Wood Cutting Bandsaw Machine

Get Price Quote

We have come out as the foremost company for providing an excellent quality C.I Body Vertical Wood Cutting Bandsaw Machine that is known for high performance, longer service life, easy operations and sturdiness. We provide these band saw machines in various specifications, as per the ever-evolving requirement of our clients.

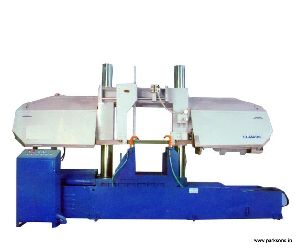

Fully Automatic Double Column Horizontal Bandsaw

Get Price Quote

STANDARD FEATURES : Hydraulically controlled dual viceclamping system Split front vice Roller bearing / carbide blade guide system Pre-set piece counter Out of stock shut off Automatic height control & rapid approach Infinitely variable blade speeds by means of piv Power driven band brush for chip removal Hydraulic blade tension Idler wheel motion detector with stalling & breakage of blade Complete electricals including motors Complete hydraulic system Complete coolant system Bimetal bandsaw blade OPTIONAL ACCESSORIES : Roller table 1500 mm Multiple indexing attachment Undle clamping attachment Variable vice pressure

Best Deals from Band Saw Machine

horizontal metal cutting bandsaw

Get Price Quote

Horizontal Metal Cutting Bandsaw Machine is supplied complete with standard accessories including suitable 440 volts, 3 phase AC electric motor, motorised coolant pump with fittings, V belt & vice. Silent Features: Horizontal Metal Cutting Bandsaw machine are designed for smoother cutting action. Uses worm gear drive. Makes optimum use of cutting blade with provision to change the effective pressure on blade using simple handle. Machine is designed for simple as well as swing cutting action of bow as desired. Machine is available for cutting maximum round bars of 175 mm diameter as well as 300 mm diameter.

Metal Cutting Bandsaw Machine

Get Price Quote

Heavy duty motorised variable speed vertical metal cutting bandsaw machine suitable for cutting of various material like wood, Asbatoss metals and alloys such as copper and aluminium pospher bronze, cast iron, tool steel etc., provided with table which tilt upto 45° wheel guards, electric motor, TEFC, gear box, starter and V-belt & Saw Blade.

Double Column Bandsaw

Get Price Quote

Hydraulic cutting feed maintains constant cutting rate regardless of work piece cross section Hydraulic blade tensioning system and guides keep blade under constant load during cutting Automatic saw frame height adjustment and blade shut off after job completion Blade breakage sensor / motion detector providing automatic shut off Roller bearings with carbide tipped blade guides Motorized chip removal wire brush Optional Automatic Version (DCA): having PLC based control panel with: Hydraulic shuttle vice with 1500 mm roller table Multiple indexing with max. 400 mm single stroke Digital piece counter and Precise length counter with 0.2 mm accuracy Please use bimetal blades for optimal cutting output Accuracy: For 100 mm diameter Cutting taper: ± 0.1 mm Cutting length: ± 0.2 mm Application: High volume cutting of bars, rods, tubes with high productivity Layer and bundle cuts of large work piece dimensions Large profiles and solid materials Accessories:Motorized Job Roller Stand, Automatic Chip Conveyor, Hydraulic Bundle Clamping, Variable Speed Drive, Digital Feed Rate Meter, Blade Tension Meter, Electrostatic Oil Filter, Floating Shuttle Vice for Uneven Bars, Bimetal blades

Bandsaw Machine

Get Price Quote

We are offering bandsaw machine . description mmt 807 mmt 808 mmt 809 mmt 810 mmt 811 mmt 812 mmt 13 size of machine 9" 12" 14" 16" 18" 21" 23" wheel size 9" 12" 14" 16" 18" 21" 23" table size 20" x 22" 20" x 22" 20" x 22" 22" x 22" 22" x 22" 26" x 26" 26" x 26" cutting plate 17 ½" x 16" 17 ½" x 16" 17 ½" x 16" 22" x 20" 22" x 20" 26" x 24" 26" x 24" max. Cutting thickness 8" x 4" 10½"x 5" 12½" x 6" 13½" x 7" 15½" x 8" 18" x 10" 21" x 11" blade size ¾ " ¾ " 1" 1¼" 1½" 1½" 1½" power required 1 hp 1 hp 1.5 hp 2 hp 2 hp 3 hp 3 hp rpm required 1500 1500 1500 1500 1500 1500 1500

Band Saw Blade, Wire Butt Welding Machine

Get Price Quote

Welding Process: - The Saw Blades or Wire Ends to be joined should be cut straight, exactly at right angles and free from burrs on special shearing attachment (optional equipment) - Welding Current, Upsetting Pressure and Upsetting Way are set according to the blade width - The blade ends are rigidly clamped in special quick acting clamps provided on the machine - By depressing the welding lever, the welding process begins - The two ends are heated to forging temperatures in a few seconds and are then automatically forged (upset). The welding current switches off automatically - The job is de-clamped and the weld completed Process for Annealing: The upsetting way switch lever is now turned to annealing and the job is clamped again with the extended jaw distance which comes in automatically on flipping the lever to annealing position. - By pressing the annealing switch on which two heat positions are provided, the job is annealed in order to normalize the brittleness of the welded area. - Depending on the type of material, the annealing process should be repeated several times if need be. Shearing Attachment (optional): Special shears with arrangement for mounting on the front of the machine are available Grinding Attachment (optional): Grinding attachment mounted on top of the machine is necessary for removing the welding flash

Portable Band Saw

38,400 Per Piece

Horizontal Band Saw

Get Price Quote

We are leading supplier of huge range of Horizontal Band Saw.

BI Metal Hole Saw Cutter

320 Per Piece

Features: Circle cutter Portable drill Drills large holes Ergonomic grip

Band Saw Machines

Get Price Quote

Standard Features 1. Precise cut off length setting. 2. Auto head elevation and quick approach control. 3. Nesting fixture device for bundle cutting. 4. Cutting piece counter with auto-shut-off. 5. Multiple stroke counter for log pieces. 6. Power-driven blade cleaning brush and coolant cleaning flush hose. 7. Carbide and roller blade guides. 8. Hydraulic shuttle vice back-jaw feed method. 9. Hydraulic blade tension control. 10. Work-area light. 11. Automatic chip conveyor 12. Two-way open rear vice jaws to insure precise bar feed repeatability even in cutting a little bit warped / surface rough works. 13. Unique split machine vice allows cutting to within as little as 50mm of bar end automatically. Automatic and Semi - Automatic Band saw machines

metal band saw machine

Get Price Quote

metal band saw machine, Hydraulic Press, Single Stage Compressor

Band Saw Machines

Get Price Quote

Band Saw Machines, Bandsaw Blades

Band Saw Machines

Get Price Quote

Band Saw Machines, adjustable angle heads, Reamers, Universal Sensor

Bandsaw

Get Price Quote

Bandsaw, Straight Shank Drill Bits, Adjustable Angle Plates, Utility Knife

Metal Cutting Band Saw Machine

Get Price Quote

Metal Cutting Band Saw Machine, Cutting Tool, Tool Bit