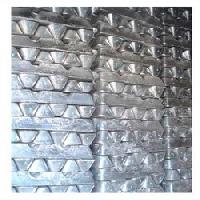

a354 Aluminium Alloy

Get Price Quote

A354 VersaCast delivers the high strength and elongation required for the most demanding structural applications. This innovative specialty alloy offers excellent fatigue resistance, high strength properties, plus 3XX casting characteristics. The result is maximum reliability, fuel economy and performance.As an importer and exporter of aluminum products, including ingot silver aluminum alloys, Phoolchand Bhagat Singh would likely work closely with aluminum suppliers and manufacturers to ensure that the products they supply meet the specific needs and requirements of their customers. This may include providing customized alloy compositions or sizes to meet the specific needs of a particular application or industry.

Aluminum Alloy 6082

Get Price Quote

Aluminum Alloy 6082 is available in Sheet and Plate, Aluminum 6082 Bar, 6082 is also available in Drawn Tube, Tube and Forging Stock.Alloy 6082 is a medium strength alloy with excellent corrosion resistance. Alloy 6082 has the highest strength of the 6000 series alloy. Due to the higher strength of Alloy 6082 it has replaced Alloy 6061 in many applications. Alloy 6082 is typically used in highly stressed applications, Trusses, Bridges, Cranes, Transport applications, Ore Skips, Beer Barrels, Milk churns.SpecificationsAluminium alloy 6082 also corresponds to the following standard designations and specification. AA6082 HE30 DIN 3.2315 EN AW-6082 ISO AlSi1MgMn A96082 Similar Specifications BS L111 Alloy 6082-T6 Bars and Sections BS L112 Alloy 6082 Forging Stock and Forgings BS L113 Alloy 6082-T6 Sheet and Strip BS L114 Alloy 6082-T6 Tube Drawn BS L115 Alloy 6082-T651 Plate BS HE30 6082 Extrusions BS HP30 6082 Plate BS HT30 6082 Tube BS HG30 6082 Wire BS HS30 6082 Sheet Werkstoff 3.2315 EN 2326 6082-T6 Extruded bar EN 2636 6082-T6 Bar (with peripheral coarse grain control) EN 4273 EN 4274 (with peripheral coarse grain control) Alcoa-920 Birmetal-071 BA 25 Durcilium-S Hiduminium-44 Anticorodal-090 AlMgSi1Mn A-SGM0.7 AECMA 2389 Tube AECMA 2390 Tube UNI 3571 UNI 9006/4 L-3453

Best Deals from Aluminium Alloy

Aluminum Alloys

Get Price Quote

We are trustworthy Supplier of Aluminum Alloys from Maharashtra, India. Made from supreme quality material, our Aluminum Alloys have high strength and robust construction. We work in close coordination with our vendors so we can easily provide Aluminum Alloys in custom-made specifications as per buyer’s need. Customers can approach us for purchasing Aluminum Alloys at nominal rates.

Aluminium Alloy

40 - 5,000 Per Kilogram

1000000 Ton (MOQ)

Calcium Aluminium Alloys

555 Per Kilogram

600 Kilogram (MOQ)

We have ready stock of calcium aluminum alloys , 7030 v 8020 grade . 100 kg packing . Call us more entail product of china , largest stockist of calcium metal in india , ready stock available , pure calcium and calcium aluminium alloys of all grade , calcium lumps , calcium granules, calcium , etc.

Aluminium Alloys

Get Price Quote

We are offering aluminium alloys. In form of sheet, plates, structural, round bars, pipes & tubes, flat bars, square bars. Alumac. Mic-6 in sheets, plates, extrusions & forgings. in almost all possible grades & temper. u.s.a. (a.a.) 1050(e.c.), 1050, 1060, 1070, 1080, 1100, 2011, 2014, 2017, 2024, 2030, 2618, 3003, 3004, 3005, 4043, 4047, 5005, 5051, 5052, 5086, 5083, 5056, 5454, 5754, 6061, 6063, 6351, 6082, 6066, 6005, 6101, 6201, 7020, 7039, 7075, 8011.

Aluminium Alloy

190 - 250 Per Kilogram

100 kg (MOQ)

We make aluminium alloy ingot adc12 - alsi132 from identified automotive scrap. The silicon metal used is of 553441 grade. We can make aluminium alloy adc12 and alsi132 from virgin ingots too. Our aluminium alloy ingots come color coded as per international norms and is accompanied with a test certificate of the alloy composition which is tested on our state of the art german spectrometer.

Aluminium Alloys

Get Price Quote

Pure aluminium is soft and ductile and most commercial uses require greater strength than pure aluminium affords. So strength is achieved by the addition of other elements to produce alloys. Further strengthening is possible by means which classify the alloys roughly into two categories, non-heat-treatable and heat treatable.

