Rebar Threading Machine

Get Price Quote

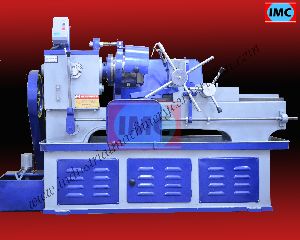

Based on advanced technology, Rebar Threading Machine is a revolutionary machine for threading forged ends of reinforcement bars. Rebar Threading Machine is designed for the precise production of Rebar, reinforcing bar, for concrete foundations. With futuristic design, Rebar Threading Machine significantly reduces effort, thus boosts productivity to a great extent. Rebar Threading Machine offers several other benefits such as low operating cost, easy installation & maintenance, non-corrosive housing and fast operation that make it worth buying. We are a Manufacturer, Exporter, and Supplier of Rebar Threading Machine, based in Ludhiana, Punjab. For further technical information, please contact us.

Rebar Threading Machine

Get Price Quote

The range we present is quality assured by the professionals and from the initial stages of procurement of raw material, we make stern quality inspections to deliver the best range. Owing to our state-of-the-art warehouse, we efficiently entertain both automated inbound and outbound consignments with utmost proficiency. The products are sorted and segregated to make sure that the delivery commences systematically. Detail : Rebar Threading Machine comprises of a Base, Head Shock, Saddle, Bed Type Clamping Vice and Die Head. During the cutting process, Die Head rotates and the bar remains stationary. This machine can be used for cutting a wide range of threads that include Matric, BSP, BSPT, NPT, UNF, BSW, Acme Threads, etc.

Best Deals from Rebar Threading Machine

Rebar Threading Machine

Get Price Quote

Rebar Threading Machine which is manufacture from Industrial Machinery Corporation is made of high quality material and requred less maintenance. The threading machine can be availed in two varieties – Bed type and Pillar type, while there are four specifications in which these machines can be manufactured. These specifications vary on the basis of things like saddle movement , spindle speed range, capacity, production per hour and requirement of power REBAR THREADING MACHINE Rebar / Bar Threading machine is manufactured with high-quality raw material. Due to this it does the noise-free operation and required low maintenance. IMC Machine is very easy to operate. Our bar Thread Cutting Machines are Running in India as well as Abroad.We have been serving every one of our customers with best of industrial machine and not just this; we have been giving excellent after deals benefit, in the event that, any of our machines face any technical issue which is extremely rare. Rebar Threading Machine is used for Cutting External Thread on bars by Chasing method. HSS Tangential Chasers are used as cutters. Rebar remains stationery and Die Head rotates. Matric, BSP, BSPT, NPT, UNF, UNC, BSW, Acme Threads B.S.F etc. threads can be cut on this machine depending upon Base Head Stock Saddle Bed or Pillar Type Clamping Vice Die Head. REBAR THREAD CUTTING MACHINE is designed to give maximum efficiency and reliable performance under the most severe conditions of service with minimum maintenance cost. All the necessary requirements are combined in this model to form the basic fundamentals of correct threading. All the gears are made of case hardened steel with extra large face with and tooth thickness and cut on hobbing machine for noiseless operation even at high speed. Naturally, they are built with high standards of workmanship, material, and quality so closely associated with COMPANY TRADITION. DESIGN & WORKMANSHIP: The Industrial Machinery Corporation thread cutting machines are designed to produce quality threads within the tolerance for which they were intended. HEAD STOCK: A heavy duty geared Head Box is of best quality casting providing support to the spindle bearings. The box is of gear type, lubricated, fitted with three extra heavy duty bearings. THE BED: The bed is pillar type having two pillars made of best quality steel nicely finished & duly hard chrome plated in the most modern hard chrome plating unit. THE SADDLE: The Saddle is fitted on two pillars very precisely. It runs on pillars very smoothly and accurately to the Head Stock alignment. The APRON: The apron gives movement to the saddle with head transfer along with pillars through steel rack and pinion arrangements. It’s all gears are made of best quality steel. VICE JAWS: The vice jaws made from the best quality alloy steel are fitted on the saddle well aligned with the head stock center fitted in a heavy duty box type vice. The jaws are heat treated. The movements of jaws are controlled by a screw on the saddle. Range of IMC Die Heads.1/4″ to 1″ do/-3/8″ to 1.1/2″ do/-1/2″ to 2.1/2″ do/-

