hot mix plants

4,000,000 - 5,500,000 Per Set

1 Set (MOQ)

Kesar Stationary Asphalt Hot Mix Plant is the Synonym for High quality. Top notch performance, Lower operating costs, Superb Service back up... translating into productivity and return in turn High profits for the customer. Conforming to international standards the DM range of Asphalt Plants also conforms fully to the latest MORTH (Ministry of Road Transport & Highway) specification. The Kesar Drum Mix Type Hot Mix Plants has a class engineered to last, Standard Make Bought outs, precision engineering, quality processes and procedures with Kesar's rich experience ensure the pride in owning. The Standard configuration of the plants comprise of the following units: Cold Aggregates Bin Feeders � Over Size Removal Vibrating Screen, Slinger Conveyor � Drying & Mixing Drum Unit - Load Out Conveyor with anti Segregation gob hopper - Bitumen Heating & Storage Tank � Mineral Filler Unit - Fully Automatic Control Panel, Weather Proof Control Cabin.

Asphalt Drum Mix Plant

3,900,000 - 4,600,000 Per Piece

1 Piece (MOQ)

Best Deals from Asphalt Road Equipment

Asphalt Batch Mix Plant

21,000,000 Per Unit

1 Unit (MOQ)

Bitumen Sprayer

625,000 - 675,000 Per piece

1 Piece (MOQ)

Mobile Asphalt Drum Mixing Plant

Get Price Quote

We Take the Pleasure in Bringing to You a Premium Quality Mobile Asphalt Drum Mix Plant, Which is Highly in Demand in the Industry. this Product is Brought to You in An Array of Dimensions Befitting the Variety of Construction Related Applications Where It Will Be Extensively Used.

Counter Flow Drum Mix Plant

6,500,000 - 9,500,000 Per Set

1 Set(s) (MOQ)

Alltech Industries India Pvt Ltd is keen to expand its footprint in the manufacturing of road construction machinery market with recently launched COUNTER FLOW DRUM MIX PLANT in India The new Counter flow drum mix plant is setting new standards for asphalt mix production since it is an advanced version of Traditional drum mix plant. The prime benefits of the plant are: • Pollution free plant with Less emission. • Facility to add RAP. • Facility to add Filler. • Drying and Mixing zones are separate which provides Homogenous mixing. • Fuel efficiency. • Centralised control cabin Alltech Counter Flow Drum Mix Plant provided with a Pollution control bag house which strictly follows the EU norms and makes it pollution free.

Drum Mix Plant - 50 (60-80 TPH)

Get Price Quote

We provide Drum Mix Plant, which is fabricated from steel plants. The rotating cylindrical drum of the Drum Mix Plant is mounted on chasis. The Drum Mix Plant we offer is of high quality and manufactured in accordance with industrial norms. There is an electronic high-pressure jet burner which is fitted on the structure and from here cold aggregate is fed into the drum. This helps in controlling temperature automatically. The thermo drum is divided into two zones i.e. Radiation Zone and Coating Zone. There is a divider plate before coating zone, which prevents fire of bitumen inside the thermo drum. Features Cyclone type dust collection system is providedExhaust is providedHigh qualityAffordable price

Hot Mix Plant

Get Price Quote

Hot Mix Plant is one of the extensively used plants in road construction industry. Mostly, it is designed using heavy-duty metal that can withstand heavy loads and impacts. Aadesh automatic stationaryasphalt drum plants manufactured in various models and ranges. Our Asphalt mixing drums confirming that Mörth Specifications. Less maintenance and design under the soles of fuel efficiency. We offer our customers better and proven industry solution technique, process controls generation and automation, along with the total installation and site support, aiming to deliver precisely mixed quality asphalt - productively and profitably. There are two types of Hot Mix Plant: Stationary Hot Mix Plant Mobile Hot Mix Plant Optional Attachments Storage silo for mix material Wet dust collector / bag house filter Unit for effective pollution control

Drum Mix Plant

Get Price Quote

We make available Drum Mix Plant which is reckoned for its make and long service life. Owing to immense experience in this domain, we became efficient in providing quality Drum Mix Plant. Buyers can rely on us for the best in line products as we prepare them using the finest grade raw material and modern techniques. Also, the basic material is sourced from the reliable places.

