water cum smoke tube boilers

Salient Features:- Ξ Higher Thermal Efficiency Ξ Minimum Refractory In Furnace Ξ Fluidised Bed Combustion Ξ Easy In Operational Maintenance Ξ Dry Steam With High Temperature Ξ Minimum Radiation Losses Ξ Higher Free Board Space And Larger Combustion Volume Ξ High Effective Heat Transfer Area Ξ Larger Water Holding And Steam Space Ξ Customized Design Ξ Expendable Ξ Multi Fuel Options Optional Ξ Dumping Great For Bagasse Firing Ξ In Bed Tube For capacity Enhancment Ξ Steam Super heater For Co-generation Ξ Ove-Bed/ Under Bed Feeding

...more

Vertical Ibr Baby Boiler

Capacity : 800 Kg./hr.

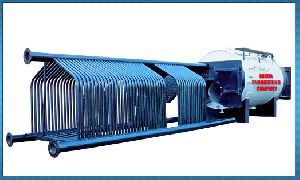

Thermic Fluid Heaters

Salient Features:- Ξ Higher Efficiency Ξ Minimum Maintenance Ξ Three Pass To Get Highest Thermal Efficiency Ξ Steam Super Heat Ξ Computer Rating And Optimized Design To Provide Max Steam Generation Per Unit Heat Surfing Ξ Expandable Ξ Manufactured To Highest Quality Standard Meeting IBR- 1950, (BS, ASME For Exports Order) Ξ State-Of-The-Art Technology Ξ Multi Fuel Options Ξ Radiant Coil For Higher Efficiency Ξ Larger Furnace Volume Ξ Separate Radiation And Convection Coils Ξ Good Quality Dry Steam Ξ Fluidised Bed Combustion Optional Ξ FBC/ Under /Over Bed Firing/ Multi Feed Ξ Steem Driven Turbo Pumps For Power Boilers Ξ Steam Turbine For Co-generation

...more

Electric Fired Boilers

Induced Draft Fan

Salient Features:- ≡ High Efficiency / High Pressure ≡ Noiseless Working ≡ Low Power Consumption ≡ Longer Life

...more

fire tube boilers

Ξ Higher Thermal Efficiency Ξ Computer Rating And Optimize Design To Provide Maximum Steam Generation Per Unit Of Heating Surface Ξ External/ Internal firing Ξ Suitable Internal Steam Separator To Ensure Good Quality Dry Stem Ξ Dry Steam With High Temperature Ξ Automatic Water Level Controller And Pressure Switch To Get Optimal Stem To Fuel Ration Ξ Suitable For Fluctuating Load Ξ Large Dial Steam Pressure Gauge, Easily Readable From a Distance Ξ Easy Operational Maintenance Ξ Fusible Plug Provide Additional Safety And Redundancy Ξ Muti Fuel Options Ξ Easy And Quick Erection And Commissioning Ξ Flue Tube Provided With Stiffness Rings and Stay Rods To Care Of Expansion And To Reduce Thermal Stress Ξ Less Susceptible To Poor Water Quality Ξ Manufacturing To Highest Quality Standards Meeting IBR, BS, ASME Code As Required Ξ Lower Power Consumption Ξ Higher Steam Storage Optional Ξ Fluidised Bed Combustion System Ξ Water/ Air Pre Heater Ξ Trema Cyclone Ξ Agro Waste Fired

...more

Forced Draft Fan

Salient Features:- ≡ High Efficiency / High Pressure ≡ Noiseless Working ≡ Low Power Consumption ≡ Longer Life

...more

ETP Water Effluent Treatment Plants

The effluent treatment plant is designed to treat the effluent coming from different areas of the plant. The treatment of different effluents varies with the type of effluent. Oily Water Effluent Treatment Oily water effluent treatment plant is designed to treat effluent mainly containing oily effluent. The oily water from the Transformer Area, Turbine building, Workshop etc is collected in common collection sump from where water is pumped through the Plate Interceptor. Oil separated from Plate Interceptor is collected in drums & clear water is lead to central monitoring basin through gravity. Sludge generated from the Plate Interceptor is led to the Sludge Pit for further treatment. Service Water Effluent Treatment The system is envisaged for treatment of effluent mainly containing turbidity and suspended solids. Service water washing effluent from different areas is collected in common collection pit and then pumped to the flash mixer where chemical mixing takes place. The effluent is dosed with Alum, Lime and Polyelectrolyte to coagulate and flocculate the suspended / colloidal matter. Water then flows through the flocculation tank for flocculation and is finally carried over to tube/lamella settler through gravity where clarification of water takes place. Clarified water is then led to common monitoring basin through gravity. Sludge generated in the process shall be collected and pumped for further treatment Coal Handling Plant & Coal Storage Effluent Treatment Effluent from the Coal handling plant and Coal storage Area is collected and is led through the inlet channel to break the turbulence. The Effluent then flow to the Coal Slurry Settling pond where the discrete particles settle down and the clear water flows to the coal decanted water sump. Decanted water is then pumped to the central monitoring basin

...more

Waterwall Panel

Trima Cyclone

Coal & Husk Screw Feeder

Fire Door & Grate

super heater

Air Pre Heater

water cum smoke tube boiler

Air Nozzles CI & SS

Industrial Economiser

water tube boilers

Water Treatment Tanks

Be first to Rate

Rate This