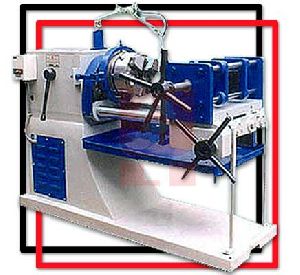

Pipe Beveling Machine

Get Price Quote

National Cutting Tools is one of the leading Manufacturers, Exporters and Suppliers of Pipe Beveling Machine. It is used for the purpose of beveling the Pipe End. Pipe is Beveled from the Outer and Front is faced by two different tools. The Pipe remains Stationery and the Beveling Head rotates and comes out of the Head Stock for cutting the Pipe End. It consists of the following:- Bed : The Bed of Pipe Beveling Machine is made of Cast Iron. It is Very Rigid and sturdy in construction so as to take maximum Load and absorb maximum vibrations. It is provided with four Nos. Foundation Holes of Dia M20 at four corners of the bed. It is also provided with Four Tapped holes of 5/8 BSW near the Foundation Holes. The Head Stock and Clamping Vice is fitted on the Bed. Head Stock : he Head Stock body of Pipe Beveling Machine is made of Cast Iron. It is Very rigid and sturdy in design. The Head Stock is designed for Four Nos. Spindle speeds. All the Gears are of helical type made out of Axle Forging. The width of gears is 50 mm. The Shifting Gears slide on Splined Shafts. The Shafts are mounted on Heavy Duty Ball Bearings. The Input Shaft will be provided with a pulley having three grooves for C-Section V-belts. The Main Spindle is mounted on two Taper Roller Bearings mounted in Hard Chrome Plated Ground Sleeve. The Sleeve along with main spindle fitted with Beveling Head is mounted in the Head Stock body and is movable To and Fro along its axis. A Hyd. Cylinder actuated electrically makes the movement of the sleeve in the Head Stock. The Movement of the Sleeve can also be made manually. The Head Stock is Oil Filled. It is provided with Oil Filling hole, Oil Drain hole and Oil Level Indicator. Clamping Vice : The Box Type Clamping Vice is fitted on the Bed. The Vice is provided with Round Clamping Jaws for each size (4, 5, 6, 7, 8,). The Vice will be Self-centering type. The movement of the Clamping Jaws is made by Pneumatic cylinder fitted on the Vice actuated electrically. The Vice will be very rigid and sturdy in design. Machine will be supplied with single clamping vice. Beveling Head : A special Beveling Head will be provided with the machine. Two Tools of HSS will be used, One for Beveling and second for Root Face. The Beveling Tool will be mounted in a special Spring Loaded Tool Holder with a Roller device. It is fitted on the main spindle that is then mounted in the traveling Sleeve.

Pipe Cutting Machine

Get Price Quote

PIPE CUTTING MACHINE Pipe cutting machine removes material from pipe or tube to create the desired profile. Typical profiles include straight cuts, mitres, saddles and midsection holes. These complex cuts are usually required to allow a tight fit between two parts that are to be joined via arc welding.

Best Deals from Pipe Making Machinery

Manual Pipe Cutting Machine

115,000 - 127,500 Per Machine

1 Machine (MOQ)

Heavy Duty Manual Pipe Cuttin Machine. Cobra Saw is a Heavy Duty High Production Manual Pipe Cutting Machine with capacity to cut round, square and rectagular pipe and tubes upto 100mm. Machine Comes in three Variants based upon their cutting capacity. Cobra Saw 500 Ex Cutting Capacity - upto 50mm Dia. Production - 4000-12000 Pcs/8Hr. Thickness - upto 5mm Cobra Saw 750 Ex Cutting Capacity - upto 750mm Dia. Production - 4000-10000 Pcs/8Hr. Thickness - upto 5mm Cobra Saw 750 Ex Cutting Capacity - upto 100mm Dia. Production - 2000-6000 Pcs/8Hr. Thickness - upto 5mm

