thailand, Tunisia, Turkey, U.A.E, USA, Vietnam. Steel TMT Chaser Rebar Threading Machine Specifications: Model 1/4" to 1" (6MM to 25MM) (Bed Type) 3/8" to 1.1/2" (10MM to 40MM) (Bed Type) 1/2" to 2.1/2" (12MM to 65MM) (Bed type) Saddle Movement 10" 10" - 12" 22" Spindle Speed Range 75-140 75-140 45-90 Number of Spindle Speed 2 2 3 Threading Capacity 1/4" to 1" 3/8" to 1.1/2" 1/2" to 2.1/2" Production per Hour 60-80 60-80 70-90 H.P. Required 3 H.P. 3 H.P. 7.5 H.P. Lead Screw Optional Optional Optional Weight (KG) Approx. 500 550 990 IMC Tangential Threading Chasers are manufactured from imported High-Speed Steel which must pass exacting metallurgical standards. Experienced heat treatment with the automatically imported heat treatment plant and imported Testing equipment, assure that they will perform satisfactorily in service and produce quality threads within the tolerance for which they ware intended. These Tangential Chasers are used in Rebar Threading Machine.

Country of Origin : India

Type : Tmt Bar

Certification : ISO 9001:2008 Certified

Brand Name : IMC

...more

Scaffolding Pipe Threading Machines

Industrial Machinery Corporation is manufacturing and offering Scaffolding Pipe Threading Machine used for Construction Scaffolding material. The scaffolding pipe can be thread by Thread Cutting or Thread Rolling Process. Hydraulic Scaffolding Thread Rolling Machines are used for high production and long threads and Scaffolding Thread Cutting Machines are used for low production and can thread upto 650mm only. For long thread and high production we recommend you to Thread with Rolling process. Industrial Machine Corporation has been in the business of manufacturing industrial machines for more than a decade now. By being in this business for so long, we have acquired a vast experience and expertise which we have applied all in manufacturing and exporting of various industrial designs to our clients from across the world. Our specialization has made us build each and every machine with utmost technology. IMC manufacturing unit based in Ludhiana is one of the most advanced units comprising of all the latest and upgraded machines, newest to newest technologies, and vastly experienced man-power who use the available resources very wisely to manufacture the best of scaffolding machines. Our zeal and intensity for giving our best every time comes from the fact that customers worldwide have unflinching faith in IMC Hydraulic Thread Rolling and Thread Cutting Machines manufactured at Industrial Machinery Corporation.

Country of Origin : India

...more

Rebar Threading Machine

When one thinks of a Rebar threading machine, the thought automatically goes to the wide range of Rebar machines that one can avail in the domain. However, each manufacturing unit or organization will have the need for one particular type of Threading Machine. For all these 10 years of being in business, we have always kept our production standards very high and ensured that there is no flaw in the entire process. One of the most important factors that you need to think about is the company you are choosing for purchase. A good company will not only give you a product that is worthy of your trust but will also ensure that you receive excellent after-sales services. A good machine, whether it is a rebar threading machine or any other, needs to be high on factors of efficiency while being used and durability as well. If you choose to purchase a rebar machine, it would be a good idea to choose a sales unit that has immense market experience. Industrial Machinery Corporation would be a good choice, as they not only offer a vast range, but also the assurance that every machine that is sent out of their unit is a piece of excellence. IMC TMT bar or Rebar Tangential Chasers are manufactured from imported High-Speed Steel which must pass exacting metallurgical standards. Experienced heat treatment with the automatically imported heat treatment plant and imported Testing equipment, assure that they will perform satisfactorily in service and produce quality threads within the tolerance for which they ware intended. Range of IMC Machine Die Heads. 1/4" to 1" do/-3/8" to 1.1/2" do/-1/2" to 2.1/2" do/- Specifications MODEL 1/4" TO 1" (6MM to 25MM) (BED TYPE) 3/8" TO 1.1/2" (10MM to 40MM) (BED TYPE) 1/2" TO 2.1/2" (12MM to 65MM) (BED TYPE) Saddle Movement 10" 13" 22" Spindle Speed Range 75-140 75 -140 45 - 90 Number of Spindle Speed 2 2 2 Threading Capacity 1/4" to 1" 3/8" to 1.1/2" 1/2" to 2.1/2" Production per Hour 60-80 60-80 70-90 H.P. Required 3 H.P. 3 H.P. 7.5 H.P. Lead Screw Optional Optional Optional Weight (KG) Approx. 500 550 990

Color : Blue

...more

PVC Pipe Threading Machine

We have lanched our new range of P.V.C. Pipe threading to solve your threading problem quality wise & Production wise, we have the above special purpose lathes with capacity from 50mm. to 250mm for 3 mtr. Pipe & 4 mtr. Pipes.

