UGP7150FS Single Axis in Line Smart Feeding PLC Interface Pouch Packaging Machine with Speed 150PPM

1 Piece (MOQ)

Brand Name : UGP

Packaging Type : Pillow Pack /pouch Pack

UGP-7050BS BOPP Overwrapping Machine to Over Tea Boxes/Perfume Boxes/Cosmetic Box

1 Piece (MOQ)

Standard Features Surfaces touching the product are made of stainless steel Flat belt conveyor infeed with automatic product transfer assembly Long seal is formed by linear Heator Slip clutch prevents damage in case of jams for safety Technical specifications Capacity: up to 50 packets /min Power consumption: 5 kW Air consumption 6 bar Wrapper: OPP, PP Max. Wrapper Roll diameter: 350 mm Electronic speed control All parts in touch with the products is stainless steel Photocell equipped precise cutting system No product and no paper (optional) Bearing systems at all moving parts

Brand Name : UGP

Capacity : 50 Packets /min,Up to 50 Bundle per Min

...more

UGP7050BS BOPP Overwrapping Machine

19 Per Piece

1 Piece (MOQ)

Material : Bopp Clear or Printed Laminate Both Side Sealable with Eye Mark

Capacity : 35 Bundle per Min

Conveying Speed : 50 BPM

Brand Name : UGP

...more

UGP-7250TS Fully Automatic 6 Axis Plc Interface Paper Overwrapping Machine

1 Unit (MOQ)

Brand Name : UGP

Material : Stainless Steel

Finishing : Chrome Finish

Driven Type : Electric

Usage : Paper Wrapping

Certification : ISO 9001:2008

Packaging Type : Metal Sheet Box

Specialities : Rust Proof, Long Life, High Performance

Dimension (LxWxH) : 275x90x285mm

Type : Paper Wrapping

Weight : 100-200 Kg

Warranty : 1 Year

...more

UGP-7100BS High Speed Bopp Overwrapping Machine with Speed 120RPM

1 Piece (MOQ)

Brand Name : UGP

Material : Clear or Printed Cellophane Wrapper Both Side Sealable Material

Conveying Speed : 120 PPM

Usage : Industrial

...more

UGP-7200TS Semi-Automatic Toilet Bar Soap Wrapping Machine

100 - 200 Per piece

1 Piece (MOQ)

Details: Soap Wrapping Machines has been designed to pack toilet soap bar/cakes in single wrap of wrapping paper Machine has been designed to handle heat sealable wrapper, laminates and Polly coated wrapping material The final result is a design of a robust, highly reliable, low maintenance, operator friendly machine having a high productivity and efficiency with negligible rejections Working Principle: The soap cakes are fed onto a continuous motion In-feed Conveyor The In-feed pushers take the soap cakes to the wrapping feed station With the help of pulling rollers, the reel fed wrapper is positioned between the cakes and tumble box The wrapper is cut to the required length as the in-feed pushers push the soap along with the cut wrapper into the turret Spring-loaded end blocks retain the product in position The turret box then indexes by 180 degrees and resulting in top folding The next incoming cake pushes the previously packed cake forward which is further pushed into the sealing zone Feature: Machine suitable for detergent bar/laundry bar Heavy duty cast structure Machine weight: Approx. 1600 Kgs Speed up to 180 TPM depending upon the product dimensions, laminate quality and feeding of soap Directly linkable to bar cutting machine through conveyor for automatic feeding of bars Fixed/Adjustable size turret assembly Designed to handle soft bar Soap moves on belts with pusher to avoid any scratch mark Double spool arrangement for wrapper to save change over time of paper roll to increase the uptime of machine No soap and no wrapper interlock through PLC AC variable speed drive unit Double chain for overhead infeed conveyor Double chain for overhead discharge conveyor Speed of machine directly proportional to soap feeding Stop-start mechanism with Geneva Drive for auto feeder belt conveyor Collator unit for easy collection of packed bars Two sided heaters and cooling unit provide better sealability Double corrugation rollers Different cut length for paper stiffener lengths can be made at a cut off unit quickly. Separate temperature controller for topside heaters and rear heater Infeed queue pressure release mechanism while transferring the soap from infeed belt conveyor to prevent dent marks Centralized lubrication system Print control system with worm and worm wheel mechanism Cooling unit for electrical panel PID temperature controllers Wrapper : Paper / Poly / Hot Melt Lamination Max Dia 450mm Core ID 70mm Stiffener: Card paper/poly laminated

