Decorticator Machine

Get Price Quote

A decorticator is a machine for stripping the skin, bark, or rind off nuts, wood, plant stalks, grain, etc. in preparation for further processing. The grains or whole groundnuts etc will be passed through the hardened knives fitted on a rotating disc which peels sensitively the surface further the Vibration system isolates the shells, Skin etc and leaving kernel / meat for next step of operation. All Metal Construction Hardened knives for long life Vibration system to separate shells and hulls Low damage to the seeds/Kernels Wide variety of applications Single and double chambers based on Capacity Energy Efficient Could be synchronized with other machines Wide range of Capacities Minimum Maintenance Easily replaceable blades and rippers.

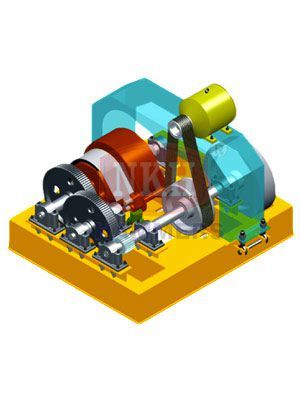

Metal Cutting Hydraulic Hacksaw Machine

Get Price Quote

Metal Cutting Hydraulic Hacksaw Machine It is equipped with feed control device, automatic lifting and lowering arrangement of saw frame with mechanical coolant pump, vice and machine belt guard.Hydraulic Control Hacksaw Machine is supplied complete with suuitable HP AC Electric motor, on-off Starter and V belts. The machine is available in different capacities from 175 mm round bar upto 600 mm round bar cutting capacity. The higher capacity machines are supplied with double cylinder Hydraulic system.

Best Deals from Sheet Metal Machinery

Flanging Machine

60,000 Per Piece

Metal Grinding Machine

Get Price Quote

With latest machines and technology, we ensure that the raw material used is as per the globally accepted standards and meet the international standards. We deliver the quality products that are manufactured using the best raw material. We have a wide supply chain network that enables us to make delivery of consignments within the stipulated time. Features : Heavy-duty, long-life industrial grinder Robust, adjustable workpiece rest Magnetic switch with lockable emergency stop function Runs quietly due to high quality bearings, grinding wheel

Head Assembly

Get Price Quote

Heavy duty head assembly fabricated from rolled steel sections is mounted on top of the columns. The drive is through v-belts from high torque A.C. Electric motor via flywheel and reduction gears to the lifter-shaft. Friction lifting system is fitted to lifter shaft which runs on double ball bearings and one central phosphorus bronze bearing which also serves as support to lifter shaft. The friction lifter consists of constantly rotating drum and break lined steel band. This band is anchored at one end to stud in lifter drum and other end is carried by camshaft running through lifter drum which actuated by lever. The lever is operated with the help of pulling cord tied to lever at one end goes to operating point by passing through capstan bush attached to lifter shaft. When the cord is pulling it tightens on to the rotating capstan bush which operate the lever resulting in tightening of brake around the brake drum with the help of cam shaft. At this stage lifter drum is rotated and to tup is lifted with the help of nylon belt provided. On release of cord the spring loaded arrangement help free fall of tup by disengaging friction band immediately from the friction drum. The spring loaded buffer work as a stopper for lifting drum is its rest position. Positive water cooling arrangement is provided to the friction drum to prevent excessive heating.

Rolling Shutters Making Machine

350,000 - 800,000 Per piece

1 Piece (MOQ)

Metal Milling Machine

Get Price Quote

Metal Lathe Machine

Get Price Quote

PNEUMATIC FLANGE NUT TAPPING MACHINE

200,000 - 450,000 Per One

1 Box (MOQ)

Metal Nibbling Machine

Get Price Quote

Sheet Pressing Machine

Get Price Quote

Metal Milling Machine

200,000 Per Piece

Metal Nibbling Machine

395,000 Per Piece

metal gathering machine

Get Price Quote

Product Specification Item Unit Rated Supply V 400 ± 10% Phase Ph. 2 Frequency Hz. 50 Load KVA 30 Max. Diameter of Rod mm 16 Max. Dia. of Gathered Head mm 50 Max. Gathered Force Kgf. 50670 Max. Lenght of Gathered head mm 75 Clamping Force Kgf. 85

metal bending machine

Get Price Quote

Sheet Metal manufacturing used in the material ranging from automobiles to tools plays a vital role in the metal manufacturing industry. Sheet Metal Bending Machine is build up of two frames with parallel cylindrical rolls mounted inside and third roll cylindrical situated between the first two rolls rotates freely helping the machine to produce conical bends. It varies in the metal fabrication ranging from the formation of different shapes to stamping, high-energy-rate forming, deep drawing, forming and hydro forming. While the shape rolling the sheet metal is bending continuously of the piece along the linear axis, it folds polished and alluring shapes without any stretches or cutting of the single plane sheet material. Sheet Metal Bending Machines which bends the plates into shapes operates with the rolls.

