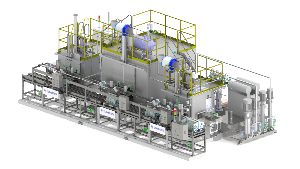

Customized Component Cleaning Machine

Get Price Quote

Introduction Customized Cleaning Machines, as the name suggests are designed specifically as per the customer needs. Cleaning processes and material handling can be highly automated. These machine are the integration of different cleaning technologies with minimum human interference. Description Various filtration systems (bag filter/compact band paper filter/cartridge filters/ hydroclone filter ) can be incorporated suitable for different applications and production rates Various modules like wash, rinse, hot air blow, cold air blow (for quick drying of components) Safe and user friendly for operators Application WIND TURBINE COMPONENTS INTRICATE EXHAUST MANIFOLD Features SS construction, highly reliable, low maintenance, state of the art after sale service. Environment friendly, aqueous cleaners. low running cost. Operator safety is built-in in the design of machine. The various options of energy for tank heating like heat pump, gas heating, heat exchanger, water heating steam heating are available. Total solution to cleaning problems.

industrial component cleaning machine

800,000 - 865,000 Per Piece

1 Piece (MOQ)

Best Deals from Component Cleaning Machine

Bearing Washing Machine

250,000 - 550,000 Per Piece

01 Piece(s) (MOQ)

industrial component cleaning machine

850,000 Per Unit

1 Unit (MOQ)

component washing machine

850,000 Per Set

01 Set(s) (MOQ)

As we believe in client's supremacy, we decide the acceptable payment methods at the time of undertaking the agreement/contract. Moreover, our payment processing methods are secured. Since, we have stringent quality control policies, our entire range of products are trusted throughout the industry. Features : mass production capacity Superior quality High reliability

component cleaning machines

Get Price Quote

All components require cleaning after they are manufactured before assembly or packing. We manufacture all types of component cleaning machines like batch type, conveyorsed type, ultreasonic or vapour cleaning. Cleaning quality in milipore can be provided. Reputed automobile manufacturer and component manufacturer are using our machines to their full satisfaction and we are getting repeated orders from them. They are like suzuki, honda cars, mahindra & mahindra, bajaj, honda motorcycle & scooters, hero, india yamaha motors, escorts ltd. And component manufactures like rico, musashi, gkn driveline, bharat gears, sona blw precision forging, fcc clutch india, jbm auto, magna rico and so many others. The equipents are manufactured in stainless with best available pumps and othe components and plc controls. All the machines are desighed to meet the cleaning requirement of the components. The rates can be quated after studying the component and its production rate.

IK 25 (Hermetic Type Industrial Component Cleaning machine)

Get Price Quote

Treatment chamber with ultrasound arrangementAutomatic loading doorRotating/rocking device with inverterManual baskets upper closingNr. 2 solvent tanksDistillation unitBlades vacuum pumpDistiller pump for sludge recirculation and dischargeStorage tank for distilled oil (7 lt)Hydraulic circuit fully stainless steelChips filter 200 micronPressure lateral flowComputer SIEMENS S7-1200 + TP700 touch screen 7”Ethernet / Router for remote connectionIntegrated electric heatingTotally closed panelsSolvent safety tray

component cleaning machines

Get Price Quote

Aqua Clean Systems caters to component cleaning machines and is an entity managed by highly experienced professionals with a wide experience in the field of parts cleaning and surface treatment technology.

Component Cleaning Machine

Get Price Quote

1 Piece (MOQ)

We are offering component cleaning machine. salient features of our machines low level float switch to protect heating system reusable filter of ss mesh. multi components cleaning. continuous cycle. used heavy duty roller conveyor as per component. pump removable for maintenance without draining tank ac drive for conveyor variable speed. plc controlled machine. automatic operation with auto manual option emergency stop button at both ends and main panel optional – air blower hot air blower optional – exhaust blower mist collector

High pressure component cleaning machine

Get Price Quote

Industrial Components Cleaning Machine

650,000 - 8,500,000 Per Piece

1 Piece(s) (MOQ)

pc 1smo ( front loading rotary /fixed table type spray washer with rinse stage ) • pc 1smo series type cleaning machine are multi - stage, single chamber design built for automatic washing rinsing with water based cleaning media followed by drying operation. • the constructional details and features of the pc1smo are based on the single stage rotary/fixed basket type but for the single /twin tank with multi tier filtration system for efficient pressure filters are installed to prevent nozzles blocking, which could otherwise reduces the cleaning performance. separate spray circuitry. For easy loading & unloading the platform is provided which is attached to chamber. pc 1smo is available in closed as well as in open system • the wash processes are as 'high pressure clean - rinsing - drying' with intermittent dwell time for wash

