POP Batching Plant

Get Price Quote

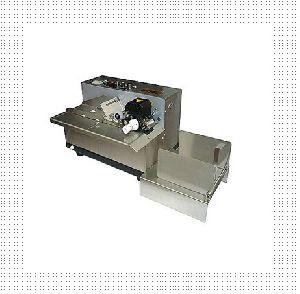

carton batch coding machine

85,000 Per Piece

1 Piece (MOQ)

Best Deals from Batching Plants

Star Batcher Concrete Batching Plant

Get Price Quote

We are an unsurpassed Manufacturer and Supplier of Star Batcher Concrete Batching Plants from Maharashtra. With the help of our Star Batcher Concrete Batching Plants, the aggregates are separated according to components and stored at ground level on a prepared surface. Depending on the concrete quality, different types of Star Batcher Concrete Batching Plants (mixed gravel) or separated fractions can be used. Weighing the aggregates takes place directly in the feeder skip.

Inkjet Batch Code Printing Machine

26,500 Per Piece

1 Piece (MOQ)

Hot Foil Batch Code Printing Machine

18,000 Per Number

1 Number (MOQ)

Candy & Toffee Batch Roller

Get Price Quote

CANDY & TOFFEE BATCH ROLLER Batch Former form conical shape of kneaded mixed and cooled batch of Lollypop / Candy / Toffee for further feeding into Rope Sizer. It is fitted with heaters to keep the batch warm. It's lifting and lowering mechanism helps the batch coming forward automatically. It is fitted with Stainless Steel Rollers. Electrical reverse and forward system is required extra for operating the batch former. There is ease of taking out rollers for cleaning operation. Stainless Steel trough is built up with stainless steel rotary conical roller clockwise & anti Clockwise which converts the cooked mass into cone shape. Batch roller can be used for toffee and candy.

manual batch printing machine

5,000 - 7,000 Per Unit

1 Piece (MOQ)

We are offering manual batch printing machine. In addition of feeding and discharging the labelscartonsbags by hand, the stroke of the machine is also operated by hand.

Used Batching Plant

2,000,000 Per Set

automatic batch coding machine

Get Price Quote

5 Line Industrial Continuous Inkjet Printing Machine. Focusing on 2 key elements we are delighted to reveal our best value for money, general purpose continuous inkjet printer designed with your needs in mind: Reliable Simple Videojet has redefined SIMPLE with the Videojet 1280 Continuous Inkjet (CIJ) Printer. From the intuitive interface to smart design features, the 1240/1280 CIJ printer is simple for operator to use. The 1240/1280 CIJ printer features an 8” tablet-inspired SIMPLICiTY™ interface, greatly reducing operator printer interactions, and helping to eliminate potential user errors.

High Speed Automatic Batch Printing Machine

Get Price Quote

Automatic Batch Printing Machine is commonly used in pharma, Food , Cosmetics edible oil ,lube oil & bakery products, and allied industries suitable to neat, sharp & registered print Batch Number, Date Of Manufacturing, Expiry Date, Prices, best before dates, applied on labels, cartons and pouches. with the help of Rubber or Polymer flat Stereos. Machine with automatic feeding System, Stack of Pouches/ cartons is pulled or pushed by roller & collected from the tray after printing the message. Specifications Over All Dimensions : 850mm X 765mm X 575mm Speed : 125/180/250 imprints per minute. Printing Media : Fast dry permanent paste ink or Liquid Ink Label, Pouch or Carton Size : Minimum 75mm X 35mm to Maximum 300mm X 200mm Motor : ¼HP/ 0.18KV 1440RPM (50Hz) Power : 230 Volts, Single Phase or 400/440 Volts, 3Phase Weight : Approx 95 kg Applications : Label & Sticker, PVC Shrink Sleeve, small carton, pouch and sachet.

Batch Coding Machine

Get Price Quote

For the tabletop system, the coder is mounted on a stand and the item to be printed is placed manually and either a foot switch is pressed or a timer activates to code semi-automatically. For the on-line system, the print head is mounted on the machine and coding is done whenever the parent machine stops for sealing. It is electronically synchronized with the packaging machine to give registered coding at exact location. DC stepper motor based very compact, lightweight and portable design. Can be used as a replacement for electro-pneumatic coders (does not require compressor) for packaging machine mounting also. low cost machine with very low operating and inventory costs. Uses standard grooved or flat stereos and fast drying coding ink. in built timer for automatic timed operation (settable) or can be connected to any sensor or foot switch for controlled operation. Imported motor and accessories provide reliability & long life.

