Centrifuge Filter Bags

Get Price Quote

Ace is one of the leading centrifuge manufacturers in India with an impressive track record in meeting customer needs. Maintaining the highest quality standards and constant innovation have been the hallmarks of our enterprise. All our products are guaranteed against defective materials and workman-ship for a period of one year. The company manufactures both 3-point and 4-point centrifuges from 12” to 72” dia. in various materials of construction.

Industrial Blower

Get Price Quote

With us, one can stay assured for safe deliveries as we make use of premium material for packaging the lot. Also, we make sure that the material is sourced from the trusted places only. Based in Mumbai(India), we have gained wide appreciation owing to our high quality products and client-centric approach.

Best Deals from Air Pollution Control Equipment

K3 Silence Dust Collector

Get Price Quote

1 Piece (MOQ)

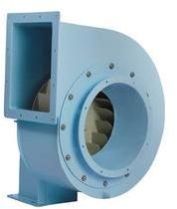

Centrifugal Blower

0 - 98,000 Per Piece

1 Piece (MOQ)

Energy efficient centrifugal blowers are designed especially for less power consumption in commercial kitchens (Restaurant/Hotels Kitchen Equipments). Fabricated by heavy mild steel sheets & plates reinforced with angle irons for sturdy support. A fan is directly mounted on motor shaft for better performance and consistent performance.

DUS 910 & DUS 915 Double Unbalanced Mechanical Seal

Get Price Quote

1 Piece (MOQ)

Suitable for a wide range of applications, Sealen engineering LLP manufactures a double unbalanced mechanical seal that is dependable and durable. Special notches increase the necessary driving torque, which makes the seals independent of rotational direction. These seals can be utilized with confidence in situations involving aggressive, abrasive, and viscous media because of their non-clogging spring construction. Additionally, our customers highly value them for their superior quality, extended service lives, exquisite finishing, portability, low maintenance requirements, and inexpensive costs. We create these items with our customers' needs for safety and security in mind. To satisfy the unique requirements of the customers, we have a cutting-edge production plant where we can create high-quality Seal and Seal Support Systems. A dedicated team of highly skilled employees that support this contemporary facility make sure that the quality and client expectations are met by adhering to worldwide standards. The professionals at our company closely coordinate their efforts to ensure consumers receive a high-quality product selection. We have assembled a group of experts. Also, our staff works diligently to eliminate workplace conflicts. The quality of our products and the affordability of our fares make us the best choice. We are compiling a lengthy list of clienteles. Our company has also established a reputable position in the marketplace through his expertise, dedication, talents, and moral business practices.

Gas Blower

Get Price Quote

1 Set(s) (MOQ)

We are offering diverse range of gas blowers with following specification: capacity : 500 cfm to 50000 cfm. we design gas blower as per client's requirement. We manufacture and supply complete air exhaust blower unit after testing. these gas blowers are manufactured in pp+frp/pph+frp/pvc+frp/pvdf+frp/frp/frv/grp etc. our impellers are dynamically balanced as per is standards. Impellers are fabricated in pp or frp. impellers are fabricated in clockwise and anti-clockwise directions as per the client's requirements. pressure and type of gas blowers are as follows type : direct drive coupling drive vee belt drive.

Air Blower

1,478 Per Piece

Centrifugal Blowers

2,800 - 3,600 Per Nos

Fume Extraction System

Get Price Quote

We follow the globally accepted packaging norms that help us in delivering the products safely. Our professionals ensure that the packing material we use keeps the product safe from external damaging factors. We are working with an aim of making available flawless lot of products and for this; we check the product quality on several grounds.

Air Filter Cages

Get Price Quote

The Air Filter Cages that are offered by us can be customized in terms of shape and size according the needs and requirements of each individual client. They have been manufactured using nothing less than the best materials that are available today. These Air Filter Cages find wide applications in air pollution control systems. These are available with us at affordable and highly competitive rates.

air bag filters

Get Price Quote

Compressed Pads manufactured from Knitted Wire Mesh are highly effective to absorb the heat, vibrations, sound. It is light weight, efficient & compact & has application in various Industries.

Electrostatic Precipitator

Get Price Quote

Activated Carbon Adsorber

4,000 Per Piece

Exhaust Air Blower

10,000 Per Piece

We are offering exhaust air blower for removing smoke, smell, fine dust from kitchen, acid industry, chemical industry etc.

