Automatic Pipe Threading Machine

Get Price Quote

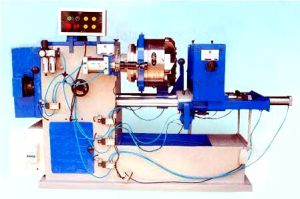

LATHE TYPE PVC PIPE THREADING MACHINE

Get Price Quote

Lathe type pvc pipe threading machine we introduce ourselves as one of the leading manufacturers of precision & high quality workshop machinery specializing in all type of lathe & pipe threading machines. we have launched our new range of pvc pipe threading to solve your threading problem quality wise & production wise, we have the above special purpose lathes with capacity from 50mm. To 250mm for 3 mtr. Pipe & 4 mtr. Pipe. We provide quick change collect system for quick loading & unloading of pipes of various sizes, with double saddle system for two operators working at a time for inside & outside threading simultaneously. pvc pipe threading machine construction the imc extra heavy duty lathes are renowned throughout the world to give maximum efficiency and reliable performance under the most severe conditions of service with minimum maintenance cost. Imc lathes are famous for precision jobs, accuracy and trouble free preformance. imc lathes have been designed to cater need of sustained accuracy and superb finishing. bed: the bed being the foundation of the lathes is carefully designed and is of high grade cast iron. It has cross-ribs to support its walls and three inverted ‘vees’ assembled with removable gap for large swing. head stock: the main spindle is of alloy steels with ground finish to give accurate results. The main spindle runs in bush or taper roller bearing. saddle: the v ways running on the bed and the slides are most accurately hand scrapped and aligned accurately with bed and the headstock.the saddle is fitted with ‘hand’ and ‘automatic travers’ along the bed with steel rack and pinion.it is assembled with cross and upper slide graduated to give desired taper turning. tool-post: the tool-post is made out of one piece steel block and can hold four different tools at a time and can be swivelled to any desired angle. apron: the apron gives movement to the saddle for screw cutting sliding and surfacing by means of enclosed gears and half nut. All gears are of steel. tailstock: the tailstock is designed to give maximum strength bolt operation.it has long bearing within the barrel and ensures true alignment. three speed gear box: the three speed gear box is provided with the lathe to obtain coarse, midium and fine cutting ranges,both longitudinal and cross on the feed bar through gears.the lead screw with accurate thread is to be used only for thread cutting and can be engaged of disengaged with a handle provided on the gear box while the other handle is for obtaining the desired three speed. standard accessories: supplied with the machine:- face plate one-catch plate one-centre two-centre adopter one-steady rest one-follow rest one-one set of 23 gears-threading dial one- motor pully and motor attachment.

Best Deals from Pipe Threading Machine

Semi Automatic Pipe Threading Machine

Get Price Quote

We are offering a heavy-duty Semi Automatic Pipe Threading Machine that is widely acknowledged for its durability and high strength. Our Semi Automatic Pipe Threading Machine is an automatic machine that is hydraulic operated and appreciated for its speedy performance. Semi Automatic Pipe Threading Machine that we offer has spindle speed of approx. 25 and 50 RPM. Features : The pillar type pipe threading and end facing machines are best suited for the tube mills, scaffolding equipment manufacturers, small pipe component manufacturers and allied industry. These machines are most robustly and ergonomically designed to give best and long term performances in most sever conditions. The tooth of the gears in the head stock are most precisely cut on the hear hobbing machine to give noiseless operation and then are undergone for the heat treatment Of flame hardening which leads to the lesser wear tear and hence leads to longer life of the gear. The spindle mounted in the headstock is provided with taper roller bearings to carry out the heavy-duty operations and all time accurate and noiseless operations. After long-term use if backlash is found in the bearings then it can be removed with the slight adjustment of check nut and locknut. The surfaces of the pillar guide-ways are grounded and are provided with hard chrome plating for smooth operation and lesser wear and tear during operation. The clamping device is provided with single set of clamps for small 0.D pipes and double set of clamps for greater 0.D of the pipes. The tooth of the clamps are insert type so that when this portion is worn out then only inserts can be easily changed rather than changing the whole of the clamp. For the end-facing machine the tool adjustment for the various diameters, can be done by single bolt clamping and declamping. For the threading machine the adjustment for the die-head can be done with the single hand operation with the box spanner, which is provided with the die-head. Additional Information : Price : 3000 USD min

