Storm-8 Wire Straightening & Cutting Machine

Get Price Quote

1 Piece (MOQ)

Copper Wire Cutting & Straightening Machine

135,000 Per Piece

1 Piece (MOQ)

Best Deals from Wire Machinery

Wire Straightening and Cutting Machine Solid-TMT

Get Price Quote

This is a highly advanced Wire Straightening and Cutting Machine. The Wire Straightening and Cutting Machines is made up of excellent quality raw material. This Wire Straightening and Cutting Machine cuts the rod and wire appropriately. It is easy to use and is portable.

Wire Cutting Machine

Get Price Quote

Wire Striating & Cutting Machine For 5 mm and 13 mm thread bar specification: 1.Thickness of Wire 5mm to 13mm 2.length of wire:25mm to 3000mm 3.Feeding Capacity per minute: 60 feet 4.Power of Motor:15 HP 1440 RPM & 3 HP 1440 RPM 5.Approx Weight: 1200 KG 6.Floor Space Required: 82x22

0.5mm - 2mm CNC Wire Straightening and Cutting Machine

790,000 - 990,000 Per piece

1 piece (MOQ)

BTI CNC Wire Straightening and Cutting Machines are user-friendly, featuring intuitive controls and interfaces. Operators can easily set up the machines for different wire sizes and cutting lengths, and the machines are designed for smooth and trouble-free operation, minimizing downtime and maximizing productivity. BTI Wire Straightening and Cutting Machines for reliable and efficient wire processing solutions. With their precision performance, durability, and ease of use, these machines are an ideal choice for wire processing operations in various industries. Specification: Diameter Range 0.5 mm to 2.00 mm. Working Speed Up to 90’ feet/min controlled by (VFD). Control Panel PLC with HMI 7” Touch Screen. Length measurement Through Encoder, {No need to set any manually measuring gauge for cutting length.} Cutting Length Tolerance ± 1mm. Wire Collecting tray Up to 2500mm long. Shear Flying cutter controlled by servo motor with Gearbox. Wire Feeding Unit Two nos. Wire Straightening unit One nos. Six Station Rotating Straightener. One set of Horizontal Straightening Rollers 4nos. Straightener Motor Power 1hp 1440rpm 3ph Crompton Motor. controlled by (VFD). (1nos.) Feeder Motor Power 1hp 1440rpm 3ph Crompton Motor. controlled by (VFD). (1nos.) FREE SPARES · One set of cutting dies & Blades extra. · One set of Cast Iron Straightening Die extra. · One Wire stand Up to 150kg capacity.

bar drawing machines

299,000 Per piece

1 Piece (MOQ)

Deep Drawing Press Machine 150 Ton

Get Price Quote

Wire Mesh Knitted Machines

98,000 Per Set

Wire Butt Welding Machine

Get Price Quote

We are offering wire butt welding machine. Butt welding machine is used to weld wire with each other. Range varies according to thickness of wire.

Wire Straightening and Cutting Machine

Get Price Quote

We are offering Wire Straightening Machine

wire making machines

13,000 Per Piece

Wire Bending Machine

Get Price Quote

We are the main supplier of this product.

wire knitting machine

25,000 Per Piece

gold wire drawing machine

89,000 - 90,000 Per Piece

Wire Straightening machine

Get Price Quote

Our robustly constructed wire straightening and Cutting Machine No. 13 is one the best performing Wire straightening machine in ludhiana and is in big demand in the market. Our products are best known for enhancing the productivity and improving quality.

Jewellery Wire Threading Machine

200,000 Per Units

1 Units (MOQ)

Wire Straightening machine

105,000 Per Unit

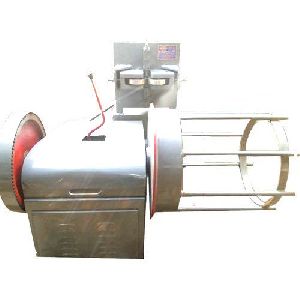

Wire Coil Wrapping Machine

Get Price Quote

Application: 1. Galvanize wire 2. PC wire 3. Pre-strand wire 4. Stainless wire 5. Razor wire 6. Wire rod. Description:HTI-W series is mainly used to packaging of steel wire coil, copper coil... which is with highly efficiency and nice packaging for saving labor and material cost Features: 1. PLC & HMI for automatic operation. 2. Special system for easy loading and unloading. 3. Manual and automatic working mode for easy operation. 4. The converter is adopted to adjust the speed of the ring and rollers. 5. Overlap of the packing tape according to requirement. 6. Automatic material cutting. 7. Guardrails, soft starts and stop for safety operation. 8. Height of the ring could be adjusted for different OD of the coil. 9. Packaging tension is adjustable by special breaker. 10. The rollers are wrapped by polyurethane for protect the surface of the coils. 11. Indicator alarms automatically when trouble occurs. Trouble can be shown automatically. 12. Special brake for the tape release device to avoid material folding. 13. Widely packing material applicable.

