Automatic Bar Bending Machine

90,000 Per Piece

Our fully Automatic Bar Bending Machine are operated through manual button as well as automatic button and deliver stable performance with optimum safety. Further, our machines enable the users to control the path and return it back automatically.

Wire Bending Machine

Get Price Quote

Saminder Singh Saan the son of Respected Mr Joginder Singh Saan is B.E.(HONS) in Mechanical Engg from London ,UK following the legacy of the family adding a new dimension to the organisation. Taking care of International Business and introducing the new concept of Machine Designing and manufacturing as per the European Standards. This machine produces cotton bail wire knots using striaghtened cut wires as raw material.

Best Deals from Bending Machine

Steel Bending Machine

Get Price Quote

Longer Life of Machine Increased Life of Blades Ease of Operation Lower Power Consumption Lower Frequency of Electrical Breakdown Lower Oil Consumption Additional Safety for Motor Monolithic Steel Structure: Spartan's newly launched premium series of Cutting machines are designed in a monolithic steel structure using higher thickness of steel plate so the number of welding joints in the body are minimal which ensures better design strength of body and longer life of the machine.

Pipe Bending Machines up to 60"

Get Price Quote

We are manufacturer and exporters of Pipe Bending Machines up to 60".

Slip Roll Bending Machine

Get Price Quote

FORMMASTER'S Slip Roll Bending Machine is the most fundamental machine for producing round cylindrical sheet metal shells Our Slip Roll Bending Machines are built primarily for sheet metal fabrication works for producing round cylindrical sheet metal shell. The machine have initial pinch type bending arrangement to produce round cylinder to high accuracy. The three roll bending machine are ideally suited for mass production & is so design to enable quick adjustment of thickness and diameter. The machine includes all the latest features. It is one of the most convenient and easy to used three roll bender available. Both the bottom roll and taper bending roll can be adjusted by mean of a single individual hand lever. The upper roll can be easily disengage and can be rotate on pivot at one end to remove the complete closed cylindrical shell. Features: Modern Initial Pinch Type Design Ruggedly Build Positioning of Rear & Bottom Roll with Single Hand Lever Swing-out Top Roll High Quality Steel Rolls Heavy Duty Construction

Bar Stirrup Bender Machine

Get Price Quote

busbar punching machine

Get Price Quote

1 Piece (MOQ)

rebar bending machines

Get Price Quote

» Hydraulic cutting machines cuts with hydraulic drive system. » Machines are with wheels can be carried to construction field easily. » Wearing and breaking can’t exist in years since the joint places boiled with special wending technology. » Easy use and routine maintenance is performed by user. » 8 sides of all machine blades can be used. » All the surfaces of the machine which works are increased their durability with heat treatment.

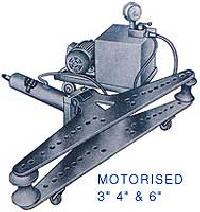

Roll Bending Machine

Get Price Quote

Roll Motorized Bending Machine have an initial pinch type arrangement. The three rolls are asymmetrically arranged to produce rolled cylinders to a high accuracy. It is ideally suited for mass production and so designed to enable quick adjustments for thickness and diameter. All the three rolls are of same diameter. The two front rolls are known as pinch rolls; the top roll is in a fix position. The lower front roll is adjustable up and down to suit the thickness of the sheetplate being rolled. The rear roll or bending roll is adjustable up and down to determine the diameter of the cylinder to be produced. The formed component can be easily removed in a few seconds simply by lowering the tail hinge & moving down the lower roll which will release the pressure on the rolled sheet & by rotating the screw at the other end which will cause the top roll to tilt thereby permitting the removal of the finished product.

Bending Machine

Get Price Quote

We are offering bending machine. Machines for bending thin sheets of metal (sheet metal) between an upper and lower tooling. Also referred to as press brakes.

Angle Bending Machine

Get Price Quote

We are offering angle bending machine. Maximum bar size:58 solid 1010 bar maximum tube size: 1.00" o.d. X .083 wall steel tube maximum degree of bend:200 degree maximum bend radius:3.00 inches bending arm speed:60 degrees per second h.p. Of hudrulic unit:1 12h.p.

Bar Bending Machine

Get Price Quote

1 Piece (MOQ)

ROLL BENDING BLOCK (MAE-WEST BLOCK)

Get Price Quote

Repair includes repair of cylinder bore by welding machining & grinding process, Hard chrome plating of piston rods, Replacement / Modification of sealing system, Rectification of Oil paths / Drills ,Re-chasing / Re-Tapping of threaded holes, Maintaining parallism of liner faces. Load testing facility up to 250 T capacity. United Van Der Horst has also manufactured new design roll bending blocks with I.D. hard chrome plated and ground surface finish along with Low friction sealing design.

busbar punching machine

Get Price Quote

We provide a quality assortment of Busber Punching Machine to the customer. Our vendors come out with absolutely flawless and reliable products that are highly corrosion resistant and durable. These products require low maintenance and are offered by us, at market leading prices to the customers.

busbar punching machine

8,500,000 Per Piece

roll bending

Get Price Quote

CONTROL Conventional COUNTRY OF ORIGIN Sweden DELIVERY TIME IMMEDIATE AGAINST PAYMENT DIAMETER 25mm LENGTH 3m ROLL DIAMETER 1040MM 3 Rolls WEIGHT OF THE MACHINERY CA. 25 Ton DIMENSIONS OF THE MACHINERY CA. 6 X 2.25 X 2M

Rebar Benders

Get Price Quote

Rebar Benders, Reinforcing Steel Bar Cutting Machine - M Series

pyramid type plate bending machine

Get Price Quote

SHEET METAL & FABRICATION MACHINE, PYRAMID TYPE PLATE BENDING MACHINE, CAPACITY THICKNESS X WIDTH : 3 X 1250 IN MM, DIA OF ROLLS: TOP 100, BOTTOM 90, MAIN DRIVE MOTOR : 2 HP, CAPACITY THICKNESS X WIDTH : 16 X 2000 IN MM, MAIN DRIVE MOTOR : 12.5Hp.

Busbar Bending Machine

Get Price Quote

Busbar Bending Machine, Fiber laser cutting machine, Busbar Cutting Machine

Channel Letter Bending Machine

Get Price Quote

Channel Letter Bending Machine, Laser Engraver, Aprint CRIS G Solvent Printer