Hydraulic Pipe Threading Machine

Get Price Quote

Raw materials are feedstock for the finished products and thus it becomes crucial to source these inputs only from certified vendors. So, as a reliable name, we do the same. Development of modular control inside our warehouse helps in proper organization of the products and ensure complete safety while storage. The entire system is properly managed by our warehousing experts. Design & Workmanship : Hydraulic Pipe Threading Machine is designed to produce precise threads within the tolerance for which they were intended. Head Stock : A heavy duty geared Head Box is of best quality casting providing support to the spindle bearings. The box is of gear type, lubricated, and fitted with three extra heavy-duty bearings. The Bed : The bed is pillar type having two pillars made of best quality steel nicely finished & duly hard chrome plated in the most modern hard chrome-plating unit. The Saddle : The Saddle is fitted on two pillars very precisely. It runs on pillars very smoothly and accurately to the Head Stock alignment. The Apron : The apron gives movement to the saddle with head transfer along with pillars through steel rack and pinion arrangements. All the gears are made of best quality steel. Vice Jaws : The vice jaws made from the best quality alloy steel are fitted on the saddle well aligned with the head stock center fitted in a heavy-duty box type vice. The jaws are heat-treated. The movements of jaws are controlled by a screw on the saddle. Range of NCT Threading Machines and Die Heads 1/2" to 2.1/2" do/- 1" to 4" Capacity Pipe 2.1/2" to 6" Capacity Pipe 4" to 8" 4" to 8" Capacity Pipe

PVC Pipe Threading Machine

Get Price Quote

We have lanched our new range of P.V.C. Pipe threading to solve your threading problem quality wise & Production wise, we have the above special purpose lathes with capacity from 50mm. to 250mm for 3 mtr. Pipe & 4 mtr. Pipes.

Pipe Nipple Threading Machine

1,750,000 Per Piece

1 Piece (MOQ)

PVC Pipe Threading Machine

Get Price Quote

Our entire range of products is made using high-quality and certified inputs, which are sourced from reliable vendors present in the market. Our quality auditors follow a strict selection process for the same. Owing to our cordial associations with the renowned logistics companies, we are capable of delivering the orders on time.

Pillar Type Pipe Threading Machine

Get Price Quote

Clients can avail high performance Pillar Type Pipe Threading Machine from us. Pillar Type Pipe Threading Machine, available with us, is highly appreciated for demanding very low maintenance. Corrosion resistant Pillar Type Pipe Threading Machine, that we provide, is in extensive demand, owing to its broad industrial applications.

Scaffolding Pipe Threading Machine

Get Price Quote

We Stand in the Midst of Specialized Circular Thread Roller Exporters. We Manufacture High Quality Thread Roller from Superlative Quality Raw Materials that Make Them Durable and Highly Resistant to Various Climatic Factors. We are One of the Predominant Flat Die Thread Roller Suppliers from India. These Thread Rollers are Manufactured as per International Standards, Under the