Centrifugal Blowers

Get Price Quote

We are one of the successful centrifugal air blowers manufacturers. These centrifugal air blowers are corrosion resistant, having high impact strength and are easy to machine. They are manufactured using thoroughly checked, peak quality rigid PVC/Polypropylene + FRP. We provide these high working capacity multistage centrifugal blowers in variety of sizes; ranging from 500 cfm to 10000 cfm. These centrifugal blowers are user friendly and highly cost effective in operation. They are mostly used in laboratory, fume cupboards, pickling plants, electroplating industries, reaction vessels, and process rooms for corrosive, hazardous fumes removals & scrubbers. Striving at providing a prolific deal to our customers we provide these high quality centrifugal blowers on very nominal rates.

Order Absorption Column

Get Price Quote

Absorption can be a chemical or physical phenomenon. Chemical absorption and physical absorption are very different to each other and possess their own several distinct characteristics. Absorption column is used in the absorption process to make the whole process more efficient. In this procedure one substance captures and transforms the whole energy. Physical absorption is all depend on the properties of the gases like its pressure level, temperature and solubility. And chemical absorption is based on the stoichiometry of the reaction as well as the concentration of the present reactants.

dust collection machine

Get Price Quote

1 Piece(s) (MOQ)

We are offering dust collection machine. Features: long lasting inlet with single dust collection bag. Sturdy suction motor. Cloth fitter bag of 5 to 10 micron with extra paper bag. Easy to fit under work bench. Down time for replacement of fitter bag 5 minute. Pvc fitting & pipe offered with machine. Silencer for lesser noise. Locking facility. Dim : 18” dia x 18” ht.

Centrifugal Blower

Get Price Quote

Our organization is engaged in offering wide range of Centrifugal Blower SINCE 1991 which is designed in order to fulfill the requirement of various industries throughout the country. These Centrifugal Blowers are manufactured by using supreme quality of raw material as to provide cooling to combustion room in various industries such as pharmaceutical, chemical, biotech and many more. These are available in different specifications. Features: Corrosion resistance High tensile strength Spark resistance High efficiency Trouble free performance High Pressure Blowers: The High Pressure Blowers are highly efficient and appropriate for combustion of air in foundries & furnaces, glass cooling, conveying chips, smoke abatement & conveyance of gases/materials. Low pressure Blowers: Our low pressure blower is suitable for general ventilation, fume & vapor smoke & dust exhaust process, drying & cooling and also used for cleaning dusty air or material conveying.

Multi-Dust Collector

Get Price Quote

Luwa's multi-dust collector automatically adapts to varying air flow rates. It does not require any additional components and ensures that filtered waste can be disposed off properly in collection bags. The component does not require any cleaning as it does so automatically by switching off its fans for short intervals of time.

Pulse Jet Bag Filter

Get Price Quote

Karyasiddhi is one of the leading names in pollution equipment design and manufacturing. We have proved our expertise through all of the Pulse jet bag filter installations all over India. All our units are designed to operate with a pressure difference of 100-125 mm W.G. In the pulse jet bag filter as name implies dust laden gas is spreads all over the bag filter through nozzles. The continuous passage of dust laden gas leads to accumulation of dust over fabric which increases pressure drop. It is been cleaned by the compressed air, passing through the blow nozzle, at very high velocity and for very short duration. This produces a shock wave, which is propagated down the bag length, causing the bag to expand and snap away from the cage, dislodging the dust cake, which falls into the hopper. Cartridge Collector : Second type is called the “Cartridge Collector Applications • Steel Industry Blast Furnace, Electric Arc Furnace, BOF, etc • Fertilizer Industry Phosphate Rock Dryers & Calciners, Dryers • Non-Ferrous Copper Reverberatory Furnace, Laea Blast Furnace • Pulp & Paper Lime Kilns, Back Liquor Recovery, Bark Boilers • Sugar Industry Boiler Flue Gas, Bagging Section • Mineral Products Asphalt Stone Dryers, Cement Kilns • Pharmaceuticals Tablet Coating Fans, etc

Bag Filters

Get Price Quote

Bags can be extremely durable. Air filters are used for separating solid particles from air on suction side of fan, compressor machine, etc.

CENTRALISED DUST COLLECTOR FOR FOUR STATIONS

Get Price Quote

» Strong suction motor. » Pocket cloth filter of 5 to 10 micron » This machine can cater to four stations» 4” dia outlet.» Foot shaker for dusting the dust in tray.» Dim : 24” x 32” x 30” (L x B x H) SPECIFICATION : » 1 Hp, 440 volts » Also available in single phase 220 Volts. » CFM : Around 200 per station. » Sound Level : 68 db (approx) » Can be available with automatic vibrating system for filter assembly. » Vibrating motor : ¼ Hp, 220 Volts

