Agitated Nutsche Filters

Get Price Quote

Associated with a diligent professionals and smart packaging facility, we are capable to undertake standard as well as tailored packaging requirements of the clients. Our products are subjected to the payment terms & conditions of our company. Patrons are provided with the terms & conditions, and can make purchases with a payment method best suited for them. Features : Quality tested Lightweight

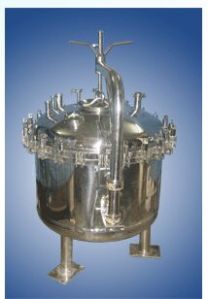

Agitated Nutsche Filters

Get Price Quote

Determined to present the utmost quality, we are involved in offering Agitated Nutsche Filters. Our capable staff keeps manufacturing process under stringent guidance to make certain our quality is in fulfillment with different quality grades set by industry. Hence, our customers can be certain of the excellence on offer. We offer a range of several designs and sizes. At their ease, customers can get them delivered. Details : Pressure Nutsches can handle a variety of flow rates and solids loading that can be discharged in dry or slurried form. They can be designed for pressures up to 75psi or full vacuum. Pressure nutsches are ideal for lab, pilot or batch applications and for easily filtered material such as carbon particles, salts and other products where a cake thickness of 6 inches or more can be attained.Pressure Nutsche Applications : Ideal for piloting of new or modified batch operation and/or processes requiring recovery of the cake. The Pressure Nutsche is excellent for lab, pilot or batch applications where cake thickness of 6” and above is achievable.

Best Deals from Agitated Nutsche Filter

Agitated Nutsche Filter

Get Price Quote

Agitated Pressure Nutsche Filter

Get Price Quote

We are offering agitated pressure nutsche filter. The agitated pressure nutsche filters offered by us has the following features : * filter vessel designed as per is asme standards * variety of materials * jackets limpet coils * the scraper assembly and discharge port can be provided with hydraulic actuation with electrical controls as an option. * cgmp finish optional

pressure nutsche filter

Get Price Quote

1 nos (MOQ)

AGITATED GLASS NUTSCHE FILTER

Get Price Quote

agitated glass nutsche filter agitated glass nutsche filter is a closed vessel designed to separate solid and liquid by filtration under vacuum. The closed system ensures odourless contamination free and non-polluting working conditions maintaining product purity and hygiene. Agitated nutsche filters are extensively used in herbal products, chemical product development, kilo lab operation, pharmaceutical manufacturing, agro chemical and the food industry. general description a typical unit consists of a dish shape vessel vessel with a perforated plate. The entire vessel can be kept at the desired temperature by using a jacketed and stirrer (blade and shaft) through which heat transfer media can flow. The vessel can be made completely leak-proof for vacuum or pressure service. The base plate is having arrangement of bolting bar to hold the filter cloth. Suitable nozzles can be provided including manhole and side discharge nozzle. Ptfe lined stirrers are used for agitator shaft and solid ptfe blades are used to take high torque generation during solid discharge and re-slurring operation. process steps of agitated nutsche filter with agitator and discharge valve are:- 1) filtration2) washing of filter cake3) repeat mix or washing of the cake4) convection drying of the cake5) smoothing with compression of the cake6) discharge of the wet or dried cake. drive assembly consist of motor with vfd, mechanical seal is provided for vacuum application. Borosilicate glass vessel with different nozzles, manual/hydraulic system is provided for movement of agitator and discharge valve. Ptfe filter support plate. advantages of glass nutsche filter vacuum filtration possible. glass being transparent, offers visibility of processes. inert gas atmosphere can be maintained. minimal contamination of the cake. very high solvent recovery. solvents are in closed systems, so no toxic vapors are let off in the atmosphere. personal safety is maintained and heat transfer surfaces can be provided to maintain filtration temperature. garg offer glass anf from 10 l to 200 l for kilo lab operations with and without jacket , with and without stirrer. Our sales/technical team will be glad to assist you desinging the best suitable system for your process requirements.

