Pneumatic Actuator Parts

Material : Metal & Plastic

Metal enclosures

Material : Metal

Shape : Rectangular, Square

Color : Gray

Pattern : Plain

Finishing : Polished

Size : Standard

...more

Lighting Parts

Type : Customised

Material : Metal

Thickness : 10-20 Mm

Certification : ISI Certified

Color : Grey

Finishing : Polished

Dimension : Standard

...more

IP65 Enclosures

Usage : Industrial use

Type : Limit Switches

Certification : ISO 9001:2008 Certified

Condition : New

Max. Voltage : 240 VAC

Surface Finishing : Power Coated

Type : Solid

Material : Metal

Size : Standard

Color : Grey

...more

Heat Sink Parts

Type : Customized

Material : Metal

Size : Standard

Application : Heat Sink

Pattern : Plain

Surface : Polished

...more

Airtight Parts

Type : Fabricated

Material : Metal

Size : Standard

Application : Industrial

Pattern : Plain

Surface : Polished

...more

Vacuum Resin Impregnation Services

Die castings commonly contain internal porosity. This porosity is generally localized to the deepest cross-sections of the part and does not extend to the outer skin. However, if the part is also machined, the internal porosity will be exposed and the part will leak if pressurized. Machined die castings that need to hold fluids are routinely sealed for life using synthetic resins. Because the sealant is internal to the part, the exterior dimensions and appearance of the part are unchanged.

...more

Differential Leak Testing Services

The differential leak tester works by measuring the pressure drop compared to a standard confirming work piece / internal zero leakage reference.Since the pressure difference is magnified 50,000 times, the machine is highly accurate. Readings for pressure drop in the testing time are available in units of Bar or Pascal.The acceptable leak rate is defined and any parts having a leak rate more than that will be declared failed by the audio and red indicator light. As the machine has a built in closed loop rejection Bin, the next cycle will not start until the faulty piece is put in the Bin.

...more

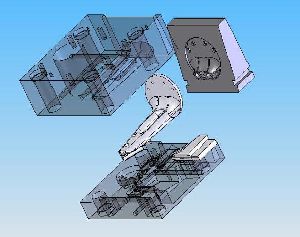

Die Making & Maintenance services

We have a full-fledged tool room complete with CNC and EDM in house, capable of meeting all the requirements of die making and maintenance. Following our quality principles, we design die cast tooling considering aspects like durability and long life. These tools can survive the most rugged conditions along with increased strength and reliability and have a long service life (we have many tools which have crossed 0.4 million shots).Special focus is given to the product’s functional areas and the designing of the product right from material to its flow and thermal and ejection balancing is adjusted accordingly, to give maximum reliability with lowest rejections even after subsequent operations such as machining for faults such as blow holes, etc. Special provision is made for creating references and geometry to ease the post processing in trimming and subsequent machining .

...more

die casting services

We are having die-casting shop with machines ranging from 75 to 800 tonnes capable of producing components from 0.5 grams to 8.5 kg. Our fully automated closed loop die casting cells maintain history of process parameters for every shot. It achieves repeatability and quality in every shot by adjusting itself automatically to reach the set parameters.We have defined special process parameters and aids to achieve wall thicknesses as thin as 1.2 mm and as thick as 10 mm without problems. We utilize Control Plans + Process Parameter Sheets and die maintenance plan, spares for every item to eliminate production errors, improve surface finish and integrity of castings, to reduce wear and tear of die to enable timely dispatches.Proof machining is carried out on all machined areas during casting cycle. Traceability is maintained up to 3 years for on line inspection reports, material composition and our suppliers heat no.

...more

Component Finishing Services

After Casting and machining process, components are finished using vibro-finishing machines which also does the de- greasing of the casting. We also use Vibro dryer where heated corn cobs absorb the part moisture and dry the part without staining.Hard Anodizing as per MIL standard (Type II), achromatizing with ROHS compliant chemicals is done by our vendors (out sourced).

...more

assembly services

Arko Engineers has experience in procuring up to 200 outsourced items such as Glass filled Nylon, Sheet metal, Rubber, Machined parts, Hardware etc ensuring their quality and maintaining their stocks Assemblies as per customer drawings are made.

...more

3D Modeling & Designing Services

We use Solid Works for making part 3D models, Die design lay out & Core Cavity extraction. Our Core competency is in identifying likely problem areas & potential weight savings while increasing the strength of the parts. This includes thermal, ejection and injection force balancing analysis; because if your die designs involve complex 3D geometry, this is a major part of the equation. We provide a turnkey solution to your 3D die design & service needs.

...moreOpening Hours