Zither Chucks

We are Deal in Zither-Bonet-Bonmac brand True Chucks and Dog Chucks.

...more

wood vices

Wood Turning Lathe Machine

Equipment & Accessories per machine : Standard bell bearing center - 1 set In board face plate 150mm dia. - 1 Screw center chuck -2 4 jaw multi - purpose chuck 80 -130mm dia Self - centering complete with metal protection - 1 Pcs Chisel, wood turning - Flat Nose - 1 pc. Chisel, wood turning- Screw, 6mm, 13mm & 20mm - 1 set. Chisel, wood turning - Round - Point, 13mm - 1pc. Chisel, wood turning - Spear - Point, 13mm - 1pc. Chisel, wood turning - Parting - Point, 20mm - 1pc. Drill chuck - 1pcs High - speed bearing bell center Knife tool with holder - 1 Standard tool kit - 1 set Wrenches.

...more

wood Trimmer Cutting machine

wood milling machine

Motorised Wood Working milling machine with adjustable & tilting work head for milling straight and cross cutting of wooden planks such as for casing, capping, grooving tennonning, etc., equipped with 3 jaws self centering true chuck for holding cutters, moulding block and circular saw cutting attachment having table working surface 23" x 8" cross travel 12" vertical travel 24" spindle speed 3500 RPM complete with 2 HP AC 440/3/50 motor and starter.

...more

Wire Straightening Machine

Automatic wire straightening and cutting machine having an exclusive and elite combination of speed and accuracy backed by intensive research of experts. These machines are used where wire is further processed in rods, coiled wire accurate straightening, close length tolerances and high output are of importance, widely used by electric welding rods manufactures, electric fan guards, refrigerator racks, cloth hangers, automobile parts, electric parts industry, gives you both financial and inner core satisfaction as it is very easy to use requires no special skill.Indefinite length of wire can be cut out without automatic attachment. The machine operates by drawing the wire from the coil through the fast rotating spinner, passes through a cutting of tool into the scaling bar where it strikes at the adjusted length and this stroke makes the cutting mechanism complete. This straightening function is performed by 5 straightening blocks which are adjustable and contains a simple to use straightening bush lets the user to make replacement to his own work

...more

WIRE FEEDERS machine

Wire feeder Units are Portable Units having Twin. Roll Drive system designed to feed 0.8 to 2.4mm dia. welding wires to a hand operated MIG welding Torch. For ease in installation & operation as well as maintenance the Wire feeders are compartmentalized for different circuitery/ parts for different operations. Maintenance is made easy with Plug-in type printed circuit Boards (PCBmodules). A specially designed hub Assembly at the rear of the Wire feeder Units, accomodates a standard 12" dia. reel of welding wire. The wire feeder units are fully solid state & Thyristor controlled, has in addition latching facility, fine control & overload protection. MIG' Welding Torches available in various types & capacities in Air or water cooled types. Suitable for different jobs with different Collets, to hold welding Wires as per the capacities of Torch from 0.8 to 2.4mm dia. The other required Accessories : Optional Extra Pressure regulater with Flow meter /CO2) CO2 Heater Inter Connections Sprayer Hard/Soft Wire Kits Water circulation Device-for Torches Spot Welding Attachment

...more

Welding Rectifier

weigh batchers

Lever type concrete batcher is useful device for weighing for production of controlled concrete, mounted on a robustly fabricated chassis of heavy steel section with four M. S. Wheels. Lever mechanism is suitably designed with gearing for proper weighing. Discharge chutes provided with hoppers are suitably designed for quick discharge of the aggregate in the mixer hopper. Suitable design for M15, M25 & M30. OPERATION : Capacity of the hopper - 250/500kgs each. Level the machine properly on platform. Clean the machine regularly to get the proper weights of sand & aggregate. Put the required weights in to the pan (100 kgs., 50 kgs., & 20kgs.) As per weight required for odd calibration, adjust the weight on the scale given. (10mm=1000gms.) Unload the material directly in the mixer hopper, outlet given on rear side.

Type : Scale Type

...more

Vibratory Sand Screening Machine

Capacity : 6m3/hrs.

