Trimming Press

Shot Blasting Machine

10 Units (MOQ)

Machine Type : Table Type

Brand Name : Rattan

Capacity : 5-10 ton/day

...more

Hydraulic Forging Press

10 Units (MOQ)

Color : Red

Automatic Grade : Automatic

Hot Forging Press Machine

SPECIFICATION OF HOT FORGING PRESS MACHINE Model UNITS RHF - 400 RHF - 600 RHF - 750 RHF - 1000 RHF - 1350 RHF - 1600 CAPACITY Tons 400 600 750 1000 1350 1600 Tonnage Rating Point MM 2 3 3 3 4 5 Stroke Length Mm 160 170 180 250 280 300 Stroke Per Minute S.P.M 110 105 100 95 90 90 Die Height MM 530 560 540 700 720 720 Adjustment Of Slide MM 6 6 8 10 10 10 Bolster Area (LR X FB) MM 600x700 680x780 730x890 920x1050 950x1250 1000x1270 Slide Area (LR X FB) MM 580x600 650x670 720x780 880x900 900x960 970x1000 Side Opening (W XH) MM 320x520 360x580 400x600 460x600 460x680 560x720 Main Motor Kw/Hp 22/30 37/50 45/60 55/75 75/100 90/120 Adjustment Motor Kwxp 0.5 0.75 1.5 1.5 1.75 1.75 Air Pressure Kg./Cm2 5.5 5.5 5.5 5.5 5.5 5.5 Upper Ejector Type MECH. MECH. MECH. MECH. MECH. MECH. MECH. 1. Capacity TON 1 1 2 3 5 5 2. Stroke MM. 15 20 30 40 50 50 3. Pin Dia MM. 40 50 50 50 55 60 Lower Ejector Type AIR AIR AIR AIR AIR AIR AIR 1. Capacity TONN 1.5 2 4 5 6 10 2. Stroke MM. 40 40 40 50 50 50 3. Pin Dia MM. 40 50 50 50 50 50

...more

H Type Trimming Press

10 Units (MOQ)

Gear Head

eavy duty gear head fabricated from rolled steel sections is mounted on the columns. The drive is through v-belts from high torque A.C. Electric motor via flywheel and reduction gears to the lifter-shaft, friction lifting system is fitted to lifter shaft which runs on double ball bearing and one central phosphorus bronze bearing which also serves as support to lifter shaft. The friction lifter consists of constantly rotating drum and break lined steel band. This band is anchored at one end to stud in lifter drum and other end is carried by camshaft running though lifter drum which is actuated by lever. The lever is operated with the help of pulling cord tied to lever at one end goes to operating point by passing though capstan bush attached to lifter shaft. When the cord is pulled it tightens on to the rotating capstan bush which operate the lever resulting in tightening of brake around the brake drum with the help of cam shaft. at this stage lifter drum is rotated and tup is lifted with the help of nylon belt provided. On release of cord the spring loaded arrangement help free fall of tup by disengaging friction band immediately from the friction drum. The spring loaded buffer work as a stopper for lifting drum is its rest position. Positive water cooling arrangement is provided to the friction drum to prevent excessive heating. Salient features of forged products:- More strength as grain Structure is improve Machining is reduced which helps in material saving Most Suitable for mass-production Cost effective

...more

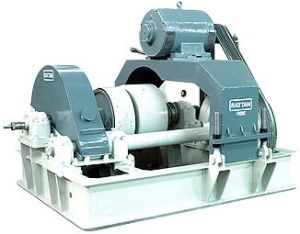

friction drop hammers

Friction Drop Hammer

10 Units (MOQ)

Automation Grade : Semi-Automatic

Material : Mild Steel

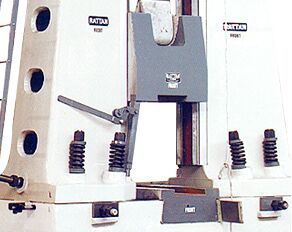

Cast Steel Columns, slides and Tup

Cast steel columns duly-annealed and machined are very stiff and robust in construction to ensure longer stability. These are positioned by a large spigot on underside of each foot which fits into a machined recess in the anvil block .The columns are locked with the help of tapered wedges of alloy steel to ensure firm alignment of columns which helps in accurate guiding of tup (made out of EN-9 cast steel.) the clearance between the tup and guide ways attached to columns is maintained with the help of tapered wedge which brings the columns inward and drawback bolt provided on anvil block on which the columns rest. It dampens the induced shock vibrations which increases the life of the tup and also ensures smooth working of the machine for longer period.

...more

BAR CROPPING MACHINE

10 Units (MOQ)

Brand Name : Rattan

Material : Mild Steel

Power : Electric

Usage : Commercial

...more

Hammers

industrial hammers

Shot Blasting Machines

Be first to Rate

Rate ThisOpening Hours