stress relieving

Stress relieving is done by subjecting the crankshaft to a temperature of about 650 ºC (1202 ºF) for about one hour or till the whole part reaches the temperature. This temperature can be adjusted as per customer requirement This removes more than 90% of the internal stresses.

...more

serration

A very special CNC special purpose machine is utilized for the purpose of producing the Serration on the gear end of specific crankshafts which may have a requirement for the same The process is called "deep rolling on serration"

...more

Quality Control

Each crankshaft is inspected for quality throughout the manufacturing process. Once the final process is complete, our crankshafts undergo a thorough final inspection. The specialised & trained technicians perform an exhaustive physical inspection of each part, ensuring the high standard of quality that our customers demand. As per customer demand all reports namely metallurgical, dimensional,etc are provided with every batch or lot supplied.

...more

Tool Post Grinding Machine

All post grinding operations are carried out on our 4-Axis HMC (Horizontal Machining Centre) & VMC (Vertical Machining Centre). The presence of Makino offers the competitive edge & shorter lead times with greater accuracy in crankshaft post grinding operations.

...more

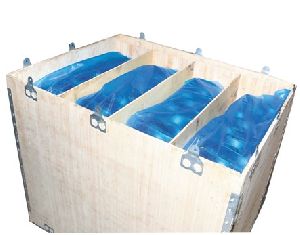

Packaging

We offer two solutions namely to our customer namely Individual & Bulk packaging solutions. An In-house packaging unit provides flexibility to customise packaging as per customer requirement. We provide Anti-rust solutions on the finished crankshafts with choices of Wax or Oil as per customer demand & feedback. In addition to the above, our In-house setup serves us with the opportunity to serve our customers with any wooden packaging requirement they may have. This can be manufactured as per customer size & requirement.

...more

OIL HOLE DRILLING

It is a process for drilling oil holes in a crankshaft. The process includes the steps of placing the crankshaft in a horizontal or vertical position as per machinery in a crankshaft holding unit and maintaining the crankshaft in a single position through the drilling process. The holding unit is then rotated on a vertical axis until the crankshaft faces the drilling unit & the holes are drilled.

...more

metallurgical testing

Metallurgical testing includes microhardness testing and microscopic and macroscopic examinations to evaluate surface and internal features, defects and material characteristics. Samples for all metallurgical testing are prepared at our laboratory.There is an in-house metallurgical lab where inward material is tested & also per lot one unit is cut to check the pattern of the hardness & material flow. The infrastructure enables conducting metallurgical tests in terms of case depth, surface hardness, etc.

...more

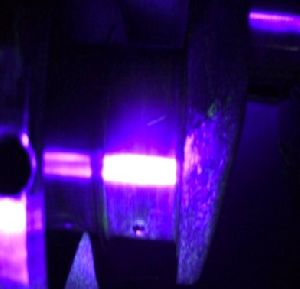

MAGNAFLUX CRACK TESTING Machine

The Magnaflux method is utilized to identify cracks in crankshafts. At ‘Balu’ a 100% Crack testing is carried out on each & every product. The Magnaflux process utilizes an electrical current to produce magnetism in the part being checked. The crankshaft having been magnetized will expose any hidden cracks on the crankshaft & utilizing the ultraviolet light clearly shows the flow crack. The Magnaflux process is a critical step where many cracks would otherwise go unnoticed. The cracks present in crankshafts are often not visible to the naked eye.

...more

Machining

'Balu' is equipped with an In-house Tool room to provide flexibility & speed in manufacturing & reduce dependence on outsourcing to provide a swifter development time to our customers. The Facing & Centering is the process of reduction of the initial imbalance of the crankshaft to be machined, thus assist in the final balancing accuracy of the crankshaft. A reduction in imbalance means less mass to reduced from the balancing weight during the process of balancing and alignment.

...more

Induction Hardening

The company has a complete integrated heat treatment infrastructure. The journals are induction hardened by inserting the coils around the journals & passing heat at 800°C. The hardness of the journals is achieved to a depth of 5 mm. There is also a provision to fillet harden the journals as per customer requirement. We maintain an average hardness as per OEM specification of 56-62 HRC. The company has achieved 10 million cycles in crankshafts manufactured without any breakage on the same, tested & approved by ARAI(Automotive Research Association of India) which is a Government of India company.

...more

gray cast iron engine block

Our 25 years of experience in the manufacturing of engine components, ‘Balu’ has strived to offer end to end solutions to its customers and with the present infrastructure capability & strong financial support, the company has ventured into manufacturing other engine components for specific customer on ‘Made to Order’ (MTO) basis.The company has also assisted companies with Assembling of certain engine parts to offer a more convenient solution to some of our customersWe are also looking forward to add Cylinder Heads, Cylinder Blocks and Camshaft amongst a few to our manufacturing range.

