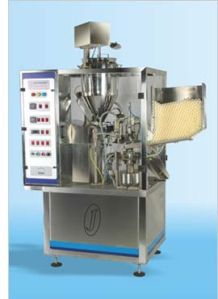

Filltube-120 Automatic Tube Filling and Sealing Machine

Get Price Quote

1 Piece (MOQ)

Automatic Tube Filling machine

Get Price Quote

1 Piece (MOQ)

Best Deals from Automatic Tube Filling Machine

Automatic Tube Filling machine

1,200,000 Per Per Machine

1 Piece (MOQ)

Salient Features: The complete line is manufactured under CGMP standard Consisting of sugar melting vessel, main syrup manufacturing vessel and storage vessel, filter press and pumps All the vessels are interconnected with pipeline and the process is fully automatic, untouched with PLC (Optional) Bottom entry stirrers to restrict overall ceiling height Externally placed inline homogenizer ensures the entire material homogenization and gives option for desired multiple passes in recirculation mode with self inbuilt pumping facility within the unit. Working platform in S.S. 304. ladder with railing at three sides of the platform will be provided Sugar charging under vacuum without vacuum without vacuumising the sugar melting vessel. (Optional) Available in various batch capacities from 500 litres to 5000 litres

Automatic Linear Tube Filling Machine

1,200,000 Per Piece

1 Piece (MOQ)

Automatic Ointment Tube Filling Machine

450,000 Per Unit

1 Unit (MOQ)

Automatic Tube Filling machine

Get Price Quote

Product Descriptions :- TUBE FILLING MACHINE is reliable, flexible and user friendly to give of 70 To 80 Tubes per minute. To make machine easy to use and quick change over, special care has been taken. The machine design provides good access for maintenance and give operator visibility at all the major machine functions. Machine is equipped with high accuracy filling system, provides clean and accurate filling at optimum speed providing high quality and product. The machine is extremely compact. Salient Features :- All Contact Parts SS 316 / 316L as per cGMP Standard.Automatic Tube Loading System.Auto Tube Orientation.No Tube No Fill System.Folding & Coating at individual Station.Simple Mechanism & Operator Friendly MachineCombo Model Suitable For Both Aluminium and Lami/Plastic Tubes.Output 70 to 80 Tubes Min - for Double Head MicOutput 35 to 40 Tubes Min- for Single Head M/c. Technical Specification :- Filling Range 3 gm to 250 gm with change oveiTube Dia. up to 25mm - for Double Head.Tube Dia. up to 45mm - for Single Head.

Automatic Tube Filling machine

Get Price Quote

Automatic Tube Filling machine

Get Price Quote

The machine is suitable mainly for pharmaceutical, cosmetic and food industry. Machine can be used for filling of cream, ointment, gel, paste, balm and other similar viscous products by means of a volumetric dosing system.

Automatic Tube Filling and Closing Machine

Get Price Quote

We are trained enough to execute the packaging of the products systematically. Thus, we follow the packaging guidelines stringently to evade damaging of the products while transportation. Our team members help us completely to deliver exceptional range of products that is in conformance with the standards. Other Details : Automatic tube loading system Auto tube orientation Combo model suitable for both aluminium and laminated/ plastic tube CGMP model PLC model (optional) Output 70 to 80 tubes min-for double head M/C Output 35 to 40 tubes min- for single head M/C Simple mechanism & operator friendly Machine No tube no filing device Lower maintenance require Automatic tube ejection Manually tube feeding Production counter available on control panel to indicate number of tube filling Tube cooling by water to circulation water outside tube for improve sealing quality

Automatic Tube Filling machine

Get Price Quote

Available in single and double head model.. The tube filling, sealing and coding machine is sturdy compact in design and simple in operation. It consists of an aluminium-rotating disc with interchangeable tube holding sockets for different tube sizes.