...more

Portable Pipe and Bolt Threading Machine

A portable pipe and bolt threading machine is more often than not, fitted with a system that is truly advanced. This allows for the machine to function not just smoothly, but also in a manner that is hassle free. High level quality processes and constant checks also ensure that the amount of money and time spent on maintenance is minimal. Apart from this, there is also the guarantee that the ultimate output offered will be on the higher side. Some of the signs of a good and reliable portable pipe and bolt threading machine would be that it incorporates features such as a resistance to abrasion and water. The machines have been built to withstand wear and tear as well as breakage. This ensures that whoever invests in this machine, receives full value for the money spent. Companies like Industrial Machinery Corporation offer portable pipe and bolt threading machine that are fabricated in accordance with the specifications provided by the customer. These include sizes for pipes, bolts, conduits, etc. Portable Pipe and Bolt Threading Machine Model No. IMC-PPBTM-1/2" to 2" Sizes for Pipe (Inches) 1/2" to 2" Sizes for Bolts 3/8" - 2 & 10 MM - 33MM Sizes for Conduits 1/2" - 2 & 12MM - 30 MM Specifications 230V/50 Hz., 750W, 27 RPM Die-Head(Inch.) 1/2" - 2 Dies Including (Inch.) BSPT or NPT 1/2" - 3/4" & 1 - 2" Approx. Wt. of the Machine 62 Kgs.

...more

pipe threading machine

We offer well designed Threading Machines in India and abroad. The Threading Machines we offer is known for superb efficiency and low operational & maintenance cost. We are counted among the top Hydraulic Pipe Threading Machine Manufacturers, Suppliers, and Exporters. We offer Threading Machines at reasonable prices. The Hydraulic Pipe Threading Machine Consists of Base, Head Stock, Saddle, Bed or Pillar Type Clamping Vice, Die Head, Apron and Vice Jaws. Pillar Type Hydraulic Threading Machine comes with self opening the die head with head stock gears hardened with power pack, with one hydraulic cylinder for lead screw box nut engaging, one hydraulic clamping cylinder and one hydraulic cylinder for die-head opening with micro switches with automation with control panel. Suitable For Matric BSP BSPT NPT UNF UNC BSW Acme threads B.S.F. threads Range 1/2″ to 2.1/2″ Capacity Pipe 1″ to 4″ Capacity Pipe 2.1/2″ to 6″ Capacity Pipe 4″ to 8″ Capacity Pipe About Components Head Stock : A heavy duty geared Head Box is of best quality casting providing support to the spindle bearings. The box is of gear type, lubricated, fitted with three extra heavy duty bearings. The Bed : The bed is pillar type having two pillars made of best quality steel nicely finished & duly hard chrome plated in the most modern hard chrome plating unit. The Saddle : The Saddle is fitted on two pillers very precisely. It runs on pillars very smoothly and accurately to the Head Stock alignment. The Apron : The apron gives movement to the saddle with head transfer along with pillars through steel rack and pinion arrangements. It’s all gears are made of best quality steel. Vice Jaws : The vice jaws made from the best quality alloy steel are fitted on the saddle well aligned with the head stock center fitted in a heavy duty box type vice. The jaws are heat treated. The movements of jaws are controlled by a screw on the saddle.

