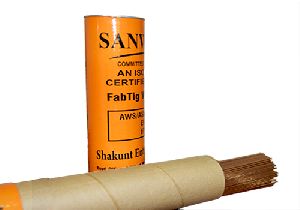

tig welding wires

Gas Tungsten Arc Welding (GTAW) (TIG) Tungsten inert gas welding process that uses non- consumable tungsten electrode to produce the weld. The weld area is protected from atmosphere contamination by an inert shielding gas(Argon or Helium) with filler metal.Tig welding allow stronger & high quality clear welding as compare to shielded metal-arc welding.Because only the necessary amount of filler metal is added to welding puddle, no-spatter or sparks are produced. No flux being used during Tig welding so there is no slag to block your view of the weld bead. Final welding also having no slag to remove.

...more

TIG Welding Wire

Gas Tungsten Arc Welding (GTAW)/ (TIG) Tungsten inert gas welding process that uses non- consumable tungsten electrode to produce the weld. The weld area is protected from atmosphere contamination by an inert shielding gas(Argon or Helium) with filler metal. Tig welding allow stronger & high quality clear welding as compare to shielded metal-arc welding.Because only the necessary amount of filler metal is added to welding puddle, no-spatter or sparks are produced. No flux being used during Tig welding so there is no slag to block your view of the weld bead. Final welding also having no slag to remove.

...more

MIG Wire Plant

new generation highly efficient copper coated Mig Wire.It has been designed to take care of welding condition which needs high speed and efficiency at a time in extreme welding condition. It takes care for your manual, semi-automatic or robotic MIGMAG welding operation to an exciting performance and all-around effectiveness. This high speed wire will have a positive impact on reducing your overall welding costs.Fabrico is an ultimate invention of new generation in copper coated wires which do not soil wire feeders, liners, torches and contact tips with unwanted particles. This result in trouble-free feeding, a high process stability, reduced consumption of wear parts and superior welding properties.With Fabrico you can increase your efficiency of welding to a considerable limit when you compare to other copper coated wires and so you have higher productivity, improved weld quality at all times. The continual usage of Fabrico will reduced the overall welding costs for sure. The Fabrico consists of wires for high strength, creep resistant and weather resistant steels.

...more

MIG Wire

a new generation highly efficient copper coated Mig Wire.It has been designed to take care of welding condition which needs high speed and efficiency at a time in extreme welding condition. It takes care for your manual, semi-automatic or robotic MIGMAG welding operation to an exciting performance and all-around effectiveness. This high speed wire will have a positive impact on reducing your overall welding costs. Fabrico is an ultimate invention of new generation in copper coated wires which do not soil wire feeders, liners, torches and contact tips with unwanted particles. This result in trouble-free feeding, a high process stability, reduced consumption of wear parts and superior welding properties.

...more

mag welding wire

Sanwalka EcoFab Extreme care for your manual, semi-automatic or robotic MIGMAG welding operation to an exciting performance and all around effectiveness. The high efficiency wire will have a positive impact on reducing your overall welding costs.Trouble-free feed ability, even at high wire feed speeds and lengthy feed distance, Trouble-free feed ability, even at high wire feed speeds and lengthy feed distance.

...more

Flux Cored Wire

Mild Steel, All Position – AWS E71T-1C-H8 KEY FEATURES Even arc transfer and low spatter Designed for welding with either 100% CO2 or 75-82% Argon/balance CO2 shielding gases Excellent freezing slag for out-of-position welding Excellent weld puddle manipulation Low spatter loss, easy slag removal CONFORMANCES EN758: T46 2 PC 1 H5/T 46 4 PM 1 H5 DIN8559: SGR1CY4643/SGR1 M 21 Y 4643 AWS/ASME-SFA-5.20: E71T – 1 TYPICAL APPLICATION Smooth arc transfer and low spatter Shipbuilding , barges and offshore platforms Heavy equipment Structural Fabrication General Fabrication SHIELDING GAS 100% CO2 75-82% Argon/Balances CO2 Flow Rate : 40-50CFH WELDING POSITION ALL

...more

Flux Cored Welding Wire

Even arc transfer and low spatter, Designed for welding with either 100% CO2 or 75-82% Argonbalance CO2 shielding gases, Excellent freezing slag for out-of-position welding, Excellent weld puddle manipulation, Low spatter loss, easy slag removal.

...more

Copper Free Mig And Mag Welding Wire

Copper Free Mig/Mag Welding Wire (EcoFab) Sanwalka EcoFab Extreme care for your manual, semi-automatic or robotic MIG/MAG welding operation to an exciting performance and all around effectiveness. The high efficiency wire will have a positive impact on reducing your overall welding costs. Distinct Features Consistent welding performance Stable arc with low feeding force Excellent arc ignition High current applicability Extreme low overall spatter Trouble-free feed ability, even at high wire feed speeds and lengthy feed distance Low fume emission Usage of Copper free wire:- General steel Fabrication Construction Automotive Shipping Thermal Power Nuclear Heavy Equipments Eco Fab Extreme is an unique invention of new family of non-copper-coated wires which do not contaminate wire feeders, liners, torches and contact tips with copper particles. This results in trouble free feeding, a high process stability, reduced consumption of wear parts and superior welding properties. With Eco-fab you can decrease your fumes up to 30% compare to copper coated wires and so you have higher productivity, improved weld quality, a cleaner work environment. The continual usage of Eco Fab will reduced the overall welding costs.The Eco-fab consists of wires for high strength, creep resistant and weather resistant steels. Eco-Fab wires has longer storage periods. That’s because of our latest process technology that creates a barrier that is highly resistant to corrosion. Chemical Analysis % : (Typical Values) CMnSipS Wire0.07-0.151.40-1.850.80-1.15< 0.025< 0.035 Weld Metal0.05-0.120.80-1.400.2-0.6< 0.025< 0.035 Mechanical Properties of the pure weld metal (Typical Values) Heat TreatmentYield Strength(N/mm2)Tensile Strength(N/mm2)Percentage Elongation (%)Charpy V Notch(J) [-29 degree Celsius] AW & SR> 400> 480> 22> 27

...more

Copper Coated Mig Wire

Copper Coated Mig Wire (Fabrico) Sanwalka’s “Fabrico” is a new generation highly efficient copper coated Mig Wire.It has been designed to take care of welding condition which needs high speed and efficiency at a time in extreme welding condition. It takes care for your manual, semi-automatic or robotic MIG/MAG welding operation to an exciting performance and all-around effectiveness. This high speed wire will have a positive impact on reducing your overall welding costs. Fabrico is an ultimate invention of new generation in copper coated wires which do not soil wire feeders, liners, torches and contact tips with unwanted particles. This result in trouble-free feeding, a high process stability, reduced consumption of wear parts and superior welding properties. With Fabrico you can increase your efficiency of welding to a considerable limit when you compare to other copper coated wires and so you have higher productivity, improved weld quality at all times. The continual usage of Fabrico will reduced the overall welding costs for sure. The Fabrico consists of wires for high strength, creep resistant and weather resistant steels. Fabrico wires has longer storage periods. That’s because of our latest process technology that creates a barrier that is highly resistant to corrosion. Distinct Featurers Consistent welding performance Stable arc with low feeding force Excellent arc ignition High current applicability Extremely low overall spatter Trouble-free feed ability, even at high wire feed speeds and lengthy feed distances Low fume emission Usage of Copper Coated Wire General steel fabrication Construction Automotive Shipping Thermal Power Nuclear Heavy Equipment

...more

CO2 MIG Welding Wire

Be first to Rate

Rate ThisOpening Hours