Table Top Batch Coding Machine

Get Price Quote

High Speed Table Top Coder Model TTC – 380 – T for registered printing of B.No., Mfg. Dt., Exp. Dt., MRP `, etc. using Print-Dry Solid Wax System. The message (upto 6 lines) to be printed is composed by assembling changeable brass or grooved rubber stereos by pushing them onto the rods on the print drum. The stereos & the replaceable circular hot wax ink cartridge are heated to a temperature of around 150oC for printing on the substrate, so it is instant drying. The labels / cartons (max. size 200 X 380 mm) are stacked or fed individually in the input tray for feeding, automatically picked up one by one by the reverse roller, passed under the print head & stacked in the collection tray at speeds upto 300/min. The location of printing is electronically settable by trim-pots & also a preset counter can be set for the coder to stop automatically when the desired production is over. (Free accessories include 2 mm Numeric Brass Character Set & Hot Wax Ink Cartridge). This coder is ideal for Automatic High Speed Coding on large quantities of labels & cartons.

Batch Coding Machine

Get Price Quote

Features : Machines based on photoelectric mechanism technology Machines providing for auto counting, adjustable print position and automatic temperature control Comes with printing roller used for both R arrange and T arrange versions For T arrange, these can print 1-10 lines with presence of 1-10 characters in each line For R arrange, machine can print 1-8 lines with presence of 1-8 characters in each line Available in options including 2mm, 2.5mm, 3mm Can work efficiently as well as automatically at high speeds up to 30pcs per minute Ideal for meeting the printing demands of labels on papers, non-absorbent plastic film, and aluminum film Printing achieved using solid ink/color ribbon Machine providing instant printing & instant dry options Machines offering choice of different colors Designed to match with vertical/horizontal packaging machine Printing roller used for R arrange and T arrange of types Can work efficiently at high speeds Suitable to printing signs like manufacturing date, lot number Fast printing speeds

hot foil coder

Get Price Quote

Hot Foil Coder Useful to print Batch Numbers, Manufacturing Date and other details on the Product, Online Process to Print details on Labels.

Table Top Batch Coding Machine

28,000 Per Piece

1 Piece (MOQ)

manual batch printing machine

2,599 - 3,499 Per Piece

1 Piece(s) (MOQ)

Hand Stamping System can be used for Printing and Marking Batch No., Mfg. Date., Exp. Date., M.R.P.Rs., etc. on pouch, Tin, Labels, Cartons, Foils etc. Manual Coding Machine is a very easy to operate by hand. It is light weight, self inking, durable & reliable hand-held manual coder. Manual Coder for the production requirement of approximately up to 500 pieces per day per to print help with special batch coding ink and Ink activator for reducer ink viscosity it stronger than permanent marker ink on most shiny surfaces, including shiny papers, most plastics, metals and glass. Hand Code is self inking by especially formulated & processed felt pad. Hand Stamping System is date printing equipment, Hand-held Coding Machine is work on imitated, absorbent & non absorbent surface. Manual batch coding machine provide interchangeable one (Letter) Grooved, Flat Rubber, Metal, Nylon Stereos Kit Box any one with each coder.

Concrete Batching Mixing Plant

Get Price Quote

We are offering concrete batching mixing plant sumedha systems pvt. Ltd. Is a leading supplier of concrete batching mixing plant. The concrete batching mixing plant has been widely used for various applications, primarily in the construction industry and is available in various specifications. We offer the mini auto batching, mixing plants, and concrete batching plant. In addition, the concrete batching mixing plant is available at competitive market prices. capacity : 30/60 cable meter

FABRIC PREPARATIONS MACHINES

Get Price Quote

The B-Tex Big-Batching Machine, BIM-BB is a combination of small processes to join small fabric rolls to big batch.With years of experience and number of Installation,We are confident to supply many possible process in one machine.BIM-BB can make big batch fabric small rolls with additional equipments like Conveyors , Anti-Weighing, Auto-Sewing operation, Inspection Table with Lights , Brushing and Beating Unit, J-Scray with Plaiter & Big-Batch output option. This BIM-BB saves lots of space,manpower,time and number of operations are possible in one go. simple Roll to Batch machine can also be supplied for fabric width from 150 cms to 600 cms. BIM-BB is fully tailor-made machine and allows to join any possible process in same machine. Benefits Suitable for all types for fabric Woven, Non-Woven & Technical Fabrics Number of process can be incorporated like Sewing, Brushing, Inspection, J-Scray, etc. Conveyor can be supplied for continous process Fabric can be delivered in Big-Batch and Plaiter also. Saves number of manpower, space and Time

batch off cooling machine

1,500,000 - 4,000,000 Per piece

1 Nos (MOQ)

Batching Machine for Textile Industries

Get Price Quote