Bead Wire GROMMET MACHINE

Get Price Quote

Application : This machine is for Bed Rubberising and Automatic Bed Coiling / Ring making Bicycle and Motor cycle size manufacturing 8" to 28" Dia for 2 no's wire let off unit to 10 no's wire let off unit : MODEL NO. HMG 301 BD 2 x 2 - 1 x 3 - 2 x 3 a). Let off unit 10 no's with self breaks. b). Wire heating unit with D.C. and A.C. variable. ( PLC) c). Cold feed and Hot feed extruder 65mm screw dia. d). Dia 650 mm cooing drum with festforner cap 30mt wire. e). No's.of wire One to Ten. f). Panel 5 HP, 7 1/2, 3 HP wtih D.C. and A.C. drive veriable controls

Wire Flat Machine

250,000 Per Piece

Wire Straightening machine

Get Price Quote

Non-Continuous Wire Drawing Machines

Get Price Quote

We are one of the leading manufacturers and exporters of a wide range of Continuous Wire Drawing Machine designed by highly trained engineers. Continuous steel wire drawing machines are manufactured under royal experience and advanced technology, enable to guarantee performance of all systems with interchangeable parts. Features offered by Continuous Wire Drawing Machine: 1. Vibration free performance 2. Fully covered 3. Driving gears made from special phosphorous bronze and worm of special alloy steel 4. Drum made from high grade C.I. Casting 5. All Gears & Bearings are oil immersed 6. All shafts made from EN8 Steel 7. Heavy duty Structure 8. Horizontally V-Belt driven

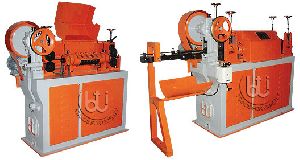

High Speed Wire Straightening and Cutting Machines

Get Price Quote

HIGH SPEED WIRE STRAIGHTENING AND CUTTING MACHINE'S DESCRIPTION: BTI High Speed Wire Straightening and Cutting Machine BTI M-06HS, M-08HS these machines present the perfect combination of speed and precision. Fabricated using latest technology, our machines feature premium grade fast rotating spinner, cutting off tool, straightening bushes and blocks, which enhance their work efficiency and reduce the time and labour involvement. BTI M-06HS, M-08HS, is ideally suitable of Welded Wire Mesh plants, Welding Electrodes, Gas Welding Rods, Umbrellas, Fan Cover, R.C.C Pipes, Kitchen wares, Fasteners, Wire fence & many more. HIGH SPEED WIRE STRAIGHTENING AND CUTTING MACHINE'S: Specially design for Welding electrodes & wire mesh plants Two sets of feed rollers for smooth & Fast feeding Heavy Duty Machines Built on rigid Steel Fabricated Frame Low Maintenance with High Productivity Cutting tools is a simple construction, easy to adjust and change Quickly and easily adjustable dies in spinner Consumes less Power

Wire Nail Machine

Get Price Quote

Dimensions (m): 0.85 x 0.85 x 0.90 1.05 x 1.05 x 1.02 1.20 x 1.20 x 1.10 1.35 x 1.25 x 1.10 1.50 x 1.50 x 1.16 1.80 x 1.90 x 1.40 2.15 x 1.96 x 1.38

Barbed Wire Making Machine

Get Price Quote

Wire Drawing Machine

Get Price Quote

This Horizontal type wire drawing machine is suitable for drawing of wire from 03mm to 40mm drum is made of C.I. steel duly SS welded and grounded for long life. A four speed gearbox is attached with the machine so that speeds can be change according to the size of wire to get maximum production.

Wire Straightener Machine

1,300,000 Per Piece

bull block wire drawing machine

300,000 Per Piece

Bar Drawing Machine

Get Price Quote

MIG Wire Plant

Get Price Quote

new generation highly efficient copper coated Mig Wire.It has been designed to take care of welding condition which needs high speed and efficiency at a time in extreme welding condition. It takes care for your manual, semi-automatic or robotic MIGMAG welding operation to an exciting performance and all-around effectiveness. This high speed wire will have a positive impact on reducing your overall welding costs.Fabrico is an ultimate invention of new generation in copper coated wires which do not soil wire feeders, liners, torches and contact tips with unwanted particles. This result in trouble-free feeding, a high process stability, reduced consumption of wear parts and superior welding properties.With Fabrico you can increase your efficiency of welding to a considerable limit when you compare to other copper coated wires and so you have higher productivity, improved weld quality at all times. The continual usage of Fabrico will reduced the overall welding costs for sure. The Fabrico consists of wires for high strength, creep resistant and weather resistant steels.