Toilet Soap Wrapping Machine

TSW-150 is designed to wrap various sizes of toilet soap with single or double wrappers. It is designed to handle both heat sealable film laminates polly coated wrapping material and glue sealable outer coated wrapping material.The machine is built from high precision components having the desired metallurgical and heat treatement characteristics, resulting in lower wear and tear, high life and less maintainance,The final result is a design of robust, highly reliable, low maintainance, operator friendly machine having high productivity and efficiency with negligible rejections.

...more

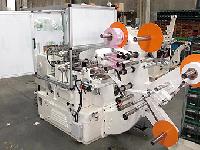

Soap Wrapping Machines

Soap Wrapping Machine

SWIFT Machine has been designed to pack detergent cakes in single wrap, handling heat sealable films, laminates and poly coated wrapping material.SWIFT is built from high precision components having the desired metallurgical and heat treatment characteristics, resulting in lower wear and tear, lesser maintenance costs and longer life. The highly reliable, operator friendly; robust design has high productivity and efficiency with negligible rejections.

...more

PLUG MAKING MACHINE

PM4, the plug making machine produces filter rods at speeds upto 2500 rods per minute (at a maximum speed of 175 meters per minute). Processed tow or paper is fed into the machine from a seperate tow processing unit driven by the PM4 or from a paper reel stand. The PM4 is suitable for handling cellulose acetate type tow and the PM4 'S' paper type materials. The continuous rod is formed wrapped in paper, sealed, cut into multiple lengths and delivered to a hand catcher, automatic tray filling unit or automatic converyer system. 'L' and 'S' model machines are supplied with fixed type drums, starch pasting unit, rod lap sealing heaters, rod cut off unit, rod break-out detectors and 1 or 2 row forward or rear facing rod hand catchers. 'L' model machines are supplied with 3-folder garnitures and 'S' model machines are supplied with single folder garnitures. Either model can alternatively be equipped with hand adjustable 'D' shaped folder garnitures. 'S' model machines are fitted with pre-compression parts, variable speed drive for main motor and the complete electrical/electronic system. TOW PROCESSING UNIT DRIVE: Main drive for tow-processing unit is transmitted by an extension shaft at the end of the machine bed. OPTIONAL EXTRAS: Expanding type drum in lieu of fixed type drum. Spring loaded paster nozzle and ceramic wheel in lieu of standard. Rod feed in device, centerline gumming, rod ejection parts, solex gauging equipment. Automatic diameter control. PVA pasting equipment. LINK UP: Suitable for linking to tray filling units (TFU) or Molins overhead spiral conveyor and resirvoir (OSCAR) to automate plug handling and inspection system (APHIS).

...more

plug assembling machine

PA 7RO, the plug assembling machine assembles filter tips to plain cigratees and produces upto 2000 filter tipped cigrattes per minute. The machine is suitable to link with Mark 8 SM cigarette making machine. It is provided with plug (filter) hopper with tray reserve, tipping material bobbin holder, adhesive reservior and applicator, single end closure deflector drum, cigratte rolling plate, multivariable cork drum with temperature control, cyclone fan unit, free standing vacuum & pressure pump unit, turning device, forward facing cigarette hand catcher and complete electrical/electronic system. The machine is build from high precision components having the desired metallurgical and heat treatment characteristics resulting in low wear and tear, low maintenance and longer life.

...more

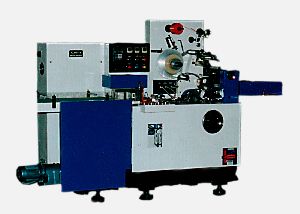

High Speed Wrapping Machine

WRAPID-350 is designed for wrapping Cigarette Packets and other Products having similar dimensions. It wraps the product in heat sealable cellophane or BOPP. A tear tape integral with the film makes film removal very convenient. The machine has twin roll film dispensing system with quick change over Suction bands together with static charge eliminator ensure continuous and positive film feeding. Application of state of the art technology using VFD for speed control, PLC, operator interface for fault display, parameter setting, optical & fibre optic devices, SMPS etc. ensures user friendliness & consistent repetitive performance and higher productivity. Wrapid-350 is a robust, highly reliable, operator friendly machine having high productivity and efficiency with neglible rejections.

...more

GENERAL PURPOSE WRAPPING SOLUTION

GPW - III Overwrapping machine does a single layerof BOPP / Cellophane on the rectangular packets with or without tear tape at speeds upto 75-80 packets per minute. The machine is built from high precision components having the desired metallurgical and heat treatment characteristics resulting in low wear and tear, less maintenance and a longer life. GPW-III is a robust, highly reliable, operator friendly machine having a high productivity and efficiency with negligible rejections. Salient Features: No product-no wrapper system to avoid wastage of wrapping material Broken film detectio Overload safety clutch on in feed self adhesive tear tape system with tear tape broken sensing Automatic retract function of sealing heater to avoid over heating of wrapped product during machine stopage PID digital temperature controller with solid state relay for heater on-off Use of VFD for infinitely variable & step less speed control of machine and in feed conveyor speed Use of PLC & solid state proximity sensors for flexible, fail safe & user friendly operation Operator interface for fault message display and parameter setting.

