Induction Brazing Machine

Get Price Quote

1 Set(s) (MOQ)

Today, we have firmly positioned ourselves as one of the distinguished High Frequency Induction Brazing Machine Manufacturers and suppliers based in India. Brazing is a process of joining of similar as well as dissimilar metals by utilizing heat and braze materials (filler materials). Our Induction Brazing Machine is manufactured from the optimum quality raw materials as per the national and international quality standards. Induction Brazing Machine offered by us is designed to offer excellent as well as repeatable brazing without smoke and flame. We provide Induction Brazing Machine within the stipulated timeframe at very competitive prices. Brazing is joining of similar or dissimilar metal (parent materials) by using heat and braze material (filler material) whose melting temperture is normally above 450 C and below the melting temperature of parent materials being joined. Microtech induction brazing machines are made to replace conventional brazing methods, with more reliable / repeatable brazing without flame and smoke. Brazing temperature can be controlled from 450 C to 1200 C for most of the brazing applications. Salient Features Uniform heating at desired area provides even flow of filler metal Lesser brazing cost comparing to conventional methods. Strong and ductile joints Suitable for dissimilar materials Controlled atmosphere brazing is possible Highly adaptable for automation Eco-friendly due to noiseless and flameless operation No statutory approvals required Lesser risk involved compared to conventional methods Application Specific Auto or manual mode operation Improved power factor. Tropicalised design Compact size. Brazing Applications Copper parts for compressors Copper components of transformers Brass components Submersible pump rotors Ring cable lugs Aluminium component joints Soldering of brass components Steel component joints Brazing of storage water heater elements Diamond tipping cutting tool Carbide tipping of cutting tools Carbide tipping of drill bits Some of the application relate components.

Induction Brazing System

Get Price Quote

1 piece (MOQ)

VEL i-Braze Series VEL i-Braze series comprises of state-of-the-art induction brazing systems designed to meet the evolving demands in the field of metal joining. It includes an advanced light weight and portable high frequency transformer and joint specific custom designed coils together known as brazing tong. The coils can be easily fitted on and removed from the transformer. The brazing tong can seamlessly integrate with robotic arms or any automation as per client’s requirements Standard Features Application based customization Wide range of output power ratings and frequencies range Tolerates abrupt discontinuities in the coil circuit (e.g., sudden insertion, removal, or geometric changes of the workpiece). Withstands severe disturbances on incoming power lines. Integrates safety-oriented design features to prevent electric shock hazards associated with the brazing tong during operation. Features an automatic machine trip mechanism in the event of accidental contact between the brazing tong and the workpiece, ensuring the integrity of both the machine and workpiece. Safety Interlocks for Water pressure, temperature, flow, etc. Power Factor > 0.90 Output regulation> 90% Intuitive user interface Simple and effective indications TECHNICAL SPECIFICATION VEL i-Braze System (Type VEL/BR/#) consists of ► Converter ► Inverter ► Microcontroller based Control, Protection & Interlocks ► Output Transformer & Inductor ► Water Cooling & Circulating System (Optional) ► Holding Fixture (Optional) ► XYZ Slide for the Brazing Tong Assembly (Optional)

Best Deals from ARC Welder

Submerged Arc Welding Machine

Get Price Quote

Owing to our exceptional automated warehouse, the human interference has decreased that help us to make on-time deliveries as well. With substantial storage space, the products are kept with utmost safety to circumvent loss during loading and unloading. Purchasers can place wholesale or retail orders with any time of the year and expect timely arrival of deliveries.

Arc Welding Machine

Get Price Quote

ARC Welding Machine (STUD TYPE)