Component Cleaning Machine

200,000 Per Piece

11 Piece (MOQ)

Component Cleaning Machine

250,000 Per Piece

1 Piece (MOQ)

CONVEYORISED COMPONENT CLEANING MACHINES

Get Price Quote

CONVEYORISED COMPONENT CLEANING MACHINES TWO STAGE AND MULTISTAGE CLEANING. R 3272 Series high performance in-line conveyor cleaner for continuous cleaning of parts and used for higher throughout. Packaged in Two and multi - stage process with single parts or parts in batches. The working principle is based on a linear movement of parts through the process, parts are conveyed through the different stages of the process at controlled and changeable speed. Parts can be moved in continuous or indexed for precision cleaning of holes and recesses. Conveyors can be designed in many ways with steel belt, chain and roller type to carry parts or baskets and with necessary parts holding fixtures. Dedicated pneumatically operated reciprocating pressurized spray manifolds with wrapping effect for precision cleaning to attain cleanliness values and to suit parts and the process requirement. Drying systems using air knife with low compressed air consumption or regenerative blowers at an elevated temperatures for water dry off effect. PlC based control panel with necessary safeties and interlocks incorporated for smooth functioning of the system. Suitable for manufacturing, automobile and aeronautical industries. The R 3272 Cleaner is a through feed machine, so parts are processed continuously. The R 3272 Cleaner is designed, so it can be placed directly in the production line or used in conjunction with a robot for a continuous cleaning of parts day and night. Therefore the R 3272 Cleaner can make the logistics in your business more efficient. Robustly constructed in stainless steel, the system has a large capacity, which means that it is capable of processing several tons of parts every hour. Noise and heat insulating panels are used in the construction of the Compo Cleaner, which greatly reduces the outer noise levels and enables the machine to carry out the required cleaning processes at high temperatures. Design and user friendliness The R 3272 Cleaner is designed totally in stainless steel both inside and out. To give the machine a more simple and neutral appearance, we have integrated a lot of components into the machine. In practice, this design means that there are few components outside the system, which could otherwise obstruct and inconvenience the machine operators. The system has a compact construction, which makes it easier to operate. On the outside, you will find only the control panel. From this it is easy to programmed and operate the machine and make various adjustments, such as setting the speed and temperature of the separate wash tanks. Wash day and night The R 3272 Cleaner is perfect for installation in any production lines, where machines have to run continuously for 24 hours. The machine is equipped with an efficient return flow system, which returns the cleaning solution through a filtration system to the wash tank. The wash water is continuously filtered and collects any loose debris from the components. On the pressure side of the pump system, efficient pressure filters are installed to prevent nozzles blocking, which could otherwise reduces the cleaning performance. Due to the modular construction of the R3272 Cleaner and the large selection of optional extra equipment, we can offer our customers a machine, which meets their exact requirements. As can be seen on the above drawing, the machine can be adapted to meet various requirements. The system can be manufactured to wash/degrease, rinse, passivate/ phosphate and/or dry components, so that they are ready either for the next stage in the manufacturing process or for dispatch.Example of wash, rinse and dry. The R3272 Cleaner is very maintenance friendly. It is designed with easy to remove panels, which provide easy access for servicing the machine. We have a large selection of different belts to suit most components. Steam condenser Mist collector, Oil separator, Oil skimmer disc/belt, Oil separator Pressure filter Inspection window Chemical dosing if necessary. For further information about extra equipment for the different machines, please contact Cleanster Machines. We will assist you by offering the best solution for your individual application.

Component Cleaning Machine

300,000 Per Piece

Metal Parts Washing System

Get Price Quote

1 Piece(s) (MOQ)

We are offering Metal Parts Washing System. The company brings forth advanced consoles and automation systems. We are a reputed manufacturer, importer and supplier of consoles and automation systems. Known for their reliable performance, reliability and longer functional life, our consoles and automation systems are high on demand in the market. The consoles and automation system that we offer is fabricated in a compact and robust design with stainless steel tubular frame. Our consoles and automation systems are precision engineered cleaning systems that are used in various industries. available in aqueous modelsemi-aqueous process model features and benefits cts series automated cantilever transport system (optional) is rugged and reliable.wash-rinse-dry design with a single point facility connection for easy installationcustom fixture baskets configured for ideal cleaning of intricate parts.it is user-friendly machine that has manually operated console available with automation upon purchase or to be added at a later dateload station (optional) with basket sensors to automatically activate transport and process cycle.tanks are constructed of 316l stainless steel.genesis generators patented constant power provides tru-sweep� sweep frequency cleaning action. Available in 25, 40, 58, 132 and 192 khz frequencies, designed for specific cleaning applications.ultrasonic wash provides high intensity heated ultrasonic wash. Filtered recirculation with overflow air weir removes oil and particulate contaminants.heated ultrasonic rinse provides a two stage reverse flow cascade rinse with spray-over immersion, conserving space and water usage. Maximizes rinses for spot-free drying.electrical box conveniently located for easy access. Operator controls designed for easy operator use. Includes electronically timed ultrasonics, p.i.d. Temperature controllers and illuminated indicator switches.sliding drying cover with optional automatic activation.high efficiency recirculating hot air dryer has unique updraft air flow to dry parts quickly. Compressed air blow off allows for speed and efficiency.

component cleaning machines

850,000 Per Piece

We are offer water based industrial cleaning machine for high precision cleaning applications with advanced Industrial Cleaning Machine for increasing component efficiency, performance and working life which reduces cost. Our products are designed for effective removal of oil, coolant, metal swarf, tapping & polishing compounds, dust etc. from components which are ready for assembly or in between operations. Our organization is backed by rich industry experience, which helps to offer our clients a wide range of Component cleaning machine.We Offer Spear part And Services For Washing.

Component Cleaning Machine

400,000 Per Piece

Component Cleaning Machine

363,000 Per Piece

Parawash

Get Price Quote

Para wash is an equipment designed for cleaning/washing of machine components after machining before assembly. Parawash is a very useful equipment for assembly and machine shops. It consists of a tank which contains cleaning agent such as Kerosene/Petrol etc, which is pumped by a positive displacement pump under pressure to enclosed cleaning chamber. Cleaning chamber is provided with transparent windows for operator to see the cleaning process. It has also provision for the operator to insert his hands through the two openings in on the front side to access the components in the cleaning chamber for manipulating the components while cleaning. This equipment helps to clean the components faster and without wastage of cleaning agent. As the cleaning operation takes place under pressure in an enc, thorough cleaning is facilitated. All the dirt, dust & loose particles removed during the cleaning process is filtered through a filter and clean cleaning agent is returned to the tank for recycling. Customized parawash can be designed & built to suit any specific application requirements of the customer.