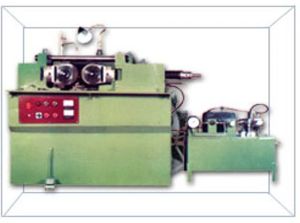

Thread Bar Machine

Using premium packaging materials, we secure our products properly for transportation and label it properly to provide information such as address of manufacturer/distributors, MRP, quantity, etc. Our raw materials are essential bottleneck assets and thus these are carefully selected by our expert quality auditors after checking against varied quality parameters. Range : Pointing machine Wire drawing machine Straightening and cutting machine Thread rolling machine Galvanised or zinc plant

Brand Name : NCT

Country of Origin : India

...more

Tangential Chaser

We stringently make complete arrangements for the vigil examination of the inputs used for the products. By this, we are capable of bringing forth reliable products that are presented after complete inspection and examination by the experts. We maintain proper schedules for the delivery of bulk or urgent consignments so as to deliver the range in set time and gain utmost customer satisfaction. Die Head Capacity Chase Section Die Head size 1/4 to 1 Chaser size 3 x 1.3/64 (Set of 4 Pieces) Die Head size 3/8 to 1. 1/2" Chaser size 4 x 1.3/64 (Set of 4 Pieces) Die Head size 1/2 to 2 Chaser size 4 x 1.1/4 (Set of 4 Pieces) Die Head size 1/2" to 2.1/2 Chaser size 4 x 1.1/4 (Set of 4 Pieces) Die Head size 1 to 4 Die Head size 1 to 2 Chaser size 4 x 1.1/4 (Set of 4 Pieces) Die Head size 2.1/2 to 4 Chaser size 5 x 2.1/4 (Set of 4 Pieces) Die Head size 2.1/2 to 6 Die Head size 2.1/2 to 3 Chaser size 5 x 2.1/4 (Set of 6 Pieces) Die Head size 3 1/2 to 4 Chaser size 5 to x 2.1/4 (Set of 6 Pieces) Die Head size 4.1/2 to 6 Chaser size 5 to x 2.1/4 (Set of 6 Pieces) Die Head size 4 to 8 Die Head size 4 to 5.1/2 Chaser size 5 to x 2.1/4 (Set of 6 Pieces) Die Head size 5.1/2 to 8½ Chaser size 5 to x 2.1/4 (Set of 6 Pieces)

...more

Scaffolding Thread rolling machine

Our organization assures distribution of wholesale as well as retail consignments of the goods as per the jointly decided period. After the goods are sternly examined by the experts, the picking, checking, labeling and packing commences in the substantial warehouse. Sprawling over a large area, we ensure that the goods are packed with utmost proficiency. Features : User-friendly Precision engineered QC verified High productivity

...more

Scaffolding Cuplock Welding Machine

We maintain proper schedules for the delivery of bulk or urgent consignments so as to deliver the range in set time and gain utmost customer satisfaction. We are instrumental in offering extensive range of products that is in compliance with the internationally accepted standards. Thus, the final products are of excetional quality. Features : Corrosion resistance Sturdiness Precision-designed Specifications : Item Unit Cuplock / Ring Lock Supply v 220 Phase Nos. SINGLE Frequency Hz. 60 Speed RPM 2 to 10 Motor Drive TYPE AC Inverter Motor TYPE 3-Phase Torch Clamping TYPE PNEUMATIC Length Adjustability mm 150 to 2400 Dimensions LxWxH 11.3 x 2.5 x 5.3 (Foot) Yes! I am interested