pipe cutting machines

160,000 Per Piece

1 Piece (MOQ)

Pipe Beveling Machine

Get Price Quote

Industrial Machinery Corporation Pipe Beveling Machine is used for the purpose of beveling the Pipe End. Pipe is Beveled from the Outer and Front is faced by two different tools. The Pipe remains Stationery and the Beveling Head rotates and comes out of the Head Stock for cutting the Pipe End. The Pipe Beveling Machine mainly consists of the following: Bed Head Stock Clamping Vice Beveling Head.BED: - The Bed of Pipe Beveling Machine is made of Cast Iron. It is Very Rigid and sturdy in construction so as to take maximum Load and absorb max. Vibrations. It is provided with four Nos. Foundation Holes of Dia M20 at four corners of the bed. It is also provided with Four Tapped holes of 5/8” BSW near the Foundation Holes. The Head Stock and Clamping Vice is fitted on the Bed. HEAD STOCK: - The Head Stock body of Pipe Beveling Machine is made of Cast Iron. It is Very rigid and sturdy in design. The Head Stock is designed for Four Nos. Spindle speeds. All the Gears are of helical type made out of Axle Forging. The width of gears is 50 mm. The Shifting Gears slide on Spline Shafts. The Shafts are mounted on Heavy Duty Ball Bearings. The Input Shaft will be provided with a pulley having three grooves for C-Section V-belts. The Main Spindle is mounted on two Taper Roller Bearings mounted in Hard Chrome Plated Ground Sleeve. The Sleeve along with main spindle fitted with Beveling Head is mounted in the Head Stock body and is movable To and Fro along its axis. A Hyd. Cylinder actuated electrically makes the movement of the sleeve in the Head Stock. The Movement of the Sleeve can also be made manually. The Head Stock is Oil Filled. It is provided with Oil Filling hole, Oil Drain hole and Oil Level Indicator. CLAMPING VICE: - The Box Type Clamping Vice is fitted on the Bed. The Vice is provided with Round Clamping Jaws for each size (4”, 5”, 6”, 7”, 8”,). The Vice will be Self-centering type. The movement of the Clamping Jaws is made by Pneumatic cylinder fitted on the Vice actuated electrically. The Vice will be very rigid and sturdy in design. Machine will be supplied with single clamping vice. BEVELING HEAD: - A special Beveling Head will be provided with the machine. Two Tools of HSS will be used, One for Beveling and second for Root Face. The Beveling Tool will be mounted in a special Spring Loaded Tool Holder with a Roller device. It is fitted on the main spindle that is then mounted in the traveling Sleeve. Note:- One set of Round Type Clamping Jaws will be provided with the machine. Other Round Type Clamping Jaws are Optional and will be supplied at an extra Cost.

Pipe Flaring Machine

250,000 - 300,000 Per piece

1 1 (MOQ)

Pipe flaring machine electrically controlled manufacture in both single and double pipe flaring system

Pipe Beveling Machine

Get Price Quote

Our organization is positioned at Ludhiana(India) and has gained immense acknowledgement and a respected place in the market. We have a well-developed all the in-house storage facility, laced with all the modern facilities. Also, we have hired a team of professionals who efficiently manage and maintain it. Bed : The Bed of Pipe Beveling Machine is made of Cast Iron. It is Very Rigid and sturdy in construction so as to take maximum Load and absorb maximum vibrations. It is provided with four Nos. Foundation Holes of Dia M20 at four corners of the bed. It is also provided with Four Tapped holes of 5/8 BSW near the Foundation Holes. The Head Stock and Clamping Vice is fitted on the Bed. Head Stock : he Head Stock body of Pipe Beveling Machine is made of Cast Iron. It is Very rigid and sturdy in design. The Head Stock is designed for Four Nos. Spindle speeds. All the Gears are of helical type made out of Axle Forging. The width of gears is 50 mm. The Shifting Gears slide on Splined Shafts. The Shafts are mounted on Heavy Duty Ball Bearings. The Input Shaft will be provided with a pulley having three grooves for C-Section V-belts. The Main Spindle is mounted on two Taper Roller Bearings mounted in Hard Chrome Plated Ground Sleeve. The Sleeve along with main spindle fitted with Beveling Head is mounted in the Head Stock body and is movable To and Fro along its axis. A Hyd. Cylinder actuated electrically makes the movement of the sleeve in the Head Stock. The Movement of the Sleeve can also be made manually. The Head Stock is Oil Filled. It is provided with Oil Filling hole, Oil Drain hole and Oil Level Indicator. Clamping Vice : The Box Type Clamping Vice is fitted on the Bed. The Vice is provided with Round Clamping Jaws for each size (4, 5, 6, 7, 8,). The Vice will be Self-centering type. The movement of the Clamping Jaws is made by Pneumatic cylinder fitted on the Vice actuated electrically. The Vice will be very rigid and sturdy in design. Machine will be supplied with single clamping vice. Beveling Head : A special Beveling Head will be provided with the machine. Two Tools of HSS will be used, One for Beveling and second for Root Face. The Beveling Tool will be mounted in a special Spring Loaded Tool Holder with a Roller device. It is fitted on the main spindle that is then mounted in the traveling Sleeve.