Conduit Pipe Threading Machine

Get Price Quote

We are reckoned as one of the eminent steel conduit pipe threading machine suppliers from India. We offer excellent quality conduit pipe threading machine that is known globally for its durability and high precision. This is highly demanded by large number of customers and we have also received various positive feedbacks from our honored customers. These are accessible at the most cost effective prices. The Pipe Threading Machine is used for Cutting External Thread on Steel Pipe by Chasing method. HSS Tangential Chasers are used as cutters. Pipe remains stationery and Die Head rotates. BSP, MATRIX, BSPT, NPT, UNF,UNC, BSW, Acme Threads can be cut on this machine depending upon the type of Chasers. The machine mainly consists the following:- Base Head Stock Saddle Pillar Or Bed Type Clamping Vice Die Head The Conduit Pipe Threading Machines are designed to give maximum efficiency and reliable performance under the most severe conditions of service with minimum maintenance cost. All the necessary requirements are combined in this model to from the basic fundamentals of correct threading. All the gears are made of case hardened steel with extra large face with and tooth thickness and cut on hobbing machine for noiseless operation even at high speed. Naturally the are built with high standards of workmanship, material and quality so closely associated with Company Tradition. Design & Workmanship : The National Cutting Tool Conduit pipe threading machines are designed to produce quality threads within the to lerance for which they were intended. Head Stock : A heavy duty geared Head Box is of best quality casting providing support to the spindle bearings. The box is of gear type, lubricated, fitted with three extra heavy duty bearings. The Bed : The bed is pillar type having two pillars made of best quality steel nicely finished & duly hard chrome plated in the most modern hard chrome plating unit. The Saddle : The Saddle is fitted on two pillars very precisely. It runs on pillars very smoothly and accurately to the Head Stock alignment. The Apron : The apron gives movement to the saddle with head transfer along with pillars through steel rack and pinion arrangements. It's all gears are made of best quality steel. Vice Jaws : The vice jaws made from the best quality alloy steel are fitted on the saddle well aligned with the head stock center fitted in a heavy duty box type vice. The jaws are heat treated. The movements of jaws are controlled by a screw on the saddle. Range of NCT Conduit Pipe Threading machine and Die Heads : 3/8'' to 1.12'' do/-

pipe threading machine

Get Price Quote

pipe threading machine

Get Price Quote

Galvanized pipes are reuired to be threaded out. So our machine is providing such threading operations which are required by the PIPE MILLS.

Hydraulic Pipe Threading Machine

Get Price Quote

Customers should stay rest assured with us for the payment procedures. They can pay us conveniently through wide-ranging payment mediums. In order to keep the products in safe condition during transit and handling, we meticulously pack them at our own packaging facility. Also, we make sure that the packaging material is sourced from the trusted vendors. Design & Workmanship : Hydraulic Pipe Threading Machine is designed to produce precise threads within the tolerance for which they were intended. Head Stock : A heavy duty geared Head Box is of best quality casting providing support to the spindle bearings. The box is of gear type, lubricated, and fitted with three extra heavy-duty bearings. The Bed : The bed is pillar type having two pillars made of best quality steel nicely finished & duly hard chrome plated in the most modern hard chrome-plating unit. The Saddle : The Saddle is fitted on two pillars very precisely. It runs on pillars very smoothly and accurately to the Head Stock alignment. The Apron : The apron gives movement to the saddle with head transfer along with pillars through steel rack and pinion arrangements. All the gears are made of best quality steel. Vice Jaws : The vice jaws made from the best quality alloy steel are fitted on the saddle well aligned with the head stock center fitted in a heavy-duty box type vice. The jaws are heat-treated. The movements of jaws are controlled by a screw on the saddle. Range of NCT Threading Machines and Die Heads 1/2" to 2.1/2" do/- 1" to 4" Capacity Pipe 2.1/2" to 6" Capacity Pipe 4" to 8" 4" to 8" Capacity Pipe