Automatic Tube Filling machine

Get Price Quote

Fully Automatic Tube Filling Machine

Get Price Quote

Optional Features: Indian Made Hot Air or Switzerland Hot Air. Jacketed Hopper with Stirrer. Tube Counting Device. Tube Orientation. Foot Operated tube sealing machine is best tube sealing machine of its class. The Sealing height of the tube is easily adjustable according to the tube sizes. Being A Manual Tube Sealing Machine its Sealing Quality is as good as Automatic Tube Sealing Machine. In single stroke, machine is capable to seal two tube at a time Greater performance with best quality tube sealing machine. The Sealing of tube is done with the Hot jaw which has Stainless Steel Cartridge heater specially made for this machine. The temperature of tube sealing machine is controlled with Digital Temperature controller for accurate and specific Temperature. Our R&D team has developed a special Electronic Timer for making sealing operation very easy and user friendly. The only Machine Available in the market which is recommended for laminated tubes as well as Plastic tubes. Only Single Person is require for sealing. The Ergonomic of the machine is so excellent that a person without any special skill can operate the machine with comfort. Batch Coding Feature in tube sealing machine. No special Change part require for changing the tube size. Best part of the machine is that the power consumption is very low just 400 Watts. The production of the machine is around 600-900 Tubes/hour. This is easy to move and the dimension of the machine is 600 x 500 x 1200 (W x L x H) which can fit in any corner without taking much space.

Fully Automatic Tube Filling Machine

Get Price Quote

Tube Filling Sealing machine is easy to Operate & compact in its design Tube Sealing Machine Can we available in both Cam Indexer as well as Geneva Mechanism with changeable tube holding unit for variable tube size. The Filling Block and filling syringe which is made in Stainless Steel is arrange in such a manner that it prevent tailing of product to be filled. The Capacity of Simple Stainless Steel Hopper is of Twenty-Five Kilograms. This machine has hot air system for best quality sealing which is imported from Switzerland. Tube Sealing Machine comes with one hot air nozzle with basic M/c. The machine production speed is 30 to 60 tubes/min. The operator just needs to load the tube in the tube holder after that tube is automatically filled , sealed with ultrasonic heater, batch coding and trimming is done after that tube is automatically ejected. Auto Tube Filling Sealing machine is compatible to seal both Lami as well as plastic tube. Description Tube Filling Sealing machine is easy to Operate & compact in its design Tube Sealing Machine Can we available in both Cam Indexer as well as Geneva Mechanism with changeable tube holding unit for variable tube size. The Filling Block and filling syringe which is made in Stainless Steel is arrange in such a manner that it prevent tailing of product to be filled. The Capacity of Simple Stainless Steel Hopper is of Twenty-Five Kilograms. This machine has hot air system for best quality sealing which is imported from Switzerland. Tube Sealing Machine comes with one hot air nozzle with basic M/c. The machine production speed is 30 to 60 tubes/min. The operator just needs to load the tube in the tube holder after that tube is automatically filled , sealed with ultrasonic heater, batch coding and trimming is done after that tube is automatically ejected. Auto Tube Filling Sealing machine is compatible to seal both Lami as well as plastic tube.

Automatic Tube Filling machine

Get Price Quote

When it is a matter of quality then we never compromise with its any aspect, we are inspired to offer you only superior quality products. We offer you automatic tube filling machine and semi automatic tube filling machine which are installed with advanced technology of Ferguson Indexer. All Contact Parts Made out Of SS 316 / SS 316 L Quality Material Conforming to cGMP norms. Moreover it is furnished with Auto feeding and positioning of tubes with �I� Mark Sensing Device. These machines carry many ore features which make them highly preferable at national and international level. Lastly we export only superior quality and high performance automatic tube filling machine. Product Code : 02 We are manufacturer of Automatic Tube Filling & Sealing Machines for Aluminum, Laminated & Plastic Tubes. Salient Features All Contact Parts Made Out Of SS 316 / SS 316 L Quality Material Conforming to cGMP norms.Sturdy and compact in design & simple in operation. Less changeover time & easy cleaning.Advanced technology of Ferguson Indexer. Overload Clutch for Self Centering Chain & Micro switch cut-off system.Auto feeding and positioning of tubes with 'I' Mark Sensing Device.Filling nozzle connected to pneumatic string cutter system for control of tailing. (Unique Rat-Tail Cut off System for drip less filling, or SUCK BACK Mechanism can also be provided).Filling based on diving principle, avoiding air entrapment during filling. Easy volume arrangement in the syringe.Batch Coding Arrangement. (Male or Female Type) Is provided."No Tube No Fill" device, which prevents Dosing action if the tube is not present and the machine, continues to run without stopping. "No Tube Ejection No Run" device helps to avoid damage ie. if the tube is not ejected at ejection station, then machine stops.Automatic Ejection Device to eject tube for cartooning process.Machine is mounted on Heavy "duty dampening pads to sustain vibration & No need of Foundation.For Plastic/Lami tubes: Hot-Air Sealing with Leister (Swiss make Heater) is provided.For Aluminum tubes: Reverse / Saddle fold or 'M' Fold can be provided.

