Fully Automatic Industrial Oil Processing Machine

6,557,000 - 6,972,000 Per Set

1 piece (MOQ)

BSRM-10 Vibtaror Feeder Thread Rolling Machine

480,000 Per Unit

1 Unit (MOQ)

Best Deals from Industrial Machine

Brolis Rotavator Rotary Tiller Machine

Get Price Quote

1 piece (MOQ)

Rotovator, an alternative name for a rotary tiller,is a farm implement used for tillage also known as rototiller, rotavator, rotary hoe, power tiller, or rotary plough.BROLIS Manufacturers Regular series of rotary tiller/Tractor Mount Rotavator is specially designed for wet land, light land & medium soil. Roatavator designed is light In weight but sturdy by structure which makes this range most suitable for paddy fields and dry field. It is available in working width of 4ft, 4.5ft, 5ft, 5.5ft, 6ft,6.5ft and 7ft. Machine can be operated with any 35 and above HP tractor having 540/1000 rpm PTO with dual clutch. Machine can be attached to the tractor using three point linkage systems. Input power supplied through PTO of the tractor using propeller shaft with universal joints.The machine is provided with the specially designed L and C type of blade to use in wet and dry land condition.Specially designed blade reduces load on tractor and minimize the tyre slippage which enhance the productivity of machine. Features Specially designed Leakproof Aluminium Casting Gear Box. Baldes are Tempered & made of Boron Steel from Italy. Available with L-Type or C-Type blades- Interchangeable. Export Quality Heavy Duty Gear Box. Nut and Bolt is made of High Tensile Steel (10.9 Grade). Side Transmission is driven through Gears providing Smooth Drive & Longer Service Life. Save Fuel & Time. Available from 1.25 mrt to 2.00 mtr size for 30 H.P to 60 H.P tractors. Heavy Duty PTO Shaft with Shear Bolt for overload protection. Advantages Recommended for Sandy Soil operation & Heavy operation. By combining disking, cultivating and planking, rotavator prepares soil quickly for sowing. Breakup the hard and dense clod and lumps of soil. Rotary Tiller has powerful Gear Type Transmission which is more powerful than chain type rotary tiller . Rotary Tiller helps in reducing tractor’s wear and tear, save fuel & time, maintain the moisture of the soil. Rotary tiller prepares all type of soil – Wet & Dry. Stubbles and residue of previous crop is chopped into pieces and thoroughly mixed in soil to form organic manure. Rotary Tiller is extremely helpful in Sugar Cane, cotton, Paddy and Vegetables cultivation. Heavy Duty PTO Shaft with Shear Bolt for overload protection.

Industrial Wire Cutting & Straightening Machine

325,000 Per Piece

1 Piece (MOQ)

Split Warping Machine

2,000,000 - 3,000,000 Per piece

1 set (MOQ)

Features : Intelligent man-machine interface, easy to operate Speed tracking servo frequency conversion control, automatic contro! detection mechanism. Computer real-time detection, intelligent tension control. Pneumatic control of beams loading and unloading, linear lifting and stable operation. Main braking adopts electromagnetic braking method, which is safe and reliable. The warping tension is even and the tension fluctuation is limited. The machine uses reliable and durable accessories, cost-effective in operation and maintenance.

Rod Polishing Machine

Get Price Quote

1 Piece (MOQ)

Briquetting Machine

Get Price Quote

Briquette Machine is used to make briquette out of any agricultural and forest waste. First of all, briquetting means reducing the size of bulk density raw material into compact form, which makes it easy for transportation, burning and increase its calorific values as well. Briquetting Machine produces quality briquettes without any need of binder or chemical. It compact the raw material with the help of high pressure mechanical punch. However, during the contraction of the material, temperature rise adequately to make the raw material emancipate the numerous adhesives that will abetment in protecting the bits together in the compressed shape.

