20 ML Polyfix Spray Activator

Get Price Quote

100 Piece (MOQ)

Bin Activator

Get Price Quote

We hold a specialization in manufacturing, exporting, and supplying a superior quality Bin Activator. Our organisation is located in Bangalore, India. Our offered Bin Activator moves horizontally in response to the forces generated by the unbalanced weights of an attached vibrator. We have enough capacity to deliver them in bulk quantities. We provide these efficient and durable activators at the market leading rates. Features High efficiency Easy for fitting Convenient installation

Best Deals from Bin Activators

Bin Vibrator

9,000 - 25,000 Per Piece

1 pieces (MOQ)

ELECTROMAGNETIC HAMMERS, are utilized in Dairy Industries, Dyestuffs Industries, Pharmaceuticals Industries, Fertilizer Industries to avoid sticking of powder particles in SPRAY DRYING PLANTS, CYCLONE SEPARATORS,HOPPER, POWDER CONVEYING & POWDER HANDLING EQUIPMENT during the process to keep the material moving.

Metal Etching Stencil Activator

Get Price Quote

We metal etching machines stencils activator readily available

Bin Activators

Get Price Quote

Product Details : This System Is Used Under The Silo’s For Moving The Stichy Matrial From The Silo’s Without Changing The Form Of Product. Power Consumption Is = To No.

Bin Activator

Get Price Quote

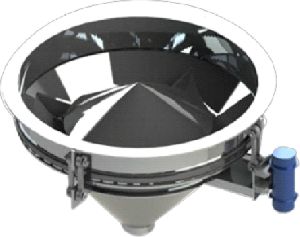

A bin activator is a vibrating bin discharger that is fitted to the outlet cone of silos and hoppers. We deal in Bin Activators which are mostly used in process industries to move dry, bulk materials out of storage on demand. Bin Activator consists of a vibrated cone that is suspended beneath the bin, replacing a major portion of the standard fixed cone. It assists in discharging dry product from a silo to prevent it from bridging or rat-holing. We also provide bin activators in Stainless Steel for Food Industries. They are available in various standard sizes with a choice of fabrication material and extreme reliance. Salient Features: · Available in Carbon Steel, Stainless Steel, and Abrasion-resistant steel· Vibratory Motor is used· Solid Steel suspension arms· Endless beaded flexible sleeve

Bin Activators

Get Price Quote

Bin Activator

50,000 Per

1 Piece (MOQ)

OPERATION : The Bin Activator designed by us consists of a conical shape discharge zone that is connected to storage silo or hopper through a set of steel hangers. The gap between the hopper and discharge zone is sealed with the help of a special flexible rubber sleeve. The material is made to flow normally through the opening provided at the discharge point with the help of one Unbalance Vibrator motor that is fixed on one side. APPLICATIONS : Bin Activator has been successfully tried on all difficult to handle products like sulphur and its compounds, fine mica powder and other minerals, ores titanium dioxide, wood chips, salt, sugar and such other fine, flaky, fibrous and sticky materials. WIDE RANGE : Available for silos from 400mm dia. To 3000mmdia. Made from M.S.,S.S – 304, S.S – 316 or abrasion resistant steel. Epoxy coated or Teflon coated for food application.