Country of Origin : India

Type : Pipe Threading Machines

Condition : New

Automatic Grade : Automatic, Fully Automatic, Manual, Semi Automatic

Brand Name : IMC

...more

Pipe End Facing Machine

Pipe End Facing Machine is used for the purpose of Chamfering and Deburring of the Pipe before Galvanizing and Threading Operation. Pipe is chamfered from the Outer, Inner and Front face by Three different tools. The Pipe remains Stationery and the Facing Head rotates. Slide Travels towards Facing Head for Chamfering manually. The Machine mainly consists of the following: - Bed Head Stock Clamping Vice Saddle

...more

Pipe Cutting Machine

The pipe cutting machine removes material from the pipe or tube to create the desired profile. Typical profiles include straight cuts, miters, saddles, and midsection holes. These complex cuts are usually required to allow a tight fit between two parts that are to be joined via arc welding. Pipe Cutting Machine Specifications:- SPECIFICATIONS IMC-500 PRODUCTION 4000 TO 10000 (PCS /8 HOURS) MAX. DIA OF TUBE TAKEN 65 SAW DIA 10 Vi ELECTRICALS 1.5 K. W/2 H.P. MACHINE DIMENSION 800MM X 1300MM GROSS WEIGHT 450KG.

Country of Origin : India

Certification : ISO 9001:2008 Certified

Condition : New

...more

Pipe Beveling Machine

Industrial Machinery Corporation Pipe Beveling Machine is used for the purpose of beveling the Pipe End. Pipe is Beveled from the Outer and Front is faced by two different tools. The Pipe remains Stationery and the Beveling Head rotates and comes out of the Head Stock for cutting the Pipe End. The Pipe Beveling Machine mainly consists of the following: Bed Head Stock Clamping Vice Beveling Head.BED: - The Bed of Pipe Beveling Machine is made of Cast Iron. It is Very Rigid and sturdy in construction so as to take maximum Load and absorb max. Vibrations. It is provided with four Nos. Foundation Holes of Dia M20 at four corners of the bed. It is also provided with Four Tapped holes of 5/8” BSW near the Foundation Holes. The Head Stock and Clamping Vice is fitted on the Bed. HEAD STOCK: - The Head Stock body of Pipe Beveling Machine is made of Cast Iron. It is Very rigid and sturdy in design. The Head Stock is designed for Four Nos. Spindle speeds. All the Gears are of helical type made out of Axle Forging. The width of gears is 50 mm. The Shifting Gears slide on Spline Shafts. The Shafts are mounted on Heavy Duty Ball Bearings. The Input Shaft will be provided with a pulley having three grooves for C-Section V-belts. The Main Spindle is mounted on two Taper Roller Bearings mounted in Hard Chrome Plated Ground Sleeve. The Sleeve along with main spindle fitted with Beveling Head is mounted in the Head Stock body and is movable To and Fro along its axis. A Hyd. Cylinder actuated electrically makes the movement of the sleeve in the Head Stock. The Movement of the Sleeve can also be made manually. The Head Stock is Oil Filled. It is provided with Oil Filling hole, Oil Drain hole and Oil Level Indicator. CLAMPING VICE: - The Box Type Clamping Vice is fitted on the Bed. The Vice is provided with Round Clamping Jaws for each size (4”, 5”, 6”, 7”, 8”,). The Vice will be Self-centering type. The movement of the Clamping Jaws is made by Pneumatic cylinder fitted on the Vice actuated electrically. The Vice will be very rigid and sturdy in design. Machine will be supplied with single clamping vice. BEVELING HEAD: - A special Beveling Head will be provided with the machine. Two Tools of HSS will be used, One for Beveling and second for Root Face. The Beveling Tool will be mounted in a special Spring Loaded Tool Holder with a Roller device. It is fitted on the main spindle that is then mounted in the traveling Sleeve. Note:- One set of Round Type Clamping Jaws will be provided with the machine. Other Round Type Clamping Jaws are Optional and will be supplied at an extra Cost.