Steel TMT Chaser Rebar Threading Machine

Get Price Quote

Specifications We have a wide range of semi-automatic Steel TMT Chaser Rebar Threading Machine which is used for site projects and it does outside threading on TMT bars. Steel TMT Chaser Rebar Threading Machine threads the standard EN8-D TMT bar. The threading is done after the Rebar TMT bar forging process. Threading Machine is used for High Production. Industrial Machinery Corporation has been offering a High-Speed Steel TMT Chaser Rebar Threading Machine. This Rebar Threading Machine is made from high-density alloys. This machine is manufactured by our experts using excellent quality components and cutting-edge technology. This Threading Machine is used for saving time and effort. List of threads that can be cut using TMT Rebar Threading Machine: Metric, BSP, BSPT, NPT, UNF, UNC, BSW, Acme Threads, B.S.F. This Threading Machine has features like robust construction, high performance, and durability. Steel TMT Chaser Rebar Threading Machine needs less maintenance and works for long hours. This Machine tool's cost is very cheap. We have gained all the vital mastery and specialized know-how to make the best Rebar Threading Machine arriving in the market. We assemble our Rebar Threading Machine with all the customizations as said by the customer preceding the beginning of production. If you need to buy the TMT rebar threading machine. Industrial Machinery Corporation is a great choice, as they not only offer a vast range, but also the assurance that each machine that is sent out of their unit is a piece of excellence. Our TMT Rebar Threading Machines are running in various countries like Abu Dhabi, Algeria, Australia, Bangladesh, Bhutan, Canada, Central America, Colombia, Germany, Ghana, Jordan, Kuwait, Lebanon, Malaysia, Maldives, Mexico, Myanmar, Nepal, Peru, Philippines, Qatar, Saudi Arabia, South Australia, Sri Lanka, Thailand, Tunisia, Turkey, U.A.E, USA, Vietnam. Steel TMT Chaser Rebar Threading Machine Specifications: Model 1/4" to 1" (6MM to 25MM) (Bed Type) 3/8" to 1.1/2" (10MM to 40MM) (Bed Type) 1/2" to 2.1/2" (12MM to 65MM) (Bed type) Saddle Movement 10" 10" - 12" 22" Spindle Speed Range 75-140 75-140 45-90 Number of Spindle Speed 2 2 3 Threading Capacity 1/4" to 1" 3/8" to 1.1/2" 1/2" to 2.1/2" Production per Hour 60-80 60-80 70-90 H.P. Required 3 H.P. 3 H.P. 7.5 H.P. Lead Screw Optional Optional Optional Weight (KG) Approx. 500 550 990 IMC Tangential Threading Chasers are manufactured from imported High-Speed Steel which must pass exacting metallurgical standards. Experienced heat treatment with the automatically imported heat treatment plant and imported Testing equipment, assure that they will perform satisfactorily in service and produce quality threads within the tolerance for which they ware intended. These Tangential Chasers are used in Rebar Threading Machine.

Rebar Threading Machine

Get Price Quote

We are one of the major organizations that deal in extremely efficient Rebar Threading Machine that is widely acknowledged for its high-speed performance and durability. Our Rebar Threading Machine is appreciated for high machining accuracy, easy operation, low breakdown rate and simple operation. Our Rebar Threading Machine is can be applied to substandard threaded steel and it also helps in reducing the labor intensity. Specifications : capacity 10mm to 40mm, motor power 3HP. capacity 12mm to 65mm, motor power 7.5HP, with lead screw arrangement various threads.