...more

Rod Threading Machine

Using only quality raw materials, our entire range of products is manufactured. We make sure that the raw materials we use are thoroughly checked against varied quality parameters. According to your convenience, to pay for an order, our company can settle on a method of payment. We are familiar with online and offline payment methods. We only want to make payment safe and secure for you. Details : The Rod Threading Machines are designed to give maximum efficiency and reliable performance under the most severe conditions of service with minimum maintenance cost. All the necessary requirements are combined in this model to from the basic fundamentals of correct threading. All the gears are made of case hardened steel with extra large face with and tooth thickness and cut on hobbing machine for noiseless operation even at high speed. Naturally the are built with high standards of workmanship, material and quality so closely associated with Company Tradition. The Rod Threading Machine is used for Cutting External Thread on Rod by Chasing method. HSS Tangential Chasers are used as cutters. Rod remains stationery and Die Head rotates. BSP, MATRIX, BSPT, NPT, UNF,UNC, BSW, Acme Threads can be cut on this machine depending upon the type of Chasers. The machine mainly consists the following : Base Head Stock Saddle Pillar Type Or Bed Type Clamping Vice Die Head Design & Workmanship : The National Cutting Tools Rod threading machines are designed to produce quality threads within the to lerance for which they were intended. Head Stock : A heavy duty geared Head Box is of best quality casting providing support to the spindle bearings. The box is of gear type, lubricated, fitted with three extra heavy duty bearings. The Bed : The bed is pillar type having two pillars made of best quality steel nicely finished & duly hard chrome plated in the most modern hard chrome plating unit. The Saddle : The Saddle is fitted on two pillars very precisely. It runs on pillars very smoothly and accurately to the Head Stock alignment. The Apron : The apron gives movement to the saddle with head transfer along with pillars through steel rack and pinion arrangements. It's all gears are made of best quality steel. Vice Jaws : The vice jaws made from the best quality alloy steel are fitted on the saddle well aligned with the head stock center fitted in a heavy duty box type vice. The jaws are heat treated. The movements of jaws are controlled by a screw on the saddle. Range of NCT Threading machines and Die Heads. 3/8'' to 1.12'' do/- 1/2'' to 2.1/2" do/-

...more

Rebar Threading Machine

The range we present is quality assured by the professionals and from the initial stages of procurement of raw material, we make stern quality inspections to deliver the best range. Owing to our state-of-the-art warehouse, we efficiently entertain both automated inbound and outbound consignments with utmost proficiency. The products are sorted and segregated to make sure that the delivery commences systematically. Detail : Rebar Threading Machine comprises of a Base, Head Shock, Saddle, Bed Type Clamping Vice and Die Head. During the cutting process, Die Head rotates and the bar remains stationary. This machine can be used for cutting a wide range of threads that include Matric, BSP, BSPT, NPT, UNF, BSW, Acme Threads, etc.

...more

Rebar Coupler

Our product is available in nontoxic and industrial-grade packaging materials that ensure the products are safe from damage and reach buyers in brand new conditions. To make our transactions secure, we allow our clients to make payment through both offline and online mediums. Cutting : The end of the reinforcement bars is sawn square. Cold Forging : With the help of cold forging, the sawn end of the reinforcing bar is then enlarged. With this the core diameter of the bar is increased to pre-determined diameter. Threading : An ISO standard metric thread is then cut. Specialties Of Our Rebar Couplers Technically Perfect : Concrete structures need to be reinforced to improve their load bearing capacity and our Rebar Couplers are perfectly designed for that. Our Rebar Couplers impart unmatched mechanical strength to the RCC structures thus ensuring complete safety even in the rugged conditions of seismic activity. The continuity of our Rebar Couplers allows for grounding electrical current. Flawless Design : Rebar Couplers, offered by us, are exemplary for their flawless design that allows better concrete flow and consolidation while at the same time reducing rebar congestion. Such designing minimizes reinforcement fixing errors and offers greater flexibility in structuring RCC. Simple Installation : Simple mechanical ways are adopted for installation of Rebar Couplers. The simplicity of the installation process saves significant amount of time and labor. The benefits are immediately reflected in the reduced costs of the construction project. Installation Of Rebar Couplers : Good quality shear cut bars with sharp perpendicular cutting or saw cutting may be used. The threading is provided on bar ends with proprietary branded threading equipment and thread cutting tools. Threading of reinforcement bars must be carried out as per NCT RE-BAR COUPLERS by trained operator. The thread checking gauge is used for checking the threads. The threads shall be covered by thread protection plastic cap while storing. The bent bars may be threaded on threading machine provided straight length of the bent bar-end to be threaded is more than 0.5 m. If not so, the bars may be threaded in straight lengths, connected thoroughly and bar bending is carried out subsequently. The bent must be minimum 100mm apart from thread bar end. The bar is connected to coupler sleeve initially by hand tightening and then with pipe wrench. The NCT RE- BAR Couplers full strength threaded butt joining that achieves strength with fully engaged threading of coupler and reinforcement bars. Therefore, it is essential to ensure adequate tightening of joining connection for effective load transfer.