...more

Detergent Soap Wrapping Machine

SWIFT Machine has been designed to pack detergent cakes in single wrap, handling heat sealable films, laminates and poly coated wrapping material.SWIFT is built from high precision components having the desired metallurgical and heat treatment characteristics, resulting in lower wear and tear, lesser maintenance costs and longer life. The highly reliable, operator friendly; robust design has high productivity and efficiency with negligible rejections. STANDARD FEATURES Photocell for Print Mark Registration 'No Product No Wrapper' System Variable Speed Control Product Output Counter Electronic Temperature Controler & Speed Indicator Double Reel Holder

...more

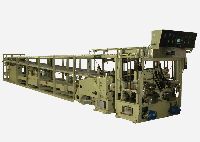

COLLATING AND PARCELLING MACHINE

COPAR Machine is a fully automatic over-wrapping machine with two modules - the Collator module and the Parcellor module. The collator module conveys the individual packets on a conveyer belt to a collating device where the single packets are collated to form two or three dimensional configuration. The Parcellor Module cuts the required length of paper or film and over wraps the collation performing the side folds and sealing on three sides The machine is built from high precision components having the desired metallurgical and heat treatment characteristics resulting in lower wear and tear, longer life and less maintenance. STANDARD FEATURES Application of pneumatic system, controlled by PLC & solid state proximity sensors for flexible, fail safe & user friendly operation. Print registeration system Scissors action for film/paper cutting knives Components in contact with product are made of stainless steel Speal arrangement for ease of loading/unloading of film/paper reel Use of VFD for in feed conveyor for infinitely variable & step less speed control Digital temperature controllers with solid state relay for heater on-off

...more

CIGARETTE PACKAGING MACHINE

M2 Duplex Packing Machine collates, foil wraps if required and continuously packs single bundles of Cigarettes into two Cartons simultaneously.The cartons are formed during the packing operation from pre-folded shells and pre-creased slides delivered from magazines on the machine.Basically the machine comprises a Cigarette Hopper,a twin track filling unit with associated foiling units where applicable, and a single track sealing unit incorporating the shell and slide magazine. The machine is supplied for normal bundle, with an option for embossed and loose front foil.The machine is built from high precision components having the desired metallurgical and heat treatment characteristics resulting in low wear and tear low maintenance and longer life.It is a highly reliable, operator friendly machine having high productivity and efficiency with negligible rejection.

...more

cigarette making machine

The Mark 8 SM produces upto 2500 cigarettes per minute. The machinery is equiped with a hopper suitable for pneumatically tobacco feeding or alternatively, a hopper for feeding tobacco by hand (skip feed). The machine is designed to suit centralized dust collection system, hydraulic weight control unit, ecreteur with plain or denser end discs, C type single or double color printer with bronzing, fixed tape drum, rod feed and rod break out detector, heater lifter, starch pasting unit, cigarette lap sealing heater, cut off unit, hand catcher, high pressure air system and complete electrical. The machine can be linked with plug assembler. The machine is built from high precision components having the desired metallurgical and heat treatment characteristics resulting in low wear and tear, low maintenance and longer life. Application of updated technology using VFD for speed control, PLC system, operator interface, solid state proximity sensing devices etc. ensures highly reliable and user friendly machine having high productivity and efficiency with negligible rejection.

...more

capsule making machine

The machine is fully automatic with combination of mechanical & hydraulic motions and makes gelatine capsule bodies and caps by a dipping process and joins them in a completely automatic process.The machine is built from high precision components having the desired metallurgical and heat treatment characteristics resulting in low wear and tear, low maintenance and longer life. It is a highly reliable, operator friendly machine having high productivity and efficiency with negligible rejection.Fully Automatic,Automatically controlled centralized two line metered lubrication system,Fail safe sensitive safety features,Use of PLC system for reliable and flexible control operation,Totally solid state sensing devices,Short circuit and overload protected low voltage regulated D.C control supply,Use of operator interface for fault messagetext display and data logging,PID auto tuned digital temperature controller with solid state switchng for heater

...more

automatic capsule making machine

packing machines

Pharmaceutical Machinery

Cement Baking Machines

Hard Gelatin Capsule Making Machines

biscuit wrapping machines

Be first to Rate

Rate ThisOpening Hours