Sugar Dust Collector System

Get Price Quote

Almost every second factory is facing serious Sugar Dust Problem, resulting in coating of dust on sugar grain due to presence of fine dust in bagging. More over the spreading of dust in Drier/Sugar hous eis not only causing serious Dust Pollution but also a sheer loss of product due to dust generated in sugar handling. The system arrest the Fine & Flying Dust, generated during drying, conveying, sizing, bagging & ensure the work area clean, free from dust build up eliminates the risk of fire and Mechanical/Electrical damages otherwise take place due to dust emission. The dust so recovered is recycled and yields additional recovery. Dust collection is a continuous and on-line process in which specially designed suction hoods are placed close to the generation of dust. The exhaust extracted by the suction hood is carried to a separation device Wet Scrubber above, through a network of ducting, finally disposed off by mixing it in recirculating water. We have successfully solved the Dust Problem as well as improved the Luster Quality of Sugar in 40 Factories.and enjoying the TREMENDOUS BENEFITS of installations. The average dust collected in almost all factories is found 125 kgs. on every 1000 quintals of sugar produced / bagged in Sugar House. We are the only top dust collector manufacturer giving the best machinery with the below features. SALIENT FEATURES OF SMB’s VENTURI TYPE SUGAR DUST COLLECTION SYSTEM: 1) High Efficiency dust collection system effectively arrest particles up to 5 micron.2) Hoods & entry to Dust collector is designed to eliminate entrainment of dust.3) Ventury type Cyclonic Wet Scrubbers are almost ideal for large amount of abrasive fine dust.4) Complete Remedy for sparks / risks of fire, frequent damages of Electricals & bearings.5) Almost 100% collection of Flying Dust, Cooling effect at Pan Station & comfortable climate.6) The State-of-the-Art Technology, Computerized Design for Scrubber & Fan for Durability & smooth performance.7) Four Important Tasks Working, Environment, Economy, Seasonal returns & Negligible Maintenance are being considered for System Design..

Fume Exhaust Systems

Get Price Quote

We at 'PULLMAN' believe that to breathe clean and fresh air is human right which is often disregarded, detioration in the quality of air directly contributes to lethargy and decrease an human performance whereas clean environment ensures better work and greater productivity. We design, manufacture, supply, install and commission following systems on turn-key basis for air, dust and fume control. VENTILATION & PRESSURIZATION SYSTEMS These systems are designed based on the area to be ventilated, heat load, number of persons in the area, type of roof, number of doors and windows for various types of industries, basement of malls to bring about desired number of air changes per hour and consist of providing fresh air supply blowers fitted with inlet filters to supply filtered air distributed through dustings controlled through grills and effectively exhausting out foul air. These systems can be provided along with evaporative cooling arrangements. FUME EXHAUST SYSTEMS These Systems are designed for exhausting out hot air, acid, alkali fumes, smoke for various industries, hotel kitchens etc. by providing guiding hoods at the source of their generation which are connected through ducting’s to Centrifugal Blower which creates negative pressure whereby fumes, smoke are sucked and are scrubbed in scrubbers or thrown into atmosphere. These systems are supplied in M.S., S.S., PP, FRP and Rubber Lined Constructions. DUST COLLECTION SYSTEMS These systems are designed for various dust producing machines for different applications by providing guiding hoods, ducting’s, blowers connected to cyclone separators/ bag filters for collection of dust from different points and areas to a single source where the dust is collected. The dust collection system shall consist of a Centrifugal blower which shall create negative pressure whereby dust emitted shall be sucked and collected at the bottom of cyclone separator placed after the blower. AIR CURTAINS Pullman manufacture heavy duty air curtains to form a efficient air barrier to prevent air, dust, flies, insect from entering a particular area even though the doors and fully open & vice-versa for preventing air conditioned air from escaping.These air curtains are available for door width 3', 3.5’, 4', 5' & for bigger door width multiple air curtains are fitted on the doors.

centrifugal steel smoke exhaust blower

Get Price Quote

STAINLESS STEEL FILTER BAG CAGE

Get Price Quote

Shakti Fabricators offers a range of Stainless Steel filter Bag cage in a variety of shapes and specifications to choose upon. These bags are manufactured in bulk and comply with the all industry specifications and standards. FEATURES 10 Wire Filter Bag Cages Carbon Steel Bag Cages Split-Section Cages 12 Wire Bag Cages Galvanized Bag Cages Corrosion Resistant Cages Special Coatings & Finishes High Pressure Bag Cages Bottom Removal 20 Wire Bag Cages Stainless Steel Bag Cages Top Removal Heavy Duty Filter Cages Reinforced Filter Cages Manufactured Bag Cages Standard Bag Cages