Fully Automatic Aluminium Tube Filling, Crimping, and Coding Machine

Get Price Quote

Salient Features ➤ Auto Feeding & Orientation of tubes with "I" mark Sensor. ➤ Contact parts made of S.S 304/S.S 316L. Quality material the conforms to CGPM Norms. ➤ LEISTER make Hotair tools for Lami Tube Sealing. ➤ No Tube no feeling Device. ➤ Quickly change over from Lami to aluminum tubes within 10 to 15 minutes. ➤ Rotary type & compact design. ➤ Production counter available on control panel to indicate number of tube filled. ➤ Filling Accuracy + 1 % Optional Accessories : ➤ Sealing & Crimping Types: Hot air/ hot jaw / ultrasonics, double triple & saddle type fold for metal tubes. ➤ Jacketed hopper & stirrer. ➤ Batch Coading Arrangement [ Male or Female ] Type is also provided. ➤ Transfers Pumps. ➤ Tube cleaning Attachment.

Semi Automatic Tube Filling Machine

Get Price Quote

For medium speed compact rotary single head type lami/plastic & aluminum tube filling, sealing, batch coding and trimming machine. To fill tooth paste. 5 Gms. To 150 gms. Output 30 to 40 tubes per minute. TECHNICAL SPECIFICATION with SALIENT FEATURES: (RAYALMAX-L35) The proposed GMP MODEL, ROYALMAX-L35 Compact rotary Medium Speed Semi Automatic Lami/Plastic tubes filling & Sealing machine. Capable to fills from 5 grm. To 250 grm. All Contact Part's will be SS 316. Filling System -Positive Suction & Displacement. Attached Pneumatic Blow Tail Cut-off with Control System. NO TUBE - NO FILL Device. And Bottom up Filling System. Filling Accuracy +/ - 0.1%. Tube Sizes max. Length & Diameter: 10 to 50 mm dia./ Length: 40 to 220 mm. Filling Speed 30 to 40 tubes per min. 12 Nos.Tube holding Cup SS-304. And SS Spring Loaded Nylon Holders One Tube Size. Indexing System Geneva Mechanism. Syringe Pump Single Head Type Insert for Filling (5 Gms. to 30 Gms.) (30 Gms. to 100 Gms.) (100 Gms. to 250 Gms.) Any one of the three sets will be provided against requested specification in your order Jacketed Hopper Double Head Type of Capacity of 40 liters. Temparetcher Controller With 3 KW SS Tubular Heater. Belt Less Stirrer Device with augur to keep the product in Continuous homogeneous condition. Geared Motor 0.5 HP, RPM-40 REMI make. With Label Sensor and controller. Feeding the empty tubes manually, and filling, sealing, Coding and Tube Ejector automatically. Lami / plastic Tube heating device Activate on Leister Model Type 3000 Hot Air Tool 8D1 Swiss Make one set. With Hot air Tool adopter Jacketed SS-304, one set. And tube-heating adopter cooling ring centers the tube so That heating is uniform around the tube. Blower: 0.5 HP. (MINI VAC Make) one set. Lami / plastic Tube Sealing Device Activate on Pneumatics. In sealing & coding wherein the tube is pressed & sealed and then coded with metal stereos coding letter punch (female 0 to 9, one set). Machine body Construction Mild Steel 50mm Sq.Box type and Machine bash plate 19mm heavy duty fabricated, with Epoxy Powder Coated And all Safty Cover18 gauge SS 304. Electronic Digital filled Tube Production Counter. Overload Clutch for Centering and Micro Switch Cut-Off System. Main Motor 1 Hp, Make Remi. And Gear Box-30 Ratio Make Elecon. With Separate Drive System. Machine Dimensions: (Length 1460 mm. x Width 930 mm. x Height 2450 mm.) Machine Weight: 425 Kgs.