...more

Forging

The Forging Process:The process of forging is carried out on forging hammers with a capacity of upto 16000 T & presses with a capacity of 4000 T. The metal is shaped in the form of a crankshaft by hammering the heated cut piece between the top and the bottom dies fixed on the hammer. The finished product through this process is stronger and superior in quality than a similar product produced by process of casting. The forgings then undergo further processes such as heat treatment, shot blasting and magnaflux crack detection as per customer requirement. A Forged crankshaft is recommended for high power transmission and high RPM applications whereas a cast crankshaft can tolerate less power. The company is equipped with an in-house die making capability, trimming press & heat treatment to eliminate the need for outsourcing. There is an annual capacity of 30000 tons per year for crankshaft forgings.AdvantagesThe Forged crankshafts provide strength and reliability that far surpass any cast or turned bar stock, making forged crankshafts the standard for any use that demands strength, consistency or quality. The general advantages of any forged product over a casting one are as follow: Greater strength Finer grain size Improved microstructure Better fatigue resistance Reduced chance of voids Continuous grain flow

...more

FATIGUE/DURABILITY TESTING

It determines convenience of metal material’s mechanical feature. We use both In-house & outsourced equipment to conduct fatigue tests as per customer requirement. The equipment used to carry out the fatigue test is pulsator & an electrodynamic shaker.

...more

CNC Turning

CNC (Computerized Numerical Control) is the automation of machine tools that are operated by precisely programmed commands encoded on a storage medium. ‘Balu’ boasts of a turning & milling infrastructure consisting of Heller & George Fisher machinery amongst others.

...more

Cnc Grinders

The presence of the state of the Art Newall grinders on our machining line offers an advantage in terms of speed & accuracy. The infrastructure consists of 20 Newall grinders which were purchased from the Ursus factory in Poland. These grinders with a large capacity enable the company to produce 1000 fully finished crankshafts on each working day.

...more

stationary engines

Forging Machine

Crank Shafts

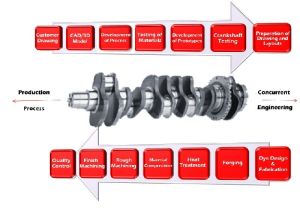

new product development

PRODUCTION PROCESS Die Design & Fabrication :The Design & Fabrication of all type of dies are done through exporting the 3D Model into our Die machining centre.Forging :The crankshafts are forged in our 16000 T hammer / 4000 T Press as per requirement & customer specification. Heat Treatment :The crankshafts undergo a heat treatment process (H & T) & 100% Crack testing (Magnaflux) before we initiate machining of the same.Material composition :The material composition & properties are perfectly checked prior to machining in our R&D Laboratory & testing centre.Rough machining :Initially Facing & Centering, Turning & Milling & Oil Hole Drilling is carried out on the CNC Machines in the Rough Machining Unit.Finish Machining :The Finish Machining Unit consists of CNC grinding, dynamic balancing, post grinding operations, superfinishing & Accessory Product and Assembly.Quality Control :The R&D Laboratory & Testing Centre consisting of metallurgical testing, Crack Testing, Fatigue/durability testing, Dimensional testing, etc ensures that every crankshaft leaving our shop floor is 100% quality checked. CONCURRENT ENGINEERING Customer Drawing :Crankshafts of any applications can be made according to drawing or sample. Through these customer specifications we receive the relevant data required for development.CAD/3D Model :The crankshaft drawings & specifications are developed in our CAD or 3D software.Development Of Processes :The company has gained expertise in manufacturing of crankshafts for more than 25 years in respect to process of material selection, heat treatment, surface treatment,etc.Testing of Material : Material testing is done in our R&D & Metallurgical laboratory. The Use of materials is decided depending upon the chemical composition as per engine running type or if specified in Customer drawing.Development of Prototype :We have a prototype division where entire process of manufacturing is done on a parallel & flexible line without affecting the series of production.a) Forging: The crankshafts are forged in our 16000 T hammers & up to a length of 2.5 metres. The crankshafts undergo a heat treatment process (H & T) & 100% Crack testing (Magnaflux) before we initiate machining of the same.b) Machining: All machining such as Turning, drilling, milling, threading, etc are done on our automated CNC machines.c) Dynamic Balancing & Final Assembly: The crankshafts are dynamically balanced & finally Counterweights & gears are installed if required. Then the crankshafts are ready to install on on the engineCrankshaft Testing :The company has an in-house testing centre & R&D laboratory where crankshafts are subject to various tests & the tests are then collected to understand the future performance of the crankshaftsPreparation of Drawings/Layouts :As the conclusion of our process of Concurrent Engineering, there is a complete documented solution in terms of drawings/layouts for the production process

...more

Dynamic Balancing

The sum of these processes optimises the running behaviour of the crankshaft in the engine and ensures that natural vibrations are as low as possible. Our computer-controlled balancing machines can dynamically balance crankshafts with a length of up to 2.5 m.

...more

metallurgical testing

Be first to Rate

Rate This