ANFD Agitated Nutsche filter

Get Price Quote

Agitated Nutsche filter (ANF) is a filtration technique used in applications such as dye, paint, and pharmaceutical production[1] and waste water treatment.[2] Safety requirements and environmental concerns due to solvent evaporation led to the development of this type of filter wherein filtration under vacuum or pressure can be carried out in closed vessels and solids can be discharged straightaway into a dryer.

Agitated Nutsche Filter

Get Price Quote

Agitated Nutsche Filter is a filtration technique used in applications such as dye, paint, and pharmaceutical production and waste water treatment. It is used for liquid or solid separation in a completely non-metallic environment. The corrosion resistant property of our product helps in handling of virtually all acids and salts at a very high temperature. Our Agitated Nutsche Filter is mounted on four legs with castor wheel for easy mobility. A thorough cleaning and product purity is obtained by the filter surface that eliminates contamination. We are a renowned Agitated Nutsche Filter Manufacturer, Exporter and Supplier in Maharashtra (India). We can process bulk orders as per the customer’s specifications.

pressure nutsche filter

90,000 Per Piece

1 Piece(s) (MOQ)

Manufacturer of standard & custom filtration equipment & systems including nutsche filters. Available as pressure nutsche filters in manual & automatic models. Pressure nutsche filters are available in different materials including carbon steel, stainless steel, titanium & Hastelloy®. Nutsche filter can be designed to handle different flow rates & pressures up to 300 psi or full vacuum. Nutsche filter is used for pilot or batch filtration in laboratory, pharmaceutical, chemical & food additive process applications. Ideal for piloting of new or modified batch operation and/or processes requiring recovery of the cake. The Pressure Nutsche is excellent for lab, pilot or batch applications where cake thickness of 6” and above is achievable.

Agitated Nutsche Filter

Get Price Quote

This filter is used for solid and liquid separation which is aided with the application of vacuum and cake squeezing by mechanical means. Agitated Nutsche Filter consists of a cylindrical vessel with a welded dished end on the top and a flat bottom or dishend. The process is totally enclosed, hygienic and safe which make it ideal for processing toxic and hazardous material human contact. This equipment can be operated under pressure or in vacuum or in combination of both. Cake discharge is done with the help of stirrer. Provision for spraying wash liquor is in build in the equipment. SPECIAL FEATURES :- It can be used as a drier to further reduce the moisture content. Solvent recovery is possible since process is totally enclosed and closed loop regulation of the speed. A hydraulically operated plug type discharge valve of Special design can be provided operated through the common power pack unit. In the detachable bottom configuration the ANF body is in two sections i.e. the main Top section and the detachable bottom section. The bottom section is provided with legs fitted with castor wheels. Once lowered the bottom section can be wheeled out and one can clean and/ or replace the filter media at ease. A spray Ball arrangement will be provided for uniform distribution of wash liquid for effective cake washing. The same arrangement could also be used during CIP to cover the Shadow areas of the CIP Spray Balls. Filter Media can be metallic screens, sintered screens or filter cloths Shaft Seal can be Mechanical seal with bellows or gland box assembly Post navigation ← Rotocone Vacuum Dryer Vertical Plate filter → Recent Products For Complete Product List Click Here © Everest Engineering. All Rights Reserved

pressure nutsche filter

360,000 Per Piece

1 Piece (MOQ)

Agitated Nutsche Filter

Get Price Quote

We are offering agitated nutsche filter.anf with electromechanical drive capacity 200 ltrs. - 20,000 ltrs. diameter 500 mm - 4,000 mm internal design pressure full vacuum to 5 kgs/sq. Cm. jacket pressure : 6 kg/sq. Cm. (max) rpm's 12 - 20