Rebar Threading Machine

Get Price Quote

Our product is packed in industrial grade packages that are recyclable and provide protection to the products from physical and chemical damage. Additionally, the product is properly labeled to provide information. We are backed with advanced logistics services owing to which we are flexible in delivering the product range of time and with utmost safety.

Rebar Threading Machine

Get Price Quote

The rebar threading machine is use to cut the external threads with the help of tangential chaser. Rebar chaser is use as a cutter in machine. The rebar remain still, die-head rotates and different type of threads can be cut parallel and taper such as bspt, bsw, bsp, npt, unf, metric, unc, acme, bsf threads.

Rebar Threading Machine

172,000 Per Piece

Rebar Threading Machine

Get Price Quote

Based on advanced technology,Rebar Threading Machine is a revolutionary machine for threading forged ends of reinforcement bars. Rebar Threading Machine is designed for the precise production of Rebar, reinforcing bar, for concrete foundations. With futuristic design, Rebar Threading Machine significantly reduces effort, thus boosts productivity to a great extent. Rebar Threading Machine offers several other benefits such as low operating cost, easy installation & maintenance, non-corrosive housing and fast operation that make it worth buying. We are a Manufacturer, Exporter, and Supplier of Rebar Threading Machine, based in Ludhiana, Punjab. For further technical information, please contact us.

Rebar Threading Machine

Get Price Quote

Based on advanced technology, Rebar Threading Machine is a revolutionary machine for threading forged ends of reinforcement bars. Rebar Threading Machine is designed for the precise production of Rebar, reinforcing bar, for concrete foundations. With futuristic design, Rebar Threading Machine significantly reduces effort, thus boosts productivity to a great extent. Rebar Threading Machine offers several other benefits such as low operating cost, easy installation & maintenance, non-corrosive housing and fast operation that make it worth buying. We are a Manufacturer, Exporter, and Supplier of Rebar Threading Machine, based in Ludhiana, Punjab. For further technical information, please contact us. Rebar Threading Machine comprises of a Base, Head Shock, Saddle, Bed Type Clamping Vice and Die Head. During the cutting process, Die Head rotates and the bar remains stationary. This machine can be used for cutting a wide range of threads that include Matric, BSP, BSPT, NPT, UNF, BSW, Acme Threads, etc.

Rebar Threading Machine

Get Price Quote

The Rebar Threading Machine is use to cut the external threads with the help of Tangential chaser. Rebar Chaser is use as a cutter in machine. The Rebar remain still, Die-head rotates and different type of threads can be cut parallel and taper such as BSPT, BSW, BSP, NPT, UNF, METRIC, UNC, ACME, BSF Threads. When one thinks of a Rebar threading machines, the thought automatically goes to the wide range of machines that one can avail in the domain. However, each manufacturing unit or organization will have the need for one particular type of Rebar Threading Machine. One of the most important factors that you need to think about is the company you are choosing for purchase. A good company will not only give you a product that is worthy of your trust,but will also ensure that you receive excellent after sales services.but will also ensure that you receive excellent after sales services. . A good machine, whether it is a rebar thread cutting machine or any other, needs to be high on factors of efficiency while being used and durability as well. If you choose to purchase a rebar thread cutting machine, it would be a good idea to choose a sales unit that has immense market experience. Rohita Industries would be a good choice, as they not only offer a vast range, but also the assurance that every machine that is sent out of their unit is a piece of excellence. Range of Rebar Threading Machine. 1/4" to 1" do/- 3/8" to 1.1/2" do/- 1/2" to 2.1/2" do/- Features: The Spindle Bore 40mm Fitted with Taper Bearing 32212 & 32211 The Machine Has Two Speeds 60 & 90 RPM All Gears are Tempered (Oil Seals 42-12-65) Motor Pulley 12" Diameter, V-belt Drive Vice Fitted with Jaw