Waste Tyre Pyrolysis Oil Plant

Output : Pyrolysis oil :- 40 to 45% Carbon black:- 30 to 35% Steel Wire:- 10 to 15% ( Depends on Type Of Tyre being used ) Pyrolysis Gas:- About 10 %

Certification : CE Certified

Weight : 100-1000kg

Voltage : 110V

Condition : New

Automatic Grade : Automatic

Power : 1-3kw

Driven Type : Electric

Warranty : 1year

...more

Vacuum And Pressure Boiling Plant

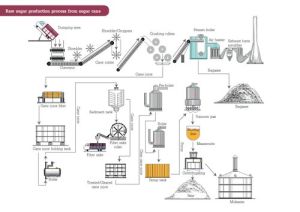

Crushing MillsAfter tipping the cane passes through a shredder, which reduces the billets of cane to a fibrous mass. The shredded cane then passes through a series of mill tandem to extract as much cane juice as possible. Most of the crushing mills are driven by electric motor. The juice from the first crushing mill is analysed in the laboratory for sugar content (CCS). Payment to growers is based on weight of cane and CCS valueSteam Generating PlantThe fibre remaining after the cane has passed through the milling train is called "bagasse". Bagasse is used as fuel for the boiler plant, which provides steam to power the entire factory including our electricity generating turbines. Bagasse is also stored for use in the lead up to the start of the crushing season and when wet weather disrupts harvesting operations. This makes our factory virtually independent of external energy needs during the crushing seasonClarificationThe cane juice, as delivered from the milling tandems, contains some soil and other undesirable impurities. To remove these, the juice is heated and lime is added to settle the unwanted material. The impurities settle out in the clarifier and then go to the rotary vacuum filters, which filter out any remaining juice. The filter mud from the vacuum filters is rich in nutrients and is recycled back to cane fields. Clear amber coloured clarified juice containing about 15% sugar is decanted from the clarifiers to the evaporatorsEvaporationThe clarified juice is concentrated to thick syrup by boiling off water in the evaporators. The juice passes continuously from vessel to vessel until it is concentrated to syrup containing approximately 70% sugar. The evaporators are operated under vacuum and in "multiple effects" configuration whereby the vapour space of one vessel is connected to the heating surface of the next throughout the set. This gives maximum efficiency in evaporation and steam usage. Boiling under a vacuum is very energy efficient because the boiling point of the liquid is much lower than at normal atmospheric pressurePan StageAt the pan stage the syrup from the evaporators is converted to crystal sugar. A charge of syrup is taken into a vacuum pan and again boiled under a vacuum. A quantity of very fine “seed” crystal is introduced. As water is evaporated fresh syrup is added and sugar is deposited on the seed crystal. This process continues until the crystals have reached the desired size (approx. 1 mm square). The resulting semi liquid mass of sugar crystals and molasses is called ‘massecuite'.CentrifugationSugar crystals are separated from the syrup in the centrifugals. The centrifugals are perforated metal baskets spun at high speed by an electric motor. While the sugar is spinning in the baskets it is given a short burst of hot water to help wash the sticky molasses off the sugar crystals.Sugar DryersSugar has to be dried and cooled to precise levels to enhance its storage life. This is done in the sugar driers. Evaporation of excess water from the surface of the crystals results in the desired cooling of the sugar. In the generally wet conditions we use large air-conditioning units to provide the cool dry air to the sugar driers. The dried and cool sugar is now ready for shipment.

Application : Vacuum Use

Weight : 100-500kg, 1000-2000kg, 2000-4000kg

Voltage : 110V, 220V, 380V, 440V

Condition : New

Power : 1-3kw, 3-5kw, 5-7kw, 7-9kw

Warranty : 1yr

Country of Origin : India

...more

Urea Formaldehyde Plant

500,000 Per Piece

As NSI Equipments Pvt. Ltd., we have completed project designing, equipment supplies and factory installation works for many plants at home and abroad successfully until now. We offer service guarantee in project designing of the most cost-effective Urea Formaldehyde plants, installation, production and assembly of equipment to be used in the plant, installation of piping systems between equipment and commissioning of the functional plant. NSI Equipments Pvt. Ltd., produces solutions that are unique and intended for the demand to satisfy the needs of Urea Formaldehyde Plants with its Team of Experienced Engineers. It offers turnkey service beginning with project design.