Single Phase ARC Welding Machine

Get Price Quote

1 Piece (MOQ)

Transferred Arc Welding Machine

Get Price Quote

1 Piece (MOQ)

Arc 250b (m) Welding Machine

Get Price Quote

Welding methods: it is a manual arc welding machine. applicable material: it is a applicable to various acidic alkaline (basic) electrodes, stainless steel electrodes, heat resistance steel electrodes, cast iron electrodes. Scope of application: it can weld low carbon steel, medium carbon steel, alloy steel etc. And widely used in light industrial manufacturing, maintenance, and civil structure installation. Excellent working performance: it has mosfets advance technology & hence energy saving features. It has good dynamic characteristics, little spatter and very good arc stability, easy to control welding pool with nice weld bead having good welding appearance and units have good auto adoptive arc force. Arc force prevents sticking & shorting of the electrodes during welding. Hsm arc400 also has manually adjustable arc force control. additional features: i) vrd anti-shock features ensure no load voltage is retained at 9v-15v to provide protection against electric shock. Ii) it has anti-pausing welding features which prevents the welding rod from sticking to the working piece and easy to operate. Iii) emc electro-magnetic compatibility functions with powerful grid filtering ability to reduces power supply contamination. iv) internal circuits and components are well-protected by excellent anti-interference design to secure stability and reliability. Input power voltage (v) - 220v+10% input frequency (hz) - 5060 rated input current (a) - 43.6 non-load voltage (v) - 60 output current range (a) - 30-200 rated output voltage (v) - 28 rated duty cycle - 60 no-load loss (w) - 40 efficiency (%) - 80 power factor - 0.73 insulation class - f protection class - ip21 weight (kg) - 9.5 size of the machine (mm) - 391x154x287

Submerged Arc Welding Machine

Get Price Quote

Submerged Arc Welding Machines By utilizing skills of our dexterous workforce, we are offering a comprehensive assortment of Submerged Arc Welding Machine. We manufacture this machine by employing optimum quality raw material and sophisticated technology in adherence to the set industrial standards.

Band Saw Blade, Wire Butt Welding Machine

Get Price Quote

Welding Process: - The Saw Blades or Wire Ends to be joined should be cut straight, exactly at right angles and free from burrs on special shearing attachment (optional equipment) - Welding Current, Upsetting Pressure and Upsetting Way are set according to the blade width - The blade ends are rigidly clamped in special quick acting clamps provided on the machine - By depressing the welding lever, the welding process begins - The two ends are heated to forging temperatures in a few seconds and are then automatically forged (upset). The welding current switches off automatically - The job is de-clamped and the weld completed Process for Annealing: The upsetting way switch lever is now turned to annealing and the job is clamped again with the extended jaw distance which comes in automatically on flipping the lever to annealing position. - By pressing the annealing switch on which two heat positions are provided, the job is annealed in order to normalize the brittleness of the welded area. - Depending on the type of material, the annealing process should be repeated several times if need be. Shearing Attachment (optional): Special shears with arrangement for mounting on the front of the machine are available Grinding Attachment (optional): Grinding attachment mounted on top of the machine is necessary for removing the welding flash

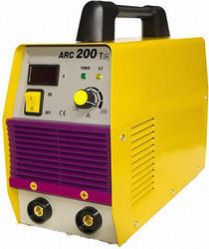

Arc 200 Welding Machine

5,000 - 20,000 Per piece

Features : Adopting 100KHz MOSFET inverter technology, extremely reliable. Auto-protection against over-voltage, over loading and over-heat, reliable and durable. Effective arc force compensation, easy arc-striking, less spark, perfect welding result. Compact size, light weight, high efficiency and power saving. Suitable for all kinds of acid and alkaline welding rod. Suitable welding materials: carbon steel, stainless steel, low alloy steel etc.

Arc Welding Machine

Get Price Quote

Submerged Arc Welding Machine

330,000 - 390,000 Per Nos

1 piece (MOQ)

DRAWN ARC INVERTER STUD WELDER

Get Price Quote

Arc Welding Machine

Get Price Quote

We make use of raw material of paramount quality that is procured from reputed vendors while manufacturing our Arc Welding Machines.

ARC Welding Polo Fusion Equipments

Get Price Quote

MMAARC Welding Polo Fusion Equipments of welding equipment both Inverter base and Transformer(Conventional Type) viz. ARC, TIG(Argon), MIG(Co2), DC Rectifier, TIG ACDC, profile Cutting, Saw( Submerged Arc Welding),

Arc Welding Machine

Get Price Quote

We offer Arc Welding Machine ->mma/tig/smaw/gtaw Welding Machines. MMA process use drooping characteristic power source and consumable electrodes which produces arc by scratching the electrode with the job forming a short circuit. It is only when the short circuit is broken, arc is formed and the main welding current starts flowing. Welding takes place as the electrode gets fused with the job under the cover of the slag. In case of TIG, arc starts between tungsten electrode (non-consumable) and the job under the cover of inert gas. Arc is started by scratching the tungsten electrode with the job or using a high frequency unit which initiates the arc between the tungsten electrode and the job.