pipe threading machine

Get Price Quote

national machinery corp. is a distinguished manufacturer, exporter and supplier of pipe threading machine in india. by offering three types of pipe threading machine namely conduit pipe threading mac, pvc pipe threading machine and steel pipe threading machine, we are ruling domestic as well as international trade channel. factors like excellent performance, minimal maintenance, and easy installation convey a lot to the preference of our pipe threading machine. design & workmanship the nationwide reducing tools thread cutting machines are developed to generate great quality threads within the tolerance for which they were developed. head stock a higher great quality designed go box is of best great quality launching offering support to the spindle bearings. the box is of equipment type, oiled, fixed with three additional great high quality bearings. the bed the bed is pillar type having two support beams created of best great quality metal perfectly finished & properly difficult firefox coated in the most modern difficult firefox plating unit. the saddle the seat is fixed on two pillars very precisely. it operates on support beams very efficiently and perfectly to the go inventory positioning. the apron the attire gives activity to the saddle with head exchange along with support beams through metal holder and pinion preparations. it's all equipment are created of best great quality metal. vice jaws the vice oral cavity created from the best great quality metal are fixed on the saddle well arranged with the top stock center fixed in a great high quality box type vice. the oral cavity is warm handled. the motions of oral cavity are managed by the saddle. range 1/4" to 1" do/- 3/8" to 1.12" do/- 1/2" to 2.1/2" do/- 1" to 4" capacity pipe 2.1/2" to 6" capacity pipe 4" to 8" 4" to 8" capacity pipe

PVC Pipe Threading Machine

Get Price Quote

Our company offers unmatched quality PVC pipe threading machine that is manufactured using superior quality materials. This further ensures high durability and effective performance due to which it is high on demand in the national and international market. We are reckoned as the most outstanding pipe threading machine manufacturers of India. Last but not the least, this PVC threading machine is easily available at the most reasonable prices.The Pipe Threading Machine is used for Cutting External Thread on Steel Pipe by Chasing method. HSS Tangential Chasers are used as cutters. Pipe remains stationery and Die Head rotates. BSP, MATRIX, BSPT, NPT, UNF,UNC, BSW, Acme Threads can be cut on this machine depending upon the type of Chasers. The machine mainly consists the following:- Base Head Stock Saddle Pillar Or Bed Type Clamping Vice Die Head The PVC Pipe Threading Machines are designed to give maximum efficiency and reliable performance under the most severe conditions of service with minimum maintenance cost. All the necessary requirements are combined in this model to from the basic fundamentals of correct threading. All the gears are made of case hardened steel with extra large face with and tooth thickness and cut on hobbing machine for noiseless operation even at high speed. Naturally the are built with high standards of workmanship, material and quality so closely associated with Company Tradition.Design & Workmanship : The National Cutting Tools PVC Pipe Threading Machines are designed to produce quality threads within the to lerance for which they were intended.Head Stock : A heavy duty geared Head Box is of best quality casting providing support to the spindle bearings. The box is of gear type, lubricated, fitted with three extra heavy duty bearings.The Bed : The bed is pillar type having two pillars made of best quality steel nicely finished & duly hard chrome plated in the most modern hard chrome plating unit.The Saddle : The Saddle is fitted on two pillars very precisely. It runs on pillars very smoothly and accurately to the Head Stock alignment.The Apron : The apron gives movement to the saddle with head transfer along with pillars through steel rack and pinion arrangements. It's all gears are made of best quality steel.Vice Jaws : The vice jaws made from the best quality alloy steel are fitted on the saddle well aligned with the head stock center fitted in a heavy duty box type vice. The jaws are heat treated. The movements of jaws are controlled by a screw on the saddle.Range of NCT PVC Pipe Threading Machines and Die Heads. 3/8'' to 1.12'' do/- Capacity Pipe & Bolt 1/2'' to 2'' do/- 1/2'' to 2.1/2'' do/- 1'' to 4'' Capacity Pipe 2.1/2'' to 6'' do/-

