Zero Hold Up Filter Press

90,000 Per Piece

We are instrumental in providing our clients a comprehensive range of excellent quality Zero Holdup Filter Press Manufacturer In India. Our complete range is designed with top quality of material in accordance with the market norms. Product range Alpro Equipments is a specialty of manufacturing and suppliers all kind of range Zero Holdup Filter Press. Alpro equipments has been actively involved in Zero Holdup Filter Press Manufacturer, which are widely used in Pharma, bulk drugs, distilleries, beverages & varies industries. we are supplier, export and zero holdup filter press manufacturer in india. our product are perform high with low maintance, alpro equipments team are expert to design and fabricate of best Zero Holdup Filter Press with industrial standard. Features of zero hold up filter press: Low noise operation. High output results. Consume less power. Description: Zero hold up Horizontal plate closed pressure filter that meets all the demands for a filtration which would discharge solid free filtrate. Design of filter press is according to cGMP & FDA approval. Other Details: Components are argon arc welded & polished to mirror finish SS jacket can be provided for hot filtration. (Optional) Provides crystal clear filtration by filtering particles up to 1 micron size. No Scavenger arrangement is required No liquid between the tank & the cartridge Top dome structure ensures fast & easy removal of cartridge assembly & cleaning of cake Uniform filter aids & cake distribution SS pump mounted on SS trolley with heavy duty trust ball bearing caster wheels for easy movement Provided with different types of pumps depending on the viscosity of liquid & output i.e. Centrifugal pump, Gear Pump, Lobe Pump, Roto Pump Etc Provided with bypass system, safety valve & sample collecting device No contamination of internal surface of the shell Horizontal plate Zero Hold Up filter press is constructed in such a manner that it prevents evaporation,Oxidation, Leakage & Fumes escaping from product Plates are available in two sizes: Deep plate for higher percentage of caking holding capacity & shallow plate for lesser percentage of cake holding capacity Filter plate & thickness of cake prevents the cake dropping as well as cracking, thus assuring better filtrate quality According to requirement filtration area & cake holding capacity can be increased or decreased

Color : Silver

Driven Type : Electric

...more

Volumetric Filling Machine

450,000 Per Piece

Containers moving on S.S. Slat conveyor, feed below the filling nozzles through a settable twin pneumatically operated stopper system. The twin pneumatically operated stopper system and reciprocating nozzles can precisely match for centering of container below nozzles, to avoid spillage of liquid on container. To minimize foaming adjustable nozzle will reciprocate according to filling dose, nozzle will go upwards from bottom level of bottle towards neck during filling. “No container-No filling” system arrangement is standard features of the machine. The motor for filling is servo drive and conveyor drive is AC Motor with synchronized variable AC Frequency Drive. PLC Controller provided to set fill volume, speed of conveyor and set fill timing this means fill size can be easily set.

Type : Volumetric Filling Machine

Certification : CE,ISO 9001-2015 Certified

Weight : 100-1000kg

Color : Silver

Voltage : 220V,440V

Condition : New

Automatic Grade : Automatic

Power : 1-3kw

Warranty : 1year

Country of Origin : India

Driven Type : Electric

Brand Name : AET

...more

Vibro Sifter

85,000 Per Piece

Vibro separators are circular unitary gyratory screens used to separate mass composition of solids from solids, liquid from solid and for gradation of materials as per particle size, having a very wide range application.This is accomplished by vibrating the screens in three different planes along the vertical axis by means of a specially designed vibratory motor having off centered weights at the top and bottom end of the motor shaft. The top weight causes vibration in the horizontal plane which causes the material to move across the screen towards the periphery. The lower weight acts to tilt the machine which causes vibration in the vertical tangential axis. The angle of lead of the lower weight with relation to the upper weight provides variable control of the screening pattern. Thus the material moves across the screens and also in the vertical and tangential planes enabling maximum screening. Vibro sifter is available with a wide range of possible screen sizes (mesh) Option for multiple deck separation is also possible. The sifter unit consists of Specially designed vibratory motor to run on 400/440V, suitable HP, 3 phase, 50 cycles electric supply, with adjustable eccentric weights at the top and bottom of the motor shafts mounted vertically at the center of the base plate of screening unit. Screening unit consists of SS 304 screen sandwiched between SS 304 hopper and bowl with the help of special clamp with gasket. This, in turn, is clamped to the base plate. Rugged Springs placed over the circular motor base amplify the vibration and at the same time restrict the vibration from being transferred to the floor.

