Toilet Soap Wrapping Machine

We are offering toilet soap wrapping machine. Khosla machines private limited is widely known for designing optimum range of toilet soap wrapping machine that comes with high-speed wrapping and packaging ability.

...more

Taping Machine

Khosla machines private limited is offers supreme quality soaps banding taping machine that comes with high-speed operation at the rate of 220 per minute arrival of soaps collation.

...more

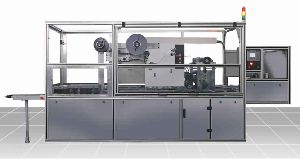

Soap Wrapping Machine

We are leading manufacturer of soap packaging machines, automatic packaging machines, wrapping machines for detergent bars, bath soaps, guest bar soaps, shaving soaps, laundry detergents and soaps, hotel soaps and horizontal form fill seal machine for soaps.

...more

Soap Wrappers

We are leading manufacturer of soap packaging machines, automatic packaging machines, wrapping machines for detergent bars, bath soaps, guest bar soaps, shaving soaps, laundry detergents and soaps, hotel soaps and horizontal form fill seal machine for soaps.

...more

soap packaging machines

We are leading manufacturer of soap packaging machines, automatic packaging machines, wrapping machines for detergent bars, bath soaps, guest bar soaps, shaving soaps, laundry detergents and soaps, hotel soaps and horizontal form fill seal machine for soaps.

...more

Horizontal Flow Wrap Machine

STANDARD FEATURES » Soap is automatically positioned by servo based 'Smart Conveyor' » Infeed conveyor with carrier lugs- soap is carried to avoid any scratch / dent marks .3 axes servo controls » Double set of sealing jaws for high speed operation » All parts in contact with soap made of stainless steel or nylon. Two wrapper spool holders » Positive drive to wrapper unwind » AC frequency control drive to infinitely vary speed from 50 to 250 ppm » Additional static heater for long seal » Fine adjustments of knives and jaw pressure by means of adjusting screws » 50V supply to heaters for operator's safety. PLC control of eye-mark registration » Touch screen HMI display of speed, shift output and settings » Trolley wheels » Additional static heater for long seal » All variable settings marked on scales for fool proof size change » Optional gusseting unit » Imported Instrumentation Highlights » High speed » High productivity » Fool proof size changeability » No parts needed to change soap size Gentle handling of soaps » Servo controlled operation » 3 axes servo controls Options » Inkjet Printer » Gussetting Unit MACHINE SPEED UPTO 250 PPM INFINITELY VARIABLE

...more

HIGH SPEED DETERGENT BAR WRAPPING MACHINE

STANDARD FEATURES » Single wrapper operation » High speed operation of upto 240 tablets per minute » Total linkability with bar cutting table » Single bar feeding by servo based 'smart conveyor' - eliminates scratch / dent marks eCapable of handling soft bars » 2 Axes servo controlled wrapper feeding and cutting » Quick timing and setting for different sizes through PLC Control. eEasy height adjustment of cutoff unit and discharge conveyor eWhite oil applicator and notched discharge conveyor for handling outside polycoated wrapper » Excelient quality of soap handling, even for soft soap. eDouble spool holder for wrapper "wrapper-break-machine-stop" interlock eSimple to maintain "no-soap-no-wrap" interlock ePLC control of eye mark registration » Optional collated discharge » Long top and side heaters with Cooling Plates for reliable sealing at high speeds » Digital temperature controllers for all heaters ( separate front and rear side heaters) » Stainless steel/ transparent guards » AIi parts in contact with soap are either stainless steel or coated with Teflon » Automatic centralised lubrication Highlights » Extremely gentle handling of detergent bars e High speeds » High quality packing » 3 axes Servo controls by Rockwell Automation e Capable of handling soft detergent bars » Low noise » Quick size change » Plant-Friendly Orientation » Human Safety Compliant » ln-Built Management Information System Options: » Inkjet coder » Flexible infeed conveyor to suit plant layout » Collator on discharge for easy pickup of soap e Conversion parts for size change » Conversion parts for size change