Hot Mix Plant

120,000 Per Piece

Asphalt Batch Mix Plant

Get Price Quote

1 Set(s) (MOQ)

It is our great pleasure to introduce our company - Alltech Industries India Pvt. Ltd. as OEM (Original Equipment manufacturer) of road construction equipments like: Asphalt Batch Mix Plant with full capacity range 80TPH --200TPH. In view of ever rising crude oil prices creating energy crises & studying current market scenario of road industry in India, the road building contractors are always under pressure to achieve their time bound targets of road projects. Hence, they prefer to buy an Asphalt Batch Mixing Plant, which guarantee maximum tonnage of Asphalt hot mix with minimum fuel consumption per ton mix and minimum downtime of plant. Considering all these important expectations of our valued customers, we introduce our UNIBLACK model Asphalt Batch Mixing Plant that fulfill all above points.

Semi-Automatic Bitumen Sprayer

120,000 Per Piece

10 Piece (MOQ)

asphalt tanks

1,000,000 Per Unit

1 Set (MOQ)

Drum Mix Plant

Get Price Quote

Indian asphalt drum mixers by manufactured by Atlas are known for reliability. Continuous asphalt mixing plant is low on running cost, maintenance and high on production.

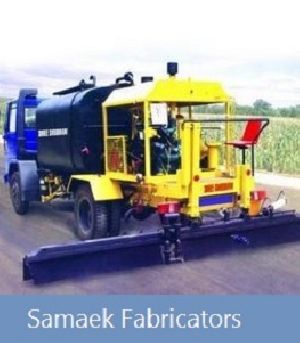

Bitumen Pressure Distributor

Get Price Quote

It is mounted on truck chasis of Ashok Layland or Tata.Bitumen pump: 2"*2" size Positive displacement gear pump with output of 350Lit./Min(Max)Driving unit: Kirloskar Engine Model HA-294,Air Cooled Electric Start, 25HP@2000RPM diesel Engine(Twin Cylinder).BItumin Spraying Pressure - 0 to 6 Kg/cm2Tachometer - Slow Speed 0.5 Meter/Min.Compressor - Make 3HP two Stage Compressor.

Asphalt Drum Mixing Plant

Get Price Quote

Sidhartatha Road Equipments offers Asphalt Drum Mixing Plant that is extensively used for road construction. These Asphalt Drum Mixing Plants are integrated with latest technology thus provide superior performance. Our Asphalt Drum Mixing Plants are manufactured in accordance with international standards and are highly demanded among the clients.

bitumen spraying machine

Get Price Quote

These sprayers are available in capacities of 4 T, 6 T, 8 T, 10 T and 12 Tons. These tar sprayers are with designed to perform in rough conditions and are tried and tested in Indian conditions. Bitumen Pressure Distributor is essential machinery for road building. It is mounted on a suitable truck chassis and moving the same will allow spraying of bitumen on the road prior to laying of hot mix asphalt. It is one of the most important machine for road building.

Asphalt Mobile Drum Mix Plant

Get Price Quote

Sidharatha drums Mobile asphalt mixing plants manufactured in various models and ranges. Drums mix asphalt plants have confirmation for MORTH specifications. We designed maintenance stations and less fuel efficient and low. For Our MDM plants have a strong structure and precision quality. Our mobile asphalt drum mix plants ranges are from 25 to 120 TPH TPH Sidharatha manufactures mobile drum mix plants in the capacities 40-60 tph; 60-90 tph and 90-120 tph. Portable drum mixing plant of capacity 120-150 tph and above are tailor made. These portable asphalt mix plants come with a chassis for aggregate feeder. The second chassis of the portable asphalt plants consists of dryer drum along with wet dust collector type pollution control system. The third chassis of the portable drum mixer consists of fuel tank for burner, bitumen tank and mineral filler. The fourth chassis of the mobile drum mixers is for control cabin, Portable asphalt plants manufactured by Sidharatha do not compromise on the quality or production of the hot mix asphalt. Moving of portable asphalt drum mixer from one place to another is easy and these portable asphalt mixing equipments can be started in few days. Standard Configurations for MDM-25 : Drying & Mixing Unit , Two Bin Feeder , Load out conveyor with GOB Hopper, LDO Tank (All are on one single chassis) Bitumen tank, Control Cabin and Panel Board (On single chassis) Standard Configurations for MDM-45 and above range plants : Drying and Mixing Unit Slinger Conveyor Single deck Vibrating Screen Four Bin Feeder Load out Conveyor with GOB Hopper LDO Tank / Fuel Tank Bitumen tank Fully automatic control panel with Fully furnished Cabin Filler Unit Special Features : No need of civil work OR any foundation work Easy to install High Fuel efficiency Trouble free performance Customized Solutions to meet specific transportation norms

