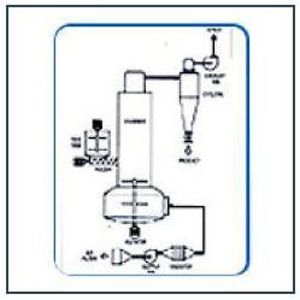

Laboratory Spray Dryer

450,000 Per Piece

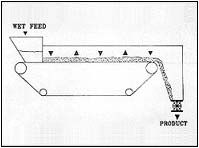

Air Impingement Dryer

Get Price Quote

We deals in manufacturing and supplier of air impingement dryer. Special features: material from remains intact - low power demand - continuous operation

Best Deals from Air Dryers

Heat Regenerative Desiccant Dryers

70,000 Per Piece

1 Piece(s) (MOQ)

Series A_TV and A_RS.

Air Try Dryer

Get Price Quote

An Air Tray Dryer Is used for the best drying results in conventional process. It consists of a double-walled cabinet with one or two doors. The gap between two walls is filled with light resin-bounded fibreglass wool insulation material to avoid heat loss.

hopper dryers

Get Price Quote

Range 12-1500Kgs. Main Features : Even heat distribution. High efficiency to save lots of drying time required. Accurate thermo control. Very high accuracy assured by excellent controller. Convenient change of raw material by two pieces of design. Reliable design. Compact in size.

Hopper Dryer

25,000 - 250,000 Per Unit

5 Piece (MOQ)

Water Chilling Plant

200,000 Per Piece

Compressed Air Dryer

Get Price Quote

The brand new KAESER compressed Air Dryer is authentic and competent for an entire drying level. The KAESER Dryer provides ideal drying of the compressed air for better application and operation of all the flow rates. As they are created like the high-end industrial machines, where you’ll get authentic safeguarding against dew destruction for your systems and its working and operations even under the critical conditions. Some of the specific features of KAESER Compressed Air Dryer are- The Compressed air dryer is composed of several types of dryers including Secotec refrigerated dryers, kryosec refrigerated dryers, TX series refrigerated dryers, High- pressure refrigerated dryers, high-temperature refrigerated dryers, etc. The dryer is equipped with solid energy-saving refrigeration dryer along with extraordinary latent heat storage. The dryer stands out in the market in terms of its high-end energy efficiency, compact design and user-friendliness. Long lasting durability- As the compressed air dryer is composed of corrosion defiant air piping and aluminium heat transfer because of which it ensures lifelong durability and strength to its built up. The dry compressed air produced by the compressor ranges from 37.5 to 90m3/min. It has an air and water cooling effect along with an operating pressure up to 16 bars. The optional FE micro filter provides the high level of air purity and also the heatless refrigeration absorption dryers. There’s plenty of potential savings during partial load operation and work pause. It provides the highest level of durability along with little maintenance system manufacturing. Enhanced Compact Built Up- The chamber of the dryer is entirely filled with the phase change material because of which it minimizes the need for storage material to gain the same capacity as of the conventional storage media. Enormous Savings in Limited Load Operation-Built up on the temperature at which the compressed air is cooled by a cycled chamber differs the size of the compressor and hence promote minimal power consumption in the partial load operation. During the limited load operation, the surplus cooling can be stored for a time in the thermal mass for cooling later on without any need for power usage.

adsorption dryer

Get Price Quote

The system consists of twin towers filled with desiccant of appropriate quality and quantity. Wet compressed air after being filtered by the prefilter and coalescing oil filter enters the distribution valve. An electrically operated valve with built in passages, which directs the air to one tower. The air is then passed through the tower and comes out in dry condition. The air is then passed through after filter to remove any carry over dust, via non-return valve. There is a by-pass arrangement with an orifice, to allow a fraction of dry compressed air to expand and pass through the other tower, here by regenerating it and making it ready for adsorption Cycle. The Regenerating air is passed out to the Atmosphere via muffler. At a preset time, the sequence control timer actuates the Distributor valve to reverse the tower function .

Air Dryers

2,800 - 3,000 Per Pack

Adsorption Air Dryer

Get Price Quote

Heatless adsorption dryers are used in certain applications where compressed air moisture can damage the process or products. With the use of activated alumina as the desiccant our heatless dryer can produce up to - 400C pressure dew point and can be raised to -700C by using molecular sieves.

Water Chilling Plant

Get Price Quote

A water chiller[1] is a mechanical device used to facilitate heat exchange from water to a refrigerant in a closed loop system. The refrigerant is then pumped to a location where the waste heat is transferred to the atmosphere. In hydroponics, pumps, lights and ambient heat can warm the reservoir water temperatures, leading to plant root and health problems. For ideal plant health, a chiller can be used to lower the water temperature below ambient level; 68°F (20°C) is a good temperature for most plants. This results in healthy root production and efficient absorption of nutrients. In air conditioning, chilled water is often used to cool a building's air and equipment, especially in situations where many individual rooms must be controlled separately, such as a hotel. A chiller lowers water temperature to between 40° and 45°F before the water is pumped to the location to be cooled.

heatless type air dryer

Get Price Quote

PNEUM SYSTEMS INC, has developed Heatless Air Dryer which is a chemical desiccant using dryer, working on adsorption principle. The system consists of twin towers filled with desiccant of appropriate quality and quantity. Wet compressed air after being filtered by the prefilter and coalescing oil filter enters the distribution valve. An electrically operated valve with built in passages, which directs the air to one tower. The air is then passed through the tower and comes out in dry condition. The air is then passed through after filter to remove any carry over dust, via non-return valve. There is a by-pass arrangement with an orifice, to allow a fraction of dry compressed air to expand and pass through the other tower, here by regenerating it and making it ready for adsorption Cycle. The Regenerating air is passed out to the Atmosphere via muffler. At a preset time, the sequence control timer actuates the Distributor valve to reverse the tower function . For lower capacities, the distribution valve and control valve are integral units, however for higher capacity these control elements comprise of discrete control valves and orifices. Our Heatless air dryers are compact, economical, pre assembled, fully automatic, “Fit and Forget” type of units with very little power consumption of around 100 watts. For detailed offer, please indicate capacity, pressure, and source of compressed air.

Air Dispersion Dryers

Get Price Quote

This is due to our streamlined packaging system that we are able to meet the customized and standard packaging requirements of the clients. Moreover, we ensure complete safety of the products. We make use of premium material for packaging the offered lot so as to ensure safe side deliveries.

Compressed Air Dryers

Get Price Quote

Compressed Air Dryers, Air Dryer, psa nitrogen plants, oxygen plants

air tray dryer

Get Price Quote

air tray dryer, Nitrous Oxide Gas Plants, Agitated Cylindrical Vacuum Dryer

air tray dryer

Get Price Quote

air tray dryer, High Shear Mixer, vacuum transfer system, Vacuum Tray Dryer

refrigeration air dryers

Get Price Quote

refrigeration air dryers, Compressed Air Filters, Fuel Filters, Gas Filters

Air Dryers

Get Price Quote

Air Dryers, Pet Stretch Bottle Machinery, Air Dryers, Blow Dies & Moulds

adsorption dryer

Get Price Quote

adsorption dryer, Screw Water Chillers, marine cooling systems