Bin Activator

Get Price Quote

It is a common experience that most-materials stored in bins. hoppers or silos do not easily flow through discharge opening.. When called upon to flow. the materials tend to plug. bridge or rat-hole because of their inherent characteristics. environmental conditions or undesirable surrounding vibrations. The conventional solutions employed. viz.. electromagnetic vibrators. air/ steam jets. pounding on the bin body or even manual packing of material from top or through discharge opening. are largely inefficient. noisy and lead to intermittant and erratic discharge of materials. The use of above techniques results in. * Loss of production * Down-time on part of down-stream requirements * Worker fatigue due to additional strenuous work and / or unpleasant vibrator noise. * Contamination, dusting and spillage of product * Damage to structure due to repeated heavy pounding * Impaired product quality and down-stream process wherever flow rates and charging time are important. SHAKTI BIN ACTIVATOR ELIMINATES THESE. PROBLEMS TO ASSURE YOU POSITIVE CONTINUOUS FLOW WITHOUT ANY OPERATIONAL HEADACHES. SHAKTI Bin Activator provides ON DEMAND. positive. trouble Tree. continuous discharge from storage. of wide range of Difficult to handle materials in a variety of densities and particle sizes. Available in preassembled form. this bin activator is built up of a specially profiled discharge head which is flexibly hung from bin. The gap between the bin and discharge head is sealed by an elastic sleeve. A specially engineered gyrator with matched characteristics imparts powerful vibrations of low amplitude and high frequency to the discharge head and hence to the material but not the bin. The horizontal vibratory thrust unpacks the contained material and throws it towards discharge opening where it falls down easily by gravity. The discharge head resolves the horizontal thrusts into strong vertical impulses which extend far up into main bin to cause loosening of contained material. The whole phenomena is silent and demands very little power and attention. * Discharge material continuously at a uniform rate on FIRST IN, FIRST OUT basis without segregation. * Material is handled gently without damaging particles. * Bin Activator offers and advantage of headroom saving. Unlike static bins, the activator permits cone angle. Hence the use of bin activator results in increased storage capacity. * Unlike in cases where compressed air/steam jets are used to loosen the material, use of our bin activator does not cause product contamination, wetting or dusting. * Besides saving labour costs. this devic''''''''''''''''e consumes minimum power and hence is economical. * It is totally reliable. rugged and safe device and is ideally suitable for continuous day-in and day-out operations. It operates quietly with virtually no maintenance. SHAKTI Bin Activator being available in preassembled form. can be rapidly installed by bolting/welding on to existing steel or concrete bins of any shape. round or square. The bin activators are available in standard sizes riqht from 300 MM diameter to 3600 MM diameter. The bin activators can be supplied separately or as a self contained ready to operate integrated unit by combining a static bin and a bin activator. This package called as SELF DISCHARGING BIN. is available in volumetric capacity ranging from 30 Liters to 20.000 Liters. The SELF DISCHARGING BINS can be designed to be supported on rigid legs or suspended from a suitable structure. The Standard units are made of carbon steel. however 304 and 316 stainless steel can also be considered if customer so desires. The external and internal surfaces can be painted with enamel paint. epoxy paint Of any other paint and colour of customer''''''''''''''''s choice. The standard motors are of totally enclosed and non vented type and work on 440 V. 3?, 50 C/S. Here two variations in specification can be considered in accordance with the requirements of application. The standard elastic sleeve is made of white food quality neoprene rubber. Besides BIN ACTIVATORS and SELF DISCHARGiNG BINS other products manufactured by SHAKTI ENGINEERS are BIN UNLOADERS. FLEXIFEEDERS. VIBRO-METERING FEEDERS. VIBRO BLENDERS and completely integrated and automated CONTINUOUS BLENDING SYSTEMS.You are most welcome to try your powders and granules on our demonstration unit free of charge and without obligation. Do contact us for the further clarification and consultation. It will indeed be our pleasure to assist you in your projects.

Bin Activator

Get Price Quote

We have developed state-of-the-art storage facility wherein we keep a large stock. It also prevents our offerings from air, duct, sunlight and other damaging factors. We have developed the entire in-house unit wherein we keep our raw material to fulfill variegated requirements of the buyers. Also, we make sure that the material is sourced from the reliable places only. Features : Sturdy construction Well designed Low power requirement Technical Specifications : Range - from 600mm (23 in) to 2,100mm (7 ft) Construction material - carbon steel, 304L / 316L stainless steel Application Areas - The Bin Activator is specialised for certain applications, especially in the flour milling industry, to facilitate discharging of powdery or granular materials from silos or hoppers. Advantages : Robust, compact design Low power requirement Extra-durable suspensions and seal Suspensions suitable for installation on aluminium silos.