Color : Silver

Automatic Grade : Automatic

Power : 1-3kw

Driven Type : Electric

Warranty : 1year

...more

Vacuum Tray Dryer

950,000 Per Piece

Vacuum Tray Dryer comprises a precision designed and highly functional range of Vacuum Tray Dryer (VTD) that find suitability in the drying of thermal sensitive materials under higher temperature. Coming with the possibility of sterilization prior to the drying process, these static vacuum dryer eliminates configuration damages of drying materials and is suitable for use in industry sectors like pharmaceutical, chemicals, and foodstuff.

Certification : CE Certified, ISO 9001:2008

Application : Pharamaceutical

Color : Silver

Voltage : 380V

Warranty : 2years

Country of Origin : India

...more

Steam Tray Dryer

110,000 Per Piece

1 Piece (MOQ)

This Steam Tray Dryer has working capacity of 400-500kg/h. As we have an efficient supply chain network, our company is able to fulfill bulk orders with ease and make deliveries on time. Safety of the products is the prime concern of the organization. Thus, we store the entire lot in a capacious and well-structured warehouse till the delivery of the orders. Details : Construction : external - 2mm thkinternal:2mm thkmoc: cgmp Surface finish : external - buffed to 150 grit matt finish internal: buffed to 220 grit mirror finish. Inlet & outlet : all dryers have a 5 micron pre filter r at the inlet and a manually infinite adjustable damper at the outlet. Door : doors at provided at the front and or rear side of the tray dryer. Door lips are lined with silicon rubber gasket to prevent any leakages. Suitable locking is provided for the doors. Air circulation : air circulation is done by specially designed recirculation blowers inside the tray dryer. The blower capacity, static & design depends on the size and model of dryer. Heating : dryers are normally supplied with either steam electric thermic fluid hot water heating system. Suitable heating coils clarifiers are provided in the dryers. Temperature control : temp control system is done by electronic digital temp controller fitted in the control panel. The temp control in the dryer is fully automatic. Trays : trays are available in s.s. 304 316 q. All trays are fully die pressed and with cooved corners. Trays are buffed to mirror finish. Trays are also available in aluminium polypropylene frp m.s. Galvanized as per clients requirements. Trolley : trolley is provided in the dryers to accommodate trays in it. Trolley truck are used to load and unload the trays into the dryer. Control panel : automatic control panel is fitted on the side of the dryer. If consists of starters, contactors, safety relays, ckt breakers, indicating lamps, push buttons , timers, controllers etc.

Material Grade : SS 316/304

Electric Supply : 3phase

Material : SS

Finishing : Polished

Condition : New

Power : 15kW

Power Source : Electric

Usage : Pharmaceutical Industry

Certification : ISO 9001:2008

Voltage : 440V

Display Type : Digital

Dryer Capacity : 60-100Kg Per Batch

Tray Size : 16 X 32 X 1.25 Inch

Batch Size : 100kg

Type : Tray Dryer

Weight : 300kgs.

Frequency : 50-60Hz

Phase : Three Phase

Warranty : 1 Year

Country of Origin : India

Max Temperature : 220

Heating Media : Electric

Air Heating Area : Yes

...more

stainless steel coating pan

135,000 Per Piece

We make available Stainless Steel Coating Pans in assorted sizes. Assistance from skilled professionals and brilliant packaging unit has enabled us to meet specific requirements of the clients. Besides this, we make sure that the material used for wrapping them is of high quality. We have a large infrastructure facility, parted into different segments and one of them is warehouse wherein we maintain a large stock for meeting bulk requirements of the clients.