Brand Name : NCT

Material : For 500 and 600 Tata Sail and Other

...more

Pipe End Facing Machine

Our organization assures distribution of wholesale as well as retail consignments of the goods as per the jointly decided period. We have massive warehouse with Individual stock keeping units (SKUs). We are capable of sorting the products in an efficient way and can easily entertain bulk requirements of the customers. Features : User-friendly Precision engineered QC verified High productivity

...more

Pipe Beveling Machine

Our organization is positioned at Ludhiana(India) and has gained immense acknowledgement and a respected place in the market. We have a well-developed all the in-house storage facility, laced with all the modern facilities. Also, we have hired a team of professionals who efficiently manage and maintain it. Bed : The Bed of Pipe Beveling Machine is made of Cast Iron. It is Very Rigid and sturdy in construction so as to take maximum Load and absorb maximum vibrations. It is provided with four Nos. Foundation Holes of Dia M20 at four corners of the bed. It is also provided with Four Tapped holes of 5/8 BSW near the Foundation Holes. The Head Stock and Clamping Vice is fitted on the Bed. Head Stock : he Head Stock body of Pipe Beveling Machine is made of Cast Iron. It is Very rigid and sturdy in design. The Head Stock is designed for Four Nos. Spindle speeds. All the Gears are of helical type made out of Axle Forging. The width of gears is 50 mm. The Shifting Gears slide on Splined Shafts. The Shafts are mounted on Heavy Duty Ball Bearings. The Input Shaft will be provided with a pulley having three grooves for C-Section V-belts. The Main Spindle is mounted on two Taper Roller Bearings mounted in Hard Chrome Plated Ground Sleeve. The Sleeve along with main spindle fitted with Beveling Head is mounted in the Head Stock body and is movable To and Fro along its axis. A Hyd. Cylinder actuated electrically makes the movement of the sleeve in the Head Stock. The Movement of the Sleeve can also be made manually. The Head Stock is Oil Filled. It is provided with Oil Filling hole, Oil Drain hole and Oil Level Indicator. Clamping Vice : The Box Type Clamping Vice is fitted on the Bed. The Vice is provided with Round Clamping Jaws for each size (4, 5, 6, 7, 8,). The Vice will be Self-centering type. The movement of the Clamping Jaws is made by Pneumatic cylinder fitted on the Vice actuated electrically. The Vice will be very rigid and sturdy in design. Machine will be supplied with single clamping vice. Beveling Head : A special Beveling Head will be provided with the machine. Two Tools of HSS will be used, One for Beveling and second for Root Face. The Beveling Tool will be mounted in a special Spring Loaded Tool Holder with a Roller device. It is fitted on the main spindle that is then mounted in the traveling Sleeve.

...more

Pillar Type Power Press

Our organization is endowed by a massive circulation system that allows us to reach purchasers wherever and distribute orders on schedule. Superior raw materials are essential for the development of a quality product. Thus, we obtain these materials only from the dependable sources available in the market. Rolling Key : Is fitted in the two parts of EN-34 alloy steel duty tempered and property ground and give a perfect service. All are being taken that the key may not break and is suitable to stand the jerks. Alignment : Heighest degree of precision maintained during the fitting of ram and it's base is checked very property on 90 angel with the dail indicator. Horizontally & Perpendicularly. Body : The press bodies are manufactured out of the close grain casting and steel fabricated as well.

...more

Manual Multi Spindle Drilling Machine

Due to our secure and hassle-free payment procedures, clients stay satisfied with us. We undertake both online and offline payment processing methods including cash and bank transfers. Purchasers can rest secure; our entire range is premium, as they are wholesaled by us after subjecting them to a string of quality control tests. Features : User-friendly Precision engineered QC verified High productivity

...more

liquid painting plant

We maintain proper schedules for the delivery of bulk or urgent consignments so as to deliver the range in set time and gain utmost customer satisfaction. The offered array of products is examined on the basis of quality of raw material and other inputs used for the manufacturing. Rest assured us for the raw material used, as we have most updated technologies to examine the quality. Liquid Painting Plant having following items : Liquid Paint Tanks – 1 Nos. Dripping Tray - 1 no Oil Fired Curing oven (Straight Type) – 1 Nos. Overhead Motorized Conveyor, with support Structure – 1 Set. Electrical Control Panel – 1 Set. Painting, and Finishing etc. – 1 Lot.