Brand Name : UGP

Production Capacity : 180 Soap Bar Per Min

Automatic Grade : Automatic

...more

Toilet Soap Bar Cutting Machine

100 - 200 Per piece

1 Piece (MOQ)

Application Electronic soap bar cutter suitable for any soap finishing line with a rotating blade directly coupled to servo driven motor shaft gives very high accurate cut at higher speed. Specification Maximum bar cutting speed up to 200 bars cut per min Maximum bar cutting thickness up to 60mm of soap bar/billet Maximum soap bar/ soap billet speed 20m/min Power requirement: 3KW Features High speed Highly accurate servo controlled VBC-250 bar cutter gives up to 200 cut of soap bar per min. Designed for very high precise/accurate right angle cuts on soap bar/soap billet Negligible Movement of inertia allow continuous motor start and stop at very high speed Blade cut the soap bar/soap billet and passes through a narrow slot High-speed soap bar/billet cutting Minimum noise level due to absence of mechanical mechanism Minimum maintenance No mechanical mechanism Trouble free cutting solutions Easy Touch colored HMI 7' Stamping machine stop than bar cutter cut the bar into small pieces and send to recycling conveyor optional

Brand Name : UGP

Usage : Industrial

Voltage : 220/110

...more

UGP-7150D Semi-automatic Laundry Bar/Dish Wash Bar/ Detergent Bar Overwrapping Machine

1 Piece (MOQ)

Details: Laundry bar wrapping Machines has been designed to pack laundry cake in a single wrap of wrapping paper. The machine has been designed to handle heat sealable wrapper, laminates and Poly coated wrapping material. This machine is built from high precision components having the desired metallurgical and heat treatment characteristics, resulting in lower wear and tear, high life and less maintenance. Working Principle: The soap cakes are fed onto a continuous motion In-feed Conveyor. The In-feed pushers take the soap cakes to the wrapping feed station. With the help of pulling rollers, the reel fed wrapper is positioned between the cakes and tumble box. The wrapper is cut to the required length as the in-feed pushers push the soap along with the cut wrapper into the turret. Spring-loaded end blocks retain the product in position. The turret box then indexes by 180 degrees and resulting in top folding. The next incoming cake pushes the previously packed cake forward which is further pushed into the sealing zone. Feature: Machine suitable for detergent bar/laundry bar Heavy duty cast structure Machine weight: Approx. 1600 Kgs Speed up to 180 TPM depending upon the product dimensions, laminate quality and feeding of soap Directly linkable to bar cutting machine through conveyor for automatic feeding of bars Fixed/Adjustable size turret assembly Designed to handle soft bar Soap moves on belts with the pusher to avoid any scratch mark. Double spool arrangement for wrapper to save change over time of paper roll to increase the uptime of machine No soap and no wrapper interlock through PLC AC variable speed drive unit Double chain for overhead infeed conveyor Double chain for overhead discharge conveyor Speed of machine directly proportional to soap feeding Stop-start mechanism with Geneva Drive for auto feeder belt conveyor Collator unit for easy collection of packed bars Two sided heaters and cooling unit provide better sealability Double corrugation rollers Different cut length for paper stiffener lengths can be made at a cut off unit quickly. Separate temperature controller for topside heaters and rear heater. Infeed queue pressure release mechanism while transferring the soap from infeed belt conveyor to prevent dent marks Centralized lubrication system Print control system with worm and worm wheel mechanism Cooling unit for the electrical panel. PID temperature controllers. Wrapper : Paper / Poly / Hot Melt Lamination Max Dia 450mm Core ID 70mm Stiffener: Card paper / poly laminated