Material : Stainless Steel

Application : Lab

Color : Silver

Feature : Rust Proof

...more

Semi Automatic Auger Filler

110,000 Per Piece

Semi-Automatic Auger Filler Machines is used for stuffing Machine. Auger product is also known as partial automated powder product which is used to complete precise body weight size powder in containers and pockets. This product is powder filling devices which is set to complete various types of powder. Semi-Automatic Auger Filler Machines is used for stuffing Machine. Auger product is also known as partial automated powder product which is used to complete precise body weight size powder in containers and pockets. This product is powder filling devices which is set to complete various types of powder. Auger filler is considered as the best available filling of powder product. Powder filling device is majorly usable for filling no cost streaming grains and non no cost streaming grains Models of Auger Filler: The sizes available include 12 inches, 16 inches, 18 inches, 20 inches, and 24 inches. Applications : Pesticides Pharmaceutical Talcum Powder Bottle Mineral Water Bottle Pickle bottle Soap Welding rods Shampoo

Weight : 1000 kg

...more

Rotary Tube Filling Machine

650,000 Per Piece

Alpro Equipments are the Rotary Tube Filling Machine Exporter In India. We have been engaged in offering an extensive range of Rotary Tube Filling Machine Exporter can fill different type of tubes including Cosmetic Creams, Pastes, Honey tube filling machine, Gel tube filling machine, Gum tube filling machine, Balms tube filling sealing machine, Ointments into the Lami / Plastic tube. We supply many Rotary Tube Filling Machines Exporter for plastic and lemi tubes. These machines have variety of filling nozzles to suit the particular type of product being filled. Technical detail (Good Quality) Stainless steel 316 hopper with capacity of 30kg. No tube no filling process preventing wastage of material. Mechanism Indexer Sealing with hot Air imported “Lister” Switzerland make 1hp air blower. Air function Filling syringe with machine5grams-30gm Gear box 30 Ratio Twelve station Cup Holder Fabrication stainless steel cup Covering Contact parts stainless steel 304 Pneumatic operated special sealing jaws Batch coding with inter Changeable digits Tube terming option for easy mobility Charge id Applicable if Different sizes are required depending upon the tube size. One size of Tube holder Cup is provider with the basic machine for different tube Size holder additional charge applicable

Type : Filling Machine

Brand Name : AET

Filling Range : 5-60grms.

...more

Ropp Cap Sealing Machine

35,000 - 300,000 Per Piece

We are engaged in manufacturing Semi ROPP Cap Sealing Machines that are widely known for their robust industrial level performance.

Condition : New

Packaging Type : Bottles

Automatic Grade : Automatic

Driven Type : Electric

Material : Metal

...more

Rapid Mixer Granulator

375,000 Per Piece

Our Rapid Mixer Granulator Manufacturer is designed to achieve excellent mixing and consistent granules at lower operating cost along with higher productivity. Alpro Equipments is well known organization for Rapid Mixer Granulator Manufacturer In India Rapid Mixer Granulator exporter in India, our experties are manufacturer, supplier and exporter of rapid mixer granulator, Rapid Mixer Granulator is designed to suit the requirements of Pharmaceutical and Chemical Industry. Mixing Bowl & Cover : S.S. 304 bowl design in three sections i.e Flat bottom, Cylindrical mid portion and conical top portion for efficient mixing operation & provided with counter balanced lid. Lid provided with vents, view ports & charging openings. Main Impeller & Drive : The main impeller consists of dual speed 750/1500 synchronous dual HP TEFC motor, coupled through a belt drive to a worm reduction gearbox with chain coupling. The impeller is designed to provide mixing at the bottom and at the centre of the bowl and is driven through a specially designed bearing housing that facilities inside wash facility for quick change over and also prevents leakage of powder from bottom entry and leads to longer life of gear box. Chopper : The chopper drive consists of dual HP Dual speed (1440/2800 synchronous speed) TEFC MOTOR. The motor shaft is of S.S. and the chopper has specially designed 4 blade S.S. Impeller. The shaft is integral with the motor. The assembly mounted horizontally into the bowl. Discharge Port : The discharge port is mounted horizontally into the bowl with vertical downward opening. The opening is operated by pneumatic cylinder and discharged can be regulated for required opening. Mounting : A sturdy M.S. channel frame is used to house the drive assembly at the bottom. The bowl is mounted on the top. A S.S. staircase and railings are provided for the platform. The platform is half covered with S.S, dimpled plates. For safe movement of operator and the area under the bowl is covered with S.S.