pipe threading machine

Get Price Quote

pipe threading machine

Get Price Quote

The Tube Threads Device is used for Reducing Exterior Line on Pipe joints by Pursuing method. HSS Tangential Chasers are used as blades. Tube continues to be invitations and Die Go moves. Matric, BSP, BSPT, NPT, UNF,UNC, BSW, Acme Discussions B.S.F etc. threads can be cut on this machine based on the kind of Chasers. The device mainly comprises the following:-Base Go Inventory Seat Bed or Principal Kind Clamping Vice Die Go. Base Head Stock Saddle Bed or Pillar Type Clamping Vice Die Head. THE PIPE THREADING MACHINES are developed to give highest possible performance and efficient performance under the most serious conditions of support with minimum servicing cost. All the necessary specifications are mixed in this design to from the basic basic principles of correct threading. All the equipment are created of case solidified metal with huge face with and teeth width and cut on hobbing machine for quiet function even at high-speed. Normally the are built with great specifications of craftsmanship, material and great quality so carefully associated withCOMPANY TRADITION. DESIGN & WORKMANSHIP: The Nationwide Reducing Tools thread cutting machines are developed to generate great quality threads within the to lerance for which they were developed. HEAD STOCK: A higher great quality designed Go Box is of best great quality launching offering support to the spindle bearings. The box is of equipment type, oiled, fixed with three additional great high quality bearings. THE BED: The bed is pillar type having two support beams created of best great quality metal perfectly finished & properly difficult firefox coated in the most modern difficult firefox plating unit. THE SADDLE: The Seat is fixed on two pillers very precisely. It operates on support beams very efficiently and perfectly to the Go Inventory positioning. The APRON: The attire gives activity to the saddle with head exchange along with support beams through metal holder and pinion preparations. It's all equipment are created of best great quality metal. VICE JAWS: The vice oral cavity created from the best great quality metal metal are fixed on the saddle well arranged with the top stock center fixed in a great high quality box type vice. The oral cavity are warm handled. The motions of oral cavity are managed by a attach on the saddle.

Pipe Threading Machines

Get Price Quote

Scaffolding Pipe Threading Machines with Lead Screw

Get Price Quote

Scaffolding Pipe Thread Cutting Machine is use to cut the external threads with the help of Tangential chaser. Chaser is use as a cutter in thread cutting machine. Component remain still, Die-head rotates and different type of threads can be cut parallel and taper such as BSPT, BSW, BSP, NPT, UNF, METRIC, UNC, ACME, BSF Threads. The Scaffolding pipe thread cutting machine mainly consists the following:- Bed Head Stock Clamping Vice Saddle THREAD CUTTING MACHINES are designed to give maximum efficiency and reliable performance under the most severe conditions of service with minimum Conditions of severe with minimum maintenance . all the necessary requirements are combined in this model to from the basic fundamentals of correct threading. All the gears are made of case hardened steel with extra large face with and tooth thickness and cut on hobbing machine for noiseless operation even at high speed. Naturally they are built with high standard of workmanship, material and quality so closely associated with COMPANY TRADITION . DESIGN & WORKMANSHIP : ROHITA INDUSTRIES thread cutting machines are designed to produce quality threads within the tolerance for which they were intended. Head Stock : A heavy duty geared Head Box is of best quality casting providing support to the spindle bearings. The box is of gear type, lubricated, fitted with three extra heavy duty bearings. The Bed : The bed is pillar type having two pillars made of best quality steel nicely finished & duly hard chrome plated in the most modern hard chrome plating unit. The saddle : The Saddle is fitted on two pillars very precisely. It runs on pillars very smoothly and accurately to the Head Stock alignment. The Apron : The apron gives movement to the saddle with head transfer along with pillars through steel rack and pinion arrangements. It's all gears are made of best quality steel. Vice Jaws : The vice jaws made from the best quality alloy steel are fitted on the saddle well aligned with the head stock center fitted in a heavy duty box type vice. The jaws are heat treated. The movements of jaws are controlled by a screw on the saddle.

Scaffolding Pipe Threading Machines

Get Price Quote

Scaffolding Pipe Thread Cutting Machine is use to cut the external threads with the help of Tangential chaser. Chaser is use as a cutter in thread cutting machine. Component remain still, Die-head rotates and different type of threads can be cut parallel and taper such as BSPT, BSW, BSP, NPT, UNF, METRIC, UNC, ACME, BSF Threads.