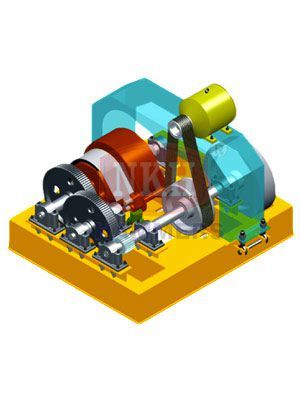

Industrial Oil Mill Machinery

Get Price Quote

Industrial Oil Mill Machinery We are manufacturer & exporter of Oil Mill Machinery on turnkey basis. We manufacturer machinery & equipment for Oil Mill Plant by using high quality material and modern technology at our state of the art machining facility. We can also customize these plants as per our valuable client’s requirements. Goyum Oil Mill Machinery is suitable for crushing various oil seeds & nuts such as: Soybean / Soya bean, Cottonseed, Groundnut / Peanut / Earthnut, Palm Kernel, Sunflower Seeds, Shea Nut, Mustard Seeds, Copra / Coconut, Sesame Seeds, Cashew Nut Shell, Rapeseed / Canola Seeds, Neem Seed, Niger Seeds, Castor Seeds, Cashew Nut Shells, Corn Germs, Jatropha Seeds, etc. Some of the basic equipment / machinery required for Oil Mill Machinery is as under: · Seed Cleaner · Oil Expeller / Oil Press · Oil Filter Press · Steam Boiler · Bucket Elevator · Screw Conveyor · Volumetric filling machine · Control Panel The Oil Mill Machinery crushing capacity starts from 15 TPD onwards. The Oil Mill Plant is designed, manufactured, supplied and installed & commissioned on turnkey basis. Are You Looking to Start a New Oilseed Mill Machinery or Further Expansion? Don’t hesitate to contact us, if you are interested to get a customised quotation with Equipment Details and Prices for Oil Mill Machinery

Wire Rod Polishing machine

250,000 - 350,000 Per piece

1 Piece (MOQ)

Best Deals from Industrial Machine

Industrial Sewing Machine

4,250 Per Piece

poonam industrial sewing machine.

Metal Nibbling Machine

395,000 Per Piece

Paper Napkin Making Machine

Get Price Quote

While purchasing the product from us, you can choose to make payment through any mode. Our personnel will assist you to pay for your purchases conveniently. We lay special emphasis on the packaging so as to ensure damage-free deliveries. For this, we make use of high quality material for wrapping our products.

Metal Nibbling Machine

Get Price Quote

Cap Knitting Machine

Get Price Quote

Cap knitting machine is a knitting machine available with computerized jacquard and automatic cutter. It has the stitch caps which make it convenient to use and operate for the customers. This stitch cap gives the facility for automatic ejection piece by piece. Our cap knitting machine is excellent with its performance. advantage : easy to operate best pricereliable qualityhigh performance specifications diameter of cylinder8" or 9"needles192 ~ 360rpm40 ~ 70supply voltage380v , 50hzpower1.5 kw

TL82 Industrial Sewing Machine

3,400 - 3,600 Per piece

Fully Automatic Cake Tray Making Machine

Get Price Quote

Fully Automatic Cake Tray Making Machine that we offer is manufactured keeping in mind the set industry standards. It is subjected to stringent quality tests so as to ensure its defect-free mechanism. We are named among the renowned Manufacturers and Suppliers of Cake Tray Making Machine from Punjab, India. We entertain retail as well as bulk orders for Cake Tray Making Machine. It can be obtained from us at the best market price. Details : DGT Automatic Cake Tray Forming Machine adopts the advanced technology introduce from Italy through digestion,integration,and self-innovation.It is the first-class level in technology at home and in the international track. It employs the new technology like manipulator clipper pneumatic in controlling the paper,automatic separating paper,mould punching-forming in heat and topping. It can make paper trays for cakes and aluminuim foil trays for cakes with different specifications through exchanging the moulds. It is characterized by compact construction,easy to operation,higher production efficiency and regular performance.

CARPET OVER SEAMING MACHINE

Get Price Quote

We are offering carpet over seaming machine. Model gc02 carpet over seaming machine 1 needle 2 thread or 3 piece for over edging the selvage of heavy carpets or rugs. stitch length : 2-7 mm overseam width : up 12 mm material thickness : up to 14 mm speed : 1800 rpm needle : dcx2#24,25,26,28

TRANSFER SYSTEM POWER FLAT KNITTING MACHINE

125,000 Per piece

1 piece (MOQ)

horizontal Rotary grinding machine

Get Price Quote

With our expertise in the concerned field, we are engaged in offering a wide array of Grinding Machinery, Lathes Machinery and Tool & Cutter Machinery that are widely used in various industries for different purposes. These are manufactured using the best quality factor inputs in order to meet the international quality standards. Further, these are available in various sizes, capacity and dimensions, and can be customized as per our clients’ specifications. We Offer: The base is made of heavy duty, closed grain grey cast iron amply proportion to give a rigid foundation. so essential for precision grinding. The base houses for electrical control, gear main driving system to work slide and coolant, arrangement. The grinding head is supported by a box type column gives regidity and minimum deflection at the wheel head. the special type motor is provided with tapper rolling bearing

Rotary Mulcher

Get Price Quote

Rotary Surface Grinding Machine

Get Price Quote

FEATURES: • This series features our rotary series with a Horizontal/ Vertical spindle. • These machines are particularly suitable for High Precision Surface grinding of thin parts of high accuracy, or circular parts where one piece is to be ground at a time flat. • In applications where batches of small parts are to be ground with a high degree of parallelism & high surface finish this type of machine is a faster alternative to reciprocating grinding. • This is because the grinding wheel is in constant touch with the grinding pieces, the operating speed of the work pieces is higher and the work pieces move continuously in one direction. • High precision cartridge type Spindle is mounted on machine, ensuring high Accuracy, Good Surface finish, No Temperature rise and long maintains free life.

