winding machine spares

Nota Industries is always committed towards after Sales Service of our products. We offer complete installation of Textile Units on turn key basis and we provide well qualified engineers assist you in all kinds of manufacturing problems & make good quality of textile products.

...more

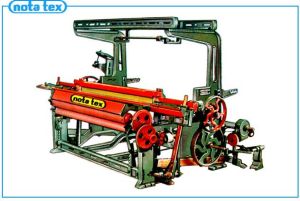

underpick loom

"NOTA-TEX" leading manufacturer of Best quality Power Looms duly registered with the Textile Commissioner, Bombay, presenting Heavy Duty Loose Reed, Plain Overpick Looms & Underpick Looms manufactured under the supervision of qualified Engineers and expert technicians in various models:- SALIENT FEATURES ( Underpick Loom ): Latest type of machine tools are used to make better quality Underpick loom. Special material is used to reduce maintenance cost and to optimum performance. Quality is controlled at every stage to make better loom. Side frames of the loom are Heavy and rigid in construction.Double Top Rail is provided and extended to mount Dobby and cloth rail is machined very smoothly. The construction of loom is done in a way so that there could be no vibration and shocks in the weaving process. Additional support of crank shaft and bottom shaft are provided for loom of 64" reed space and above. All the gear wheels are machine cut. Crank shaft & tappet shaft are made of superior quality tested mild steel. TAKE UP MOTION: Latest designed take up motion is provided to give even density of picks. Emery Roll can be covered with steel or rubber emery. Metal cloth Roller of 3½" or 4" dia is supplied with the loom. Tension roller is planted. LET OFF MECHANISM: Fully positive let off mechanism is fitted on the frame to give uniform warp tension throughout the weaving process. Two bar vibrating back rest operated from cam on the crank shaft or single loose moveable pipe back warp rest is also provided. A separate let off mechanism in a rigid frame can also be provided. WEFT FORK MECHANISM: Side weft fork mechanism is provided for better quality of cloth. PICKING MECHANISM: Loom is provided with the latest picking mechanism which produces smooth picking action for the longer life of shuttles, pickers, picking sticks, picking cam and picking nose. One set of Pickers, Buffers, Picking sticks are supplied with each loom. SLAY: Slay and its cap is made from good quality seasoned wood. All the angles on slay are given properly. Slay sword and its bearings are machined for correct setting of slay and proper flight of the shuttle. REED MOTION: There are two types of reed motions provided in machine. One is fast reed and other is loose reed motion. For fast reed motion a special type of stop system is provided to minimize the break down. POWER REQUIRED: Reed Space 36" to 60" 1 H.P. 750 RPMReed Space 64" to 72" 1.5 H.P. 750 RPMReed Space 76" to 60" 2 H.P. 750 RPM DROP BOX: A better quality of drop box can also be provided with the Loom, according to the customer's requirement. Drop Boxes are available in 1x2, 1x4, 2x2, and 4x4 Shuttle.

...more

reeling machine

SALIENT FEATURES: The structure of the machine is simple, compact, stable and reliable. The full hank stop motion is effected by a pair of contactors on the differential gear with one tooth difference, electrically controlled for stop at signal for full hank. The end break stop motion is controlled by electrical dropper which is connected with electrical loop making it sensitive and reliable. The red and green signal lamps are fitted on the top cover of the headstock, End break and full hanks are indicated respectively, for observation. The electromagnet is used for sensitive and reliable brake. A group formation device is equipped with simple and reliable. There is a collapsible special pipe equipped in the swifts for the convenience of patina them shut when doffing the hanks, thus decreasing labour intensity.

...more

Rapier Weaving Looms

350,000 - 1,500,000 Per Piece

Voltage : 220V

Automatic Grade : Fully Automatic

Brand Name : Nota Tex

Application : Weaving

Production Capacity : 200 Meters Daily

...more

Rapier Looms

300,000 - 1,200,000 Per

1 Pair (MOQ)

Rapier Loom series are mainly used to weave natural fibers (cotton, wool, hemp), artificial fibers, fancy yarns and chenille yarns into light, medium and heavy fabrics.This rapier loom meets the requirements of the textile weaving industry with its high performance price ration. It is controlled by micro-computer and equipped with automatic warpweft stop devices and semi-automatic oil supply. The wall boards are strengthened to offer better performance for weaving heavy and higher density fabrics. It enjoys the features of stable performance,, low noise, ice appearance, easy operation and maintenance.

