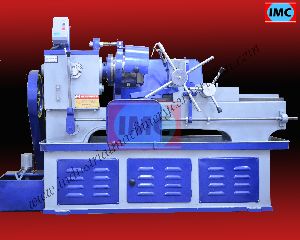

Steel TMT Chaser Rebar Threading Machine

Get Price Quote

Specifications We have a wide range of semi-automatic Steel TMT Chaser Rebar Threading Machine which is used for site projects and it does outside threading on TMT bars. Steel TMT Chaser Rebar Threading Machine threads the standard EN8-D TMT bar. The threading is done after the Rebar TMT bar forging process. Threading Machine is used for High Production. Industrial Machinery Corporation has been offering a High-Speed Steel TMT Chaser Rebar Threading Machine. This Rebar Threading Machine is made from high-density alloys. This machine is manufactured by our experts using excellent quality components and cutting-edge technology. This Threading Machine is used for saving time and effort. List of threads that can be cut using TMT Rebar Threading Machine: Metric, BSP, BSPT, NPT, UNF, UNC, BSW, Acme Threads, B.S.F. This Threading Machine has features like robust construction, high performance, and durability. Steel TMT Chaser Rebar Threading Machine needs less maintenance and works for long hours. This Machine tool's cost is very cheap. We have gained all the vital mastery and specialized know-how to make the best Rebar Threading Machine arriving in the market. We assemble our Rebar Threading Machine with all the customizations as said by the customer preceding the beginning of production. If you need to buy the TMT rebar threading machine. Industrial Machinery Corporation is a great choice, as they not only offer a vast range, but also the assurance that each machine that is sent out of their unit is a piece of excellence. Our TMT Rebar Threading Machines are running in various countries like Abu Dhabi, Algeria, Australia, Bangladesh, Bhutan, Canada, Central America, Colombia, Germany, Ghana, Jordan, Kuwait, Lebanon, Malaysia, Maldives, Mexico, Myanmar, Nepal, Peru, Philippines, Qatar, Saudi Arabia, South Australia, Sri Lanka, Thailand, Tunisia, Turkey, U.A.E, USA, Vietnam. Steel TMT Chaser Rebar Threading Machine Specifications: Model 1/4" to 1" (6MM to 25MM) (Bed Type) 3/8" to 1.1/2" (10MM to 40MM) (Bed Type) 1/2" to 2.1/2" (12MM to 65MM) (Bed type) Saddle Movement 10" 10" - 12" 22" Spindle Speed Range 75-140 75-140 45-90 Number of Spindle Speed 2 2 3 Threading Capacity 1/4" to 1" 3/8" to 1.1/2" 1/2" to 2.1/2" Production per Hour 60-80 60-80 70-90 H.P. Required 3 H.P. 3 H.P. 7.5 H.P. Lead Screw Optional Optional Optional Weight (KG) Approx. 500 550 990 IMC Tangential Threading Chasers are manufactured from imported High-Speed Steel which must pass exacting metallurgical standards. Experienced heat treatment with the automatically imported heat treatment plant and imported Testing equipment, assure that they will perform satisfactorily in service and produce quality threads within the tolerance for which they ware intended. These Tangential Chasers are used in Rebar Threading Machine.

steel pipe threading machine

Get Price Quote

Our payment procedure is not only easy but also safe ensuring your long-term reliance upon us. Whether it is online payment procedure, cash, bank deposits or others, we are here to guide you throughout the process. To easily organize and stack the entire lot of products in our warehouse, we have installed an automated warehousing system. It is supervised by our warehousing experts. Details : The Pipe Threading Machine is used for Cutting External Thread on Steel Pipe by Chasing method. HSS Tangential Chasers are used as cutters. Pipe remains stationery and Die Head rotates. BSP, MATRIX, BSPT, NPT, UNF,UNC, BSW, Acme Threads can be cut on this machine depending upon the type of Chasers. The machine mainly consists the following : Base Head Stock Saddle Pillar Or Bed Type Clamping Vice Die Head The Steel Pipe Threading Machines are designed to give maximum efficiency and reliable performance under the most severe conditions of service with minimum maintenance cost. All the necessary requirements are combined in this model to from the basic fundamentals of correct threading. All the gears are made of case hardened steel with extra large face with and tooth thickness and cut on hobbing machine for noiseless operation even at high speed. Naturally the are built with high standards of workmanship, material and quality so closely associated with Company Tradition.Design & Workmanship : The National Cutting Tools Steel Pipe Threading Machines are designed to produce quality threads within the to lerance for which they were intended.Head Stock : A heavy duty geared Head Box is of best quality casting providing support to the spindle bearings. The box is of gear type, lubricated, fitted with three extra heavy duty bearings.The Bed : The bed is pillar type having two pillars made of best quality steel nicely finished & duly hard chrome plated in the most modern hard chrome plating unit.The Saddle : The Saddle is fitted on two pillars very precisely. It runs on pillars very smoothly and accurately to the Head Stock alignment.The Apron : The apron gives movement to the saddle with head transfer along with pillars through steel rack and pinion arrangements. It's all gears are made of best quality steel.Vice Jaws : The vice jaws made from the best quality alloy steel are fitted on the saddle well aligned with the head stock center fitted in a heavy duty box type vice. The jaws are heat treated. The movements of jaws are controlled by a screw on the saddle.Range of NCT Steel Pipe Threading Machines and Die Heads : 3/8'' to 1.12'' do/- Capacity Pipe & Bolt 1/2'' to 2'' do/- 1/2'' to 2.1/2'' do/- 1'' to 4'' Capacity Pipe 2.1/2'' to 6'' do/- 4 to 8 do/-

