ZXS Heavy Duty Shredders

ZXS – Heavy Duty Shredders The ZXS shredders have been designed for the most demanding and high throughput applications in recycling industries. The input materials can be all kinds of plas- tics, wood, paper, cardboard, e-waste, post consumer waste, rubber, etc. in various shapes and sizes. Typical input materials are: fridges, purges, tires, pallets, bales, drums and barrels, pipes, film and so on... Advantages of the ZXS Single Shaft Shredders Low speed, high torque gear drive Powerful two speed hydraulic swing type pusher Heavy Duty design+ High throughput rates Suitable for very large and heavy parts Big diameter rotor (750 mm)

...more

ZSS General Purpose Shredders

ZSS – General Purpose Shredders The ZSS shredders have been designed for a wide array of applications and industries such as in house and general recycling, electronic waste and post-consumer waste handling with a wide variety of input materials. Depending on input material and the following process the shredded material can be used directly or go into the next step of size reduction for example in a GSH granulator. Advantages of the ZSS Single Shaft Shredders Low speed, high torque gear drive Powerful hydraulic swing type pusher Proven well engineered design Smaller footprint compared to traditional shredders with horizontal pushers Bolted in drive shafts Multiple rotor designs and materials Two speed hydraulic comes standard

...more

ZRS Pipe Shredders

ZRS – Pipe Shredders The main focus of the ZRS shredders is the shredding of large diameter pipes or bundles of smaller pipes and profiles made from HDPE, PP and all kinds of PVC. Further the machines can be used for recycling of other plastic parts, such as large lumps, stacked wheelie bins and pallets. In combination with other ZERMA size reduction equipment such as granulators and pulverizers we are able to provide a complete turn key recycling solution. Advantages of the ZRS Single Shaft Shredders No pre cutting of pipes of up to 1200 mm diameter necessary Virtually risk free, automated operation Elimination of amperage peaks High throughput rates Feeding of bundles or nested pipes and profiles Big diameter rotor (up to 1500 mm)

...more

ZIS Big Volume Shredders

ZIS – Big Volume Shredders The ZIS shredders have been designed with big volume parts such as IBCs, pallets and big barrels in mind. While it can be used for in house recycling in big volume blow moulding operations it is also versatile enough to be used for general recycling in the plastic and wood industry. Like all ZERMA shredders the ZIS can be equipped with a wear package for processing of highly abrasive or filled materials. Advantages of the ZIS Single Shaft Shredders 35% more internal volume compared to the ZSS series Internal hydraulic pusher Variable faster pusher movement Smaller footprint compared to traditional shredders with horizontal pushers Closed cutting chamber to avoid material spillage All advantages of the ZSS series

...more

washing lines

Output: from 500 up to 6000 kg/h Continuous process, not based on batches, with a substantial saving of water. The flakes produced are suitable for the following applications: Bottle to Bottle Bottle to Packaging Bottle to Fibres Bottle to Sheet Bottle to Strapping

...more

Vibrating Sieve

Our vibrating sieve can be used to separate materials into various sizes for further processing. Main Features of Vibrating Sieve High efficiency Compact and durable design Easy to change screen, operate and to clean Automatically discharge impurities No mechanical operation, easy to maintain Can be used as single or multi-layer Stainless steel for whole unit

...more

Vertical Injection Moulding Machine

V-S Series Clamping Force: 35-250Ton Vertical clamping, vertical injection, easy to insert S-single slide table (1 upper mold, 1 bottom mold) In-Out table design, more convenient.

...more

Vertical Cooling Mixer

Our vertical cooling mixer has good function in storage, drying, cooling and even Vertical Cooling Mixerspreading. Double layer cooling cover is available upon customers’ requirements. Main Features of Vertical Cooling Mixer Direct driven decreases the rate of maintenance Boiler with interlayer is good for heat conduction Stainless steel cover is convenient to open and close Polished interior wall of boiler is easy to clean Unique cooling function of the cooling cover can enhance the processing capacity