Country of Origin : India

Application : Resin Making

...more

Ultra Fine Air Classifying Mill

Salient Features: Grinding and Classifying in one machine Cool and smooth grinding Steep particle size distribution Sharp Classifier cut point, instantly adjustable. Easy cleaning and maintenance. Low specific energy requirement Compact space saving design. Principle Of Operation: The material to be ground is conveyed from a hopper by screw feeder or pneumatically fed through Rotary Air Lock Feeder to the grinding chamber of the Air Classifying Mill (ACM). The pins/bars of the rotor break the particles of the material. These particles are entrained by an air stream which enters below the pin rotor and are carried up between the inner wall and the shroud ring with baffles which decrease the air swirl. These particle then enter the classifying section where the fine material is carried out with the air through the classifier rotor to the outlet, the course material is thrown against the shroud rind and carried down to the pin rotor for further reduction. After leaving the micron air mixed with fine particles enter the bag filter where the fine particles are separated and the clean air is discharged to the atmosphere.

...more

U Shaped Horizontal Ribbon Blender

200,000 Per Piece

A ribbon blender consists of a U-shaped horizontal trough containing a double helical ribbon agitator that rotates within. The agitator’s shaft is positioned in the center of the trough and has welded spokes on which the helicalribbons (also known as spirals) are welded. Since the ribbon agitator consists of a set of inner and outer helicalribbons, it is referred to as a “double” helical ribbon agitator. The gap between the ribbon’s outer edge and theinternal wall of the container ranges from 3 to 6 mm depending on the application. The ribbon agitator is poweredby a drive system comprised of a motor, gearbox, and couplings. The agitator shaft exits the blender container ateither end through the end plates bolted or welded to the container. The area where the shaft exits the containeris provided with a sealing arrangement to ensure that material does not travel from the container to the outsideand vice-versa. The blender assembly along with the drive system components viz. motor, gearbox, couplings andbearing supports is mounted on a supporting frame.The charging of material in the blender is generally throughnozzles or feed-hoppers mounted on the top cover of the blender. The inlet cover also provides maintenance andcleaning access to the inside of the blender. An external jacket can also be provided on the blender container forapplications which require heating or cooling of product material. The materials to be blended are loaded into theblender, this is generally up to the level of the outer ribbon’s tip. The ribbon agitator is designed to operate at aperipheral speed (also known as tip speed) of approximately 100 meters / minute, depending on the applicationand the size of the equipment. A spray pipe for adding liquids can be mounted above the ribbons. For materialsthat tend to form agglomerates during mixing, high speed choppers can be provided for disintegration of theagglomerates. During the blending operation, the outer ribbons of the agitator move the material from the ends tothe center while the inner ribbons move the material from the center to ends.Radial movement is achievedbecause of the rotational motion of the ribbons. The difference in the peripheral speeds of the outer and innerribbons results in axial movement of the material along the horizontal axis of the blender. As a result of the radialand the counter-current axial movement, homogenous blending is achieved in short time. After blending, thematerial is discharged from a discharge valve located at the bottom of the trough. The discharge can be fitted withany of various valves, viz. slide-gate, butterfly, flush bottom, spherical and other types depending on theapplication. The operation of the valves can be manual or pneumatically actuated. Ribbon blenders can bedesigned for multiple discharge ports. Unlike tumbling blenders where discharge of material is achieved by gravity,in a ribbon blender the material is discharged by rotation of the ribbon agitator.