...more

Pipe and Rod Polishing Machine

We, "Industrial Machinery Corporation" established in 2011, have been recognized as a coveted supplier of a wide assortment of Threading Machine, Bar Threading Machine, Bolt Threading Machine, Rod Threading Machine, Rebar Threading Machine. The offered range comprises Cuplock Welding Machine, Mig Welding Machine, Base Jack Welding Machine, Inner Prop Welding Machine and Outer Prop Welding Machines for High production. In addition, we also offer Scaffolding Machinery Unit, Hydraulic Thread Rolling Machine, Power Press Machine, Scaffolding Pipe Threading Machine, Pipe Cutting Machine, Pipe and Rod Polishing Machine, Buffing Machine and Scaffolding Machines. These machines are developed using premium-grade spare parts, components and advanced technologies. Our products are acknowledged for their features such as robust construction, low maintenance cost and high performance. Backed by a sophisticated infrastructure, we have been able to position ourselves ahead of our competitors. This infrastructure aids us in streamlined execution of all the tasks related to our business operations. Moreover, our infrastructure is efficiently managed and controlled by a team of adroit professionals, which are hired by us. These professionals are highly experienced and work in tandem with each other for the successful accomplishment of the assigned tasks. Owing to the dedicated professionals and sprawled infrastructure, we have been able serve our clients in an effective and efficient manner. With the evolving time, we are adopting the technological advances and trying to offer a wide scope of Pipe and Rod Polishing Machine. It is made by our specialists utilizing optimum grade materials. This is utilized for polishing the pipe rods in the required amount. Moreover, this Pipe and Rod Polishing Machine is accessible in particular models and different details at market leading costs. We are engaged in manufacturing and supplying of an extensive variety of Pipe Polishing Machines. These minimal estimated machines are strong in development and guarantee greatest solidness and toughness. Pipe and Rod Polishing Machine Features: Negligible maintenance Robust construction Energy efficiency Automatic Grade Semi-automatic, Fully-automatic Power (HP) 3 H.P., 1440 RPM Specifications : Dia in Wire/Rod 3 to 25 Dia in Pipe 6 to 50 Abrasive Belt 50 x 2000 Power of Motor 3 H.P., 1440 RPM Approx. Weight in Kg. 400/500 Kg. Floor space required 27"x 20"

Country of Origin : India

Automatic Grade : Semi Automatic, Fully Automatic

Type : Automatic Polishing Machine

Certification : ISO 9001:2008

Condition : New

Warranty : 1 Year

...more

Outer prop welding machine

Automatic Outer prop welding machine is used to weld base plate with pipe and sleeve without making any joint between them, it gives high production and accuracy to product. Outer prop is used with combination of Inner prop and base jack to make a structure. All the components are used in combination of each other Base jack welding machine, Inner prop welding machine, Outer prop welding machine, Cup lock welding machine, Ring lock welding machine. This system is based on circular welding on both base plate with pipe and pipe with threaded sleeve from both positions as from top side or inside of sleeve for fastest production and uniform welding and it helps operator be safe from burning skin of continuous welding process. This unit is base on 380 -415 volts 50-60 hz. Ac as input supply and control led with Siemens make plc system and motor drive, clamping of job and de-clamping is pneumatically operated for movement of welding torches. Specifications :- Electric Supply Single Phase 220 Volt HZ 50/60 Speed 2 to 10 RPM Motor Drive AC Inverter Type Motor Type AC 220-Volts-3-Phase Torch Clamping PNEUMATIC Length Adjustment 150 to 2400 mm Dimension L x W x H 11.3x2.5x5.3 (Foot)

Color : Red

...more

MIG welding machine

Mig welding machine that are useful in fixings objects or mounting on any suitable surface. These diode & mig welding machines are manufactured using extreme quality of precision and hardened ground parts. These have high gripping power and are widely demanded due to dimensional accuracy, durability and toughness. Specifications:- ITEM UNIT MIG300 SUPPLY V 380 TO 415/ _+ 10% PHASE PH 3 FREQUENCY HZ 50/60 LOAD KVA 6 OCV(DC) V 22-48 OUTPUT STEPS NOS 8 CONTROL CIRCUIT V 42 TORCH MODEL AK-25(2.75 METERS) MOTOR TYPE PERMANENT MAGNET TORCH CONNECTOR MODEL EURO STANDARD WEIGHT KG 143 KEY FEATURE: - FOR HIGHER PRODUCTION AND RADIO GRAPHIC WELDING