Automatic Tube Filling machine

Get Price Quote

We have developed a flexible range of machinery that can be used for wide variety of products from different industries like health care, beauty care, cosmetics, pharmaceutical, food processing and many more. We are reputed manufacturer and exporter of Automatic tube filling machine that displays punctual automation with proper synchronization. Our automatic tube filling machine for pharmaceutical and automatic tube filling machine for cosmetics is widely used for many products of respected industry. It can be used for variety of materials like aluminium tubes, laminated and plastic tubes. Different volume of material can be set easily. It is specially built to perform varied function in one stroke. It is a compact and versatile model construct as per GMP standard. It is robustly made to offer continuous filling cycle. It contains 12 stations and contains 40 to 50 tubes per minute. It is also provided with efficient systems for temperature and other controls.

automatic tube filling machines

375,000 Per Units

Automatic Tube Filling machine

Get Price Quote

Automatic Tube Filling Machine Tube filling machine is automatic tube filling machine.Tube filling machine is available in semi-automatic tube filling machine alsoTube filling machine is widely used to fill and seal tubes with viscouse liquids filling ,paste filling, cream filling, tooth paste filling,cosmetic cream filling,gel filling,adhesive filling,ointment fillingTube filling machineis high speed & medium speed tube filling machine series. Tube filler is suitable for Aluminium, Lami, Plastic, LDPE, HDPE etc. tubes. Suiatble to fill 0.5hm-300gm of Ointments, Liquids, Pastes, Creams, Honey, Adhesives, Lotions, Balms, Cosmetics etc. Available in Single Nozzle, double Nozzle for different output. Sealing- Hot Jaw Sealing, Crimping etc. Rotary tube filling machine and linear tube filling machine are 2 major types of BLENZORDrip free filling is main feature of our tube filling machine Technical Specifications : Features The pump unit has a vertical dosing system, which aids in easy suction Bottom-up filling coupled with shut-off nozzle ensures accurate & clean fill without air entrapment Indexer is absolutely smooth. Tool-less adjustments coupled with faster reproduction of settings (aided by position indicators and tri-clover fittings) make changeover quite effortless. Product level sensor, centralised lubrication and a host of safety features like detection of reverse tube, jammed tube, air pressure drop etc. are part of basic machine. Optional equipment Saddle fold Multi-colour filling Designer seal in plastic tubes Gas flushing before & after filling Key Features : Transmission portion on the worktable underside , security Reliable , sanitation. Filling seal tail part build in worktable, half seal no static visible window,easy to observe easy to operate easy to Maintenance. Adopt PLC Control. The dish turn around is using cam drive,high speed,high precision. Slanting suspension type tube warehouse,on the tube organization has the vacuum adsorption equipment, guarantees on the automatic tube accurately to enter the tube socket. The photoelectricity to the sign workstation, tube design using motor control located the correct position. Fills the mouth to have breaks the material organization, guarantee filling the quality. Seal use (Leister sirocco gun ) tube tail , inside calefaction , exterior using temperature cooling device. Input code workstation automatically character code printing in technological requirement position. Tube tail cut mode have the right angle or the fillet supplies the choice. Remind Malfunction,remind haven't tube,the door opens motor automatism stop work , overloads stop work. Count & ration Compact design and auto tube feed. Driving part fully-closed. Tube washing and feeding marking identification, filling, folding, sealing, code printing and finished product output all conducted by a fully auto control system. Tube washing and feeding conducted pneumatically, accurate and reliable. Auto picketage effected by photoelectric inductance. Easy adjustment and dismantling Intelligent temp control and cooling system makes operation easy and sealing reliable. With easy and quick adjustment, it is suitable for using multiple kinds of soft tubes for filling. The part contacting materials is made of 316L stainless steel, clean, sanitary and conforming to CMP for medicine manufacture. With safety device, the machine is shut down when the door is opened and filling carried out only with tubes fed. Overload protection provided. Use: The Model RGNF-30D is suitable for filling all kinds of pasty and high viscous fluid and the materials alike into large diameter plastic and composite tubes and then internally heating tubes, sealing and printing lot number and date. It is used in the industries of pharmaceutics, foodstuff, cosmetic and bond and so on. Parameter Item Parameter Filling volume 5-250ml, Adjustable Productive speed 1800-2400 Tubes/hour., Adjustable Hopper volume 40L Filling accuracy

Semi Automatic Tube Filling Machine

Get Price Quote

We are a Tube Filling Machine Manufacturer based in India. The range of tube filling and sealing machine fabricated by us is used for filling various products in tubes and then sealing it. Various products that can be filled by these machines are cream, gel, ointment, shampoo, tooth paste, and food products such as adhesives, grease, sauce, & others. Basically, products having different characteristics of flow and viscosity are packed by tube filling machine. The machinery is strictly according to GMP norms and has a compatible design, which is ideal for sealing and filling lami as well as aluminum tubes. But, for aluminum crimping a separate attachment is required. Specification Driven Type: Electric Material: Stainless steel