Nickel Anodes

Get Price Quote

With our domain expertise, we are capable of supplying Nickel Anodes in the Indian market. The Nickel anodes, we offer, are suitable for diverse industrial requirements owing to their excellent properties. The clients can avail the Nickel anodes from us in varied specifications to cater to the diverse requirements. We further offer the Nickel Anodes at affordable price.

Electroplating Aluminium Anode

Get Price Quote

Cited below are the quality attributes of offered aluminium anodes: Optimum polishing Excellent performance Fine finishing Corrosion resistance

Best Deals from Anodes

Phosphorus Copper Anode

460 Per Kilogram

lead anodes

Get Price Quote

2 Ton (MOQ)

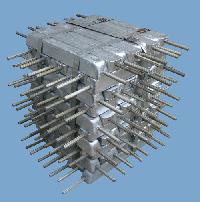

HMS Metal Corporation is a Leader in the production and Supply of Anodes used in copper, zinc and nickel refining. Our electrowinning anodes integrate years of experience, research and development.With fully Integrated & 100% in-house production facility we are able to Internally controlled workmanship for alloying, rolling blade, head bar tinning and casting, welding, cutting & packaging. Although anodes are manufactured to client’s designs, with each stage of manufacture using the best quality raw materials and controlled by a strict quality process system, anodes are produced efficiently and consistently within estimated time. Anodes made of lead alloys are used in the electrowinning and plating of metals such as manganese, copper, nickel, and zinc. Rolled lead-calcium-tin and lead antimony alloys are the preferred anode materials in these applications, because of their high resistance to corrosion in the sulfuric acid used in electrolytic solutions. Lead anodes also have high resistance to corrosion by seawater, making them economical to use in systems for the cathodic protection of ships and offshore rigs. Rolled lead anodes have become the industry benchmark with the benefits of fine grain structure, less segregation and elimination of cracks and voids resulting in more uniform corrosion of the anode. The shape and size of the copper bar and the anode plate are made to customer specifications The copper bar is tin-plated and then given a homogeneous coat of lead several millimeters thick as protection from corrosion caused by aggressive acid mist. This method of protecting the anode bar also ensures the best possible bond between lead and copper for improved current flow and long service life. Chemical Composition The lead anodes are manufactured in calcium-tin-lead (Ca/Sn/Pb), antimonial lead (Sb/Pb) and silver-lead (Ag/Pb) alloys which are the preferred alloys for these applications with their high resistance to corrosion in the sulphuric acid based electrolyte solutions. Lead anode alloys generally consist of tin, Calcium, and Antimony. The favoured alloys, based on the specific application, are lead- antimony as well as lead-Calcium-Tin alloys. One reason for this is because of the alloys’ resistance to corrosion in the sulfuric acid that’s used for electrolytic solutions. (Lead-alloy anodes are used in electro winning – also known as electro extraction – as well as for plating metals such as manganese, copper, nickel, and zinc.) Lead anodes have superior attributes, such as being highly resistant to the corrosive effects of seawater. We also offer custom Lead Alloys to meet your specifications We specialize in manufacturing complete Lead Anode and Anode Plates for Zinc, Nickel and Copper extraction electrolysis plant. Electrowinning of copper, nickel, cobalt and zinc in SX-EW processing of ores. Ca/Sn/Pb alloy is generally used for copper, nickel and cobalt applications. Ag/Pb alloy is the preferred alloy in zinc electrowinning Packing The finished anodes are packed together in wooden pallets with thick thermocol in between each Anode to prevent the individual anodes from bending.Do's & Dont;'s Remember, proper care of anodes will pay off in longer life. Try these suggestions with new Republic anodes. Do not leave new anode in chromium solution when tank is idle. Instead, remove them and place them in clean water after use until a uniform brown film of lead peroxide is formed on the surface. Do not confuse this dark brown lead peroxide coating with lead chromate. Lead chromate (PbCrO4) is yellow in color and acts as an insulation. This should be removed in order to restore the anode to the most efficient service level. We recommend that approximately two inches of lead anode be above the solution level at all times. We do not recommend mixing old and new anodes together. Adding new anodes intermittently in order to obtain amperage needed could result in new anodes scaling up very rapidly. If it is not practical to replace all anodes at one time, we suggest extreme care be given to the new anodes to assure proper breaking in for efficient performance.

Copper Anodes

480 Per Kilogram

50 Kilogram (MOQ)

We make sure that the offered lot complies with the stated quality norms, thus check the product quality on several stages. We have hired a team of experts who have developed a system for making safe and secure transactions. Our system has offline as well as offline options for payment. Phosphor copper- plating anode, is widely used in acidic bright copper plating,PCB electroplating industries. High-quality phosphor copper anode is the important plating raw materials of perfectly multi-storey decorative steel products, zinc die-casting, plastic, aluminum die-casting, aluminum part and aluminum zinc alloy manufacture. High-quality PCB phosphor copper anode is an important material of advanced electronic circuit boards. We used the high technology in the melting method and the process. We manufacture a series of PCB grade and metal plating grade phosphor anodes in difference specifications, basing on the United States highest quality standards in the similar industry.

aluminum hull anodes

230 Per Kilogram

We are the main supplier of this product.