Bin Activator

Get Price Quote

Bin Activator is extensively required by a number of industries to give free flow discharge to any powder or granual form material. The Bin Activator is designed as per the current technology and promises high performance. The Bin Activator has MOC in mild steel and SS304. Clients can avail Bin Activator in varied capacities from us. We are a reputed name as Bin Activator Manufacturer, Supplier and Exporter in Nagpur, Maharashtra. Capacity : Ranges from 1 tph to 50 tph Areas of Operation : Power Plant, Steel Plant, Rice Mill Plant, Cement Plant, Ash Handling Plant, Flour Mill Plant, Foundries, Solvent Extraction Plant, Distilleries & Breweries, Food Processing Plant, Poultry Feed Plant, Dyes & Stuff, Rubber Industry, Dairy Plant, Chemical Plant.

Bin Activators

Get Price Quote

Bin Activators have been proven worldwide to give a continuous, but controlled flow of difficult-to-handle materials from bulk storage silos, through the controlled use of vibration.AL!X – solves the difficulty by cutting off the lower cone section of the bin and replacing it with a Bin Activator consisting of a relatively flat dished head and baffle. These flat support surfaces carry the overhead load without permitting the additional compression that occurs in a conical bottom.The Bin Activator is flexibly hung from the upper bin by rubber-bushed forged steel hangers. An elastic sleeve of reinforced rubber seals the small gap between the main bin and movable bottom. An integral baffle relieves head load over the outlet.AL!X - line of dependable and economical Bin Dischargers are available to system suppliers and OEM’s. These units are ruggedly built, simple to install and come with AL!X’s - unconditional performance guarantee. Our Bin Discharger’s simple, compact design incorporates all of the important features customers have come to expect from AL!X.It has been established that under vibration the shear strength of the product in a storage vessel decreases. The action of the Bin Activator is to break down the shear strength and thus induce flow. When the Activator is switched off the material shear strength is restored and product once again ceases to flow.By careful design, the Bin Activator eliminates ratholing, degradation and segregation of products within the silo, ensuring an even flow of material on a mass-flow basis (the first-in, first out principle).Bin Activators are ideally suited to a cylindrical vessel, but can be successfully applied to square or rectangular bins. Their low profile allows for a substantial reduction in the silo height and its associated building costs.

Silo Bin Activator

Get Price Quote

Bin Activators

Get Price Quote

We are engaged in offering Bin Activators that offer total solution to overcome all flow related problems like Bridging, Choking, Rat Holing etc. of the Dry Bulk Solids from the storage. Our Bin Activators ensure trouble-free positive discharge on demand, continuous or intermittent and on First�in & First�out basis. We make Bin Activators available in various models to suit the variegated demands of the customers. Further, we are a renowned Manufacturer, Exporter and Supplier of Bin Activators. Working Our Bin Activators discharge the stored Dry Bulk Solids at a desired output upon getting Gyratory type Vibratory Forces produced in the horizontal plane by a Vibration Motor. A Baffle Cone mounted inside the machine transmits this Gyratory force into the stored Bulk Solids by converting it into linear pulsating type vibratory forces. This is most effective and economical way to fluidize the stored solids to achieve a trouble free discharge.

Bin Activators

Get Price Quote

Bin Activator, the silo Discharge Aid, offer total solution to overcome all flow related problems like Bridging, Choking, Rat Holing etc. of the Dry Bulk Solids from the storage. The equipment ensures trouble free positive discharge on demand, continuous or intermittent and on First–in & First–out basis. Properly designed Bin Activator Overcome all the Flow Problems. Bin Activator discharge the stored Dry Bulk Solids at a desired output upon getting Gyratory type Vibratory Forces produced in the horizontal plane by a Vibration Motor. A Baffle Cone mounted inside the machine transmits this Gyratory force into the stored Bulk Solids by converting it into linear pulsating type vibratory forces. This is most effective and economical way to fluidize the stored solids to achieve a trouble free discharge.