Four Head Round Steel Pipe polishing machine

400,000 - 1,080,000 Per piece

1 piece (MOQ)

Pipe Cutting Machine

Get Price Quote

pipe cutting machines

Get Price Quote

we are manufacturer of pipe machinery used by steel pipe industry. we manufacture different type of pipe processing machineries, an following is the list of our pipe products: pipe threading machine pipe end facing machine pvc pipe threading machine pipe bevel machine square threading machine scaffolding props jack pipe threading machine rod threading machine conduit pipe threading

Pipe Beveling Machine

Get Price Quote

Conduit Pipe Threading Machine

Get Price Quote

We are reckoned as one of the eminent steel conduit pipe threading machine suppliers from India. We offer excellent quality conduit pipe threading machine that is known globally for its durability and high precision. This is highly demanded by large number of customers and we have also received various positive feedbacks from our honored customers. These are accessible at the most cost effective prices. The Pipe Threading Machine is used for Cutting External Thread on Steel Pipe by Chasing method. HSS Tangential Chasers are used as cutters. Pipe remains stationery and Die Head rotates. BSP, MATRIX, BSPT, NPT, UNF,UNC, BSW, Acme Threads can be cut on this machine depending upon the type of Chasers. The machine mainly consists the following:- Base Head Stock Saddle Pillar Or Bed Type Clamping Vice Die Head The Conduit Pipe Threading Machines are designed to give maximum efficiency and reliable performance under the most severe conditions of service with minimum maintenance cost. All the necessary requirements are combined in this model to from the basic fundamentals of correct threading. All the gears are made of case hardened steel with extra large face with and tooth thickness and cut on hobbing machine for noiseless operation even at high speed. Naturally the are built with high standards of workmanship, material and quality so closely associated with Company Tradition. Design & Workmanship : The National Cutting Tool Conduit pipe threading machines are designed to produce quality threads within the to lerance for which they were intended. Head Stock : A heavy duty geared Head Box is of best quality casting providing support to the spindle bearings. The box is of gear type, lubricated, fitted with three extra heavy duty bearings. The Bed : The bed is pillar type having two pillars made of best quality steel nicely finished & duly hard chrome plated in the most modern hard chrome plating unit. The Saddle : The Saddle is fitted on two pillars very precisely. It runs on pillars very smoothly and accurately to the Head Stock alignment. The Apron : The apron gives movement to the saddle with head transfer along with pillars through steel rack and pinion arrangements. It's all gears are made of best quality steel. Vice Jaws : The vice jaws made from the best quality alloy steel are fitted on the saddle well aligned with the head stock center fitted in a heavy duty box type vice. The jaws are heat treated. The movements of jaws are controlled by a screw on the saddle. Range of NCT Conduit Pipe Threading machine and Die Heads : 3/8'' to 1.12'' do/-