Brand Name : UGP

Capacity : 180 Soap Bar Per Min

Packaging Type : Over Wrapping/envelope Type

Air Pressure : 5LPM

Usage : Laundry Bar Paper Overwrapping Machine

...more

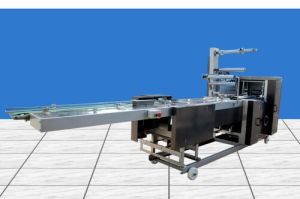

UGP-7120FS Straight Line Feeding with Mechanical Auto Feeder with Speed 120PPM

6 - 8 Per Piece

1 Piece (MOQ)

Brand Name : UGP

Power : 1-3kw,3-5kw,5-7kw

Application : Paper Pouch Packing Machine,Plastic Pouch Packing Machine

Certification : CE Certified, ISO 9001:2008

Voltage : 110V, 220V

Weight : 100-500kg

Country of Origin : India

...more

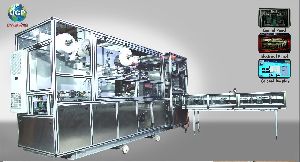

UGP-7250FS Fully Automatic Multiple Axis PLC Interface High Speed 250PPM

1 Piece (MOQ)

Details Detergent Bar Packaging Machine has been designed to pack detergent cakes/ Laundry cake in single wrap of wrapping paper Machine has been designed to handle heat sealable wrapper, laminates and Poly coated wrapping material The machine is built from high precision components having the desired metallurgical and heat treatment characteristics, resulting in lower wear and tear, high life and less maintenance Working Principle The soap cakes are fed onto a continuous motion In-feed Conveyor The In-feed pushers take the soap cakes to the wrapping feed station With the help of pulling rollers, the reel fed wrapper is positioned between the cakes and tumble box The wrapper is cut to the required length as the in-feed pushers push the soap along with the cut wrapper into the turret Spring-loaded end blocks retain the product in position The turret box then indexes by 180 degrees and resulting in top folding The next incoming cake pushes the previously packed cake forward which is further pushed into the sealing zone Feature Machine suitable for detergent bar/laundry bar/oil cake/Toilet soap Heavy duty cast structure Machine weight: Approx. 1600 Kgs Speed up to 300 PPM depending upon the product dimensions, laminate quality and feeding of soap Directly linkable to bar cutting machine through conveyor for automatic feeding of bars Fixed/Adjustable size turret assembly Designed to handle soft bar Soap moves on belts with pusher to avoid any scratch mark Double spool arrangement for wrapper to save change over time of paper roll to increase the uptime of machine No soap and no wrapper interlock through PLC AC variable speed drive unit Double chain for overhead infeed conveyor Double chain for overhead discharge conveyor Speed of machine directly proportional to soap feeding Stop-start mechanism with Geneva Drive for auto feeder belt conveyor Collator unit for easy collection of packed bars Two sided heaters and cooling unit provide better sealability Double corrugation rollers Different cut length for paper stiffener lengths can be made at a cut off unit quickly. Separate temperature controller for topside heaters and rear heater Infeed queue pressure release mechanism while transferring the soap from infeed belt conveyor to prevent dent marks Centralized lubrication system Print control system with worm and worm wheel mechanism Cooling unit for electrical panel PID temperature controllers Wrapper : Paper / Poly / Hot Melt Lamination Max Dia 450mm Core ID 70mm Stiffener: Card paper/poly laminated

Brand Name : UGP

...more

Fully Automatic High Speed 6 axis PLC interfaced

100 - 200 Per Piece

1 unit (MOQ)

HIGH SPEED 6 AXIS PLC INTERFECED SERVO CONTROLLED FOR WRAPPER AND STIFFNER CONTROL AND 5 STATION VACUUM PICK AND PLACE CONTINOUS MOTION UNIT T O HANDLE THE SOFT SOAP ALSO MACHINE MODEL UGP7250TS 6 axis wrapper, toilet soap wrapping machine with smart infeed conveyor, high speed continuous motion 5 stations vacuum pick and place mechanism for soaps, 4 axis servo control for cut-off system, discharge conveyor to control the skew for band less soap shape, side support sealing, cooling unit for sealing at higher speed, machine guarding with category 4 with Advanced features

Color : Grey

Type : Soap Bar Paper Over Wrapping Machine

Country of Origin : India

...more

UGP-7150FS Semi-automatic Flow Wrap to Pack Scrub Pad with Speed 120PPM

100 - 200 Per Piece

1 Piece (MOQ)

Specifications:Principle Of Operation: Products are placed on a flat belt conveyor, either by link up conveyor (not a part of the of the machine) or manually. These soaps are transferred to the infeed lug conveyor of the machine. In feed conveyor then transfers soap into wrapping film that has been formed into a tube by means of forming folder. Bottom seal is made by three sets of rollers. Cross sealing and cutting knife separate the packed soaps. Heat sealable material like BOPP or laminates is used. Individual Machine Features: This machine is designed to give a speed output up to 120ppm depending upon products shape, size, feeding option and laminate characteristics Customized for packaging of toilet soap, laundry soap and detergent bars Designed to pack single packs or like a string pack Multiple soaps can also be packed in one pouch (depending on product dimensions) Options Features: Date Printing unit inkjet/thermal/laser Variable speed control drive Machine on wheels for easy mobility of machine

Brand Name : UGP

Voltage : As Per Customer Req

...more

Automatic Soap Packing Machine

100 - 200 Per pieces

Opening Hours

About us

Established in the year 2013, we at United Global Packaging LLP are a highly admired manufacturer and supplier of efficient BOPP Overwrapping Machine, Packaging Machine, Wrapping Machine, Toilet Soap Wrapping Machine, Laundry Bar Wrapping Machine, Toilet Soap Bar Cutting Machine, etc. We are engaged in offering the best quality of machines and that’s too at a competitive price. We are based in MOHALI, Punjab (India).

These products are broadly renowned for their durability, simple installation, easy operation, less power usage and least maintenance required. The products are manufactured using the quality tested components at our modern infrastructure area. The latest technology is incorporated to bear out a proficient production procedure. The machines offered by us are verified according to their performance and quality before their final dispatching. We make sure for the expert quality. Focusing more on the quality, we have been proficient to fulfill the varied needs of different sectors by providing the top quality machines according to the global quality values. Our production team uses up high-quality components and advanced technology to manufacture products. Components used in manufacturing machines are obtained from trustworthy vendors of the market. Moreover, we give products with dissimilar technical expertise at an affordable cost.

Our team members and Operation Head Mr. Sunil Bhardwaj are using their distinct skills that assist us to earn the business needs of different countries while evaluating our prospective.