Bin Activator

Get Price Quote

Avail from us Bin Activator that is ideal equipment for collecting most of the material. We provide Bin Activator that eliminates various problems assuring continuous flow of stored material without any operational headache. Our Bin Activator is made available in preassembled form providing ease of installing it without causing any trouble. We also manufacture Bin Activators as per clients’ specific requirements and demands. Clients can avail Bin Activator at industry leading rates from us. features Strong construction Easy to install Safe functioning Saves headroom Permits cone angles Saves labor cost Reliable functions Quiet operations Increased storage capacity Consumes minimum power Trouble free performance Easy flow of material through discharge opening Provides continuous discharge from storage Handles material gently without causing any damage Suitable for continuous day-in and day-out operations Availability Size : from 300 MM diameter to 3600 MM diameter Volumetric capacity ranging from 30 Liters to 20.000 Liters

Bin Activator

Get Price Quote

Called as the most innovative form of engineering, the bin activator offered by us is one of a kind. We offer modernist bin activator machine that is used in a number of industrial units for variegated application. We are one of the leading sanitary bin activator manufacturers and suppliers in India; known for delivering optimal quality products at most competitive prices

Bin Activator

Get Price Quote

Rajdeep’s Bin activator provides positive, trouble free, continuous discharge from storage. The operation is silent , needs no attention & consumes little power Bin activator consists of a specially profiled discharge head with baffle above and in line with the discharge opening. It is hung from support ring by means of hangers. Bellow type sealing sleeves on upper and lower ensure that there is no spillage of material. One or two electric vibrators fitted to the unit generate vibration makes the material flow normally through the discharge opening of Bin Activator It can be rapidly installed by bolting / welding to silo of any shape round or square It is simple, rugged, and reliable & maintenance free device. Bin activators are available in various sizes from 600 mm to 3600 mm diameter MOC: Carbon steel SS-304 SS-316 Flexible Sleeve: Food Quality white neoprene, Viton with canvas, Nylon, fibre glass reinforcement External & internal surface can be painted by two coats of rd oxide followed by synthetic enamel paint. Bin Activators are used in various industrial applications to facilitate discharging of powdery or granular materials from silos or hoppers. Applications: Bin Activator can handle all difficult products like:- Soya Flour , All grain flour Whey powder , Milk powder Sodium Bicarbonate Soda Ash Lime Talcum Powder Gypsum Fly ash Industries we serve : Food & Pharma Agri & agrochemicals Soaps & detergents Steel & foundry Cement & allied Distillery & brewery And many more

Bin Activator

Get Price Quote

Commonly know as Vibratory Bin Discharger. “INDPRO” Bin Activator is The ultimate solution for Discharge Problems of all types of stored Bulk Solids, wide range is to take care of virtually all the possible silo geometries. Available constructions are Carbon Steel, SS 304 SS 316 with required finish.

Bin Activator

Get Price Quote

We are offering bin activator. Some times material stored in the hopper does not flow at all, even after fixing vibrator or unbalance motor on outside surface. This is due to physical properties of powder its particle size and moisture content. For such difficult powders our “bin activator” is the right answer.

Bin Activator

Get Price Quote

Designed to overcome all flow related problems like Bridging, Rat holing of Bulk Solids in the storage vessels like bins, hoppers, silos, depending upon the characteristics of material. FEATURES Available in wide range to take care of any material stored in any sized and shaped vessel Specially developed fixtures & tooling ensures concentricity within various parts Careful design of Suspension Hangers to give complete resilience to the vibrating dish head. Sturdy design to take care of machine load and material head load High performance and low energy consuming Vessel assembly with bolting or welding option Well-equipped laboratory for optimizing equipment configurations Available in Mild Steel, SS304 & SS316 as Vibration motor even for hazardous application Sealing sleeve in food grade white neoprene with nylon reinforcement Flexible connections at Inlet & Outlet