Asphalt Drum Mix Plant

Get Price Quote

We are Manufacturer of Asphalt Drum Mix Plant Since 1991. and we are exporters of Asphalt Drum Mix Plant, leading Supplier of Asphalt Drum Mix plants in India DRYER DRUM The dryer is accurately fabricated to ensure proper heating of aggregates with minimum heat loss. Specially designed flights lift and cascade the aggregate to reduce the final moisture content to 0.5% (by weight). It is supported on steel rollers through steel tyres with idlers and guide rollers and is provided with segmented driving sprocket. A fully automatic high-pressure auto jet burner is mounted at one end of the drum. The discharge chute design discharges heated aggregate directly onto the loadout conveyor. FOUR-BIN FEEDER It is of single chassis construction. At each Bin a radial gate is provided which can be opened in any position to regulate the aggregate flow. Individual endless belts are provided below the gates to discharge material onto the gathering belt. VIBRATING SCREEN A single-deck vibrating screen is provided on the slinger conveyor to remove oversize aggregate received from the 4-bin feeder. SLINGER CONVEYOR An inclined conveyor mounted on idlers receives aggregate from the gathering conveyor and feeds it to the dryer LOAD OUT CONVEYOR Mixed aggregate from the dryer drum is discharged on an inclined conveyor provided with a hydraulic hopper at delivery end for feeding the Mix into Tippers. BITUMEN TANKS One/Two Bitumen Tanks of 15/20/30 MT capacity each are provided, fabricated from steel plates with 50 mm glasswool insulation, manhole, thermocouples, etc. Bitumen is pumped to the dryer drum through pipe lines. Tanks are fitted with independent on-off type burners. MULTICYCLONE EXHAUST The dust collection system consists of enclosed multiple cyclones, exhaust fan and chimney. MINERAL FILLER Fabricated from steel plates, it feeds the required quantity of mineral to the drum. CONTROL CABIN A fully automatic control panel with feather touch controls is provided for controlling the quantity and quality of production with operator sitting in Air-conditioned comfort. All systems are completely synchronized with automatic / manual control of burners, load cells, mix temperature, cold feed / mineral / bitumen proportions, etc. Manual control is possible through over-ride system. Adequate safety measures are adopted to avoid overloading, short-circuit, etc. LDO TANK One LDO Tank of 2000 / 4000 Ltrs. Capacity is provided with each plant. OPTIONALS • Wet type air pollution control system. • Baghouse filter system. • Hot mix storage silo. • Portable plants.

Mini Bitumen Sprayer

Get Price Quote

FEATURES An attachment on Truck, tractor & Jeep. Chassis and linkage holder are entirely made of steel. Both Heating System, Wood Fire Bhatthi & Burner System. 2.5 Ton Capacity. Heavy Duty Chassis & Structure. Safe & easy Operation. Hand Spray System.

Drum Mix Plant

Get Price Quote

We present a comprehensive range of drum mixers, asphalt drum mixers, drum mix plant, asphalt drum mix plant which are able to perform accurately. These are precision engineered through state of the art technology and can be easily operated. Our ISO certified range of drum mix plant includes drum mix plant -45 (40-60 TPH), drum mix plant -50 (60-90 TPH), drum mix plant -60 (90-120 TPH) etc. Capable of working efficiently in adverse conditions, our range of drum mixers are made by our expert engineers using state-of-the-art technology. Assuring the clients of higher output, our range of machines are require less maintenance and are also easy to operate.