Country of Origin : India

Type : Mig Welding Machinery

Condition : New

Brand Name : IMC

Country of Origin : India

...more

Lathe Machines

While there are a number of lathe machines available in the market today, there are some that are specialized and can be used only for specific purposes. These are used for specific purposes and are meant for certain industries. Standard Accessories Face Plate Motor Plate Steady Rest Follow Rest Full Norton / Semi Norton Gear Box Gear Set Optional Accessories Dog Chuck True Chuck Electric Motor, R/F Starte Lathe Machines Specifications Model BL 4.5' BL 6' BL 8' BL 10' BL 12' Length of Bed 4.5 6 8 10 12 Width of Bed 300 350 400 450 500 Height of Center 250 300 350 400 450 Swing Over Bed 500 600 700 800 900 Swing in Gap 700 800 950 1150 1300 Swing Over Saddle 325 375 450 500 550 Admit Between Center 600 900 1300 1800 2250 Spindle Hollow 40 75 90 100 100 Power Required 1 H.P. 2 H.P. 2 H.P. 3 H.P. 5 H.P. Lead Screw Pitch 2 2 2 2 2 Spindle Speed 6 6 6 6 6 Standard Accessories Face Plate Motor Plate Steady Rest Follow Rest Full Norton / Semi Norton Gear Box Gear Set R/F Starter Optional Accessories Dog Chuck True Chuck Electric Motor, Pully Specialization Semi Gear Head Model (Belt Hardened Bed for Long Life (Optional) Lathe machines Specifications Model L - 4.5' L - 6.5' L - 8.5' L - 10' Length of Bed 4.5' 6.5' 8.5' 10' Width of Bed 275 300 325 325 Height of Centre 225 250 300 300 Swing Over Bed 450 500 600 600 Swing in Gap 550 600 725 725 Swing Over Saddle 200 225 250 250 Admit Between Centre 450 1000 1500 1925 Spindle Hollow 40 75 75 75 Power Required 1 H.P. 2 H.P. 3Â H.P. 3 H.P. Lead Screw Pitch 4 4 4 4 Spindle Speed 6 6 6 6 Standard Accessories Face Plate Motor Plate Steady Rest Follow Rest Semi Norton Gear Box Gear Set Optional Accessories Dog Chuck Motor Pully Electric Motor, R/F Starter Lathe machines Specifications Model LB - 10' LB - 12' LB - 14' LB- 18' LB - 20' Length of Bed 10' 12' 14' 18' 20' Width of Bed 500 500 550 600 650 Height of Centre 450 450 500 550 550 Swing Over Bed 875 875 975 1050 1050 Swing in Gap 1300 1300 1400 1550 1550 Swing Over Saddle 550 550 600 650 650 Admit Between Centre 1800 2250 2700 3600 4050 Spindle Hollow 90 104 104 104 104 Power Required 3Â H.P. 5Â H.P. 7.5 H.P. 10 H.P. 10 H.P. Lead Screw Pitch 2 2 2 2 2 Spindle Speed 6 6 6 6 6 Standard Accessories Face Plate Motor Plate Steady Rest Follow Rest Full Norton / Semi Norton Gear Box Gear Set R/F Starter Optional Accessories Dog Chuck True Chuck Electric Motor, Pully. Lathe machines Specifications Model LBL - 4.5' LBL - 6' Length of Bed 4'6" 6' Width of Bed 250 250 Height of Centre 200 200 Swing Over Bed 390 390 Swing Hollow 42 42 Admit Between Centre 500 1000 No. of Spindle Speeds 8 8 Range of Spindle Speeds 50 - 1200 50 - 1200 No. of Feeds 32 32 Range of T.P.I. Thread 4 -- 56 4 -- 56 T.P.I. of Lead Screw 4 4 Power Requirement 2 H.P. 2 H.P. Standard Accessories Face Plate Motor Plate Steady Rest Follow Rest Gear Set R/F Starter Optional Accessories Dog Chuck True Chuck Electric Motor, Pully Full Norton Gear Box Extra Feed Shaft Specialization Hardened Bed for Long Life (Optional) More Accurate Lathe machines Specifications Model LB - 10' LB - 12' LB - 14' LB 18' LB - 20' Length of Bed 10' 12' 14' 18' 20' Width of Bed 500 500 550 600 650 Height of Centre 450 450 500 550 550 Swing Over Bed 875 875 975 1050 1050 Swing in Gap 1300 1300 1400 1550 1550 Swing Over Saddle 550 550 600 650 650 Admit Between Centre 1800 2250 2700 3600 4050 Spindle Hollow 90 104 104 104 104 Power Required 3Â H.P. 5Â H.P. 7.5 H.P. 10 H.P. 10 H.P. Lead Screw Pitch 2 2 2 2 2 Spindle Speed 6 6 6 6 6

