Refrigerated Air Dryer

35,000 - 150,000 Per piece

Refrigerated Air Dryer that we offer is widely acknowledged for effectively removing the water vapors from the compressed air. Manufactured using superior grade material, our Refrigerated Air Dryer is highly accredited for its sturdy construction, low maintenance, and longer operational life. Moreover, our Refrigerated Air Dryer delivers a dew point not lower than approximately -35 °F (2 °C). We make available bulk quantities of Refrigerated Air Dryer at the most competitive rates.

Hot Air Dryer

Get Price Quote

We manufacture a qualitative range of hot air dryer, that is mainly used for the automobile sticker drying. Widely used in printing industry, these are ideal equipment for screen printed stickers on PVC. Fabricated using the best quality material, these are known for energy efficiency and low operating cost. Incorporated with advanced features, our dryers provides unique air distribution which guarantees uniform drying.

Best Deals from Air Dryers

Hot Air Dryer

Get Price Quote

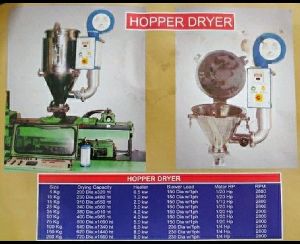

Hopper Dryer

40,000 Per Set

1 Piece (MOQ)

Price of the machine will be according to the size

Refrigeration Air Dryer

Get Price Quote

Product range : 10 to 1000 cfm Due point -20°C Low Maintenance Cost

Air Classifying Mill

Get Price Quote

We are a trusted Manufacturer and Supplier of Air Classifying Mill. Air Classifying Mill, offered by us, performs classifying, grinding, collecting, and conveying operations. It also offers milling in a closed loop operation with inert gas or dry air if necessary. This flexibility enables the plant to handle explosive heat sensitive, explosive, or hygroscopic materials. This Air Classifying Mill consists of safety devices, electrical equipment, machine frame, rotor assembly, grinding chamber, and drives. Principle The material to be ground is conveyed from the hopper : to the grinding chamber by the variable fees screw mechanismThe grinding occurs when the product comes into contact with a pin or bar type rotor disc.As the product size is reduced it is conveyed by an airstreams which enters below the rotor assembly via shroud and baffle ringThe particles are then deflected by an air dispersion ringTo the separator assemblyAcceptable product is drawn through the exhaustAnd is collected by a Dust Collector Oversize particles are returned by the internal airstreams to the rotor disc for further reduction. Safety Devices All ACM mills are required with protection devices for safe operation. These measures include a safety switch on he cover of he grinding chamber. It is there by ensured that the drive motors cannot be switched on when the grinding chamber cover is open. Electrical Equipments : The plant is supplied along with a control panel and MCC, which provide the necessary interlocks and operating switchesMachine Frame : The mill and all drive components are mounted on a rigid welded steel frame. All rotating parts are dynamically balanced floor smooth operation. There is no need for special foundation.Rotor Assembly : The assembly comprises of the following components: the separator wheel assembly, the rotor disc, bearing housing and the V-belt pulleys. The complete assembly is secured to the grinding chamber housing by four retaining bolts. All bearing is lubricated and are protected against ingress of ground product and dirt, moisture by means of special sealing rings.Grinding Chamber : The Grinding Chamber is sealed by a hinged cover held in position by hand wheels. When the hand wheels are released the entire cover assembly tilts upwards giving access to the milling components, these consist of: the air dispersion ring, the shroud and baffle ring, multiple deflector liners and the rotor assembly.Drives : All driven motors are fixed to the chassis and are easily accessible, power is transmitted by V-belts. A tachometer is supplied to indicate the speed and allows operator at a glance to select the correct speed for any pre-determined product fineness. ACM Plant Includes ACM Mill for grinding and classifying.Dust Collector fully automatic Pulse Jet cleaning ensures dust free operation.Rotary Airlock used as an air seal and discharge material from dust collector.Fan to provide air flow through the mill and the collector for product conveying and cooling.Control Panel for sequential starting and stopping of the milling plant.