Metal Cutting Hacksaw Machine

Get Price Quote

�Kwality Machinery Exports� is proud to offer world class Metal Cutting Hacksaw Machine which is capable of sawing through different kinds of metals irrespective of the strength and thickness. Equipped with a prismatic guide, our Metal Cutting Hacksaw Machines offer parallel cuts with great precision Specialty : Unique ConstructionEnsures parallel and precise cutsAutomatic OperationsSturdy BedEnhanced Trip MechanismDrive Mechanism with two speedsAdjustable V Belts for tension controlEnclosed Coolant Tank Continued Operations for long working hours Applications : Metal Processing UnitsForging ApplicationsMachine Manufacturing Units Optional Accessories : Electric MotorStarterV-Belts

Metal Cutting Hydraulic Hacksaw Machine

Get Price Quote

Metal Cutting Bandsaw Machine

Get Price Quote

We have designed considering requirement of low cost bandsaw machines for steel traders, workshops and toolrooms. This machine has horizontal swing action for cutting. ECO 220 has heavily fabricated structure and precise parts which ensures break free cutting for longer time. Due to low vibrations the blade life on this machine is observed more than other similar machines available in the market. We provide our machine fully functional with complete electrical,V belt ,Motor and coolant pump

Can Beading Machine

Get Price Quote

1 Piece (MOQ)

Metal Shaping Machine

Get Price Quote

We bring forth proven range of Metal Shaping Machine that is widely used for metal shaping operations in different industries. These machines are appreciated for their universality and superior performance in the international markets. Moreover, Metal Shaping Machine is duly checked on different parameters of quality by our quality controllers on each stages of production process. Highlighting Features Large T-slotted work TableExtensive lubrication by Automatic Lubrication systemEasy interchangeabilityHeavy duty ribbed cast iron structureHigh performanceLonger service life Consists of Automatic lubricationSensor switchesTool boxTest chart and high endurance certificateInstruction and maintenance manual Technical Specifications Model JP-S12 JP-S18 JP-S24 & 26 JP-S30 JP-S32 JP-S36 JP-S42 JP-S48 mm mm mm mm mm mm mm mm Length of Ram Stroke 305 457 660 762 815 915 1070 1215 Length of Ram 660 914 1325 1400 1536 1640 2135 2285 Length x Width of Ram Bearing 660x178 711x245 995x280 995x280 1145x300 1145x300 1600X405 1650x430 Max/min Distance of Table from Ram 257/41 406/89 485/109 485/109 521/340 521/140 521/140 521/140 Working Surface from Table 300x228 381/279 610x330 762x370 810x387 915x387 1050X562 1200x570 Max. Horizontal Table Travel 419 457 665 670 762 865 1070 1215 Max. Vertical Table Travel 140 305 332 435 381 381 457 460 Angular movement of Table +60 DEG +60 DEG +60 DEG +60 DEG FIX FIX FIX Fix Max Tool Shank Size 16x22 30x16 38x21 38x21 38x21 38x21 38X25 40x27 Max. Vertical Travel of Tool Slide 140 152 152 152 152 228 305 330 Max. Swivel of Tool Head +-60 DEG +-60 DEG +-60 DEG +-60 DEG +-60 DEG +-60 DEG +-60 DEG +-60 DEG Diameter of Clutch Pulley 235 311 311 311 405 405 405 405 Number of Ram Speed/Strokes 3 4 4 4 4 4 4 4 Range of Ram Stroke per min. 30 to 90 17 to 75 12 to 72 12 to 72 12 to 67 12 to 67 10 to 60 10 to 60 Diameter of Motor Pulley 76 89 89 89 100 100 100 100 Range of Table Feed/StrokeM 0.22 0.88 0.22 0.88 0.22 0.88 0.22 0.88 0.22 0.88 0.22 0.88 0.22 0.88 0.22 0.88 Tool Head Feed Hand Feed Hand Feed Hand Feed Hand Feed Hand Feed Hand Feed Hand Feed Hand Feed Main Motor Drive 960 Rpm 1.5 H.P. 2 H.P. 3 H.P. 3 H.P. 5 H.P. 5 H.P. 7.5 H.P. 7.5 H.P. V-Belt Section B-35 B-55 B-60 B-60 B-72 B-72 B-85 B-92 Motor Starter 3.5 Amp 3.5 Amp 5 AMP 5 AMP 15 AMP 15 AMP 03:00:00 PM 15 AMP Length 1290 1580 1980 2080 2100 2200 2400 2600 Width 838 948 1067 1117 1500 1650 1900 2100