Weight : 100-1000kg, 1000-2000kg

Feature : Durable, High Performance, Low Maintenance, Rustproof

Voltage : 110V, 220V, 380V

Condition : New

Power : 1Kw, 500W, 750W

Warranty : 5years

Country of Origin : India

...more

Top Driven Type Centrifuge Machine

150,000 Per Piece

Application : Lifting Heavy Loads

Weight : 100-200kg, 200-300kg, 300-400kg, 400-500kg

Voltage : 110V, 220V, 380V

Condition : New

Power : 1-3kw, 3-6kw, 6-9kw

Warranty : 5years

Country of Origin : India

...more

Top Driven Centrifuge

Brand Name : NSI Equipments

Type : Top driven bottom discharge type

Three Point Suspension Centrifuge

Material : Stainless Steel,Mild Steel

Application : Industrial

Thermosyphon Evaporator

300,000 Per Piece

Advantages Ideal for clear, heat sensitive foaming and corrosive solutions. Continuous, single pass operation with minimized retention time. Single or multiple units with high heat economy. High heat transfer co-efficient. Low power requirement. Simple construction. Low floor space requirement. Applications Food Herbal extracts Pharmaceuticals Dairy Dyestuff Ammonium Nitrate. Sugar Syrups

...more

Table Top Type Centrifuge Machine

100,000 Per Piece

Product Features Provides for smooth & soft start options Provided with safety lid interlock provision Provided with microprocessor based controller Low sample temperature rise Inverter fault detection Help in imbalance detection Gives stable speed output Featuring motor overload protection Dynamic brake support Chamber is made of stainless steel, which make it easy to clean

Application : Lifting Heavy Loads

Weight : 100-200kg, 200-300kg, 300-400kg, 400-500kg

Voltage : 110V, 220V, 380V

Condition : New

Power : 1-3kw, 3-6kw, 6-9kw

Warranty : 5years

Country of Origin : India

...more

Sweet Sorghum Cane Crusher Mill

100,000 Per Piece

The Sorghum Crusher Mills consists of three roller mills, grooved rollers with under feed toothed roller and Donnelly type chutes for feeding of fiberized cane to Mill.The roller would be of coarse grain cast iron .The cast iron shell would be hot shrunk on forged steel shaft .All the shafts would have square ends of square. The bottom roller would be provided with the juice rings and removable guards to prevent entry of juice into the bearings. The cast steel crown pinion is keyed to shaft and suitable mild steel guard and troughs provided. The bracket for roller bush bearing would be of cast steel with gun metal bush with water cooling arrangements.The mills are provided with cast steel trash plate supported on heavy steel brackets with pivoted journals & adjustable by means of tie rods. Top roller and discharge roller scrappers would be of floating type secured on square shaft and provided with lever for adjusting device. Each mill would be provided with hydraulic loading systems, consisting of hydraulic accumulator, one for each of the journal for the top roller and accessories such as pumping set, receiver tank, gauges.One forced feed oil lubricator for each mill having 16 no. of points is provided so as to have 2 points for each bearing, one bearing as standby. Juice trough under the mills is provided of SSDetails Toothed under feed roller :Toothed type under feed roller having nominal diameters, would be provided. The shaft would be of EN 8 quality & supported by means of bush bearing. The under feet roller would be driven by top rollers through chain sprocket to give surface speed Donnely chute : Each Donnely chute is provided to feed the Each Mill at a suitable height . Slat type intermediate carriers : Rake type / slat type intermediate carriers, between the mills would be provided. The width of the carrier truck would be suitable to accommodate Each carrier drive would consist of one motors with speed reducer, flexible coupling, common bed frame & a set of open sprockets & chains with guards Mill Drive: Suitable electric motors provided to drive the Mill separately Mill Gearbox: Suitable Planetary gearboxes provided to drive each mill separately. Each mill drive to be coupled through CI . The mill top roller would be connected to transmission gear shaft by means of forged steel tall bar and CI couplings.Two cast Iron coupling would be provided.