Agitated Nutsche Filter

Get Price Quote

DESCRIPTION: Agitator Nutsche Filter / Dryer consists of a cyllindrical shell with top dished and welded flat bottom. The base plate is stiffened by supports welded under the base plate. The base plate is having arrangement of bolting bar to hold the filter cloth. Suitable support mesh is provided under filter cloth to facilitate the flow of filtrate. Solid bar is used for agitator shaft and solid plate for blades made in specially “S” curved to take high torque generated during solid discharge and re-slurring operation. FILTER MEDIA : Sintered metal multiply of Textile M.O.C : Stainless Steel, Carbon Steel, Hastelloy, halar coated. ADVANTAGE : Filtration. Drying Washing of Filter Cake. Toxic and hazardous materials can be processed Reduced manpower & no manual handling of product Minimum hold up of filtrate in the equipment Repeat mix or washing of the Cake Convection drying of the Cake Smoothing with compression of the Cake Fully Automatic discharge of the wet or dried Cake The equipment is functionally safe and easy to operate Agitator moves clockwise, anticlockwise, up & down, this ensure through washing & re-slurring of the cake OPTIONS : Bottom detachable Arrangement type is for easy cleaning/cloth fixing Agitator inside Heating System Different Stirrer design based on physical characteristic of material. Complete Automation is with PLC

Agitated Nutsche Filter

Get Price Quote

Agitated Nutsche Filter

Get Price Quote

as per requirement Piece (MOQ)

Agitated Nutsche Filter Salient Features Closed batch types operation Repeated & effiecient wash with reslurrying. Vacuum or pressure filtration Operation from Control panel No toxic fumes in operating area Very high Solvent recovery Minimum Labour required Drying of wet cake under Vacuum Application Pharmaceuticals Pesticides Organics/ Inorganic Chemicals Material of Construction Carbon Steel Stainless Steel MS Rubberlined Hastelloy Filtering Operation : Slurry is charges to gravity or pump vacuum is applied in bottle section through filte receiver Filtrate is collected through the filter bed & collected in Receiver, located below the lower compartment of filter & cake layer begin to form slowly on filter plate. After 1st filtration is over, cake shall have almost 10 to 30% moisture After 1st stage filtration , wet cake can be reslurried & spray washed by rotation agitator in clockwise & anticlockwise direction with up & down movement of agitator. Cake is further pressed & Squeezed by rotating agitator in up & down motion to minimize liquid content in wet cake. Cake is discharged through Discharge nozzle by rotating agitator in reverse direction. Drying Operation For maximum recovery of liquid & drying vacuum is applied on top chamber & cake is heated by applying hot water / steam to form solvent vapour, which is turn is condensed in the condesor & collected in receiver. Cake is finally discharged automatically by vertical & reverse rotary movement of agitator.

pressure nutsche filter

80,000 Per Piece

Agitated Nutsche Filter

Get Price Quote

Our special fabric improves the degree of filtration effectiveness and enables the mechanical discharge of the solid. An even filter cake forms on the horizontal base of the filter, which ensures the best possible recovery of the solid.

Agitated Nutsche Filter

Get Price Quote

Agitated nutsche filter, Kumar process has designed unique Non-agitated type Nutsche Filters. Conventional Nutsche filters use PP Polyester cloth which could release fibers leading to product contamination. We offer cleanable, non-fiber particle releasing Sintered SS316L filter discs. This is a major advantage in applications requiring filtration of antibiotics, vitamins etc. in sterile rooms where ordinary centrifuge cannot be used and use of conventional filter cloth is ruled out. The design of Nutsche filter allows easy handling for the user without having to call the maintenance team inside the clean room, thereby saving a lot of time during loading and unloading operation. Davit arm arrangement in SS is also provided for larger units. The cleanable SS316L filter disc can be offered in any one of the standards. Micron rating available with us is between 100 Micron and 0.5 Micron to suit filtration application covering a wide range of products having different filtration characteristics. The filter disc can be cleaned by water appropriate solvent wash and thus be repeatedly used for a number of years which makes it highly cost effective as compared to conventional Nutsche filters that use cloth.Features Cleanable non-fiber releasing SS316 Filter disc Ease of operation Entire product cake can be recovered cleanly CIPSIP possible

pressure nutsche filter

Get Price Quote

The Nutsche Filter are mainly used for filtration process for separation of solid particles known as cake from liquid. These Industrial Nutsche Filter are designed with special consideration such as Pressure, Temperature and Chemical used for filtration with special filter cloth with different microns as per user’s requirement.

Agitated Nutsche Filter

Get Price Quote

ANF is a closed vessel designed to separate solid and liquid under pressure and Vacuum. The closed operation ensure odourless, contamination free and non polluting working conditions maintaining product purity and hygiene.