ledger for cuplock

Get Price Quote

scaffolding plank

85 - 95 Per kilogram

15 Ton (MOQ)

With us, buyers are free to place orders and can expect timely deliveries of the same. Buyers will not regret purchasing our products, as they conform to industrial quality management standards.

Best Deals from Scaffold Ladder

Angle Iron Cross Braces

Get Price Quote

200 Piece (MOQ)

Scaffolding Base Plate

Get Price Quote

Scaffolding Base Plate, Scaffolding Materials, Scaffolding Clamps

mason frame

759 Per Piece

Scaffolding Ledgers

Get Price Quote

Scaffolding Single Ladder Frame

1,200 Per Piece

1000 Piece(s) (MOQ)

Scaffolding Pipe

Get Price Quote

Industrial Machinery Corporation is manufacturing and offering Scaffolding Pipe Threading Machine used for Construction Scaffolding material. The scaffolding pipe can be thread by Thread Cutting or Thread Rolling Process. Hydraulic Scaffolding Thread Rolling Machines are used for high production and long threads and Scaffolding Thread Cutting Machines are used for low production and can thread upto 650mm only. For long thread and high production we recommend you to Thread with Rolling process.

Steel Shuttering Plates

Get Price Quote

To protect our products from being damaged during transit/ handling, we use industrial grade packaging materials. Furthermore, we ensure the packs are appealing for marketing purposes. Our entire array of products is sternly manufactured using certified array of raw materials. These inputs are sourced only from trustworthy vendors present in the market.

Scaffolding Materials

12 - 1,000 Per Piece

500 Piece (MOQ)

hii, this is surindra steels ludhiana punjab we are manufacturing all types of scaffolding accessories (couplers & cuplock accessories)

Scaffolding Pipe Threading Machines

Get Price Quote

Industrial Machinery Corporation is manufacturing and offering Scaffolding Pipe Threading Machine used for Construction Scaffolding material. The scaffolding pipe can be thread by Thread Cutting or Thread Rolling Process. Hydraulic Scaffolding Thread Rolling Machines are used for high production and long threads and Scaffolding Thread Cutting Machines are used for low production and can thread upto 650mm only. For long thread and high production we recommend you to Thread with Rolling process. Industrial Machine Corporation has been in the business of manufacturing industrial machines for more than a decade now. By being in this business for so long, we have acquired a vast experience and expertise which we have applied all in manufacturing and exporting of various industrial designs to our clients from across the world. Our specialization has made us build each and every machine with utmost technology. IMC manufacturing unit based in Ludhiana is one of the most advanced units comprising of all the latest and upgraded machines, newest to newest technologies, and vastly experienced man-power who use the available resources very wisely to manufacture the best of scaffolding machines. Our zeal and intensity for giving our best every time comes from the fact that customers worldwide have unflinching faith in IMC Hydraulic Thread Rolling and Thread Cutting Machines manufactured at Industrial Machinery Corporation.

Scaffolding Base Plate

Get Price Quote

products are: cuplock, ringlock, jacks, prop, fork head, tri pod for prop holding, forge couplers, guard rail & tie system with tie rod, forge anchor nut, wing nut, waller plate, water barrier etc .

Ledger O-Type Scaffolding

400 Per Piece

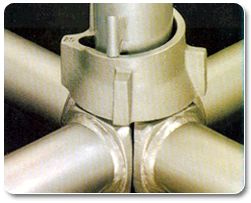

Cup Lock Type System

Get Price Quote

A multipurpose scaffold system which can be used for all forms of access and support structures in the building and construction industries, ship building, offshore construction and industrial maintenance.It provides major savings in erection and dismantling times thus minimizing on-site costs. When not in use, its modular construction ensures minimal space requirements for storage.A unique node point connection allows up to four horizontal members to be connected to a vertical member in one single action - without the use of nuts and bolts or wedges. The locking device is formed by two cups, a fixed lower cup which is welded to the vertical component at pre-located intervals and a sliding upper cup. The forged blade ends of the horizontal components are located into the lower cup, the upper cup is moved down and rotated to secure the components in place and a hammer blow then results in a positive and rigid connection.It is extremely versatile. It can be erected for straight, curved and circular configuration for both access and support, and also for independent and mobile towers. Both vertical and horizontal members are manufactured from 48.3mm overall diameter x 3.2mm gauge high tensile steel to British Standard 4360 Grade 50 (minimum ultimate tensile stress = 534N/mm2).With no loose parts and with corrosion protection by hot dip galvanizing to British Standard 729, minimum thickness of the zinc coating is 85 microns.Conforms to BS1139 Part 5, HD1000, OSHA and Australian New Zealand Standards HIGHLIGHTS Quick fastening of horizontals. Four horizontals can be fastened at one time with firm clamping action of top cup making the joint rigid. Quick erection and dismantling results in time and labour saving. Versatile use in construction, demolition or maintenance projects for any type of structure i.e. straight or curved. Easy erection with no loose components. Lightweight but high loads carrying capacity up to 57 KN per vertical. Low maintenance. Safety with proven track record.

Cantilever Beam Frame

Get Price Quote

Cuplock Scaffolding System

Get Price Quote

Cuplock Scaffolding System. This type of cuplock systems permits up to four horizontals to be connected in vertical manner in one single action without using bolts and nuts. The locking devices are quite versatile and are formed with two cups, the upper cup is sliding, and the lower cup is welded to the vertical component at pre-located intervals. The upper cup is lowered down and revolved to secure the components in place and then a hemmer blow result in a rigid and positive connection, the forged blade ends of the horizontal components are located into the lower cup.

kwick stage systems

Get Price Quote

Ledger ( EIRL-01B ) Size (mtr.) Weight (kg) 1.2 5.55 1.8 6.95 2.4 8.85

Scaffolding Pipes

Get Price Quote

Ringlock Scaffolding

60 Per Piece

This is Steel casting Ledger end with high quality material. We are the main supplier for this product from Ludhiana.

Cuplock Ledger

Get Price Quote

Made from 48.3mm diameter high grade steel tube with forged steel blade ends, which locate into the bottom cups of the Standard (Vertical) and are locked in place by the corresponding top cups.