...more

Valve-gate systems

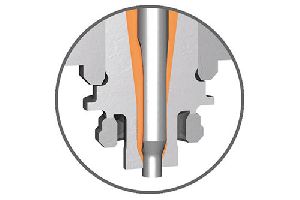

The modular nozzle design allows a rapid replacement of components when required. The two-component shaft (patented) with varying design features assures excellent insulation in the front area of the shaft and the least possible loss of heat between the hot runner nozzle and the cavity. Where requirements are high in terms of appearance, reduced cycle times, minimum shear stress and large gate cross-sections, valve-gate technology provides the solution. Replaceable Valve Pin GuidesThe new innovative design of the contouring needle guide and the optimised valve-gate needle allow non-contact and low-wear gate closing. The PM needle guide made of metallurgical powder steel ensures economical and virtually wear-free operation. While closing the needle is first centered through a tapered guide until it lowers precisely into the cylindrical guide. Another advantage is the separation of needle guide and material tube, which means that any necessary change of needle guide is a simple procedure. Gate diameters of 1.0 mm to 4.0 mm are selectable. Type LAThe needle is centred by means of a conical guide, until it fully and precisely enters the cylindrical guide (to the axis of the gate bore). Advantages: Long service life, since virtually no wear Replaceable needle guide Needle guide immerses to the article and is contour-shaping Recommended for wearing materials By exchange of the PM pieces, the optimized shut-off needle can enlarge or reduce the gate Ø without reworking the mould nest. The exact needle guide achieves a virtually wear-free seal and a clean gate without burrs. Tightest tolerance between the needle guide and the gate.

...more

Industrial Tire Recycling Shredders

A complete ZERMA tire recycling system consists of 5 main components The ZXS Pre-shredder shreds the complete tires down to a size of around 150 mm The ZTTS Intermediate shredder cuts the tires down to a size of

Country of Origin : India

Type : Tyre Recycling Machine

...more

Tyre Debeader

The Tyre Debeader removes the beads from radial truck tires. Operation of the unit makes it a natural for shredding operations. Removal of the bead wire prior to shredding allows for a cleaner end product and provides less wear on the moving parts of the shredder. This not only provides a smooth shredding operation, but also cuts down on expensive maintenance down time. General Features Stationary, horizontal, electrically operated Manual feeding Constructed from heavy gauge steel metal sheet with reinforcing structure Equipped with necessary electrical-hydraulic control, necessary guards and protections for safe operation The supplier shall install, test, commission and operate the machine and train the needed staff. Suitable for passengers, medium and heavy trucks tyres, and adjustable tyre sizes by altering the location of knifes relative to the supporting grip wheel.

...more

Two Roller Mill

Two Roller Mill This two roll miller is an ideal option for mixing, sample sheet making for color check. Main Features of Two Roller Mill Robust design Two independent PID constant temperature control for the two roll Roll surface is quenched and chromate, supported by graphite self-lubricated bearing Anti-corrosion painting

...more

Thin Thermoforming

We offer thin thermoforming. He new thermoforming machines by amut: a complete manufacturing programme in-line systems

...more

Temperature Controllers

Control Technology for Hot Runner Systems: Safe and Comfortable 1, 2, 3, 5-channel temperature controllers DP1, DP2The compact controllers for economical and comfortable control of small hot runner systems. Total connected value 1-phase 230 V 16 A Fuzzy PID control behaviour Set / actual display for each control point Gentle softstart function Pulse group control Power limitation Temperature reduction during production breaks Regulated operation in case of failed thermal probe possible Counter for hours of operation Continual error monitoring Multi-channel temperature controllers DPT5, DPT10, DPT15, DPT20, DPT45The multiple controllers of the DPT series offer extensive functions for the safe control of complex hot runner systems. Four selectable temperature programs Fuzzy PID control behaviour Gentle softstart function Control-TechnologySet/actual display for each control point Limited power during start-up Start-up ramp for even heating of different heating circuits Phase control and pulse group control Temperature reduction during production breaks possible Regulated operation in case of failed thermal probe possible Diagnostic function for detection of wiring errors Up to 3500 W per control zone Counter for hours of operation Continual error monitoring Connectors of thermocouples and heating elements physically separated Retrofitting of up to 15 control zones is feasible Optional with serial interface for connection of injection moulding machines by ARBURG, ENGEL, KRAUSS-MAFFEI, FEROMATIK, etc. Multi-channel temperature control cabinet DPT multi zone for operation with multiple tools with a high number of cavities. This new development especially for the operation of multiple tools with a high number of cavities offer a comprehensive range of functions: Expandable from 40 up to 150 control circuits (in steps of 5), the LCD touch-screen display guarantees the simplest operation for highly complex tools. The control is executed by means of a Windows software. Graphic tool display with freely moveable display fields. Full-text error messages. Log files for monitoring errors and status. Possibility of managing two tools separately. Print function for temperature records. Various remote maintenance possibilities via standard PC interfaces. Controller eValve-4The controller "eValve-4" is able to control up to four bistable electromagnets, which are used for nozzles with needle valve. The electrical lift magnets generate a mechanical lift of 10 mm. The two end position are fixed with permanent magnets. Electric power is only used for changing the position of the magnetic fixed lifting cylinder.