...more

Semi Automatic Snacks Packaging Machine

Brand Name : Khosla

Automatic Grade : Semi-Automatic

Driven Type : Electric

...more

SEAL MACHINE FOR BISCUIT STACKED ON EDGE

EASY, QUICK AND FOOL PROOF CHANGE OVER Logipac 51E uses multiple axes servo control for timing the machine. All the machine timings after the optimization can be stored as a receipe for that size and can be quickly recalled whenever machine has to be set for that size. A few position settings that need to be done manually are simple and can be marked on graduated scale. » NO - PACKET - NO WRAP INTERLOCK In a slug packing machine many times a slug is taken off the infeed conveyor for quality reason. If the wrapper keeps flowing continuously it results into empty pack which is counted as wastage. Logipac 51E has a feature to stop wrapper for empty infeed cycle that would have got wasted. » OPTIONS FOR STACK CONTROL In a slug wrapping machine, the slug after it enters the wrapper needs to be held from sides. This can be done either by means of soft pressure belts that gently press the stack so that the biscuits donot tip over, or by means of chain mounted tuckers that press the wrapper in the empty space between the stacks. Both the methods have their relative advantages. Logipac 51E allows you to select any of these two options for any size change. » SPLICING OF WRAPPER Logipac 51E has the feature of automatic splicing of wrapper as its roll finishes, thereby reducing the downtime for roll change. HIGHLIGHT » Fastest biscuit size change in its class » No size change parts needed » ‘No biscuit no pack’ interlock » Discharge with 2 in 1 option: Dual belt/chain system » 7 servo\PLC system with touch screen HMI

...more

paper packaging machines

Automatic Grade : Semi-Automatic

Driven Type : Electric

Horizontal Form Fill Seal Machine For Soap

We are offering horizontal form fill seal machine for soap. Horizontal form fill seal machine is suitable for packing requirement of detergent bars and laundry soaps, which are available in individual and chain pack options.

...more

HORIZONTAL FLOW WRAP MACHINE FOR SOAPS

PRINCPLE OF OPERATION: 2 rows of soaps are placed edge ways on flat belt conveyor, either by link up conveyor (not a part of the of the machine) or manually. Autofeeder transfers these soaps to the infeed lug conveyor of the machine. Infeed conveyor then transfers multi soap into wrapping film that has been formed into a tube by means of forming folder. Bottom seal is made by three sets of rollers. Cross sealing and cutting knife separate the packed soaps. Heat sealable material like BOPP or laminates is used. STANDARD FEATURES All surfaces over which soaps are transported are made of stainless steel Flat belt conveyor infeed with Transfer Unit Long seal is formed by means of three pairs of rollers, axes of which can be tilted to get best results Torque slip clutch to prevent damage in case of accidental jams Low voltage heaters for safety Individual temperature controls for heaters rint registration unit for printed wrapper Heavy distortion-free cast structure Highlights » High speed » High productivity » Fool proof size changeability » No parts needed to change soap size Gentle handling of soaps » Servo controlled operation » 3 axes servo controls Optional Features: » Date Printing unit » Variable speed drive (AC frequency control) » Castors for mobility of machine MACHINE SPEED UPTO 120 PPM INFINITELY VARIABLE

...more

Horizontal Flow Wrap Machine For Laundry / Multipurpose Bars

We are offering horizontal flow wrap machine for laundry / multipurpose bars. Khosla machines private limited makes horizontal flow wrap machine for laundrymultipurpose bars available in 2x2 or 2x3.

...more

HIGHSPPED TOILET SOAP WRAPPING MACHINE

STANDARD FEATURES » Outer wrapper and inner stiffener » High speed operation of upto 220 tablets per minute with total linkability with soap stamping machine » Vacuum pick and place with continuous rotary motion » 4 Axes servo controlled wrapper/stiffener feeding and cutting » Quick timing and setting for different sizes through PLC control » Easy height adjustment of cutoff unit and discharge conveyor » Gripped discharge conveyor for tight packing » Excellent quality of soap handling, even for soft soap » Double spool holder for wrapper and stiffener » Wrapper-break-machine-stop” interlock » Simple to maintain “no-soap-no-wrap” interlock » In line discharge » Optional collated discharge » Long top and side heaters with Cooling Plates for reliable sealing at high speeds » Vacuum pick and place with continuous rotary motion » Digital temperature controllers for all heaters (separate front and rear side heaters) » CE compliant stainless steel/ transparent guarding » All parts in contact with soap are either stainless steel or coated with Teflon. Conveyor belt is of food grade quality » Automatic centralised lubrication Highlights » Extremely gentle handling of soap » High speeds » High quality packing » Servo controls by Rockwell Automation » Low noise » Quick size change » CE compliant safety guarding » Imported instrumentation » Plant-Friendly Orientation » Human Safety » In-Built Management Information System Options: » Packing date printer » Flexible infeed conveyor to suit plant layout » Collator on discharge for easy pickup of soap » Conversion parts for size change