Pipe and Rod Polishing Machine

Get Price Quote

We, "Industrial Machinery Corporation" established in 2011, have been recognized as a coveted supplier of a wide assortment of Threading Machine, Bar Threading Machine, Bolt Threading Machine, Rod Threading Machine, Rebar Threading Machine. The offered range comprises Cuplock Welding Machine, Mig Welding Machine, Base Jack Welding Machine, Inner Prop Welding Machine and Outer Prop Welding Machines for High production. In addition, we also offer Scaffolding Machinery Unit, Hydraulic Thread Rolling Machine, Power Press Machine, Scaffolding Pipe Threading Machine, Pipe Cutting Machine, Pipe and Rod Polishing Machine, Buffing Machine and Scaffolding Machines. These machines are developed using premium-grade spare parts, components and advanced technologies. Our products are acknowledged for their features such as robust construction, low maintenance cost and high performance. Backed by a sophisticated infrastructure, we have been able to position ourselves ahead of our competitors. This infrastructure aids us in streamlined execution of all the tasks related to our business operations. Moreover, our infrastructure is efficiently managed and controlled by a team of adroit professionals, which are hired by us. These professionals are highly experienced and work in tandem with each other for the successful accomplishment of the assigned tasks. Owing to the dedicated professionals and sprawled infrastructure, we have been able serve our clients in an effective and efficient manner. With the evolving time, we are adopting the technological advances and trying to offer a wide scope of Pipe and Rod Polishing Machine. It is made by our specialists utilizing optimum grade materials. This is utilized for polishing the pipe rods in the required amount. Moreover, this Pipe and Rod Polishing Machine is accessible in particular models and different details at market leading costs. We are engaged in manufacturing and supplying of an extensive variety of Pipe Polishing Machines. These minimal estimated machines are strong in development and guarantee greatest solidness and toughness. Pipe and Rod Polishing Machine Features: Negligible maintenance Robust construction Energy efficiency Automatic Grade Semi-automatic, Fully-automatic Power (HP) 3 H.P., 1440 RPM Specifications : Dia in Wire/Rod 3 to 25 Dia in Pipe 6 to 50 Abrasive Belt 50 x 2000 Power of Motor 3 H.P., 1440 RPM Approx. Weight in Kg. 400/500 Kg. Floor space required 27"x 20"

Paper Cup Handle Making Machine

Get Price Quote

1 Set(s) (MOQ)

Our company is recognized as one of the prime Manufacturers and Suppliers of Paper Cup Handle Making Machine in India. We have two working stations, which produce two different sizes of cups at a time. Our machine is suitable for 5-12 ounce paper cups. This machine is available from us at market-leading rate without compromising its optimum quality and standard performance. We can process bulk orders. Machine Description : SZB Paper Cup Handle Machine has two working station, which can produce different size products. Through changing the moulds, this machine is suitable for 5-12ounce paper cup. Price - 250000/-Rs

Pedal Filling Machine

Get Price Quote

TGJ Pedal filling machine This machine can be used to fill foods,medicine,cosmeticand chemicals in liquid or semi-liquid form,like beverage,tooth-aste,craem,jam,shoe polish,ink,starch gum,cold cresm,butter etc,The filling capacity is adjustable,turstworthy action,ac-tion,accurate measure. Specification Filling speed: ArtificialNet Weight: 40KgFilling volumes range: 10ml-150ml 30ml-300mlFilling accuracy: ±1%Capacity of bumker: 30KgMachine Size: 600mm×410mm×1500mm

Biscuit Rotary Cutting Machine

1,200,000 Per Piece

Can Reformer Machine

65,000 Per Piece

Rotary Surface Grinding Machine

Get Price Quote

FEATURES: • This series features our rotary series with a Horizontal/ Vertical spindle. • These machines are particularly suitable for High Precision Surface grinding of thin parts of high accuracy, or circular parts where one piece is to be ground at a time flat. • In applications where batches of small parts are to be ground with a high degree of parallelism & high surface finish this type of machine is a faster alternative to reciprocating grinding. • This is because the grinding wheel is in constant touch with the grinding pieces, the operating speed of the work pieces is higher and the work pieces move continuously in one direction. • High precision cartridge type Spindle is mounted on machine, ensuring high Accuracy, Good Surface finish, No Temperature rise and long maintains free life.

Wire Rod Polishing machine

250,000 - 350,000 Per piece

1 Piece (MOQ)

cap printing machine

Get Price Quote

TRANSFER SYSTEM POWER FLAT KNITTING MACHINE

125,000 Per piece

1 piece (MOQ)

Tubler Knee Cap Bandage Machine

Get Price Quote

Clients can avail from us the technically efficient Tubler Knee Cap Bandage Machine at very reasonable price. The Tubler Knee Cap Bandage Machine is made as per the latest technology and is quite dependable.