Country of Origin : India

Type : Lathes

Certification : ISO 9001:2008

Color : Blue

Condition : New

Brand Name : IMC

...more

Inner prop welding machine

Automatic Inner prop welding machine is used to weld base plate with pipe without making any joint between them, It gives high production and accuracy to product. Inner prop is used with combination of Outer prop welding to make a structure. All the components are used in combination of each other Base jack welding machine, Inner prop welding machine, Outer prop welding machine, Cup lock welding machine, Ringlock welding machine. This system is based on circular welding on both base plate with pipe and pipe with threaded sleeve from both positions as from top side or inside of sleeve for fastest production and uniform welding and it helps operator be safe from burning skin of continuous welding process. This unit is base on 380 -415 volts 50-60 hz. Ac as input supply and control led with Siemens make plc system and motor drive, clamping of job and de-clamping is pneumatically operated for movement of welding torches. Specifications:- Electric Supply Single Phase 220 Volt HZ 50/60 Speed 2 to 10 RPM Motor Drive AC Inverter Type Motor Type AC 220-Volts-3-Phase Torch Clamping PNEUMATIC Length Adjustment 150 to 2400 mm Dimension L x W x H 11.3x2.5x5.3 (Foot)

Brand : IMC

...more

Hydraulic Pipe Threading Machine

Hydraulic Pipe Threading Machine comes with control panel to operate the machine with automatic and manually. We provide it with power pack and five cylinder to operate the machine more conveniently. It is also available in PLC control with which you can easily maintain the thread length and you don't need to change any settings with one click you can change the thread length of the job. There are many more features come with this machine please send us email and we let you know about it details. In an industry that is increasingly becoming competitive and cut-throat. The only way for any organization to survive is to provide the best product that it can. While in the market of threading machines, the competition is no less and there are a number of companies that are fighting to reach the pinnacle by offering the best in hydraulic pipe threading machine and others. However, there are a few companies that are able to stand heads and shoulders above others and one such company that has carved a niche for itself in the domain of fabricating high-grade threading machine, especially threading machine is the Industrial Machinery Corporation. The pipe threading machine offered here is basically a pillar type threading machine. Which is fitted with an opening mechanism that operates automatically. Which means minimal human labor is required. This threading machine has five separate hydraulic cylinders which ensure the best possible working. While one cylinder is for the pipe clamping process, another is placed to engage the lead screw box nut. The third cylinder has been placed in the machine so as to allow to cover the distance between die-head opening and the job. The fourth cylinder is to open and close the die-head and the final cylinder is to stop the job before the die-head to maintain the thread length required. The Industrial Machinery Corporation too ensures that it manufactures threading machine not only in accordance with industry standards but also keeping in mind the varied requirements of the customers. This is the reason why they offer models with different specifications, including requirement of power, saddle movement, threading capacity, spindle speed range and production per unit time. So, for anyone looking for a hydraulic pipe threading machine, it is important that they consider the above-mentioned factors and ensure that the machine they are picking, has all. Range of IMC Die Heads.1/2" to 2.1/2" Capacity1" to 4" Capacity2.1/2" to 6" Capacity4" to 8" Capacity Hydraulic Pipe Threading Machine Specifications: Model 1/2" to 2.1/2" (12MM to 65MM) (Pillar Type) 1" to 4" (25MM to 100MM) (Pillar Type) 2.1/2" to 6" (65MM to 150MM) (Pillar Type) 4" to 8" (100MM to 200MM) (Pillar Type) Saddle Movement 12" - 16" 10"- 12" 8" 8" Spindle Speed Range 60-90-120 40-75-115 25-50 25-50 Number of Spindle Speed 3 3 2 2 Threading Capacity 1/2" to 2.1/2" 1" to 4" 2.1/2" to 6" 4" to 8" Production per Hour 70-90 35-40 20-25 15-20 H.P. Power Require (960 RPM) 7.5 H.P. 12.5 H.P. 15 H.P. 20 H.P. Lead Screw Automatic Automatic Automatic Automatic Weight (KG) Approx. 990 1600 1900 2500