...more

Ledger Welding Machine

We are accredited for providing faultless array of products. This has become possible owing to the efforts of our quality auditors who strictly check the inputs before procurement. Our company has worked hard to establish an efficient distribution network. Therefore, buyers can order the product in mass and expect on time delivery. Technical Specifications : I Ledger welding Double Side Electric Supply - Single Phase 220 Volt HZ 50/60 Speed - 2 to 10 RPM Motor Drive - AC Inverter Type Motor - Type AC 220-Volts-3-Phase Torch Clamping - PNEUMATIC Length Adjustment - 150 to 2400 mm Dimension - L x W x H 11.3x2.5x5.3 (Foot) Key Features - High production , Easy to operate, Easy to maintain, Uniform welding results

...more

Jack Welding Machine

With our years of experience and expertise, we strive to make available high quality Jack Welding Machine at competitively low prices. For the safe storage of the entire lot, we have installed our own facility that is laced with all the modern amenities for complete quality satisfaction. Details : Technical Specifications : Outer Prop welding machine Electric Supply: Single Phase 220 Volt HZ 50/60 Speed : 2 to 10 RPM Motor Drive : AC Inverter Type Motor : Type AC 220-Volts-3-Phase Torch Clamping : PNEUMATIC Length Adjustment : 150 to 2400 mm Dimension : L x W x H 11.3x2.5x5.3 (Foot) Use : Jack Welding Machine is used to weld base plate with pipe and sleeve without making any joint between them,It gives high production and accuracy to product. Outer prop are used with combination of Inner prop and base jack to make a sctructure. All the components are used in combination of each other Base jack welding machine,Inner prop welding machine,Outer prop welding machine,Cuplock welding machine,Ringlock welding machine. National Cutting Tools provides complete solution for scaffolding and formwork by providing Automatic scaffolding machines. Key Features : High production , Easy to operate, Easy to maintain, Uniform welding results

...more

Hydraulic Pipe Threading Machine

Raw materials are feedstock for the finished products and thus it becomes crucial to source these inputs only from certified vendors. So, as a reliable name, we do the same. Development of modular control inside our warehouse helps in proper organization of the products and ensure complete safety while storage. The entire system is properly managed by our warehousing experts. Design & Workmanship : Hydraulic Pipe Threading Machine is designed to produce precise threads within the tolerance for which they were intended. Head Stock : A heavy duty geared Head Box is of best quality casting providing support to the spindle bearings. The box is of gear type, lubricated, and fitted with three extra heavy-duty bearings. The Bed : The bed is pillar type having two pillars made of best quality steel nicely finished & duly hard chrome plated in the most modern hard chrome-plating unit. The Saddle : The Saddle is fitted on two pillars very precisely. It runs on pillars very smoothly and accurately to the Head Stock alignment. The Apron : The apron gives movement to the saddle with head transfer along with pillars through steel rack and pinion arrangements. All the gears are made of best quality steel. Vice Jaws : The vice jaws made from the best quality alloy steel are fitted on the saddle well aligned with the head stock center fitted in a heavy-duty box type vice. The jaws are heat-treated. The movements of jaws are controlled by a screw on the saddle. Range of NCT Threading Machines and Die Heads 1/2" to 2.1/2" do/- 1" to 4" Capacity Pipe 2.1/2" to 6" Capacity Pipe 4" to 8" 4" to 8" Capacity Pipe

...more

HSS Threading Tap

We do not have to worry about stock-out situations or meeting bulk requirements, as we have an equipped warehouse facility. It has the latest inventory control and management software and helps us maintain continuous product availability. We provide customized as well as standard packaging of the products. With the assistance of our streamlined packing system, we are able to provide damage-free products to the clients. Features : Thread - TPI or Pitch : 1/8 in - 27 NPT, 1/4 in - 18 NPT, 3/8 in - 18 NPT, 1/2 in - 14 NPT, 3/4 in - 14 NPT, 1 in - 11 1/2 NPT Material : Carbon Steel, HSS Includes : Wooden Case, Taps, Dies Type : Tap & Die Special Taps : Your tapping requirement may be unique for various reasons, but one common requirement in all applications is successful tapping. Some examples of why your application may be special. Material characteristic such as swarf type, elasticity, strength and hardness. depth of hole thread size pitch thread form reach holding. There are essentially four qualities in successfully designing and manufacturing a tap. Theoretical knowledge and practical experience are intrinsic in this process. Size form geometry texture or finish Base material, its heat treatment, and final surface coating are significant factors; but they would be irrelevant without the correct geometry. Tap geometry involves a combination of features tailored to all the above... thread and flute cutting angles, flute pattern, cutting force reduction features. The culmination of these geometrical features is the knowledge we refer to. Our knowledge combined with processes and equipment, allow consideration of all these variables.