Type : Rapid Mixer Granulator

Certification : CE Certified,ISO 9001-2015 Certified

Condition : New

...more

Planetary Mixer

300,000 - 1,000,000 Per Piece

The planetary mixer is an industrial equipment conceived/made to prepare food, chemical, ceramic dough or other type of product, replacing manual labor through a mechanical system that allows to produce, continuously, large quantities of dough. Discription : Bowl for ingredients placement Mixing element (whisk, hook, flat beater, scrapper or other system) Motors that start the bowl and whisk movements Interconnection of technological process that allows to the operator the control of the mixing process and other labour process (programming times and speeds; mixing elements) The name “planetary mixer” comes from the system used in the equipment that mixes the dough in the planets rotation direction. The planetary mixers Ferneto are ideal to produce pastry products such as emulsions, creams, batters and other sophisticated desserts witch require larger, faster and powerful rotation movements. The range of the planetary mixers Ferneto include an extended equipment set of, suitable for small and large productive bakery and pastry units as well as other food units (catering, hospitality and similar industries). This equipments are available in standard, stainless steel and marine version. The main differences are based on: construction structure, raw material and esthetics features. Do you want home made products with the added value of a machine? Are you looking for an equipment that can assist you? Do you want productive performances keeping higher quality standards? Find out the planetary mixer and know how to improve the quality of your production.

Type : Planetary Mixer

Brand Name : AET

Certification : CE,ISO 9001-2015 Certified

...more

Lab Model Ointment Manufacturing Vessel

150,000 - 350,000 Per Piece

Country of Origin : India

Material : Metal

Shape : Cylinder Shape

Certification : CE Certified, ISO 9001-2015 Certified

Color : Metallic

Feature : Anti Corrosive, Low Maintenance

Condition : New

Working Temp : 50-100 Deg C

Warranty : 1year

...more

Ointment Manufacturing Plant

1,150,000 Per Piece

1 Piece(s) (MOQ)

Application Lotion / Cream Creams Delicacies Hair Cosmetics Products Skin Cosmetics Gels Emulsions Lotions Tooth Paste Jams Dressings Technical Specification It is specially designed to take care of two critical factors which directly affects the quality of the Ointment / Creams. Minimum man handling of Ointment. Negligible vacuum drop during mixing & blending Delicacies Hair Cosmetics Products Skin Cosmetics Gels Emulsions Lotions Tooth Paste Jams Dressings The Range of Our Supply : Manufacturing Vessel OR Jacketed Planetary Mixer Wax Phase Vessel Water Phase Vessel Storage Vessel Vacuum Pump Control Panel Product Piping Load Cells for Manufacturing Vessel for weight automation Vacuum Transfer Systems for Oil & Water Phase PLC based Automation system suitable for SCADA connectivity Dedicated Skidded CIP & Sanitization System Working Platform Material Transfer Pump to Transfer material from Manufacturing Vessel OR Planetary Mixer to Storage Vessel & Storage Vessel to Ointment ( Tube ) Filling M/C. ( 02 nos.) This system consist of a closed circuit Manufacturing facility from feeding of Wax / Water Phase to loading the hopper of filling machine The Wax and Water at required temperature are transferred to Manufacturing Vessel or Planetary Mixer, by vacuum through conical filter. The product during emulsion formation is recirculated through Ointment Transfer Pump The Pump also discharges the product in the Storage Vessel. The Storage Vessel is then taken to the filling area and it is connected to again Ointment Transfer Pump. Or Storage Vessel remain fixed ( In bigger size ) & pump transfer the ointments in the hopper of the Ointment Filling Machine. The entire Plant can be operated by centralised operating panel by one operator. Minimum two batches per shift of the same product can be assured in this plant.