Country of Origin : India

Type : Hydraulic Pipe Threading Machine

Automatic Grade : Automatic, Semi Automatic

Warranty : 1year

Brand Name : IMC

...more

Hydraulic Pipe Thread Rolling Machine 3Roll Type

IMC Hydraulic Scaffolding Pipe Thread Rolling Machine is used to produce high quality scaffolding pipe threads. They are ideal for high volume production, are highly economical and ensure excellent dimensional accuracy. Industrial Machinery Corporation is a well known hydraulic machines manufacturer, supplier and exporter of Hydraulic Rolling Machines-Two Roll Types, Hydraulic Rolling Machines-Three Roll Types, etc. These hydraulic machines are ideal for mass production purposes and help in creating the best surface finishes. The 3 rollers IMC-3R Hydraulic Pipe thread rolling machine operates hydraulically. The simultaneously and concentrically of three forces at 120 assure stability of the work piece during the rolling and as a consequence the maximum geometrical precision of the work piece. The elimination of the support blade consents a better finishing of the piece and the execution of particularly delicate profiles. The hydraulic thread rolling machine is suitable for rolling pipes, rolling bolts, lapping work with a high class precision and for mass production of Scaffolding pipe jack and solid jacks screws etc. The maximum values specified above can not be achieved simultaneously Hydraulic Thread Rolling Machine Model IMC-3R-25 IMC-3R-50 IMC-3R-75 Work Range Out Side DiameterThread Length in FeedThread Length Through Feed (8-25 MM) (1/2"- 1")(38 MM) (1.1/2")(Indefinite) (Indefinite) (25-50 MM) (1"- 2")(50 MM) (2")(Indefinite) (Indefinite) (32-75 MM) (1.1/4"- 3")(75 MM) (3")(Indefinite)(Indefinite) Roll Dies Max. Out Side Dia.Max. Inside DiaSpindle Box 1406040 1406040 1708054 Motor For Roll Spindle 3 H.P. 3 H.P. 7.5 H.P. 3 Phase AC For Hydraulic System 1 H.P. 1 H.P. 3 H.P. Coolant Pump 0.1 H.P. 0.1 H.P. 0.1 H.P.

Brand Name : IMC

...more

HORIZONTAL LEDGER WELDING SYSTEM

Horizontal ledger welding machine designed to weld ledger blades together at the same time, machine hold and weld the blades proportional to each other. This unit is pneumatically operated for clamping the ledger blades with pipe and also the movement of welding torches, the machine has screw wheel drive to adjust the length from 500mm to 2500mm. As per own requirement. Machine itself has adjustments for different welding angles as 360 angle adjustments. Left to right adjustments & height adjustments available for better penetration. Automatic Ledger welding machine is used to weld ledger blades with pipe without making any joint between them, It gives high production and accuracy to product. Ledger post are used with combination of Cup lock welding to make a structure. All the components are used in combination of each other. Base jack welding machine, Inner prop welding machine, Outer prop welding machine, Cuplock welding machine, Ringlock welding machine. Specifications :- Ledger welding Double Side Electric Supply Single Phase 220 Volt HZ 50/60 Speed 2 to 10 RPM Motor Drive AC Inverter Type Motor Type AC 220-Volts-3-Phase Torch Clamping PNEUMATIC Length Adjustment 150 to 2400 mm Dimension L x W x H 11.3x2.5x5.3 (Foot)