Certification : CE Certified

Application : Crushing Sugar Cane

Voltage : 110V, 220V, 380V

Condition : New

Power : 1-3kw, 3-6kw, 6-9kw, 9-12kw

Driven Type : Electric

Warranty : 5years

Country of Origin : India

...more

Sugarcane Crusher Mill

100,000 Per Piece

The Sugarcane Crusher Mills consists of three roller mills, grooved rollers with under feed toothed roller and Donnelly type chutes for feeding of fiberized cane to Mill.The roller would be of coarse grain cast iron .The cast iron shell would be hot shrunk on forged steel shaft .All the shafts would have square ends of square. The bottom roller would be provided with the juice rings and removable guards to prevent entry of juice into the bearings. The cast steel crown pinion is keyed to shaft and suitable mild steel guard and troughs provided. The bracket for roller bush bearing would be of cast steel with gun metal bush with water cooling arrangements.The mills are provided with cast steel trash plate supported on heavy steel brackets with pivoted journals & adjustable by means of tie rods. Top roller and discharge roller scrappers would be of floating type secured on square shaft and provided with lever for adjusting device. Each mill would be provided with hydraulic loading systems, consisting of hydraulic accumulator, one for each of the journal for the top roller and accessories such as pumping set, receiver tank, gauges. One forced feed oil lubricator for each mill having 16 no. of points is provided so as to have 2 points for each bearing, one bearing as standby. Juice trough under the mills is provided of SSDetails Toothed under feed roller :Toothed type under feed roller having nominal diameters, would be provided. The shaft would be of EN 8 quality & supported by means of bush bearing. The under feet roller would be driven by top rollers through chain sprocket to give surface speed Donnely chute : Each Donnely chute is provided to feed the Each Mill at a suitable height . Rake type/ slat type intermediate carriers : Rake type / slat type intermediate carriers, between the mills would be provided. The width of the carrier truck would be suitable to accommodate Each carrier drive would consist of one motors with speed reducer, flexible coupling, common bed frame & a set of open sprockets & chains with guards Mill Drive: Suitable electric motors provided to drive the Mill separately Mill Gearbox: Suitable Planetary gearboxes provided to drive each mill separately. Each mill drive to be coupled through CI . The mill top roller would be connected to transmission gear shaft by means of forged steel tall bar and CI couplings.Two cast Iron coupling would be provided.

Application : Crushing Sugar Cane

Voltage : 110V, 220V, 380V

Power : 1-3kw, 3-6kw, 6-9kw, 9-12kw

Driven Type : Electric

Warranty : 5years

Country of Origin : India

...more

Sugar Plant

Cane CarrierThis is used to transport cane to the milling tandem, and consists of chains and slats. Its width is normally equal to the mill size.MillA cane-crushing unit having normally consisting of three rollers in a heavy steel housing. Cane first passes between the top and front rollers, then between the top and back rollers, to extract the juice.CrushersA cane crushing unit, preceding the first mill to crush the cane prior to extraction of juice, for the purpose of improving the quantity of juice extracted. Normally consists of two rollers.ShredderThis has the same purpose as the crusher, but a different principle. Consists of a drum, with a concentric shaft, on which hammers are mounted on arms.Mill TandemA complete mill is complex, consisting of crusher (or shredder) and all mills, together with drives and reducing gears.Cane KnivesThese are mounted on cane carriers prior to entrance to mills, for preventing entire cane stalks from entering the mills, straightening and precutting the cane, for the purpose of improving juice extraction and saving driving power at the same time.Intermediate CarriersThese transport the milled cane (bagasse) from one mill to the next. BAGASSE CARRIER This carries the bagasse from the last mill to the boilers, and its excess to storage.Power PlantThis produces electricity by means of non-condensing steam turbines, which drive generators. Juice HeaterA heat exchanger in which juice is heated by using steam as a medium, normally a multi-pass system. Juice flows through tubes, while steam passes along the outside of the tubes, in the cylindrical body.ClarifierIt is a large vertical cylindrical tank, where juice is given time for decantation, to separate the clear juice from the turbid, which still contains the mud. Juice flow is continuous.Drum FilterA device to separate the mud from the turbid juice; normally of the rotary vacuum type. , to let the juice pass and retain the mud on its surface.EvaporatorA series of vessels, in which excess water from the juice is evaporated to form a more concentrated liquid, now called syrup. The vessels work in series under increasing vacuum conditions, to reduce the boiling temperature gradually as the concentration increases step-wise. This prevents overheating of juice and loss of sucrose. The vessels together form a triple-, quadruple- or quintuple-effect evaporator.Vacuum PanSimilar to an evaporator vessel, a continuation of the evaporating process, but carried so far that crystallization occurs. Also boils under vacuum for reduced boiling temperature. The syrup is now transformed into massecuite , which is a mixture of crystals and molasses.CrystallizerA strike receiver in which the charge from the vacuum pan is stored before going to the centrifugals. Its purpose is cooling, to increase grain size and reduce sucrose left in molasses.CentrifugalA machine with a fast spinning drum and a screen, inside, through which the molasses can pass while the crystals are retained. Separation is based on the difference in specific gravity, amplified by centrifugal force.DryerA long drum-like rotating cylinder, where sugar is brought in contact with heated air, to reduce its moisture content.CoolerSame as a dryer, but air is dry and cooled to reduce temperature of sugar, heated by the dryer. This is to prevent caking during storage. The combination of dryer an