Type : Ointment Manufacturing Plant

Certification : CE Certified,ISO 9001-2015 Certified

Color : Silver

Voltage : 380V,440V

Condition : New

Capacity : 25 Kgs To 2000kgs.

Automatic Grade : Semi Automatic

Driven Type : Electric

Warranty : 1year

Country of Origin : India

Application : All Types Of Cream Ointment Lotion etc.

...more

Octagonal Blender

125,000 Per Piece

1 Piece(s) (MOQ)

Alpro Equipments is leading Octagonal Blender Manufacturer In Vasai and Octagonal Blender Exporter In India, near by Mumbai. The Octagonal Blender is an efficient and versatile blending machine for mixing and lubrication process of dry granules homogeneously. Two third of the volume of the Cone Blender is filled to ensure proper mixing. Our expertise allows us to manufacture and export a wide range of Octagonal Blenders Machines that is available in different capacities ranging. The Octagonal Blender gives best result for granules due to very slow speed and octagon shape of container. It can be used for Pharmaceutical, Food, Chemical and Cosmetic products etc. In every granules comes from all sides due to the octagonal shape of the product container, hence requirement of RPM is less. Suitable mainly for Crystalline & Granular type material. This type of material gets sufficient continuous movement due to their shape if container have only slow movement and will results in good quality of blending / lubrication of granules. We are offer Octagonal Blender with superb quality componets and ultramodern techniques with the guidance of aroit professinal, we are Otagonal Blender Manufacturer in Vasai and Octagonal Blender Exporter In India, Octagonal Blender that is widely used for mixing of powder and granules dry in various industries. Special Features of Industrial Octagonal Blender : Suitable for dry mixing of products in granule form Easy for loading and unloading of material Easy for cleaning All contact parts are made out of SS 304 / SS 316 or SS 316 L quality material, as per customer requirement The octagonal shape & slow speed of rotating gives sufficient continuous movement to the granules, result in good quality Simple design requires minimum maintenance General structure & safety guards made out of mild steel & coloured in Standard Model and made out of SS 304 & polished to the matt finish in GMP Model Maximum care has been taken to ensure safe operation of the unit Manual rotating facility with hand wheel for inching Bigger size batch at low power consumption Other Options Available: Contact parts made out of SS316 instead of SS304 Flame proof drive motor along with flame proof starter Vacuum Loading facility for material charging Cylindrical container with cone for material charging

Certification : CE Certified, GMP

Feature : High Performance, Low Maintenance, Sturdy Design

Voltage : 380V, 440V

Automatic Grade : Semi Automatic

Driven Type : Electric

Warranty : 2years

Brand Name : AET

...more

Multi Mill

85,000 - 375,000 Per Piece

Applications : Multi mill is widely used for wet and dry granulation, pulverization, etc. in Pharmaceuticals, Chemicals, Cosmetics, Ceramics, Colours, Dyestuff, Food products etc. It also finds application in Pesticides, Fertilizers, Spices, Detergents, Insecticides, Plastic, and Resins Industries. Multi Mill unit consists of S.S. 304 quality hopper and processing chamber (can be provided is S.S. 316 quality at extra cost) with beaters assembly, motor, reversible switch, DOL starter, four speed step pulley, Suitable screen with painted pillar mounted on base plate, with castors. Operation Multimill operates on the principle of variable force swing beaters having both knife and impact edges rotating within a selected screen to get the required size reduction. Material fed in the hopper, goes down to the processing chamber where it moves to the periphery and passes through the screen radially and tangentially. Finally the processed material gets collected in the container kept below the processing chamber. Output and quality of the final product depends on three main factors Shape of beaters (knife/impact edges), Speed and Screen. Salient Features : Direction of beaters can be changed by reversible switch from knife to impact forward and vice-versa. All contact parts can be easily and quickly dismantled and cleaned. Multimill Machine is designed for continuous operation. Cylindrical screen for higher output. Castors provided for mobility. Flame proof electrical can be provided at extra cost. Beaters and scrapper blades of SS 410 quality are hardened and hard chrome plated.