steel pipe threading machine

Get Price Quote

The desire to offer the highest level of satisfaction to our clients induced us to manufacture genuine quality Steel Pipe Threading Machine. Steel Pipe Threading Machine manufactured by us is widely used in pipe, bolt, rod, scaffolding pipe, ERW pipes, steel bars, Rebar, PVC pipes, conduit pipes, GI pipes etc. We are one of the bona fide pipe threading machine manufacturers. These machines are manufactured in such a way that they offer high resistance to heat, wear & tear and abrasion. All these qualitative features have assisted us to stand amid the best thread machine suppliers in India.The Pipe Threading Machine is used for Cutting External Thread on Steel Pipe by Chasing method. HSS Tangential Chasers are used as cutters. Pipe remains stationery and Die Head rotates. BSP, MATRIX, BSPT, NPT, UNF,UNC, BSW, Acme Threads can be cut on this machine depending upon the type of Chasers. The machine mainly consists the following:- Base Head Stock Saddle Pillar Or Bed Type Clamping Vice Die Head The Steel Pipe Threading Machines are designed to give maximum efficiency and reliable performance under the most severe conditions of service with minimum maintenance cost. All the necessary requirements are combined in this model to from the basic fundamentals of correct threading. All the gears are made of case hardened steel with extra large face with and tooth thickness and cut on hobbing machine for noiseless operation even at high speed. Naturally the are built with high standards of workmanship, material and quality so closely associated with Company Tradition.Design & Workmanship : The National Cutting Tools Steel Pipe Threading Machines are designed to produce quality threads within the to lerance for which they were intended.Head Stock : A heavy duty geared Head Box is of best quality casting providing support to the spindle bearings. The box is of gear type, lubricated, fitted with three extra heavy duty bearings.The Bed : The bed is pillar type having two pillars made of best quality steel nicely finished & duly hard chrome plated in the most modern hard chrome plating unit.The Saddle : The Saddle is fitted on two pillars very precisely. It runs on pillars very smoothly and accurately to the Head Stock alignment.The Apron : The apron gives movement to the saddle with head transfer along with pillars through steel rack and pinion arrangements. It's all gears are made of best quality steel.Vice Jaws : The vice jaws made from the best quality alloy steel are fitted on the saddle well aligned with the head stock center fitted in a heavy duty box type vice. The jaws are heat treated. The movements of jaws are controlled by a screw on the saddle.Range of NCT Steel Pipe Threading Machines and Die Heads. 3/8'' to 1.12'' do/- Capacity Pipe & Bolt 1/2'' to 2'' do/- 1/2'' to 2.1/2'' do/- 1'' to 4'' Capacity Pipe 2.1/2'' to 6'' do/- 4 to 8 do/-

Hand Pipe Bender

Get Price Quote

Semi Automatic Pipe Cutting Machine

Get Price Quote

Tube clamping and slide movements and giverned simultaneously by pressing the foot pedal.The operator's both hands are free enabling him to feed with one hand and stock the cut material with the other hand.The Material to be cut is fixed in a special quick clamping vice and the cutter is move by hand lever up and down. Vertical type machine which can be moved on two axis from 0 to 45.Tube Mills, Tube Drawing and conduit making units, Automobile ancillary units engaged in manufacturing of shock absorbers, propeller shafts, silencers, fuel injection equipments etc,Furniture and Bus body building organizations

Pipe Cutting Machine

Get Price Quote

We are offering pipe cutting machine.

Hydraulic Pipe Cutting Machine

230,000 Per unit

Automatic Pipe Cutting Machine

140,000 Per Units

1 Units (MOQ)

Socket

Get Price Quote

Cold Forged & Machined Available in Bright Chrome Finish & Satin Finish

steel pipe threading machine

Get Price Quote

Our payment procedure is not only easy but also safe ensuring your long-term reliance upon us. Whether it is online payment procedure, cash, bank deposits or others, we are here to guide you throughout the process. To easily organize and stack the entire lot of products in our warehouse, we have installed an automated warehousing system. It is supervised by our warehousing experts. Details : The Pipe Threading Machine is used for Cutting External Thread on Steel Pipe by Chasing method. HSS Tangential Chasers are used as cutters. Pipe remains stationery and Die Head rotates. BSP, MATRIX, BSPT, NPT, UNF,UNC, BSW, Acme Threads can be cut on this machine depending upon the type of Chasers. The machine mainly consists the following : Base Head Stock Saddle Pillar Or Bed Type Clamping Vice Die Head The Steel Pipe Threading Machines are designed to give maximum efficiency and reliable performance under the most severe conditions of service with minimum maintenance cost. All the necessary requirements are combined in this model to from the basic fundamentals of correct threading. All the gears are made of case hardened steel with extra large face with and tooth thickness and cut on hobbing machine for noiseless operation even at high speed. Naturally the are built with high standards of workmanship, material and quality so closely associated with Company Tradition.Design & Workmanship : The National Cutting Tools Steel Pipe Threading Machines are designed to produce quality threads within the to lerance for which they were intended.Head Stock : A heavy duty geared Head Box is of best quality casting providing support to the spindle bearings. The box is of gear type, lubricated, fitted with three extra heavy duty bearings.The Bed : The bed is pillar type having two pillars made of best quality steel nicely finished & duly hard chrome plated in the most modern hard chrome plating unit.The Saddle : The Saddle is fitted on two pillars very precisely. It runs on pillars very smoothly and accurately to the Head Stock alignment.The Apron : The apron gives movement to the saddle with head transfer along with pillars through steel rack and pinion arrangements. It's all gears are made of best quality steel.Vice Jaws : The vice jaws made from the best quality alloy steel are fitted on the saddle well aligned with the head stock center fitted in a heavy duty box type vice. The jaws are heat treated. The movements of jaws are controlled by a screw on the saddle.Range of NCT Steel Pipe Threading Machines and Die Heads : 3/8'' to 1.12'' do/- Capacity Pipe & Bolt 1/2'' to 2'' do/- 1/2'' to 2.1/2'' do/- 1'' to 4'' Capacity Pipe 2.1/2'' to 6'' do/- 4 to 8 do/-