Aluminum Alloys

Get Price Quote

Aluminium Alloy, Aluminium Extrusion

Get Price Quote

We are offering aluminium alloy, aluminium extrusion is well acknowledged due to their significant properties such as sturdy construction, resilience, reliability and long lasting. We fabricate these products using optimum quality materials based on ultra modern technology in complying with the quality standards. These products are available in a variety of sizes, shapes and design as per the clients’ requirements. manufacturing capabilities a. The circumscribing circle diameter (ccd) generally for solid profiles: maximum 330 mm* for hollow profiles: maximum 225 mm* the range may vary depending on profile alloy b. Alloy and temper standard alloys: 1100, 1050, 2014, 5052, 5086, 6063, 6060, 6061, 6101, 6066, 6351, 6082, 6005 and 7075 standard tempers: o, f, t4, t5 and t6 is :64430 (he-30), is : 65032 (he-20), is:243456 (he-15), is : 54300 (n-8), is : 53000 (n-5), is : 52000 (n-4), 19500, 19000 in shapes of sheets, plates, round bar, flats, pipes in 'o', 'm' , 'ww' & 'wp' condition. form of :sheet, plate, strip, flat & blank specification: is, bs, astm etc. grade: 6351 gr. T-6, 6063 gr. T-6, 5052, 1100 etc.

Aluminum Alloy

Get Price Quote

20 Kilogram (MOQ)

We are the leading supplier of this products.

Aluminium Alloys

Get Price Quote

Aluminium Alloys have high strength together with excellent machining characteristics. Aluminium Alloy commonly used in many aerospace structural applications due to its high strength. Other applications include military vehicles, bridges, weapons manufacture and structural applications. 7075 is one of the highest strength aluminum alloys. It is not weld able and has less corrosion resistance than other aluminum alloys. The mechanical properties depend on the temper of the material. Commonly used in the bicycle industry, aircraft structures, and in rifles for the American military. Specificationn : Available shapes: Sheet, Plate, Flate, Round, Pipe & Squares Grade - 1100, 2014, 2024, 5052, 5083, 6061, 6063, 6082, 7050 & 7075.

Aluminium Brazing Alloys

Get Price Quote

The company is known as a highly trusted Manufacturer & Supplier of Aluminium Brazing Alloys. The Pure Aluminium Brazing Alloys, offered by the company, are manufactured to perfection using the best grade materials and technologies. The Aluminium Brazing Alloys can be availed in a wide range and the industrial demands are met with timely deliveries. RangeAluminum Brazing RodPure Aluminum with 99% aluminiumMaximum 0.25% silicon and othersUsed for welding/brazing pure aluminum products5% with 93 to 94% aluminium4.5 to 6% silicon and othersUsed for welding/brazing aluminum-silicon alloys having 6% silicon12% with 88 to 90% aluminium11 to 13% silicon and othersUsed for welding/brazing aluminum-silicon alloys having 12% silicon

Aluminium Alloys

Get Price Quote

We are engaged in providing Aluminium Alloys to the clients. The Aluminium Alloys are made of high quality Aluminium. These Aluminium Alloys are demanded in varied industries for different purposes all over the world. We make our Aluminium Alloys available in different materials, shapes, grades and specifications. Additionally, these Aluminum Alloys are economically priced.

Calcium Aluminium Alloys

465 Per Kilogram

600 Kilogram (MOQ)

calcium-aluminum is an interalloy in metallurgical industries and plays a role in desulfuration, deoxidization and purification. it is also used as the reducing agent for smelting of rare metals application: battery plate, lead refining, battery and lead recycling, middle alloy refining and deoxidizing agent.

Aluminium Round Rods in 6082 T6 Alloys & Temper

Get Price Quote

ANY Kilogram (MOQ)

Authorised stockist of hindalco industries ltd. We are suppliers of aluminium round rod in 6082 t6 6351 t6 6063t6 alloys & temper.