...more

High Speed Soap Wrapping Machine

We are offering high speed soap wrapping machine, high speed toilet soap wrapping machine is used in packaging toilet soaps of various shapes and sizes.

...more

High Speed Packaging Machine

» EASY AND QUICK CHANGE All Wrapper 8000T’s timings for a particular size can be stored in the HMI as a recipe for that size. In future, whenever that size needs to be run, a simple click on its recipe restores timings of the machine suited to that size. Digital scale for future setting reference. » HIGH PACKAGING QUALITY Wrapper 8000T offers unique soap handling and wrapper control systems. Special emphasis is given to the soap feed system to give dent-free soap and on the discharge conveyor for positive control of wrapper skew. » AUTOMATIC SPLICING Machine has provision for mounting double rolls of wrapper and stiffener. As soon as the roll finishes it splices with the new rolls so that machine continues running. This saves the downtime for roll change and saves wrapper that gets wasted while threading the new roll. »SPEED MATCHING TO SOAP STAMPERS Wrapper 8000T offers 300+packs per minute output which makes it suitable for direct linkup with stampers. For high speed stampers, 2 Wrapper 8000T machines can be configured per line. Highlights » Fastest speed in its class » Fully automatic link up to toilet soap stamper » 7 Servo/PLC system with touch-screen controls by Allen Bradley » Fully integrated safety Auto splicing of wrapper & stiffener rolls to save time

...more

Gas Flushing Sealing Machine

Voltage : 220V

Material : Mild Steel

Frequency : 50 Hz

Brand Name : Khosla

Power Source : Electric

Application : Industrial

...more

FLOW WRAP MACHINE FOR BISCUIT PILE PACK

PRINCIPAL OPERATION: FINSEAL 11 HS flow wraps piles of twin biscuits(1 to 4 biscuits in a pile). Biscuits are drawn from the bottom of twin magazines, which are adjustable for different sizes of biscuits. Infeed conveyor transfers the biscuits into wrapping film that has been formed into a tube by means of forming folder. Bottom seal is made by three sets of rollers. Cross sealing and cutting knife separate the packed biscuits. Heat sealable material like BOPP or laminates is used for wrapping. Output can either be individual packs or chain packs. STANDARD FEATURES » All surfaces over which biscuits are transported are made of stainless steel » Long seal is formed by means of three pairs of rollers, axes of which can be tilted to get best results » Low voltage heaters for safety » Twin cutting knives for high speed operation » Individual, digital PID temperature controls for all heaters » Automatic centralized lubrication » Print registration unit for printed wrapper » Heavy distortion-free cast structure HIGHLIGHT » Date printing unit » Variable speed drive (AC frequency control) » Castors for mobility of machine » Parallel to infeed conveyor orientation of magazines » Twin pile packing arrangement Machine speed upto 250 PPM infinitely variable

...more

Electric Bundling Machine

Automation Grade : Automatic

detergent packing machine

Driven Type : Electric

Brand Name : Khosla

Speed : 1000 - 1500 Pieces /Hr

...more

Detergent Bar

We are offering detergent bar. Khosla machines private limited develop prime range of detergent barlaundry soap wrapping machine that are used for wrapping and packing detergent bar and laundry soap, which are majorly employed by fmcg industry.

...more

cookies machine

Material : Mild Steel

Biscuit Wrapping Machine

We design & develop our comprehensive range of biscuit packaging machines, biscuit wrapping machines that are superior in quality, long lasting in nature & function with utmost precision. Our machines are available in various models to serve diverse packaging solutions. All our manufactured machines are visually compelling and functionally superior then ordinary packaging machines. The specifications of our cost effective biscuit packaging machines are given below:

...more

Biscuit Packing Machine

Automatic Grade : Automatic

Driven Type : Electric

Be first to Rate

Rate ThisOpening Hours