Weight : 100-1000kg, 1000-2000kg

Voltage : 110V, 220V, 380V

Condition : New

Power : 1-3kw, 3-5kw, 5-7kw, 7-9kw

Warranty : 1year

Country of Origin : India

...more

Spin Flash Dryer

100,000 Per Piece

Advantages Energy consumption is much less than spray dryers, fluidized bed dryers, flash dryers, rotary dries, tray driers etc. Space requirement for installing this dryer is much less than spray dryer, pneumatic dryer, fluidized bed dryer and rotary dryer etc. It is a completely automatic plant with temperature controller etc. Dry product discharge section of the dryer can be installed in your product packing section, hence cost of transport of dry product to the finished product section can be eliminated. Pulverizing after drying will not be required. The unit will dry, classify and convey all in a single operation. Wet cake can be directly fed from filter/centrifuge to lump breaker bin, which feeds the cake in to the dryer and hence all intermediate handling of material can be eliminated. The entire system is closed and hence any chance of contamination is eliminated. Since it is a closed system, wastage and dusting etc. are totally eliminated resulting in clean environment, zero wastage and total recovery of product and pollution free atmosphere. It is possible to vary the bulk densities also by minor changes in the classifier situated near the top of the dryer. Feature High drying efficiency and low energy costs. The energy efficiency of such systems is up to eight percent, which is very high for such types of drying systems. Direct drying and no initial diluting. Continuous processing with short drying time. Ideal for replacing conventional drying systems such as Fluid Bed Dryers, Pneumatic Flash Dryers etc. Pulverizing, conveying, classifying etc. can be done on the same system. Space utilization is most economical and operations are totally automatic. Most of the time, the product can be directly bagged or sent for further processing. Self-regulating, self-adjusting system, which involves minimal attention even while operating at capacity. The system being under negative pressure, there is no dusting and therefore no wastage. The area is free from environmental hazards. Clean operation with minimal manual handling is an important feature of the system. Application Direct contact dryers for bulk drying of various products such as inorganic chemicals, bulk drugs, dyestuffs, insecticides foodstuffs etc. Chemical industry products like Zinc Carbonates, Calcium Carbonate, Magnesium Carbonate, Cobalt Carbonate, Zirconium, Red Ferric Oxide, Aluminum Hydroxide, Lead Sulphate, Zinc Sulphate, Fire retardant Super - fine Calcium Carbonate, Zinc Oxide, Barium Sulphate, kaolin, Pigment, Dyestuff, Pesticide, Mancozeb etc.

Material : Stainless Steel

Weight : 50 Ton

Voltage : 350 V

Power : 120 Kw

Warranty : 1 Year

...more

Single Effect Type Evaporator

300,000 Per Piece

After this is completed, both the product vapour and the concentrated product are forced into the separating chamber where the vapour is drawn off and may be used elsewhere. The concentrate is then pumped off to another part of the process.