Vertical Turning Lathe

STANDARD ACCESSORIES : One Ram Head on Cross Rai Automatic lifting of the Cross Rail Jaw chucks - 4 Nos. Centralised Lubrication System Thyristor centralised DC drive for stepless Table speed. Antifriction material coating on main slide for smooth feed motions. Fully centralised control stations. SPECIAL ACCESSORIES : Additional Ram head on Cross Rail Turret head on Cross Rail Threading head on Cross Rail Side Ram Head Grinding Head

...more

Vertical Spindle Moulder

Vertical Rotary Surface Grinder

STANDARD EQUIPMENTS : Diamond Tool Holder, Grinding Cup wheel, Electric Motors with Penel Board & Coolent Pump, Table Guards.EXTRA EQUIPMENTS :Magnet Chuck 24" OR 26" OR 28" Diamond Tool Spare wheel Grinding.

...more

Vertical Milling Machine

Vertical Head Block Surface Grinder Machine

STANDARD EQUIPMENTS : Micrometer with frames (Indian Make) Tool Bits Nos. 2 Pin Set 5 No. Small and Big Size Allen Key Set one Pc. One Spanner

...more

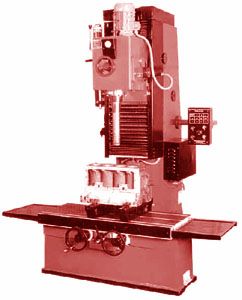

vertical fine boring machine

Vertical Fine Boring Machine is specially designed for fine and accurate machining of cylinder bores. Manufacturers ensures years of trouble free operation as every phase of manufacturer is under strict quality control. Base and column are of high grade casting. Boring head travels on a Hardened & Grounded finished guide ways column protected with bellows. Boring head is fitted with hardened alloy gears to give smooth feed and side on column. Controls are provided on one side of the machine on a comfortable position and easy operation. The Machine is supplied with the following standard equipment : Boring tool setting device complete with micrometer. Two tool holders for boring. Portable Grinder with suitable Grinding/Lapping Wheels. Two Block Jacks. Two Sets of Parallel Blocks. Service Spanners. One spindle fitted with the Machine, bore dia capacity 64-135 mm.

...more

Vertical Bandsaw Machine

Heavy duty vertical bandsaw machine provided with cast iron machine table and guards for safety of the operator with saw guide for alignment of the saw blade complete with suitable electric motor 3 phase 440 volts, motor pulley, V belt starter and motor attachment.

...more

vertical attachment

is of special design, mounted from top of the column with power transmitted through gears, with this design. No vertical space is wasted while using Vertical Attachment.

...more

variable rake angle hydraulic shears

Ram & Table designed with inclined member and box type structure for maximum strength. Positive holding of Hyd. Hold downs avoids slippage of sheet during cutting stroke. HCHCr Blade suitable to MS & SS. Hardened Transfer bars. Front gauging by disappearing stoppers mounted on front squaring arm. SPECIAL FEATURES The stable robust, all welded steel frame from ultrasonically tested plates are of top quality. Ramand table designed with special inclined member and box type structure for maximum strength. The top beam is guided by three point roller with replaceable hardened liners for least wear.This eliminates lubrication of guides. Roller guide made of hardened & ground bearing steel to provide better quality of cutting for a long time. Rake angle can be varied to permit shearing of higher thickness than nominal capacity and facilitating distortion free shearing of thin sheets. The fastest and easiest way of blade clearance setting without need of feeler gauge, which helps Burr-free edges. Positive holding by hydraulic holddowns before shearing avoids slippage of sheets and independent operation of holddowns for clamping of sheet helps checking of mark without taking shear stroke. Front gauging by disappearing stoppers mounted on left squaring arm. Robust, heavy & accurateback gauging to set cutting width. Hydraulic cylinder are designed with both low and high pressure sealing, Hard chrome plated rod also with special type guide for long life without leakage. Hydraulic components of international quality assembled in our own factory with specially designed compact manifold STANDARD ACCESSORIES Main Drive motor Electric Control Panel Operational Console Pre selector switch to adjust rake angle Lever operated blade clearance with calibration Fine stroke adjustment rod with limit switch Front sheet support Squaring arm on right end with steel rule Hardened transfer bar mounted on table Hold down cylinders Shadow light Indicator Four edge HCHCR / HCSR blade interchangeable & suitable to shear mild and St. Steel Manual back gauge OPTIONAL ACCESSORIES Second squaring arm on left side Motorised back gauge with DRO NC back gauge with ball screw Front support with rolleraccording to required length Rear sheet support Ball transfer table Degree protector for angular cutting Stroke counter Design with throat depth First fill of hydraulic oil