Best Deals from Steel Machinery

steel pipe threading machine

Get Price Quote

The desire to offer the highest level of satisfaction to our clients induced us to manufacture genuine quality Steel Pipe Threading Machine. Steel Pipe Threading Machine manufactured by us is widely used in pipe, bolt, rod, scaffolding pipe, ERW pipes, steel bars, Rebar, PVC pipes, conduit pipes, GI pipes etc. We are one of the bona fide pipe threading machine manufacturers. These machines are manufactured in such a way that they offer high resistance to heat, wear & tear and abrasion. All these qualitative features have assisted us to stand amid the best thread machine suppliers in India.The Pipe Threading Machine is used for Cutting External Thread on Steel Pipe by Chasing method. HSS Tangential Chasers are used as cutters. Pipe remains stationery and Die Head rotates. BSP, MATRIX, BSPT, NPT, UNF,UNC, BSW, Acme Threads can be cut on this machine depending upon the type of Chasers. The machine mainly consists the following:- Base Head Stock Saddle Pillar Or Bed Type Clamping Vice Die Head The Steel Pipe Threading Machines are designed to give maximum efficiency and reliable performance under the most severe conditions of service with minimum maintenance cost. All the necessary requirements are combined in this model to from the basic fundamentals of correct threading. All the gears are made of case hardened steel with extra large face with and tooth thickness and cut on hobbing machine for noiseless operation even at high speed. Naturally the are built with high standards of workmanship, material and quality so closely associated with Company Tradition.Design & Workmanship : The National Cutting Tools Steel Pipe Threading Machines are designed to produce quality threads within the to lerance for which they were intended.Head Stock : A heavy duty geared Head Box is of best quality casting providing support to the spindle bearings. The box is of gear type, lubricated, fitted with three extra heavy duty bearings.The Bed : The bed is pillar type having two pillars made of best quality steel nicely finished & duly hard chrome plated in the most modern hard chrome plating unit.The Saddle : The Saddle is fitted on two pillars very precisely. It runs on pillars very smoothly and accurately to the Head Stock alignment.The Apron : The apron gives movement to the saddle with head transfer along with pillars through steel rack and pinion arrangements. It's all gears are made of best quality steel.Vice Jaws : The vice jaws made from the best quality alloy steel are fitted on the saddle well aligned with the head stock center fitted in a heavy duty box type vice. The jaws are heat treated. The movements of jaws are controlled by a screw on the saddle.Range of NCT Steel Pipe Threading Machines and Die Heads. 3/8'' to 1.12'' do/- Capacity Pipe & Bolt 1/2'' to 2'' do/- 1/2'' to 2.1/2'' do/- 1'' to 4'' Capacity Pipe 2.1/2'' to 6'' do/- 4 to 8 do/-

Steel Coil Wrapping Machine

Get Price Quote

The HTI provides packaging solutions for the metal coil industry. Our commitment to the industry has resulted in the development of innovative, cost efficient products that address problems like loose, irregular packaging. Our sales, equipment service, customer service and engineering departments can help you design the optimum protective packaging system for your application. To learn more about HTI coil wrapping machine for steel coil, please check the following information HTI-S series is steel coil wrapping machine which mainly used to steel coil, steel strip packaging, slit strip...with highly efficiency and nice packaging for saving labor and material cost. The packaging is with eye crossing wrapping, which allow steel coil a nice, firm for dustproof, waterproof. Features: 1. PLC & HMI for automatic operation. 2. Special system for easy loading and unloading. 3. Manual and automatic working mode for easy operation. 4. The converter is adopted to adjust the speed of the ring and rollers 5. Overlap of the packing tape according to requirement. 6. Automatic material cutting. 7. Guardrails, soft starts and stop for safety operation. 8. Height of the ring could be adjusted for different OD of the coil 9. Packaging tension is adjustable by special breaker. 10. The rollers are wrapped by polyurethane for protect the surface of the coils. 11.Indicator alarms automatically when trouble occurs. Trouble can be shown automatically. 12. Special brake for the tape release device to avoid material folding. 13. Widely packing material applicable.

Stainless Steel Hydro Extractor Machine

Get Price Quote

We make sure that the packing of our products is done using quality materials and advanced machines. Our packaging experts handle the entire task of packaging keeping in mind the requirements of the clients. Our company has worked hard to establish an efficient distribution network. Therefore, buyers can order the product in mass and expect on time delivery. Features : Low running cost Continuous production machine Stable temperature

Carbon Steel Heavy Duty Sewing Machine

10,000 Per Piece

Steel straightening machine

Get Price Quote

Steel straightening machine, saw sharpeners, card fusing machine

rough steel forging machinery

Get Price Quote

rough steel forging machinery, Engine Crankshaft, Gears