Type : Rapier Looms

Certification : ISO 9001:2008

Weight : 2000-3000kg

Color : Grey, Light Green

Voltage : 440V

Condition : New

Automatic Grade : Fully Automatic

Power : 1-3kw

Driven Type : Electric

Warranty : 1year

Country of Origin : India

Brand Name : Nota Tex

Application : weaving

Production Capacity : 200 meters daily

After-Sales Service Provided : yes

Year : 1 year

...more

rapier loom machine

100,000 - 1,500,000 Per

2 Piece (MOQ)

NT736 Rapier Loom is specially designed for weaving heavy fabrics.The wefting mechanism adopts 6-lever structure and can ensure the adjustment of the rapier entry and exit time and ensure stable wefting and insertion motion.This machine adopts 4 levers, short connectors and short sley to complete the beating motion, the rock shaft adopts 110 mm seamless tube to ensure the beating strength and can be suitable for high-speed motion and weaving of heavy and high density fabrics. The rapier transmission box adopts the advanced helix umbrella gears to ensure stable transmission. The tension device adopts 3 rear beam tension structure, which is specially designed for balancing the warp tension of high-density weaving and can improve the quality of the weaving fabrics. The new let-off mechanism is of same design as air jet loom, and is maintenance free. The wide adoption of bearings for the moving parts provides easy maintenance and smooth performance. The adoption of two pressing rollers on the fabric winding roller enables the worker to unload the fabric without stopping weaving.

Type : Rapier Looms

Certification : ISO 9001:2008

Weight : 1000-2000kg

Color : Grey, Light Green, Light White

Condition : New

Automatic Grade : Automatic, Fully Automatic

Power : 1-3kw

Driven Type : Electric, Mechanical

Warranty : 1year

Country of Origin : India

Brand Name : Nota Tex

Application : weaving

Production Capacity : 200 meters daily

After-Sales Service Provided : yes

Year : 1 year

...more

Power Looms

50,000 - 250,000 Per

2 Pair (MOQ)

Power Looms duly registered with the Textile Commissioner, Bombay, presenting Heavy Duty Loose Reed, Plain Overpick Looms & Underpick Looms manufactured under the supervision of qualified Engineers and expert technicians in various models, Latest type of machine tools are used to make better quality Underpick loom. Special material is used to reduce maintenance cost and to optimum performance. Quality is controlled at every stage to make better loom. Side frames of the loom are Heavy and rigid in construction.Double Top Rail is provided and extended to mount Dobby and cloth rail is machined very smoothly. The construction of loom is done in a way so that there could be no vibration and shocks in the weaving process. Additional support of crank shaft and bottom shaft are provided for loom of 64" reed space and above. All the gear wheels are machine cut. Crank shaft & tappet shaft are made of superior quality tested mild steel.