Bin Activator

Get Price Quote

Bin Activators are suitable for discharge of dry Bulk Materials out of Storage Bins, on demand. Selections of the Equipment are based on the Characteristics of the Material, Bin Design, Venting and Flow Rate etc. The following common problems related with the mass flow from Storage Bins are easily avoided: Briding Arching Particle Segregation Blockage Funnel Flow Rat Holing Fluidising Flushing Seamless molded Neopreprene Rubber Sleeves, with Nylon reinforcements are available. Special Food Grade materials are also available. Heavy duty unbalanced Motorised Gyrators are fitted. Forged steel Hangers with Vibration isolators are provided. Accessories like outlet Sleeves, Clamps, Maintenance Gates are available.

Bin Activator

Get Price Quote

Bin Activator

Get Price Quote

Flowability of certain powders is sometimes so poor that extraction from bins or silos with flow aids like fluidization pads, pneumatic hammers, hammer blasts or air cannons is impossible. The Bin Activator is the ultimate flow aid and extracting device for such materials. To fit the Bin Activator,the silo cone has to be shorter than usual,leaving a wide outlet section. A flange supplied together with the Bin Activator is welded to the silo outlet on site. Special spring suspensions and a flanged polymer seal form a flexible connection between silo and Bin Activator. One or two unbalanced motors fitted to the unit generate vibration of the Bin Activator every time the feeding device beneath the silo is started for material extraction. During operation the Bin Activator makes a gyratory movement which is transmitted to the material inside the silo.The result is smooth material flow through the Bin Activator outlet into the connected feeder. Depending on the material handled Bin Activators are manufactured in carbon steel or different types of stainless steel. According to the size, Bin Activators are equipped with one or two vibrators.

Bin Activator

Get Price Quote

Flowability of certain powders is sometimes so poor that extraction from bins or silos with flow aids like fluidization pads, pneumatic hammers, hammer blasts or air cannons is impossible. The Bin Activator is the ultimate flow aid and extracting device for such materials. To fit the Bin Activator,the silo cone has to be shorter than usual,leaving a wide outlet section. A flange supplied together with the Bin Activator is welded to the silo outlet on site. Special spring suspensions and a flanged polymer seal form a flexible connection between silo and Bin Activator.

Premium Zinc Activators

Get Price Quote

We offer premium zinc activator ( liquid). microbial zinc solubilizer - 1 x 108 cfu /ml zinc is a major nutrient and its deficiency may result into lower yield and diseased crop.premium zinc activator improves the availability of zinc in soil and suitable for all crops.zinc activator produces acids and converts the insoluble zinc sulphides, zinc oxide and zinc carbonate into available zn+ through lowering the soil ph and breaking down the complex.it increases the crop yield and improves the soil health by enhancing the nutrient content

VIBRATORY BIN ACTIVATOR

Get Price Quote

UNBALANCE MOTORISED BIN ACTIVATORElectro Magnetic Industries Bin Activators are recognized worldwide as the most effective means for discharging dry materials from storage Bins. It assures positive, continuous flow from storage on a first-in, first-out basis. It eliminates bridging, jamming, segregation and retooling. Even such difficult to handle materials as prepared foundry sand, titanium dioxide, wood chips, brown sugar and wet shale are discharged freely on demand.Micron-sized particles, ore chunks, fibers, flaky, sticky and fragile materials all have been handled successfully by the Bin Activator.Available in standard diameters from three to sixteen feet. Electro Magnetic Industries Bin Activator attaches to the enlarged opening of any new or existing bin. It operates quietly and continuously with virtually no maintenance. Delivered completely assembled and ready to install. Bin Activators Can be attached to any bin, round, square, steel or concrete. The preassembled mounting ring permits rapid installation field welding

Bin Activator

Get Price Quote

Bin Activator, Bucket Elevator, Screw Conveyor, Rotary Airlock Valves

Bin Activator

Get Price Quote

Bin Activator, Bin Discharger

Bin Activator

Get Price Quote

Bin Activator, bag slitting machine, Bag filling Machines, Pressure Vessels