Vertical Rotary Grinding Machine

Get Price Quote

With our expertise in the concerned field, we are engaged in offering a wide array of Grinding Machinery, Lathes Machinery and Tool & Cutter Machinery that are widely used in various industries for different purposes. These are manufactured using the best quality factor inputs in order to meet the international quality standards. Further, these are available in various sizes, capacity and dimensions, and can be customized as per our clients’ specifications. We Offer: The base is made of heavy duty, closed grain grey cast iron amply proportion to give a rigid foundation. so essential for precision grinding. The base houses for electrical control, gear main driving system to work slide and coolant, arrangement. The grinding head is supported by a box type column gives regidity and minimum deflection at the wheel head. the special type motor is provided with tapper rolling bearing

Rod Polishing Machine

Get Price Quote

Rotary Mulcher

Get Price Quote

Automatic Strap Knitting Machine

215,000 Per Piece

Paper Cup Making Machine

750,000 Per Piece

1 Piece (MOQ)

Number Plate Making Machine

Get Price Quote

Our products are kept under safe conditions in our well-maintained warehouse. The facility is installed with all required amenities and supervised by experts for safe storage. With our years of experience, our company name figures amidst the most responsive and responsible Suppliers of Number Plate Making Machine. Features: Precision engineered High productivity Reasonably priced

CARPET OVER SEAMING MACHINE

Get Price Quote

We are offering carpet over seaming machine. Model gc02 carpet over seaming machine 1 needle 2 thread or 3 piece for over edging the selvage of heavy carpets or rugs. stitch length : 2-7 mm overseam width : up 12 mm material thickness : up to 14 mm speed : 1800 rpm needle : dcx2#24,25,26,28

Hand Lever Crown Capping Machine

7,500 - 7,800 Per Piece

1 Piece (MOQ)

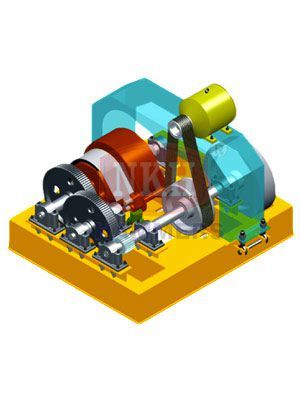

Head Assembly

Get Price Quote

Heavy duty head assembly fabricated from rolled steel sections is mounted on top of the columns. The drive is through v-belts from high torque A.C. Electric motor via flywheel and reduction gears to the lifter-shaft. Friction lifting system is fitted to lifter shaft which runs on double ball bearings and one central phosphorus bronze bearing which also serves as support to lifter shaft. The friction lifter consists of constantly rotating drum and break lined steel band. This band is anchored at one end to stud in lifter drum and other end is carried by camshaft running through lifter drum which actuated by lever. The lever is operated with the help of pulling cord tied to lever at one end goes to operating point by passing through capstan bush attached to lifter shaft. When the cord is pulling it tightens on to the rotating capstan bush which operate the lever resulting in tightening of brake around the brake drum with the help of cam shaft. At this stage lifter drum is rotated and to tup is lifted with the help of nylon belt provided. On release of cord the spring loaded arrangement help free fall of tup by disengaging friction band immediately from the friction drum. The spring loaded buffer work as a stopper for lifting drum is its rest position. Positive water cooling arrangement is provided to the friction drum to prevent excessive heating.

battery cutting machine

700,000 Per Each piece

Battery Recycling Plant

4,500,000 Per Set

Battery Recycling Plant:- We are the most prominent turnkey suppliers of complete Battery Recycling Plants in the region & machinery of Secondary Lead & Battery Recycling which includes: 1. Battery Cutting Machine. 2. Rotary Furnace Shell & Driving System. 3. Air Pollution Control System. 4. Fugitive Emission Control System. 5. Lead Refining Kettle. 6. Ingot Casting Machine. 7. Heating & Pumping Unit. Features: Easy installation Commercial production

BFC-09 - Multi-purpose locking and capping machine

Get Price Quote

Name£º JGS-980 Multi-purpose locking and capping machine Model£º JGS-980 Description£º Summarize:JGS series multi-purpose locking and capping machine is suitable to theft-proof locking/capping revolving shell, turning cap and embossing in various kinds of glass, plastic, porcelain and polyester bottles.

Cap Knitting Machine

Get Price Quote