...more

Telia Maxi (Gearless Presses)

Telia Maxi is the latest development of the FSC (Fast Sleeve Change) system applied to our gearless technology. Main features: Totally interchangeable printing decks with identical mechanical components for each deck to simplify maintenance; Dual high precision linear guides; Step-by-step motors to repeat every position previously recorded; New self-cleaning pneumatic doctor blade chamber; "FSC" system for sleeve change and rapid deck opening with horizontal movement; Integrated automatic deck wash-up system; Air Recirculation Bridge to increase drying efficiency; Motorised bridge threading and passage; Automatic Pressure and register control system; Electrical equipment in climate controlled container. Technical Data: Number of decks : 6/8/10 Useful printing width : up to 2.800 mm (87") Anilox and plate mandrels : carbon fibered Minimum print repeat : 350 mm Maximum print repeat : 1.100 mm (43") - 1.250 mm (49") - 1.400 mm (55") Mechanical speed : up to 450 m/min

...more

Telia FSC (Gearless Presses)

Telia 8 FSC is the latest development of the FSC (Fast Sleeve Change) system applied to our gearless technology. Main features: Totally interchangeable printing decks with identical mechanical components for each deck to simplify maintenance; Dual high precision linear guides; Step-by-step motors to repeat every position previously recorded; New self-cleaning pneumatic doctor blade chamber; "FSC" system for sleeve change and rapid deck opening with horizontal movement; Integrated automatic deck wash-up system; Air Recirculation Bridge to increase drying efficiency; Motorised bridge threading and passage; Pressure and register remote control; Electrical equipment in climate controlled container. Technical Data: Number of decks : 6/8/10 with or without in line roto or flexo units Useful printing width : up to 2.200 mm (87") Anilox and plate cylinder : sleeve type Minimum print repeat : 300 mm Maximum print repeat : 900 mm Mechanical speed : 500 m/min

...more

Stretch Film PE based

AMUT DOLCI BIELLONI delivers Stretch Film Lines from 3 to 7 layer configurations (as standard configurations) or with Micro layer / Nanolayer technology (27 - 31 or more layers). Net width available is from 1 up to 4 meters, for net productions up to 2300 kg/h. Design of new screw profiles to comply with newly introduced resins and film formulations. New generation of high-speed automatic winders, capable to reach 1000 m/min speed WINDERS High speedAutomatic winder for hand and machine rolls, bleeded or bleedlessAutomatic robotized winder for machine and Jumbo Rolls, bleed or bleedlessAll winders with automatic re-coring and cores storage Automatic winders for HAND, MACHINE and JUMBO rolls.

...more

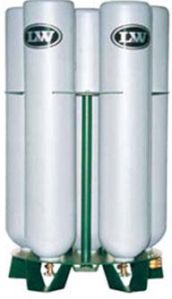

Storage tanks Compressor Accessories

Storage tanks are frequently used to provide extra filling capacity during peak periods. The storage cylinders can either be opened „all at once" in a single stage, or „cascaded" into the cylinders to be filled, usually in 3 stages. Ideally the storage pressure should be higher than the filling pressure, 300 bar storage systems are the most common. The storage systems can be used with most compressors and are best suited for automatic operation (e.g. ECC or auto start option). L&W has a full range of storage modules each of which can be combined with other modules for individual configuration.

...more

Solar Line Extrusion

EVA, Ethylene-Vinyl-Acetate, is the type of material produced with AMUT’s extrusion foil line and it is especially reserved for the production of solar-photovoltaic panels.EVA foil protects the photovoltaic cell, encapsulating and wrapping the silicon cells, and enables a perfect sealing and a high adherence with the outer glass sheet and with the back-sheet (lower layer). The EVA foil delivered with AMUT lines assures: The maximum light transmission; The absence of deformations or shrinkages; A great capacity to achieve a good cross-linking level (necessary to end the panel lamination very quickly); The satisfaction of TÜV or CEI EN 50086 certificates requirements. All units of the line are purposely designed for this application and to not compromise the foil dimensional stability. There is not cross-linking during the extrusion process. The innovative winding system can wind-up, directly in-line, the foil in reels or permit to laminate in-line a separating film sheet (mask film) or a silicone paper foil to protect EVA foil completely.