...more

Valve Seat Cutting Machine

Formtools, small (20-30 mm dia) : 1. 15° x 45° x 75°-1 mm seal width2. 0° x 30° x 60°-1 mm seat width3. Counter boring tool 1 No1 No1 No Formtools, -large (30-62 mm dia) : 1. 15° x 45° x 75°-1 mm seat width2. 0° x 30° x 60°-1 mm seat width3. Counter boring tool 1 No1 No STANDARD KIT :The Standard Kit consists of the basic machine, power control unit, operating tools, carrying case, formtools and pilots as detailed. WALL MOUNTING BRACKET : Suitable for fixing all types of cylinderheads. The wall mounting bracket increases the efficiency of the seat cutting operation and reduces operator fatigue. This unit is essential for working on aluminium cylinder heads. (The bracket is supplied along With counter bore special mounting bolts.) COUNTER BORING TOOL SETTING MICROMETFR :With the use of the optional Counter Boring Tool Setting Micrometer, the counter borecutting tools can be set to any specified diameter.

...more

Valve Refacer Machine

SPECIAL FEATURES : 6 to 17.46 mm valve stem capacity. 0° to 90° valve angle adjustment. 27 to 79 mm valve head capacity (wet). 700 ml coolant water pot with baffle plates and filter. 4-point bearing mounting on both work and wheel tables for achieving better stability and precision. Bearing adjustment on feed screws with automatic end play take-up. Multi-start feed screw for rapid feeding of the workpiece. Quick damping collets. Diamond wheel dresser (which comes as standard) for grinding wheel dressing.

...more

Universal Wood Working Machine

Accessories and Tooling with the machine: 4nos Planner blades {filed will the cutter block) 1 no. Rebating/groowing culler with changeable knives. Drills for making holes & morfising size 3/8 Grinding attachment with grinding wheel and blade holder Grease gun & oil can. Pipe wench. Appropriate key and spanner set. One moulding tool (carbide tips) One collet for holding drills One plane and grooved roller for moulding One circular sawdiameter 300 mm

...more

Universal Swaging Machine

Universal swaging machine is designed for various operations such as swaging, wiring, flanging, jennying, necking or jogging and closing. Arranged for bench or floor mounting. Hand operated or motorized. The bottom spindle is adjustable in the horizontal plane, giving perfect alignment, with a lock to retain the adjustment. Pressure on the rolls is obtained by a hand wheel and screw on the top spindle. Each roll is recessed on the outside face, so that the nuts on the spindle with suitable speed reduction Gears, mounted on stand provided with motorization attachment.

...more

Universal Sheet WorkING MACHINE

Universal Ironworker so far as the shearing, punching, notching / coping and cropping of flats, plates, squares, rounds and structural sections of any shape are concerned. The coping head is of vary study design and construction and can be easily and quickly turned into a notcher or alternatively into a punching head. Agin it can be fitted with special tool holder and tools for notching T section in both flanges simultaneously. Back stops and gauges can be supplied for production job at extra cost and they will in no way interfere with the shearing of plates or other operations. The standard machine is equipped with clutch : Mechanical hand lever operatedGears : Made of steelMotor : AC, 440/3/50 totally enclosed fan cooled with V belts, pulley, Starter and sturdy guards.Blades : To cut sheets, flats, angles, T, Round, Square bar cutting, V notching or punching attachment (specify while ordering) OPTIONAL ATTACHMENTS : Wheel mounting cabinet stand Special attachment & tools such as blaes, punches and dies to obtain a wider range of application possiblites

...moreBe first to Rate

Rate ThisOpening Hours