Aluminum Cube

Get Price Quote

Aluminium Anodes

250 Per Per Kg Approx

Aluminum Cube 6061

280 Per Piece

Tin Anodes

Get Price Quote

The clients can avail LME Registered Tin andoes from us. The Tin anodes we offer are procured from the certified vendors of the market. The Tin anodes are majorly used as an alloy than its pure elemental form. The clients can avail the Tin anodes from us in varied specifications to cater to the diverse requirements. We further offer the Tin anodes at very affordable price. Specifications Of Tin Anodes Purity : 99.85% Ingot Size : App. 29.5 kg Brand : Malaysia, Indonesia Uses Of Tin Anodes Used for making super conducting magnets Useful in electroplating, soldering and chemical formulation Used as coating for steel cans Used in instrumentation cables. Used for making tin alloys.

Zinc Tank Anodes

Get Price Quote

We are counted among the trusted Manufacturers, Exporters and Suppliers of Zinc Tank Anodes in the market. These Zinc Tank Anodes are extensively used to the exposed steel for prolonging the life of coating and structure. Our Zinc Tank Anodes are developed in compliance with international quality standards by using superior quality raw material and techniques. Our Zinc Tank Anodes are available with us at the most affordable prices. Features High strengthDurableSmooth finishingLow maintenance

Aluminium Cube

Get Price Quote

500 Kilogram (MOQ)

We are a reliable manufacturer of aluminum cubes that have high purity levels. These aluminum cubes are used as de-oxidant agents in steel industries. Our products are checked and tested on laboratory by quality analysts to ensure their purity and composition. Grades : aluminum used is 96% and 97% pure

Hull Bolted Zinc Anodes

300 Per Kilogram

Copper Anodes, Copper Nuggets

Get Price Quote

We Manufacture Copper Anodes/nuggets from Genuine Copper Cathode. They are Highly Used for Decorative, Rotogravure and Printing Circuitry. It is also Used in Electrical Ground Rod and other Functional Plating Applications. We Provide Copper Anodes that are in Different Size and Shapes Having Different Levels of Phosphorous. Our Copper Anodes Provides Good Control and Reliable Performance. Copper Anodes that We Manufacture are By Far the Best in the Market with the Finest Reliability and Dependability.

Copper Anodes

Get Price Quote

We are offering copper anodes. “kriscop” copper anodes are precision manufactured using pure copper cathode that makes these highly useful in application areas like for making decorative items, used in rotogravure machines for printed circuitry, used as electrical ground rod, in electro-forming applications and in many other functional uses. Available grades: phosphorised copper anodes and electrolytic copper anode available shapes: oval, slabs, balls, rods, nuggets and others. With our capability to provide these in end finishes as per customer's requirements, the range offered by us under this includes copper nuggets and copper balls.

anodes

Get Price Quote

anodes, Laser Deep Engraving, Laser Cutting Machine

Zinc Anodes

Get Price Quote

Zinc Anodes, Metal, Aluminium, Alloys

Zinc Anodes

Get Price Quote

Zinc Anodes, transformer rectifiers, butyl rubber tape, coal tar tape

Zinc Anodes

Get Price Quote

Zinc Anodes, Stainless Steel Sheet, Aluminium Forging, Aluminium Round Bar

electro plating anodes

Get Price Quote

electro plating anodes, Titanium Sheet, Titanium Fastener, Flange Bolt

Aluminum Tank Anode

Get Price Quote

Aluminum Tank Anode, Nonferrous Alloy Bushes, Ci Casting, zinc rod

Titanium Mesh Basket Anode

Get Price Quote

Titanium Mesh Basket Anode, Boron Carbide Powder, titanium nut bolts

Tin Anodes

Get Price Quote

Tin Anodes, Nickel Ingot, Ferro Chrome, Nickel Cathodes, Nickel Anodes

zinc anode

Get Price Quote

zinc anode, Tin Anodes, Lead Pipe, lead rod, zinc rod, Zinc Alloy

Antimani Chrome Anode

Get Price Quote

Antimani Chrome Anode, Nickel Additive, NICKLE SULPHATE

Cadmium Anode

Get Price Quote

Cadmium Anode, Nickel Anodes, Bismuth Metal, Cadmium Rod, Zinc Wire

other anodes

Get Price Quote

other anodes, Non Ferrous Metals, Nickel, Stainless Steel Sheet, Coil

Copper Anodes

Get Price Quote

Copper Anodes, Copper Capillary Tubes, Stainless Steel Eye Bolts, Eye Bolts

anodes

Get Price Quote

anodes, Wires, Tin Sheets, Sleeves, RODS, Reaction Vessels, Pipes

Zinc Anodes

Get Price Quote

Zinc Anodes, Steel Profiles, Round Hollow Bars