Pipe Cutting Machine

15,600,000 Per

Pipe Flaring Machine

Get Price Quote

Backed with expertise & knowledge in this domain, we are counted amongst the foremost manufacturers and exporters of Pipe Flaring Machine. This type of flaring machine finds wide application in automobile industries. Due to its precise construction and corrosion resistant surface, our offered Pipe Flaring Machine is mostly preferred by clients over other ordinary brands available in market. Only quality tested raw materials and components are used for manufacturing these flaring machines. In market, these machines are available in varied specifications at industry leading prices.

Socket

Get Price Quote

1/2" Square Drive MM Size. Chrome Vanadium Steel, Hardened & tempered. Chrome Plated, Fully Polished, Hex/Bihexagonal Sockets. SPECIFICATION 31CRV3 Cold Forged Size : 8 to 24mm

Socket

Get Price Quote

H.A. Overseas is a leading exporting company of Socket, which is chrome plated, fully polished.

Pipe Beveling Machine

Get Price Quote

The Pipe Beveling Machine is used for the objective of beveling the pipe end. Pipe is beveled from the External and Front side is experienced by two different resources. The Pipe continues to be Invitations and the Beveling head moves and comes out of the head stock for reducing the Pipe end.The Pipe Beveling System mainly includes the following:Bed Head Stock Clamping Vice Beveling Head. Bed Head Stock Clamping Vice Beveling Head. BED: - The Bed of Pipe Beveling Machine is created of cast iron. It is Very Firm and durable in development so as to take highest possible Fill and process max. Oscillations It is offered with four Nos. Base Gaps of Dia M20 at four sides of the bed. It is also offered with Four Utilized holes of 5/8” BSW near the Base Gaps. The head stock and Clamping Vice is fixed on the Bed. HEAD STOCK: - The head stock whole body of Pipe Beveling Machine is created of cast iron. It is Very rigid and durable in style. The Go Inventory is developed for Four Nos. Spindle rates of speed. All the Equipment are of helical kind created out of Axle Developing. The dimension gears is 50 mm. The Moving Equipment move on Splined Golf club shafts. The Golf club shafts are installed on Large Responsibility Football Bearings. The Feedback Base will be offered with a lever having three lines for C-Section V-belts. The Primary Spindle is installed on two Blend Curler Bearings installed in Difficult Firefox Coated Floor Sleeve. The Sleeve along with main spindle fixed with Beveling Go is installed in the Go Inventory whole body and is portable To and Fro along its axis. A Hyd. cylinder tube actuated electronically creates the activity of the sleeve in the Go Inventory. The Movement of the Sleeve can also be created personally. The head stock is Oil Loaded. It is offered with Oil Stuffing gap, Oil Strain gap and Oil Stage Signal.

Pipe Beveling Machine

Get Price Quote

Pipe Beveling Machine, GI Pipe Threading Machine, Pipe Threading Machines

hdpe bag sewing machines

Get Price Quote

hdpe bag sewing machines, bath mat making machines

Pipe Benders

Get Price Quote

Pipe Benders, woodworking machines hand tools

Pipe Cutting Machine

Get Price Quote

Boiler Pipe, cordless pipe cutting machine, pipe cold cutting machine

pipe cutting machines

Get Price Quote

pipe cutting machines, Rod Threading Machine, pipe threading machine