Industrial Sewing Machine

Get Price Quote

Zig Zag Sewing Machine, Table Stand, button cover machine

Head Assembly

Get Price Quote

Heavy duty head assembly fabricated from rolled steel sections is mounted on top of the columns. The drive is through v-belts from high torque A.C. Electric motor via flywheel and reduction gears to the lifter-shaft. Friction lifting system is fitted to lifter shaft which runs on double ball bearings and one central phosphorus bronze bearing which also serves as support to lifter shaft. The friction lifter consists of constantly rotating drum and break lined steel band. This band is anchored at one end to stud in lifter drum and other end is carried by camshaft running through lifter drum which actuated by lever. The lever is operated with the help of pulling cord tied to lever at one end goes to operating point by passing through capstan bush attached to lifter shaft. When the cord is pulling it tightens on to the rotating capstan bush which operate the lever resulting in tightening of brake around the brake drum with the help of cam shaft. At this stage lifter drum is rotated and to tup is lifted with the help of nylon belt provided. On release of cord the spring loaded arrangement help free fall of tup by disengaging friction band immediately from the friction drum. The spring loaded buffer work as a stopper for lifting drum is its rest position. Positive water cooling arrangement is provided to the friction drum to prevent excessive heating.

Automatic Strap Knitting Machine

215,000 Per Piece

Dough Feeder Machine

Get Price Quote

The Dough Feeder system comprising various types of machines is required to feed the Dough Feeder automatically either to the laminator or rotary biscuit moulding machine in pre-sheeted form or in lumps form. Design The Dough Feeder machine, comprising tub hoist-cum-tilter, single tilter, dough sheeter with crumblier and reciprocating conveyor for even distribution onto to the next machine in process. Capacity As per the length and width of the oven, the system can handle up to 5000 kg / hr of dough. Salient Features: All contact parts of Dough Feeder in Stainless steel. PLC controlled with optional metal detector.

Industrial Sewing Machine

Get Price Quote

We offer Industrial Sewing Machine. Model - 103 K Model - 103 K INDUSTRIAL SEWING MACHINE (TA-1): 1 Needle, 2 Threads, high speed lock stitch sewing machine for Industrial use. Balance rotary hook system driven by spiral bevel gears. Presser Foot control by hand or by knee lifter. Quick reverse action lever. Stitch Length : 5 to 30 stitches per inch Speed : 3000 RPM Net Weight : 14.0 (Head only)

Festooning Machine

Get Price Quote

Festooning Machine, carding machines, textile mill

Mini Compact Rice Mill Machine,

275,000 Per Piece

Cap Knitting Machine

Get Price Quote

We offer Flat Knitting machine for Caps.

Knee Cap Making Machine

Get Price Quote

With the help of our team of experienced designers, we manufacture, export and supply superior quality Knee Cap that is widely demanded by sportsmen and athlete. This product is designed using optimum grade fabric and other allied material by our designers in order to fulfill the ongoing fashion trends. For ensuring the quality of this cap, our quality analysts test this product on various parameters prior to dispatch it from our end. Our offered Knee Cap is made available in different designs, colors and sizes to meet our clients' vast demands.

linking machine

Get Price Quote

computerized cap embroidery machine

Get Price Quote

Metal Nibbling Machine

100,000 Per Piece

rotary sheet cutter machine

Get Price Quote

Bopp Self Adhesive Tapes

Get Price Quote

We are one of the renowned suppliers of a wide range of packaging products such as BOPP Tape. Our tapes are made of thin plastic films and offered in different sizes and surface finishing so as to fulfill the broad demands of the industry. Salient properties of our plastic tapes are light weight, superior fixing strength and moist proof.

Industrial Sewing Machine

Get Price Quote

Sewing Heads For Conveyor Systems

Get Price Quote

RC-8D - Twin needle, four thread, parallel double chain-stitch sewing headThe RC-8 sewing head is a rugged, simple to operate and efficient bag closing machine for conveyor systems. Simple mechanism for adjusting the stitch length from 5 mm to 9 mm makes the RC-8 ideal for stitching filled bags of all kinds of HDPE, PP, Jute, Hessian and various types of kraft-wall paper bags with synthetics or cotton thread. The moving parts inside the machine are sealed against dirt and dust particles to ensure less maintenance is required than conventional conveyor bag closing sewing heads. It is used for closing mouths of bags filled with fertilizers, sugar, rice, flour, cattle feed etc. The mechanical cutter is available as standard in both the RC-8 models which helps severs the thread chain with ease after the bag has been securely stitched.The RC-8 sewing head is available with a wide choice of slat or belt conveyor systems in various lengths. Conveyors can also be custom manufactured to different specified lengths. The machine also has provision of a variable speed pulley allows synchronization with existing conveyor systems.