Zinc Flake Coating

Coatec India supplies the Dip Spin Machine for Zinc Flake coating for bulk parts like fasteners. The equipment can be used for other coating painting liquids as well. It raises the corrosion resistance (salt spray test - from 200 hours to 1000 hours) and is useful for coating Clamps, U bolts, Nails, Screws, etc. Dip Spin coating minimizes cost of both material & waste disposal. Process >> It involves placing the abrasive cleaned and or zinc phosphate pre-treated products in a mesh basket submerged in coating solutions & spun to remove the excess coating. >> The machine can run in the manual mode. >> All controls and alarms are through the touch screen. >> The machine can handle 10 Kg of fasteners per batch. >> The maximum RPM is 400 and the time for each batch will depend upon the process sequence and the timings selected. >> Normally a cycle time of 5 minutes is considered taking loading and unloading into account. The machine comes with two baskets. >> This process is not directly suitable for coating of sheet metal parts with flat surfaces. Such components with flat surfaces can be coated with a modified dip spin method or best by simple spray and bake method. Machine is available in three models >> Dip Spin >> Dip Spin Tilt >> Dip Spin Tilt with chiller

...more

Teflon Coating

Coatec India supplies the complete technology and the equipment for Teflon coating. Teflon - Registered Trade Mark of DuPont. Salient Features of Teflon Coating >> Unique non-stick property, chemical inertness, good dielectric stability and low coefficient of friction. >> Teflon coated products are easy to clean, acts as dry lubricants, is abrasion resistant, and can withstand high temperatures of over 200°C. >> It can be insulating or conductive depending upon the type of Teflon application. >> Type of Teflon Coatings: Powder and liquid form. >> Unlimited applications covering a wide variety of material and configuration due to versatility of these coatings. >> Various formulations are available to meet the multifarious requirements of the industry. >> Applications cover both Industrial and Food Grade coatings. >> The coating is extensively used in rubber moulds, ball moulds, biscuit and bread dies where mould release is an essential part of the process. >> It is also used in industries where ease of flow or dry lubrication is necessary.

...more

Surface Pre-Treatment

Pre-Treatment Systems Before the metal surface can be painted, it needs to be prepared for the paint layer. It is similar to laying the foundation. The purpose of pre-treatment is to >> Clean the surface for oil, physical contamination and rust >> Create a surface condition which has superior adhesion to paint >> Reduce the chances of reaction of paint with the base metal >> Add to corrosion resistance Generally the following stages are used for a good pre-treatment line. However, depending upon the quality specifications, the stages may be decreased or increased. >> Knock off degreasing >> Degreasing >> Water rinse >> De rusting >> Activation >> Phosphating >> Sealer rinse >> Hot water rinse

...more

Rubber To Metal Bonding Adhesive Coating

Coating machines are custom designed according to the requirements of the items to be coated. These are used for both anti-vibration products as well as valves used in automotive inflatable tyre tubes. 'Chemlok' is the proprietary product of Lord Corporation. 'Megum' is the proprietary product by Rohm & Haas. Salient Features >> Exceptionally reliable in rubber to metal bonding. >> This type of coating is required in rugged automotive & industrial applications like industrial lining, hydraulic hoses, military components, brake shoes & automotive vibration control components. >> Design custom equipment for automobile tube valve stem Coating Process >> A fully automatic process with complete cycle is controlled by PLC. >> Vertical motion of the guns is on linear axis with servo motors. >> A heating system for baking and a built-in program for cleaning cycle. >> SS tanks are used for supply of coating chemical as well as the cleaning solvent. >> The system is fitted with pneumatic paint stirrers >> Settings can be done from the touch screen for the linear movement of the spray guns, which can be set according to the length of the components. This prevents over spray.

...more

Powder Coating

It is applied with a free-flowing dry powder. The main difference between a conventional liquid paint and a powder coating is that the powder coating does not require a solvent to keep the binder and filler parts in a liquid suspension form. >> Typically apply electrostatically and then cure under heat to allow it to flow and form a "skin". >> Usually used to create a hard finish that is tougher than conventional paint. >> Mainly used for coating of metals - white ware, aluminum extrusions,automobile& bicycle parts. >> Newer technologies allow other materials, such as MDF- medium density fiberboard, to be powder coated using different methods. Categories of powder coatings >> Thermosetting variety >> Thermoplastic variety

...more

Liquid Spray Painting

Liquid paint can be applied in many different ways determined by: the product, the volume, the quality requirements and other factors. Application method: handheld spray guns, high volume low pressure (HVLP) guns, automatic guns, automatic rotary bells or disk. >> Spray equipment: non-electrostatic or electrostatic. >> Typical paint is used for such wet on wet process is epoxy or polyurethane. Paint is normally baked. Painting components with corners & crevices >> Spray cannot reach each & every area. >> In addition, if the component needs high corrosion resistance, then electrophoretic technology will be more appropriate for depositing the primer paint and is followed by spray with top coat of paint. >> Typical components requiring this technology are auto components. Painting large components >> These are shot blasted, can be given a zinc phosphatelayer followed by primer coat of paint which is either applied through manual spray or electrostaticspray. >> This is followed by spray top coat (normally polyurethane acrylic) and is forced to dryat 70-80°C temperature. >> Also for plastic parts, spray painting is used.

...more

Glide Coating

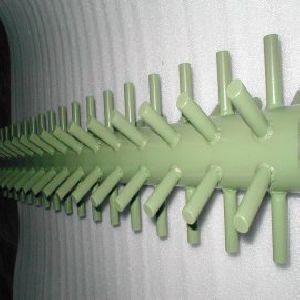

Coatec India supplies Glide coating systems for variety of applications. >> Glide Coating is a generic name for Polyamide Coating. >> It is a friction minimizing coating and offers resistance to galling. >> Categories: Fluidized bed and Powder spray. >> Applications like Gear Shifting Fork & Spline Shafts. Process >> The component is cleaned for all traces of oil and rust. >> If necessary, it is sand shot blasted or given zinc phosphate pre-treatment. >> It is spray coated with an adhesive primer and baked. >> The component is mounted on a PLC controlled dip coating system, which can be programmed for speed and different time intervals. >> The coating equipment dips the component into the coating bath and holds it there for a preset time. >> It then takes out the component and again holds it for a second preset time interval. >> The component is again dipped for a second time to achieve proper coating thickness and subsequently cured.

...more

Cathodic Electrocoating

Cathodic Electro Deposited coating is used extensively in the automotive industry. In this process, the component after phosphate pre-treatment is dipped in the bath of E-coat chemicals and given an electric charge. The coating gets deposited on the component and then it is removed from the bath, washed and then baked. A complete E-coat system consists of the following >> Pre-treatment line >> E-coat line >> Material handling system >> Oven This technology gives an organic finish on metal part component by electrically depositing paint on it.

...more