Material : Metal

Application : Chemical Industry, Food Industry

Feature : Easy To Use, High Working Efficiency, Low Maintenance

Voltage : 110V, 220V, 380V

Condition : New

Country of Origin : India

Evaporation Capacity : 0-1000lts/h, 1000-2000lts/h, 10000-11000lts/h, 11000-12000lts/h

...more

SINGLE EFFECT EVAPORATORS

Finishing : Polished

Automatic Grade : Semi Automatic

Feature : Rust Proof

Phase : Double Phase

Steam Pressure : 0.5Mpa

Evaporation Capacity : 2000-3000lts/h

...more

Screw Conveyor

Screw Conveyor is a general type conveyor. It’s mainly used for conveying granule, powder and compound material. Two models as your choice: – Horizontal Screw Conveyor and Inclined Screw Conveyor. According to customer’s different requirements and industry, we can do special design for your company.This machine is mainly used in conveying powder, particles of ascension, suitable for pharmaceutical, chemical, food and other industries.Advantages and Features With cover, whole sealing structure, without pollution to the environment. Conveyor length can be customized according to your need. Simple structure, use little material to manufacture, save cost for you. Conveyor angle can be 0-20 degree. Save space on the site. Screw pitch can be customized according to require of different material. According to real working conditions, trough screw conveyor machine can be multiple inlets and outlets. Adopts hanging bearing to connect screw blades which is longer than 3-4m. Adopts the method of spot welding to weld spiral blade on the screw shaft. Reducer motor brand can be domestic or imported: Tailong, SEW, Siemens etc. Easy to disassemble into several sections, save space during transportation. Details Screw conveyors can be designed without a center pipe. This type of conveyor is called a shaft less screw conveyor and is designed for conveying wet, sticky, sluggish products such as industrial sledges and bio solids. Screw conveyors can be used to cool, heat or dry products in transit. Depending on the heat transfer requirements, a screw conveyor can be jacketed, or a hollow-flight design utilized to provide the necessary heat transfer for the application. Screw conveyors can be designed to be vapor-tight or hold an internal pressure. This is very important when conveying toxic or hazardous products such as those in the chemical industry. Screw conveyors can provide an air lock between upstream and downstream equipment. This product is widely used in Pharmaceuticals, Chemical, Bulk Drug, Food, Milk powder feed, Plastic, Paint, Pesticides, Cement and building materials.

Voltage : 380V

Condition : New

Finishing : Polished

Width : 10-20 Inch, 20-30 Inch, 30-40 Inch

Machine Weight : 100-200 Kg, 200-300 Kg, 300-40 Kg

Rated Power : 1-3 KW, 3-5 KW, 5-7 KW

Country of Origin : India

...more

Rubber Lined Type Centrifuge Machine

200,000 Per Piece

Apart from this, our MS Rubber Lined Centrifuges are based upon advanced technology, and can be customized as per specific requirements of the customers.

Weight : 100-1000kg, 100-500kg, 1000-2000kg, 2000-3000kg

Voltage : 220V, 440V

Condition : New

Rated Power : 1-3kw, 5-7kw, 9-12kw

Driven Type : Electric

Country of Origin : India

Warrenty : 5 Years

...more

Rubber Lined Centrifuge

Material : Stainless Steel,Mild Steel

Application : Industrial

Rotary Vacuum Dryers

Application Area: Pharmaceutical Industry Intermediate Compounds and Fine Chemicals Organic Chemicals and Agro Chemicals Pesticides, Insecticides and Dyes Food Products

Weight : 400-1200 Kg

Warranty : 1 Year

Max Temperature : 200 Degree Celcius

Finishing : Polished

...more

Rotary Vacuum Dryer

500,000 Per Piece

Working PrincipleThe drying in a rotary vacuum dryer is a batch operation under vacuum. It is possible to dry heat sensitive materials at well below boiling points of water and solvents. Drying time depends on material being dried, amount of solvent or water to be removed, desired final moisture content, permissible jacket temperature etc. The dryer is available in sizes ranging from 100 liters to 20,000 liters gross volume. The volume of wet material loaded into the dryer is usually restricted to 50% of gross volume.Application Area Pharmaceutical Industry Intermediate Compounds and Fine Chemicals Organic Chemicals and Agro Chemicals Pesticides, Insecticides and Dyes Food Products