Type : Multi Mill

Certification : CE Certified,ISO 9001-2015 Certified

Weight : 0-10kg,

Color : Silver

Voltage : 220V

Condition : New

Driven Type : 1-3kw

Warranty : 1year

Country of Origin : India

Automation Grade : Semi Automatic

...more

Medicament Storage Tank

100,000 - 400,000 Per Bag

Cylindrical shell will be made out of 2mm thk.SS 316 Sheet welded to the flat bottom. Bottom should be taper position towards outlet. Flange should be welded to the top of the shell. Top Lid Type Cover. Medicament Storage Tank Cylindrical shell will be made out of 2mm thk.SS 316 Sheet welded to the flat bottom. Bottom should be taper position towards outlet. Bottom should be taper position towards outlet. Top Lid Type Cover. Nozzles Product Outlet Bottom Side with 1”BSP / TC Ball Valve Nos. 4” dia P.U. castor wheel with S.S. Bracket shall be provided to the Vessel. The vessel is provided mirror finish inside and outside – 220 grit. All contact parts must be SS 304.

Country of Origin : India

Material : Stainless Steel

Shape : Vertical

Certification : Vertical

Application : Vertical

Color : Metallic

Condition : Metallic

Capacity : Metallic

Surface Finishing : Polished

Constructional Feature : Heat Resistance,Highly Reliable

...more

MEDICAMENT MIXER

700,000 Per Piece

The SS 316 Cylindrical bowl with torrispherical dish bottom with inside surface polish to smooth finish Alpro Equipments is Medicament Mixer Exporter In India, offering Medicament Mixer in affordable rates. Description of Medicament Mixer Machines : The ss 316 cylindrical bowl with torrispherical dish bottom with inside surface polish to smooth finish. The vessel shall have s. S. Jacket on cylindrical and torrispherical area to operate on 3kg/cm2 along with pressure gauge, vent cock release valve etc. The vessel jacket shall have glass wool insulation 50mm thick & clad with 16 swg m. S. Sheet duly polished. Bowl also suitable for vacuum application without vacuum pump. Bowl fitted with 4nos. Of caster wheel, two swivels and one fixed type. Top Dish S. S . Top dish for covering the bowl with s. S. Flange having groove for fixing the sealing the gasket. Necessary connection with serrated nozzle provide for connection. Light & sight glass to be provided. Drive Mechanism for Agitation Assembly 5 h. P. X 1400 r. P. M. Tefc motor hindustan make to work on 415 volt 3 phase ac line with suitable worm reduction gear box coupled by means of belt and pulley arrangement with vfd Electrical Control Panel:The control panel will be fabricated out of s. S. 304 body and will comprise of following electrical fittings. Main isolator switch with r. Y. B. Indicator light. Main switch gear with circuit breaker for 5 hp motor with ‘on’ ’off’ switch with indicating lamp. Main vessel lamp lighting the vessel inside. Digital temperature controller. “on” “off” switch for vacuum pump. on/off switch for electrical heater of jacket 2nos. 3kw. Each.