Country of Origin : India

Type : Horizontal Ledger

...more

H Type Power Press Machine

The raw material used in the manufacturing of our H Type Power Press Machine is drawn from the best and most reliable resources and prior to getting used, it is checked meticulously for and hidden flaw or fault. If any part is found defected or of low quality is straight away restricted from getting used. We love to maintain the quality of our H Type Power Press Machine to a sky height as we realize that the competition s stiff and there are many companies who are behind us and are trying continuously to leave us behind. The technical staff working with us is alert day and night to make sure that the quality of our H Type Power Press Machine is unmatched and unparalleled with H Type Power Press Machine of any other company. We are proud of our H Type Power Press Machines which are considered best in terms of quality, efficiency, durability, compatibility, adaptability, strength and prices. We use state-of-art technology and have the industrial expertise to construct these heavy-duty machines. Also, the speedy and accurate performance of Our H Type Power Press Machine has made the work simple for various Industries. Moreover, we are consistently marching ahead in providing products of international standard in this fiercely competitive market scenario. This not only ensures maximum customer satisfaction but also enables us in earning varied clientele in the international market. Our H Type Power Press Machine is widely accepted around the world in various industries sectors. Specifications of H Type Power Press Machine : Â Model 10 Ton 20 Ton 30 Ton 50 Ton 75 Ton 100 Ton 150 Ton 200 Ton 250 Ton 300 Ton 400 Ton 500 Ton Bed Size 300 X 350 350 X 400 400 X 450 450 X 500 550 X 600 600 X 650 650 X 700 750 X 800 800 X 850 900 X 950 1000 X 1050 1100 X 1100 Bed To Ram Bottom 250 250 300 375 400 450 465 500 550 600 650 700 Stroke Length 55 60 80 95 110 125 150 160 175 200 200 200 Gear Dia 450 525 600 650 750 850 1000 1050 1200 1200 1200 1250 Crank Shaft Dia 70 80 90 110 125 150 175 200 225 250 300 300 Fly Wheel Dia 525 650 700 800 900 1000 1100 1200 1300 1375 1500 1500 Hole in Ram Clamping Die 25 28 32 40 45 50 55 60 70 80 100 110 No of Stroke per minute 55 55 50 50 45 40 40 35 30 25 20 20 Power Required in HP 2 2 3 5 7.5 10 15 20 25 25 30 35 Motor 1440 1440 1440 1440 1440 1440 1440 1440 1440 1440 1440 1440

Country of Origin : India

Certification : ISO 9001:2008

Condition : New

Type : Power Press Machine

Brand Name : IMC

...more

Flat Die Thread Rolling Machine

Each work in our industries requires specific machine, which gives reason to manufacture a variety of machines for different purposes. This is indeed helpful, but when it comes to pick the right machine for the right work, users get in a tight spot. Let's talk about making ridges on bolts. Now, there are different companies that claim their machines to be the finest in doing this job, however when it comes to the actuality, the world knows that Flat Die Thread Rolling Machine is the only one to do it with excellence. If you have been perplexed with the variety of options available, then you have landed on the right spot, as here we will guide you in and out about this special cast of Flat Die Thread Rolling Machines. This article will give you all the information about this Thread Rolling Machine, which is specialized in making ridge on bolts. We use bolt in our daily life very often, but rarely think how these are made? Or, how they get ridges on it? Well, answer of these questions is Flat Die Thread Rolling Machine. It does not really make bolts, but gives them shape.. The flat die thread rolling machine, also give ridges to the bolts, which are used in the supply of liquid material, from one place to another place. It comes in various models. There are models with which one can make helices on a bolt, whose diameter is less than an inch. Speed of execution of a thread also varies from model to model. Base model of this Machine manufacture 80 pieces in one minute, while the top model of this Machine produce 20 pieces in one minute, but the top model, create helices on four inches bolt. The electricity consumption of Flat Die Thread Rolling Machine also varies with their models, as the base model guzzles two horsepower while the top model guzzled twenty horsepower, which is really a big number, in the consumption of electricity. If you are planning to start the business of producing thread, Industrial Machine Corporation is one of the best manufacturers of these Flat Die Thread Rolling Machines. Flat Die (For thread the job) is also available in our ready stock. The D2 raw material is use to manufacture of these flat die. Flat Die Thread Rolling Machine: Model No. FDTRM-1 FDTRM-2 FDTRM-3 FDTRM-4 FDTRM-5 FDTRM-6 FDTRM-7 Min. Max. Dia Can Be Rolled 1/16"x1/4" 1/8"x3/8" 1/8"x1/2" 1/4"x5/8" 1/4"x3/4" 1/4"x7/8" 3/8"x 1" Max. Length of Thread 2" 2.1/2" 3" 3" 4" 4" 4" Dimension of Fixed Dia 3"x2"x 1" 5"x2.1/2"x 1" 5"x3"x1" 6"x3"x 1" 6"x4"x 1" 7"x4"x 1" 8"x4"x1.1/2" Dimension of Moving Dia 4"x2"x 1" 6"x2.1/2"x 1" 6"x3"x1" 7"x3"x 1" 7"x4"x 1" 8"x4"x 1" 9"x4"x1.1/2" Production in Pieces Per Minute 80 60 60 50 30 30 20 Power Required in H.P. 2 3 5 7.5 10 15 20

Color : Green

...moreBe first to Rate

Rate ThisOpening Hours