...more

C Frame Power Press

Conforming to international quality management systems, our product range is of unparalleled value. We make certain that the offered array of products is sternly tested for the raw material as well. This makes our offered array of products completely reliable and genuine. Features : User-friendly Precision engineered QC verified High productivity

...more

Bolt Threading Machine

Our payment terms are clear and the methods we use are practical. New customers can connect with us any time for further payment related queries and learn about our policies. Our product range is secured properly with premium packaging materials that protect the products from mechanical damage and ensure the product delivery is safe and without damage. Design & Workmanship : The National Cutting Tools Pipe & Bolt Threading Machines are designed to produce quality threads within the tolerance for which they were intended. Head Stock : A heavy duty geared head box is of best quality casting providing support to the spindle bearings. The box is of gear type, lubricated and fitted with three extra heavy duty bearings. Range of NCT Bolt Threading machines and Die Heads : 3/8'' to 1.12'' do/- 1/2'' to 2 .1/2" do/-

...more

Bar Threading Machine

We have latest machines and cutting-edge technology thus, we ensure that the raw materials used are as per set standards and meet the international norms as well. We deliver only quality products, manufactured using the raw material. We maintain proper schedules for the delivery of bulk or urgent consignments so as to deliver the range in set time and gain utmost customer satisfaction. Design : The National Cutting Tool Bar threading machines are designed to produce quality threads within the tolerance for which they were intended. Head Stock : A heavy duty geared Head Box is of best quality casting providing support to the spindle bearings. The box is of gear type, lubricated, and fitted with three extra heavy duty bearings. The Bed : The bed is pillar type having two pillars made of best quality steel nicely finished & duly hard chrome plated in the most modern hard chrome plating unit. The Saddle : The Saddle is fitted on two pillars very precisely. It runs on pillars very smoothly and accurately to the Head Stock alignment. The Apron : The apron gives movement to the saddle with head transfer along with pillars through steel rack and pinion arrangements. It's all gears are made of best quality steel. Vice Jaws : The vice jaws made from the best quality alloy steel are fitted on the saddle well aligned with the head stock center fitted in a heavy duty box type vice. The jaws are heat treated. The movements of jaws are controlled by a screw on the saddle. Range 3/8'' to 1.12'' do/- 1/2'' to 2 .1/2" do/-

...more

Automatic Multi Spindle Drilling Machine

We make sure that the packaging of products is done using qualitative material in order to deliver the products safely. Only after complete inspection, we deliver the products in the dedicated time span. We are a noteworthy name and work hard to attain complete client satisfaction. And, for achieving this objective, we facilitate them with easy payment modes. Details : Features of the Multi-Spindle Drilling Machine Specially designed for Scaffolding pipes drilling operation. Machine will have the capacity to load 40 NB, 2000mm length pipes, for auto mode and 3000mm in semi auto mode Drilling Pitch will be 120mm Please note that our machine has 14 spindles fixed in particular pitch. They are not adjustable. If any change in, pitch and no of holes to be drilled, is required please specify in your enquiry. For Drill height adjustment-adjustable Sleeves Type Din 6327 with MT-2 Taper will be provided. (Max drill size 17.5 mm with MT2 taper shank) Machine will be equipped with automatic loading of the pipe from loading table to the V-Block for drilling. Machine will have Manual/semi-auto and Automatic Mode Selection in operation. In manual mode, individual functions of the machine can be operated manually during initial machine setup. After machine setup is completed, it can be run in Semi auto or Automatic-mode by selecting Semi auto or Auto Mode Automatic cycle sequence is as below : Positioning of the pipe. Clamping of the pipe. Slide up with rapid movement till the drill point. Coolant ON & Slide up with feed movement to drill the pipe on one side.

...more

Agro Products

Be first to Rate

Rate This