Width : 1.050 - 2.100 mm

...more

Single stage extrusion coating lines

Single stage extrusion coating lines for the production of coated paper, coated non-woven/woven webs for food packaging, industrial application and disposable items. Single stage extrusion coating / laminating lines for the production of paper / PE / alufoil webs or BO films / PE / Metallized BO films for pharmaceutical, cosmetic, industrial or general applications. Double stage extrusion coating / laminating lines for the production of complex-multicoated webs for pharmaceutical, cosmetic, food pack, industrial, sanitary and insulation industry. Tripe stage extrusion coating / laminating lines for the production of multilaminated paper board for UHT aseptic (liquid) packaging. Production Range:Line width: from 800 to 2500 mmLine speed: up to 200 or up to 500 m/minRolls diameter: from 800 to 1600 mmExtrusion dies: Non-automatic or automatic with external or internal deckling systemExtruders size: from 55 to 180 mmRange of up-stream / downstream accessories: Corona or flame treater, ozonizing bars, reversing bars, primer stations, single or differential gauge controls, in-line flexo printing stations, in line creasing stations, video camera and web inspection instruments.Type of unwinders: semi-automatic or automatic turret type (flying spice), butt-splicers shafted or shaftless Type of rewinders: contact type or automatic turret type with in-line multi-slit station, shaftless or shafted

...more

Shredder

We offer shredder. The zss shredders have been designed for a wide array of applications and industries such as in house and general recycling, electronic waste and post-consumer waste handling with a wide variety of input materials. Depending on input material and the following process the shredded material can be used directly or go into the next step of size reduction for example in a gsh granulator.

...more

Semi-automatic Socketing Machine

Second Hand Extrusion machines

Next Machines offer over 400 extrusion machines and downstream machines made by GRAEWE and other manufacturers. Tested quality from the market leader: Ensure Tender, advice and quality check in all respects when purchasing extrusion machines. Assured that the wear parts of every machine have been renewed and the most important aggregates have been overhauled or replaced, this means tested quality from the market leader. Large choice and fast availability: The extrusion machines form an important part of process cycle. An unexpected failure can have grave consequences for production. To prevent this, one of the mainstays of our range of services is fast availability. From a range of more than 400 extruders and extruder downstream equipment, select the type that is exactly tailored to your purpose at a reasonable second-hand price.This will make decision-finding process easier for projected purchases. For us it is important not to deliver the extrusion machine before the machine has been submitted to an all-inclusive professional inspection, to a thorough servicing, and not before any repairs that were required have been completed. Our Service Comprises, Among Other Points:· Overhaul, respectively replacement of screw and cylinder· Replacement of melt pressure and temperature sensors· Replacement of the sealing packages and gas removal pumps· Replacement of heaters· Overhaul of the motor· Checking of the gears· Gear oil change· Oil filter change· Replacement of the V-belts Our Special Next Service Comprises:· Finishing customized to client’s colours· Trial run· Recording of the output capacity. Universal experience for individual solutions: Over the past 20 years Next Machines sold well over 4000 second-hand extrusion machines and have become an established market leader in this market segment. Every single installed system differs a little from the next - and all the experience and know-how gathered over the past two decades will flow into an individual solution for your special requirements. And, because the special details often become so very important, it shall be our pleasure to invest some more time in consultation and advice. To get notification and updates on New Second Hand Machines simply fill in the form given below. You will receive appropriate details in your inbox shortly.

...more

screws barrels

Screws Barrels Harden Industries Ltd. provides feed screws and barrel for Extrusion, Injection Moulding & Blow Moulding Machine of any make. Founded in 1990, Harden Industries Ltd. is the premier designer, manufacturer and rebuild of feed screws and barrels in china for the plastics, medical, rubber and food industries. Harden has supplied feed screws and barrels to some of the major plastic processing machine manufacturers in China and around the world. Harden Industries strive to exceed client expectations with their products and services. Product Characteristics: Choice of Proper Metallurgy Cost Effective Product: Comprehensive pre- planning ensures all works is done in the most cost-effective manner to produce totally cost effective product Trouble free Performance: Detailed post manufacturing inspection assures products ready for trouble free performance Broad Range of Application: Harden has the expertise to design feed screws and barrels with various material of construction to match the expectations of broad range of applications Harden provides high surface area and low shear screw design which optimizes the homogeneity of the melt, maximizes the productivity of the extruder, and provides long lasting life for both the screws and barrels. Products Range Includes: Single Extruder Screws and Barrels: Ø 15 mm- 300 mm, L/D Ratio: 15-46 Conical Twin Screws and Barrels: Screw Diameter (Smaller End) 35-92 mm Parallel Twin Screw and Barrel: Ø 50 mm- 180 mm, L/D Ratio: 16-35 Bimetallic Screw and barrels: ID Ø18 mm- Ø300 mm, Max. Length: 5000 mm Screws and Barrels for Injection Moulding Machine: Clamping force 25kN- 32,000 kN, Injection Weight 30g-25,000g

...moreBe first to Rate

Rate ThisOpening Hours