Electrostatic Precipitator

Get Price Quote

The company is a preeminent Manufacturer, Supplier and Exporter of Electrostatic Precipitator. We manufacture the Precipitators using the latest technology in compliance with international quality standards. Precipitators we make available feature unique space saving modular design. Bulk orders of the machines are processed by us as per the specific requirements of the buyers. Why to invest in VT CORP’s ESP? VT CORP is a leading manufacturer of Electrostatic Precipitators (ESPs) with more than 200 installations in varied industries like sponge iron, power plant, Paper mills, co-generation plant in Sugar Industry etc. in India and abroad. Complete gas cleaning solution including Electrostatic Precipitators (ESPs) and Forced draft coolers (FD Cooler) on turnkey basis customized to suit your requirements. Backed by team of Designers having vast years of experience in designing world class ESPs. Service Network across the country. We are catering to all manufacturing and process industry with all size range for electrostatic precipitator. We have entered into collaboration with M/s. Envirotherm GmbH, Germany, Allied Technologies Group Company for ESPs in thermal power plants. You may be aware that M/s. Envirotherm GmbH has taken over environmental division of LURGI GmbH, Germany who are the leaders worldwide in providing ESP technology & have more than 13,000 installations globally. Salient Features of V T Corp’s ESP : Unique space saving modular design. Self adjusting pendulum design structure which eliminates the use and maintenance of bridge bearings. Trapezoidal design of collecting electrodes to facilitate more efficient dust collection. Specially designed ‘X’ type gas distribution plates based on fluid dynamics to ensure uniform distribution of gasses throughout the ESP. Varying design of discharge electrodes in different fields to achieve optimal current/voltage characteristics. Trusted tumbling hammer type rapping system. Some of the applications for Electrostatic Precipitators : Power and production plants for cement and limestone (mills, kilns and coolers) Coal and oil-fired boilers, coal mills and coal driers. Incinerators. Power plant boilers in power generation plants. Co – gen plants in sugar and pulp and paper industry. Biomass fired boilers in renewable energy industry. Various exhaust applications in steel processing plants.

Gas Filter Housing

Get Price Quote

BAGACILLO SEPARATOR

Get Price Quote

The Hydrocyclone based Bagacillo Separator is installed for MJ degritting and crush remival after DSM screen and before weighment for obvious advantages of low cost, high return on investments. Our latest design is very effiecient, economical and designed for capacities 1850 TCD to 10,000 TCD Plants, with complete construction in SS 304/SS 316. Our sophisticated engineering ensures longer life, leak proof operation seasons after season and Nil maintenance by virtue of no moving parts and guaranteed removal of grit and bagacillo from screen juice. PROCESS ADVANTAGES: a) Guaranteed removal of fine grit Bagacillo 10,000 kgs / 100 TCH / Day.b) Bagacillo content in juice not exceeding 1.5 - 2gm / litre.c) Increased efficiency of clarification / JH / Evaporator, hence permitting higher through put.d) Improved recovery of sugar due to less mud volume.e) Less load on Rotary Filter due to reduction in mud volume.f) Less steam consumption due to better heat transfer as less scaling in tubes.g) Less consumption of SO2, lime, viscosity reducer and other chemicals due to less bagacillo in MJ thereby eliminating colouring salts during Juice Boiling.h) Improved Crystallisation in Pans and reduced choking in Centrifuges. ECONOMIC BENEFITS: 1) Production of sparkling white sugar, additional revenues due to higher selling price.2) Extra revenues of Rs. 5000/- pe day (3000 TCD) on sales of Bagasse, saved from mud.3) Lower production cost due to savings of chemical, steam and less mechanical damages of pumps impellers / screens and less maintenance of machines and equipments.4) Higher sugar production due to sugar saved in press mud.5) Quick payout of full investment in 50 to 60 days of crushing on account of 1 to 4.

fluid bed dryer bag

Get Price Quote

The operation of the fluid bed dryer is very simple whereby the drying of the material takes place by forced air circulation inside the chamber. The atmospheric air is drawn through the air micron filter by a specially designed blower mounted on the top of the dryer. The clean air then passes through the heating elements (electric cheater steam thermic fluid radiator) to reach the required temperature. The hot air then passes through the product container and the product gets dries faster by air fludization. The air circulation is controlled by means of dampers. A Filter bag provided inside the drying chamber prevents the finest of particles of the material from entering the air stream. The main chamber is provided with on explosion flap to protect against pressure buildup inside the chamber. Digital temperature controller for the inlet air and temperature indicator for the outlet air comes as a standard. Higher capacity models are provided with automatic operation like automatic bag shaker timer, pneumatic damper (butterfly valve) operation, process timer, sampling valve with bottle, etc is provided as a standard. Fully automatic operation with data logging through a PLC is provided as an option.