Color : Silver

Application : Pharma

...more

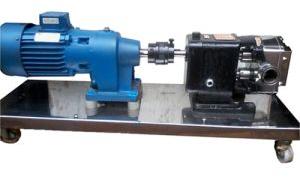

Lobe Pump

45,000 - 250,000 Per Piece

Lobe Pumps are non-contacting and have large pumping chambers, allowing them to handle solids such as cherries or olives without damage. They are also used to handle slurries, pastes, and a wide variety of other liquids. Lobe pumps are used in a variety of industries including, pulp and paper, chemical, food, beverage, pharmaceutical, and biotechnology. They are popular in these diverse industries because they offer superb sanitary qualities, high efficiency, reliability, corrosion resistance, and good clean-in-place and sterilize-in-place (CIP/SIP) characteristics. These pumps offer a variety of lobe options including single, bi-wing, tri-lobe (shown), and multi-lobe. Rotary lobe pumps are non-contacting and have large pumping chambers, allowing them to handle solids such as cherries or olives without damage. They are also used to handle slurries, pastes, and a wide variety of other liquids. If wetted, they offer self-priming performance. A gentle pumping action minimizes product degradation. They also offer reversible flows and can operate dry for long periods of time. Flow is relatively independent of changes in process pressure, so output is constant and continuous.

Weight : 10-20kg

Color : Silver

Automatic Grade : Semi Automatic

Driven Type : Electric

Warranty : 1year

...more

Volumetric Liquid Filling Machine

650,000 - 2,500,000 Per Piece

1 Piece(s) (MOQ)

Discription - This system consist of a closed circuit Manufacturing facility from feeding of Sugar / Water Phase to loading the Volumetric Liquid Filling Machine. Discription : The facility consists of: Sugar Syrup Vessel. Online sugar syrup prefilter. Manufacturing Vessel. Storage Vessel. Vacuum system for transfer of sugar syrup. Filter press / Inline Homogeniser. Product piping. Control panels. Unique features of the facility: The liquid oral manufacturing plant is designed to be operated by one operator and one helper, saving on precious man-power costs. Sugar syrup and manufacturing vessels are provided with limpet coils for heating and cooling, designed for internal vacuum to facilitate transfer of sugar directly from stores to sugar syrup vessel. Sugar syrup is transferred to manufacturing vessel through online sugar syrup prefilter by vacuum. Entry of all propeller agitators are from bottom through a specially designed cartridge mechanical seal with TC/TC seal face. The advantage of the bottom propeller agitator over the conventional agitator is that there are no vibrations of shaft, no couplings in the drive assembly, leading to lower maintenance cost for liquid oral manufacturing plant. Pipes, pipe fittings and valves are of SS 316, seamless, internally electropolished with DIN standard unions and silicon Gaskets. Manhole of all the vessels are equipped with davit fitting and the cover of the manhole slides instead of being lifted. Process Control: Values like current, product temperature are displayed digitally on the electrical control panel. The mechanical seal is equipped with a water circulating system and has a water detection sensor which trips the motor, if the water circulation to the seal is interrupted.

Country of Origin : India

Type : Volumetric Liquid Filling Machine

Certification : GMP

Application : Use For Making Sugar Syrup & Oral Suspension

Weight : 4000-5000kg

Voltage : 380V

Brand Name : AET

Warranty : 2years

...more

Liquid Filling Line

1,250,000 Per Piece

1 Piece(s) (MOQ)

Liquid Filling Line Exporter In India is Compact versatile and elegantly matt finished unit totally enclosed in stainless steel having most of the features of automatic machine. The basic unit consist of reciprocating filling, nozzles, container platform, container centering device, syringe holder, HDPE tubes And pipes and on-line starter. Our expertise of Manufacturer And Supplier Of Liquid Filling Line Manufacturer In India.

Type : Auto And Semi Auto

Brand Name : AET

Material : Stainless Steel

Certification : ISO 9001-2015 CE GMP

Voltage : 220V

Finishing : Polished

Automatic Grade : Automatic

Packaging Type : Wooden Box

Driven Type : Electric

Pressure : Medium Pressure

Warranty : 2 Year

Country of Origin : India

Corrosion Resistance : Yes

Machine Structure : Horizontal

Usage : Medicine Liquid

Specialities : Rust Proof, High Performance

Filling Valve Head : Multi-Headed

...more

Linear Tube Filling Machine

475,000 Per Piece

Alpro Equipments are the Linear Tube Filling Machine Exporter In India. We offer machines that has manufactured under the guidance of our dilligent professionals using optimum grade components at our Factory. We have been consistently betrothed manufacturing and supplying the premium range of Linear Tube Filling Machine Exporter. Linear Tube Filling Machine are widely used to fill fluid in Jars, Tubes etc.