Application : Increasing Weaving Speed

Weight : 1000-2000kg

Condition : New

Automatic Grade : Automatic, Manual, Semi Automatic

...more

pirn winding machine

salient features: there are some characteristic like: compact and sturdy construction. Elegant, economic, easy maintenance and trouble – free operations. rigid quality control. 24 hrs. Working before dispatches. strict supervision by highly qualified technical staff, backed by 30 years experience. functions & uses: being an automatic pirn winding machine, it is most ideal for winding synthetic polyethylene fiber yarn, cotton (10 counts to fine – superfine) filament yarn, silk, nylon terry line, terry cot and woolen yarn. operations: empty pirn (bobbins) used for winding are arranged in an adjustable magazine, according to pirn size. when the dimensions of pirn are adjusted the rotating pirn is held between the back and front carriers and, is also adjusted by moving the slipper box. the desired pirn diameter can be adjusted by regular wheel, mounted on left of spindle box. The cones are placed on platform above the machine. The yarn is unwounded from the cones passing through tension device, stops motion eyes and yarn guides and winds the pirn. being and automatic machine it is automatically operated for pirn changing when the required length of yarn has been wound on the pirn. The wounded pirn is replaced by the empty one. Simultaneously, the weft is caught again and cuts in time. Moreover the machine stops automatically in case of breakage of yarn without loss of time. technical data: the basic unit consists of spindles. It can be jointed together to obtain 8 spindles. Each unit of 4 spindles and 8 spindles driven individually. Each unit of 4 spindles driven individually by ½ hp electrical motor connected to a counter shaft mounted underneath the spindle box. 8 spindle units are driven by the gears mounted in spindle box. Oil circulating device is provided for continuous and thoroughly lubricating specially developed fiber gears for smooth and long life. Other parts are made from highly graded materials to obtain higher efficiency and zero maintenance.

...more

Overpick Loom

"NOTA-TEX" leading manufacturer of Best quality Power Looms duly registerred with the Textile Commissioner, Bombay, presenting Heavy Duty Loose Reed, Plain Overpick Looms & Underpick Looms manufactured under the supervision of qualified Engineers and expert technicians in various models:- SALIENT FEATURES ( Underpick Loom ): Side Frames are heavy and rigid in construction. Top Rail one piece is extended to mount dobbies and cloth rail is machined very smoothly. All the Gear Wheels are mcahine cut. All the Gear iron parts of loom are manufactured from Special Grey iron Castings. All the bearings of Crank shaft Picking shaft and Tappet shaft and other parts are well finished to reduce the maintenance cost. Crank shaft, Tappet shaft and Picking shaft are made of superior quality tested mild steel. Maximum speed with minimum vibration Simplicity, accessibility and easily interchangeability of parts permits maximum efficiency and flexibility for the production of a variety of fabrics viz. cotton, silk, staple, fibre, monofilament plastic yarns, H.D.P.E./P.P. , strip, plain & twill. PERFECT WORKMANSHIP: All the materials used throughout the production of our looms are of the highest quality. At every stage of manufacture of these looms, great care is taken to ensure a long running period without replacement of parts and to give longer life to the machine. Loosed Reed Motion and Fast Reed Motion. For Fast Reed Motion a special stop system is provided to minimize the brake down. Additional supports for Cranks & Bottom Shaft are provided for 64" reed space and above. Dobby can be easily mounted on top rail. Side Weft Fork Machanism. Metal Cloth Roller of 3½" or 4" dia pressed in contact with the take up toller by means of leavers and springs. Warp Beams up to 24" dia flanges can be fitted. Tappet shaft is extended for dobby drive. OVERPICKING SYSTEM: Strong overpick picking motion with picking plates, picking boss, picking nose, picking bowl and picking shaft. TAKEUP MOTION: Pickle's 7 Wheel Take Up Motion with take up Roller. WARP REST: (a) Two Bar Vibrating back warp rest operated from cam on the crank shaft and easily removable and adjustable. (b) Single loose movable pipe back warp rest can also be provided. SLAY: Well polished slay made from good quality Seasoned Wood with Sheesham Wood race board and fitted with polished slay cap. Well polished shuttle plates with shuttle guards to suit 14½" shuttle. All the angles on slay are given properly. Slay sword and it's bearings are machined for correct setting of slay and proper flight of the shuttle. DRIVE: Group or Individual driving. POWER REQUIRED: Reed Space 36" to 60" 1 H.P. 750 RPMReed Space 64" to 80" 1.5 H.P. 750 RPMReed Space 105" 2 H.P. 750 RPM DROP BOX: A better quality of drop box can also be provided with the Loom, according to the customer's requirement. Drop Boxes are available in 1x2, 1x4, 2x2, and 4x4 Shuttle.

...more

hank reeling machine

150,000 - 250,000 Per per pcs

1 Piece (MOQ)

The full hank stop motion is effected by a pair of contactors on the differential gear with one tooth difference, electrically controlled for stop at signal for full hank, The end break stop motion is controlled by electrical dropper which is connected with electrical loop making The red and green signal lamps are fitted on the top cover of the headstock, End break and full hanks are indicated respectively, for observation.it sensitive and reliable. There is a collapsible special pipe equipped in the swifts for the convenience of patina them shut when doffing the hanks, thus decreasing labour intensity.