Induction Pan Brazing

Get Price Quote

High frequency Induction Brazing Machines for sandwich cladding /capsule cladding of SS utensils. High frequency inverter for higher efficiency(less running cost). Higher productivity. Better & uniform cladding. Ensures fast & heating uniform brazing. Consistent homogeneous production quality. Modular constructions (single/double/three/ four station) Two station with indexing table. Touch screen PLC based operator friendly M.M.I. Sturdy mechanical system. Fully integrated machine with built in DM water cooling system. Near unity power factor 0.94 to 0.95 State of the art design. Tropicalised design.

ARC 200G Welding Machine

9,500 Per Piece

Arc welding machine feature adopts advanced mosfet technology. Auto protection against over voltage, over current and thermal protection. Soft switching technology brings higher efficiency and more stable performance. Arc dig function, good arc stability, less spatter and satisfactory welding appearance. High welding quality, deep bath and strong weld strength. Suitable for all kind of basic rods. Model arc 200g input supply input voltage 230vacâ±15% frequency 5060hz power factor 0.73 output no load voltage 59v output voltage 28v duty cycle 60% efficiency 80% insulation grade f housing protection grade ip21 max. Electrode diameter 3.2 mm output current 30-200 package net weight 8 kg dimension 375x155x232 mm

Gas Tungsten Arc Welding

Get Price Quote

Applications Butt and fillet welding of carbon steel for pressure vessels, tubes, ships. Characteristics on Usage 1. Use welding grade Ar 100% gas. 2. All position welding and steel sheet welding can be performed quite easily. 3. Most suitable for one- side welding of tubes.

Arc Welding Machines

6,580 Per Piece

air plasma welding machine

Get Price Quote

Arc Welding Machine

Get Price Quote

General Information INARC 200 IDS is Discrete IGBT Based Welding Power Source with inverter Technology. These machine can be used for ARC Welding of Acid and basic type of electrodes. The machine is ultra Compact and very light in weight and can be used to weld electrodes from 2 ~ 3.15mm. FEATURES : Ultra Compact and Light in weight IGBT Based for better reliability Better Welding Performance Higher Efficiency and better power factor PACKAGE INCLUDES : Power Source : INARC 200 IDSAccessories : 1.8 Meters of Welding cable with welding holder and Earthing cable with Earth Clamp.

electron beam welding machine

Get Price Quote

Electron Beam Welding (EBW) Service, backed up by experienced staff and comprehensive metallurgical facilities. Feasibility and application studies are undertaken to enable potential users to evaluate the suitability of the technique for their products. Small batch production welding is also carried out.

Submerged Arc Welding Machine

Get Price Quote

Submerged Arc Welding (SAW) is a common arc Welding process. It requires a continuously fed consumable solid or tubular (flux cored) electrode. Molten weld and the arc zone are protected from atmospheric contamination by being “submerged” under a blanket of granular fusible flux consisting of lime, silica, manganese oxide, calcium fluoride and other compounds. When molten, the flux becomes conductive and provides a current path between electrode and the job. The thick layer of flux completely covers the molten metal thus preventing spatter and sparks as well as suppressing the intense ultraviolet radiation and fumes that are a part of the SMAW process.

Inverter submerged arc welding machine

Get Price Quote

The power supply can be used for submerged arc welding, MMA welding, air carbon arc gouging. New design and specific processing treatment for special environment , greatly increase reliability of welder, suitable for various working environment. Adopts up to date and the most advanced control principle and each technical index reaches class A grade. Excellent welding performance, deep molten pool, high intensity good appearance. Widely applied for automatic welding of various carbon steel, alloy steel, stainless steel pressure vessel. Built in over heat, over current, over voltage and low voltage protection circuit, operating safely

Arc Welding Machine

Get Price Quote

Creating a niche of Arc Welding Machine such as Arc 200, Arc 250, Arc 300, Arc 400 MOS and Heavy Duty Welding Machine at its best, with utmost quality. Features: Smooth Edges Easy to maintain Better Performance

Arc Welding Machine

46,000 Per Piece

1 Piece (MOQ)

Argon Welding Machine

Get Price Quote

We are agents of RILONRILOX welding machinery. The products be it arc welding, tig welding or mig welding have been for years now used by large number of companies and have been a successful product. These machine come with 1 year warranty and service would be provided on site in most of the locations of India. Do go through the series of machinery along with its specifications and get back to us if you need any more clarifications. RILON makes ARC Welding Machine of 200 Amperes, 250 Amperes, 315 Amperes, 400 Amperes, 500 Amperes, and 630 Amperes.

Arc Welding Transformer Machine

20,000 Per Piece

1 Piece(s) (MOQ)

Arc Welding Machine

6,000 Per Piece