...more

Rotary Kilns

Application:Rotary kilns are used for the calcinations of Titanium dioxide, Illeminate, kaolin, Barium Carbonate, Magnesium Carbonate, Silica Gel, Lime, Activated Carbon, Vermiculite, Barium Sulphide, Magnesium Oxide, Petroleum Coke, Clay, Gypsum, Alumina etc.

Weight : 0-5000kg

Voltage : Related located Voltage

Power : 125 kw

Driven Type : Electric

Warranty : 1 Year

...more

Rotary Kiln

100,000 Per Piece

ApplicationRotary kilns are used for the calcinations of Titanium dioxide, Illeminate, kaolin, Barium Carbonate, Magnesium Carbonate, Silica Gel, Lime, Activated Carbon, Vermiculite, Barium Sulphide, Magnesium Oxide, Petroleum Coke, Clay, Gypsum, Alumina etc.

Certification : CE Certified, ISO 9001:2008

Application : Recovering Gas Heat, Recovering Heat, Reducing Particles Size

Weight : 0-5000kg, 10000-15000kg, 15000-20000kg, 20000-25000kg

Voltage : 110V, 220V, 380V, 440V

Condition : New

Power : 1-3kw, 12-15kw, 15-18kw, 18-21kw

Warranty : 5years

Country of Origin : India

...more

Rotary Dryers

Description: The Rotary Dryer is a type of industrial dryer employed to reduce or to minimize the liquid moisture content of the material it is handling by bringing it into direct contact with a heated gas to evaporate the water. Rotary Dryers are suitable for drying of wide range of materials continuously because of its ability to process materials having considerable variation in size and composition. Despite introduction of new technologies the long established Rotary Dryer is still widely regarded as the workhorse of many process industries. The robust yet simple construction combines flexibility with reliability enabling this type of dryer to handle vast range of materials.

Type : Rotary

Weight : 41 Ton

Voltage : 380 V

Specialities : High Performance & Durability

...moreBe first to Rate

Rate ThisOpening Hours

NSI Equipments Pvt. Ltd. is a well-known name from Meerut (Uttar Pradesh) that is engaged in the production of different kinds of machinery and equipment. We serve as a reliable manufacturer, exporter and supplier (wholesaler & retailer) of industrial plants, sugarcane crusher parts, sugarcane crusher, sorghum crusher, hopper dryer, rotary dryer, rotary vacuum filter, vacuum pan, juice heater, centrifugal machine, industrial evaporator, and industrial crystallizer. We make the equipment available in different specifications to cater to the diverse needs of our customer. We ensure timely-delivery of the products with the aid of swift logistics support and vast distribution channel.

NSI Equipments Pvt. Ltd. was established in the year 1969, and Mr. Lokesh Varshney is the CEO of the organization. He is determined enough to bring forth an exclusive range of equipment that have immense demand in the market. The company’s core business philosophy is to grow while satisfying the patron with premium products and world-class services.

Team

We owe our success to our dedicated team of engineers and other skilled labourers. They work in harmony to offer quality process plants and equipment in stipulated time frame. We work as a team and our engineers work hard to fabricate plants and equipment in different capacities.

Why Us

Owing to our expertise in this field, we have been able to provide the clients with a comprehensive and quality range of Mini Sugar Plants, Sugar Mill Plants, Hydraulic Sugar Cane Crusher. Some of the other factors for which our clients give preference to us are as follows:

Clientele

Our uncompromising attitude towards quality products and services has enabled us to serve our clients in the best possible manner. We have supplied more than 300 plants in India and exported abroad countries like USA, Egypt, Indonesia, Kenya, Tanzania, Russia, Mauritius, Bangladesh, Zambia etc.