Type : Hank Reeling Machine

Weight : 100-1000kg

Color : Light White

Voltage : 220V

Condition : New

Automatic Grade : Automatic

Power : 1-3 Kw

Driven Type : Electric

...more

Fabric Rolling Machine

Inspection - Rolling Machine is mainly used in weaving mills, dyeing plant, wholesale shops, garment factory, man made fur factory, artificial leather factory for the inspection of various types of fabrics for full-width rolling and metre counting.The machine is driven by imported gear box with electric motor, Inverter Drive for controlling rolling Speed, Anticurling Device for uniform fabric rolling.

...more

Fabric Inspection Machine

Inspection - Rolling Machine is mainly used in weaving mills, dyeing plant, wholesale shops, garment factory, man made fur factory, artificial leather factory for the inspection of various types of fabrics for full-width rolling and metre counting.The machine is driven by imported gear box with electric motor,Anticurling Device for uniform fabric rolling.

...more

electronic jacquards machine

Based on the strong capacity, high quality, low cost and excellent performance, our electronic jacquard machine has replaced the European ones successfully and worn a high reputation.The machine adopts the mature interface compatible with rapier, air-jet, projectile looms such as Dornier, Nissan, Picanol, Smit, Somet, Sulzer, Toyato, Vamatex and Chinese looms. The working speed reaches up to 600 picks per minute, and different shed modes are executed by means of a variety of communication interfaces.The machine enjoys its high performance/cost ration and convenient maintenance.A 50% reduction in power consumption and less heat generation are achieved thanks to the adoption of latest PWM current drive.

...more

dobby loom

400,000 - 600,000 Per Piece

The wefting mechanism adopts 6-lever structure and can ensure the adjustment of the rapier entry and exit time and ensure stable wefting and insertion motion. This machine adopts 4 levers, short connectors and short sley to complete the beating motion, the rock shaft adopts 110 mm seamless tube to ensure the beating strength and can be suitable for high-speed motion and weaving of heavy and high density fabrics. The rapier transmission box adopts the advanced helix umbrella gears to ensure stable transmission. The tension device adopts 3 rear beam tension structure, which is specially designed for balancing the warp tension of high-density weaving and can improve the quality of the weaving fabrics. The new let-off mechanism is of same design as air jet loom, and is maintenance free. The wide adoption of bearings for the moving parts provides easy maintenance and smooth performance. The adoption of two pressing rollers on the fabric winding roller enables the worker to unload the fabric without stopping weaving.

Color : Green

Country of Origin : India

...more

Cone Winding Machine

Please mention us your Bed dimension before you are going to place your order. Along with the development and improvement in our machine, dimensions and specifications may be change without prior notice.

...more

CONE WINDER MACHINE

SALIENT FEATURES: Total Bed Dimension : as required according to yarn Maximum compressible length : 10” Capacity : 5 kg to 15 Duration : 1 Minute Electric Motor : 3HP ~ 5 HP/ 1440 rpm* Cylinder : single Cylinder (Double Piston) Total Height of structure with cylinder : 56” (Approx)Please mention us your Bed dimension before you are going to place your order. Along with the development and improvement in our machine, dimensions and specifications may be change without prior notice.

...more

BUNDLING PRESS HYDRAULIC

SALIENT FEATURES: Total Bed Dimension : as required according to yarn Maximum compressible length : 10” Capacity : 5 kg to 15 Duration : 1 Minute Electric Motor : 3HP ~ 5 HP/ 1440 rpm* Cylinder : single Cylinder (Double Piston) Total Height of structure with cylinder : 56” (Approx)Please mention us your Bed dimension before you are going to place your order. Along with the development and improvement in our machine, dimensions and specifications may be change without prior notice.

...more

Jacquard Machine

under pick loom

Be first to Rate

Rate ThisOpening Hours