Application : Filling Tubes

Weight : 100-500kg

Feature : Easy To Operate, Good Capacity

Voltage : 230V

Automatic Grade : Automatic

Driven Type : Electric

Warranty : 1year

...more

Jar Filling Machine

300,000 Per Piece

Alpro Equipments, Jar Filling Machine Manufacturer In India, we are engaged in delivering Jar Filling Machine Manufacturer to our clients with international quality standards, Jar Filling Machine is appreciated for its simple electric control and easy adjustment. Jar Filling Machine Manufacturer In India are recognized in the industry for their capability to efficiently handle the requirements of filling liquids in both low as well as high viscosities through volumetric filling. With the machines being tested on defined parameters that assures their compliance with defined industry laid norms as well as standards, these Jar Filling Machine Manufacturer can also be manufactured in adherence with defined functional standards and norms as required by the customers. Some areas these are used in include for filling detergent, paints, syrups, edible oil, lubricants and other similar products. Cap Hopper : Gerard Motor .0.25 H.P. (0.33 k.w.) 1440RPM – 440VAC Hopper Capacity 100 Caps At a time Programmable Logic Controls ( PLC ): Inputs = Photo Sensor Inputs = Photo Sensor Filling Valves 1” BSP 230 VDC SS Tank 35 Ltr. For Chemical and Hot Water Proximity Switches 24VDC M18 Size (For No Bottle No FILL SYSTEM) Shrink Tunnel 4.5KW (440VAC). Conveyor 3 feet SS Roller Conveyor Material of construction SS304 Roller material SS304 Adjustable width for different size of bottle Machine size in feet Machine Only:–L = 11’x W = 3’ x H = 5.5’ Machine With Conveyor and all accessory:–L = 11’ x W = 3’x H = 5.5’

Finishing : Polished

Specialities : Rust Proof

Material : Stainless Steel

Color : Silver

Voltage : 220V

...more

Inline Homogenizer

90,000 - 300,000 Per Piece

2 Piece(s) (MOQ)

In Inline agitation system, the possibility of materials –Liquid or Solid passing through it, without subjected to intense hydraulic and mechanical shear actions is zero. Here suction pipe (inlet pipe) is centrally mounted & outlet is radially mounted, therefore it is physically impossible for any material to pass from inlet to outlet without exposed to agitation. Inline Homogenizer 3HP: In Inline agitation system, the possibility of materials –Liquid or Solid passing through it, without subjected to intense hydraulic and mechanical shear actions is zero. Here suction pipe (inlet pipe) is centrally mounted & outlet is radially mounted, therefore it is physically impossible for any material to pass from inlet to outlet without exposed to agitation. The stator which surrounds rotor is available with various type of opening i.e. round, square, rectangular & with perforation also so that all the critical demand of Mixing, Emulsifying, Disintegration & Dispersion of solids, suspension can be met out by same equipment. The machine is versatile & has completely revolutionized the traditional mixing techniques. Here close tolerance of rotor with the stator produces high hydraulic shearing & mechanical action that ensures that material entrapped between rotor & stator is subjected to tremendous shearing actions each minute.

Application : Lab

Color : Silver

Application : Chemicals, Pharmaceuticals, Food Processing

...more

Industrial Reverse Osmosis Plant

135,000 Per Piece

Manufacturer of reverse osmosis plant for industrial use like Pharmaceuticals, Chemicals, Cosmetics, industries Capacity: 100 ltrs. up to 3000 ltrs.

...moreBe first to Rate

Rate ThisOpening Hours