Water Chilling Plant

Get Price Quote

Our Water Chilling Plants are energy efficient and environment friendly. They are in high demand with our clients. The equipment is used for removing heat from water. Highly reliable, our Water Chilling Plants are used in various commercial, industrial & institutional establishments. These Water Chilling Plants have a sturdy construction and require minimal maintenance. The Water Chilling Plants are reliable and deliver consistent performance. Our Water Chilling Plants are available to clients at economical prices. Usage : Air conditioning systems to transfer sensible & latent heat which results in cooling the air stream.Industries where these plants are required for controlled cooling of products, mechanisms and various types of factory machinery.To cool high-heat and specialized items such as MRI machines and lasers. Additional Usage In : Analytical equipmentChemical processingCompressed air and gas coolingDie-castingFood and beverage processingInjection and blow moldingMachine toolingMetal working cutting oilsPharmaceutical formulationPower generation stationsPower suppliesSemiconductorsVacuum systemsWelding equipmentX-ray diffraction

Air Classifying Mill

Get Price Quote

ACM is an air-classifying mill with integrated grinding, classifying, conveying and collecting operations. The milling if required may be carried out in a closed loop operation with dry air or inert gas if required.

Hot Air Dryer

Get Price Quote

We manufacture a qualitative range of hot air dryer, that is mainly used for the automobile sticker drying. Widely used in printing industry, these are ideal equipment for screen printed stickers on PVC. Fabricated using the best quality material, these are known for energy efficiency and low operating cost. Incorporated with advanced features, our dryers provides unique air distribution which guarantees uniform drying.

Compressed Air Dryers

Get Price Quote

Refrigeration dryers A microprocessor based control device is an advanced solution for drying compressed air. Compressed air is fed into the dryer and precooled in the air-to-air heat exchanger by the cold compressed air. The pre-cooled air passes through the refrigerant-to-air heat exchanger where it is further cooled to the required pressure dew point. The moisture in the compressed air condenses and is collected and discharged automatically. Finally, the cold discharged air is re-warmed by the incoming compressed air. This saves energy and prevents any moisture from forming downstream of the dryer in the compressed air system. Advantages at a glance : Multi-functional display Load controlled energy consumption; reduction down to 10% of nominal energy consumption Load controlled drain Low voltage monitoring Optional dry contact for alarm signal and analog signal 0-10 V for dew point temperature Maximum operation parameters: inlet temperature 60° C, ambient temperature 50° C for the whole series One component refrigerant R 134a, ozone factor zero Compact and easy to install cabinets Adsorption Dryers Purifying compressed air on demand, free of particles and condensate, helps decrease running costs. Equipment consisting of integrated pre- and after-filters and an electronically level-controlled drain ensure pure, dry and oil-free compressed air with no loss of compressed air from condensate drainage. Economical drying is guaranteed by an integrated microprocessor, which controls the adsorption and regeneration cycles. Heat regenerative driers can be offered with the following options: Explosion proof version Pressure dew points of -70° C Steam regeneration systems and dryers for higher pressures and higher flow rates All functions, sequences, operating states and faults are displayed by LEDs on flow charts and they are monitored continuously Control of the air recovery temperature

Air Dryers, Filters,Valves

Get Price Quote

Manufacture and supply of airgas dryers,filters, heat exchangers, valves,silica gel, activated alumina, molecular sieves, heaters, coolers, moisture separators in the range of 5 cfm -10000 cfm, pressure range upto 80 kgcm2g.

Laboratory Spray Dryer

Get Price Quote

Laboratory Spray Dryer

scroll air compressor

Get Price Quote

scroll air compressor, Fridge Compressor

Air Chilling Plant

Get Price Quote

Air Chilling Plant, Chilling Plants, Refrigeration Equipment

Air Dryers

Get Price Quote

Air Dryers, Ammonia Cracker, Gas Purification System, industrial gas dryers

Air Dryer

Get Price Quote

Air Dryer, compressor air products

air conditioner plant

Get Price Quote

air conditioner plant, Air Cooling System, Air Ventilation System

Air Dryer

Get Price Quote

Air Dryer, Molecular Sieves, Dehumidifier, Air Cooled Heat Exchanger

hot air dryers

Get Price Quote

hot air dryers, Ultrasonic Cleaning Machine, cleaning systems