Aluminium Alloy

Get Price Quote

We offer aluminium alloy. Applications of 6063 aluminium aluminium, aluminium bronze, manganeese bronze. Aluminium alloy 6063 is used in: in balustrading the rails and posts are normally in the t6 temper and formed elbows and bends are t4.t4 temper 6063 aluminium is also finding applications in hydro formed tube for classis. Chemical composition of 60636063a aluminium chemical composition for aluminium alloy 6063 and 6063a element 6063% present 6063a% present si 0.2 to 0.6 0.3 to 0.6 fe 0.0 to 0.35 0.15 to 0.35 cu 0.0 to 0.1 0.1 mn 0.45 to 0.9 0.6 to 0.9 mg 0.0 to 0.1 0.0 to 0.9 zn 0.0 to 0.1 0.0 to 0.15 ti 0.0 to 0.1 0.1 cr 0.1 max 0.05 al balance balance tempers for 6063 aluminium the most common tempers for 6063 aluminium are: â�¢annealed wrought alloy â�¢t4-solution heat treated and naturally aged â�¢t6-solution heat treated and artificially aged 6063 aluminium mechnical properties mechnical properties for aluminium alloy 6063 temper proof stress 0.20% (mpa) tensile strength (mpa) shear strength (mpa) elongation a5(%) hardness brinell hb hardness vickers hb hardness vickers hv fatigue endur limit (mpa) 0 50 100 70 27 26 25 85 110 t1 90 150 95 26 24 45 45 150 t4 90 160 110 21 21 50 50 150 t5 175 215 135 14 13 60 65 150 t6 210 245 150 14 12 75 80 150 t8 240 260 155 9 80 85 6063a aluminiummechincal properties mechnical properties for aluminiumalloy 6063a. Temper t4 t6 minimum proof stress 0.2 % (mpa) 90 190 minimum tensile strength (mpa) 150 220 elongation a5 (%) 10 5 physical properties of 6063 aluminium physical properties for aluminium alloy 6063. Property value density 2700 kgm3 melting point 600â°c modulus of elasticity 69.5 gpa electrical resistivity 0.035 x10-6î�.m thermal conductivity 200 wm.k thermal expansion 23.5 x 10-6 k

Aluminium Alloy Products

Get Price Quote

Purchasers will not be disappointed buying our range of product, as it adheres to industrial quality regulation systems. Our company guarantees to make delivery of bulk as well as retail orders of the product within the mutually decided timeframe. Aluminium Alloy and Its Importance :Pure aluminium is soft and ductile and most commercial uses require greater strength than pure aluminium affords. So strength is achieved by the addition of other elements to produce alloys. Further strengthening is possible by means which classify the alloys roughly into two categories, non-heat-treatable and heat treatable.Non-heat-treatable Alloys :The strength of alloys in this group depends upon the hardening effect of elements such as manganese, silicon, iron and magnesium. Since these alloys are work-hardenable, strength levels are controlled by various degrees of cold working, denoted by the ‘H’ series of tempers. Alloys containing appreciable amounts of magnesium when supplied in strain-hardened tempers are usually given a final elevated-temperature treatment called stabilizing to ensure stability of propertiesAluminium Alloy and Its Importance : Aluminium Sheet Aluminium Bar Aluminium Round bar Aluminium Flat bar Aluminium Square / Hex bar Aluminium Plate Aluminium Tread Plate / Chequered Plate Aluminium Square tube Aluminium Round tube Aluminium Rectangular tube Aluminium Angle Aluminium Channel Aluminium Tee sections Aluminium customized Profile Aluminium Forgings Aluminium Seamless Tube Aluminum Drawn Products Aluminium Architectural / Building profile

Aluminum Alloy

Get Price Quote

Sheet 6082(T651), Aluminium Alloy Plate Sheet 5052, Aluminium Alloy Plate Sheet 6061 T651, Aluminium Alloy Plate Sheet 5086, Aluminium Alloy Plate Sheet 3003-h14, Aluminium Sheet And Plate 2024, Aluminium Alloy Plate Sheet 1050 '0' (Soft), Aluminium Alloy Plate Sheet 2014, Aluminium Alloy Plate Sheet 5251 - H24, 2024 Aluminium Alloy Plate Sheet And Plate Aluminium alloy 5083 contains 5.2% magnesium, 0.1% manganese and 0.1% chromium. In the tempered condition, it is strong, and retains good formability due to excellent ductility. 5083 has high resistance to corrosion, and is used in marine applications. It has the low density and excellent thermal conductivity common to all aluminium alloys. Typical Applications require a weldable alloy of high to moderate strength, with good corrosion resistance. Marine applications, unfired welded pressure vessels, TV towers, drilling rigs, transportation equipment, armour plate. Description Aluminium 5083 is a strong magnesium-manganese-chromium-aluminium alloy. It can be hardened by cold work, but is not heat treatable to higher strength. It has good ductility for the strength level, better than most other 5000 series alloys (see figure). Corrosion Resistance Alloy 5083 has excellent resistance to general corrosion, and is used in marine applications. Resistance is excellent in aqueous solutions in the pH range 4 – 9. The corrosion resistance of aluminium alloys relies on a protective surface oxide film, which when damaged is readily repaired by the rapid reaction between aluminium and oxygen. However, the high reactivity of the base metal can give rapid corrosion if the film cannot be repaired, so aluminium alloys are not suitable for use with reducing media. Alloy 5083 can be anodised to improve the corrosion resistance by thickening the protective surface film. Alloy 5083 can be susceptible to exfoliation corrosion in severe applications. Material in the H116 temper is least susceptible, and passes the ASTM G66 Exfoliation Susceptibility Test (ASSET Test). AS 1734 suggests alloy 5083 should not be used above 65°C. Pressure Vessels AS1210 Pressure Vessels prequalifies alloy 5083 for pressure service for temperatures up to 65°C in the O, H112 & H321 tempers.

Silver Aluminum Alloy

Get Price Quote