Clean Dry Mix Plant

Get Price Quote

Asphalt Batch Mix Plant

Get Price Quote

4-Bins for cold aggregate feeders are all-welded and modular in construction, permitting easy addition of bins to meet growing needs. Steep bin-walls and valley-angles allow free flow of aggregates from the feeders minimizing hold-up of materials in the corners and bridging with sticky aggregates. There is a bin vibrator mounted on walls of dust bin. The bins are supplied with adjustable calibrated gate openings and variable speed feeder drives together offer a total proportional control, greater flexibility and accuracy of operations. Belt scrapper perfectly cleans wet dust stick on return belt of gathering conveyor. A single-deck vibrating screen removes over size aggregates from main flow to prevent any damage of dryer internal flights. Feeding belt-conveyor further feeds material into a rotary dyer. Field proven Dryer drum with high aggregates drying efficiency at very low maintenance cost has gained top reputation among present day's asphalt batch plant manufactures in India. The drum is equipped with 4-wheel drive by gear motors. The dryer also has an unique feature of air-preheat system, which improves drying efficiency, aid power saving, reducing the thermal stresses on the drying drum by burner. Two heavy dyer rings fitted on drum shell & 4-trunning rollers with pressure-fitted shafts & heavy duty bearing pedestals have long working life which are special design features of our dryer. The modulating type dryer burner operates on high fuel-atomizing pressure (40bar) suitable for LDO/Furnace Oil with automatic controls, and of wich a wide turn-down air/fuel ratio saves your money... A temperature-sensor(PTR/thermocouple) fitted at discharge chute senses temperature of dried hot-aggregates. Burner controls this temperature at desired set level. FULLY AUTOMATIC PLANT CONTROL SYSTEM Fully computerized air-conditioned control cabin, with on-board electrical power control console, distribution switch board, fully automatic process and sequence controls are a standard on our batch plants. User-friendly software on the computer with a parallel PLC man machine interface gives you total reliability and ensures top notch performance. Fail proof power interlocks and auto process controls. Online fault detection with remote connectivity and solution. Docket printing and inventory management. Provisions to print, store and email productions details, mix proportions, etc. Automatic cold aggregate feeder controls linked with mix design and hot bin levels. Automatic free fall compensation. The controls is equipped with function-keys and numeric-keys, and does not require special skills for operation. The operator can monitor the complete process control, motor status and pneumatic controls through the colour CRT display.

mobile drum mix plant

Get Price Quote

The Sweeper is constructed from pressed steel shell which give excellent strength to weight ratio. It is a tractor mount sweeper driven from the tractor PTO shaft and is available with small debris collector box and water spray equipment as optional. The sweeper is designed for use with almost any tractor which is fitted with hydraulic lift, three point linkage and power take off and can be fitted or detached in less than five minutes. Brush sections are supplied in crimped steel wire or polyproplyene and are easily replaceable. The castor wheels fitted to the rear enables the sweeper to follow road undulations. The sweeper may be used to sweep straight ahead (for collection) or in two angled positions either side. The splash guard fitted to the sweeper is easily removed the allow the collector attachment to be bolted into place. FEATURES Steel wire, polypropylene or combination brush section. Rigid pressed steel shell. Easily adjusted for brush wear. Different lengths available to special order Optional water tank and sprinkler attachment.

Bitumen Pressure Distributor

Get Price Quote

We hold expertise in the manufacture of Bitumen Pressure Distributor with high functionality. These Bitumen Pressure Distributors are manufactured with precision and with the use of latest technology to offer very high capacity up to 7000ltr. Fitted with Pressure Cleaning System (PCS), our Bitumen Pressure Distributors uniformly coat hot bitumen on hot surface. Attributes Of our Bitumen Pressure Distributor : High capacityAccurate and robust constructionHigh performanceLong service life

Bitumen Sprayer

Get Price Quote

Himalaya engineering company - manufacturer & exporter of bitumen sprayer. Our product range also comprises of asphalt drum mix plant, paver finisher and wet mix plant.

Bitumen Pressure Distributor

Get Price Quote

Bitumen Pressure Distributor, Concrete Mixing Plant, Mechanical Broom Sweeper

Bitumen Pressure Distributor

Get Price Quote

Bitumen Pressure Distributor, ashpalt paver finishing machine, Vitrified Tile

bitumen hand sprayer

Get Price Quote

bitumen hand sprayer, batch mix plant, Slinger Conveyor Set, Wet Mix Plant

Truck Mounted Bitumen Sprayers

Get Price Quote

Truck Mounted Bitumen Sprayers, Asphalt Paver Finishers, bitumen sprayers