fire brick refractory

Get Price Quote

ARPL Fire Refractory Bricks

Get Price Quote

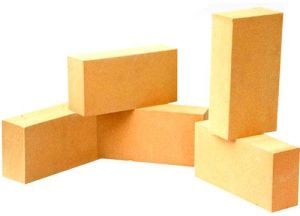

Fire clay is a range of refractory clays used in the manufacture of ceramics, especially fire brick or Refractory Materials . Fire clay is defined as a mineral aggregate composed of hydrous silicates of aluminium (Al2O3·2SiO2·2H2O) with or without free silica. We have Refractory Bricks catering to a wide range of applications including Ceramic Furnances,Die-Casting,InductionFurnance, Rolling Mills , Pizza Ovens,Etc. We offer Refractory Bricks in different sizes,Thickness , Thermal Properties , and Arches. Fire bricks have an Alumina content that can be as high as 30–80% . Most Common Sizes are : 230 x 115 x 76mm (Regular /Side Arch /End Arch) 230 x 115 x 51mm (Regular /Side Arch /End Arch) 230 x 115 x 26mm (Regular /Side Arch /End Arch) NOTE : - Size Tolerance : Ȃ± 1.5 % OR 2mm Whichever Is Greater. The Above Data are On Average Result Basis.

Best Deals from Refractory Fire Brick

Refractories Fire Brick

12 Per Piece

5000 Piece (MOQ)

Refractory Fire Bricks

Get Price Quote

1000 piece (MOQ)

Refractory Fire Brick

15 - 500 Per piece

Refractory Fire Brick

15 Per Piece

Refractory Fire Bricks

Get Price Quote

1000 Ton (MOQ)

Empowered with a qualified team and a sound infrastructural base, we have been growing in leaps and bounds in the Refractory Fire Bricks market. Our Refractory Fire Bricks are made up from the superior quality fire clay under strict quality controls. Highly valued in the quality cautious markets, our Insulating Fire Bricks are in compliance with national and international quality standards. Widely used in the kilns, lining furnaces, fireplaces etc.

Refractory Fire Brick

Get Price Quote

A fire brick, firebrick, or refractory brick is a block of refractory ceramic material used in lining furnaces, kilns, fireboxes, and fireplaces. A refractory brick is built primarily to withstand high temperature, but will also usually have a low thermal conductivity for greater energy efficiency. Usually dense firebricks are used in applications with extreme mechanical, chemical, or thermal stresses, such as the inside of a wood-fired kiln or a furnace, which is subject to abrasion from wood, fluxing from ash or slag, and high temperatures. In other, less harsh situations, such as in an electric or natural gas fired kiln, more porous bricks, commonly known as "kiln bricks" are a better choice.[1] They are weaker, but they are much lighter, easier to form, and insulate far better than dense bricks. In any case, firebricks should not spall, and their strength should hold up well during rapid temperature changes.

Refractory Fire Brick

Get Price Quote

refractory shapes, Fireclay, Fireclay Bricks, boiler bed materials

Refractory Low Iron Fire Bricks

Get Price Quote

Refractory Low Iron Fire Bricks, Alumina Fire Bricks, Clay Refractory Bricks

refractory fire clay bricks

Get Price Quote

refractory fire clay bricks, Refractory Castable Mortar

refractory fire clay bricks

Get Price Quote

refractory fire clay bricks, silica fire bricks, refractory magnesia bricks

Fire Refractory Bricks

Get Price Quote

Fire Refractory Bricks, silica refractory bricks