William Torque Multiplier

9,999 Per Piece

1 Piece (MOQ)

Provides the operator with nut-turning power that requires only a fraction of the force required when using conventional tools Input and output rotation is in the same direction Reaction bar rotation is opposite to input direction and must rest securely against a rigid object to withstand the generated reaction force By removing 4 screws, heads may be easily disassembled for inspection, cleaning and lubrication

Weight : 13.38 Pounds

Application : Garage

Material : SS

...more

VDE 1000v Insulated Toolkit Trolley

49,999 Per Piece

1 Piece (MOQ)

### **VDE 1000V Insulated Toolkit Trolley: An In-Depth Overview****Introduction**A VDE 1000V insulated toolkit trolley is a specialized piece of equipment designed to safely and efficiently transport and organize insulated tools for electrical work. The VDE (Verband der Elektrotechnik) certification ensures that the tools in the trolley can handle voltages up to 1000V, providing essential safety when working with live electrical circuits. Here’s a comprehensive guide to understanding the features, benefits, applications, and maintenance of a VDE 1000V insulated toolkit trolley.---### **Features**1. **VDE Insulated Tools**: - **High-Voltage Safety**: The tools included in the trolley are insulated to safely handle voltages up to 1000V, adhering to VDE standards for electrical safety. - **Tool Variety**: Typically includes a range of insulated tools such as screwdrivers, pliers, wrenches, and other essential instruments.2. **Trolley Construction**: - **Durable Material**: The trolley is constructed from high-quality materials like steel or heavy-duty plastic, ensuring robustness and durability. - **Design**: Features a sturdy frame with wheels for easy mobility and compartments or drawers for organized storage.3. **Organizational Features**: - **Tool Storage**: Equipped with compartments, drawers, and holders to securely organize and store tools. This helps in quick access and prevents tool damage. - **Labeling**: Some trolleys include labeled compartments or custom trays for specific tools, enhancing organization and efficiency.4. **Mobility**: - **Wheels and Handles**: Fitted with robust wheels and a handle for smooth movement across various surfaces. The wheels are often designed for easy maneuverability, even in tight spaces. - **Stability**: Includes locking mechanisms to keep the trolley stable and prevent unwanted movement when stationary.5. **Ergonomic Design**: - **User Comfort**: Designed for ease of use with ergonomic handles and well-organized compartments to minimize strain and improve access to tools. - **Accessibility**: Tools and compartments are positioned to ensure that frequently used items are easily accessible.6. **Safety Features**: - **Insulated Handles**: Tools have insulated handles to provide protection against electrical shock. - **Secure Locking**: Drawers and compartments often feature secure locking mechanisms to prevent accidental opening and tool loss.---### **Applications**1. **Electrical Work**: - **Live Circuit Maintenance**: Essential for professionals who work with live electrical circuits, as the VDE insulation ensures safety against electric shocks. - **Installation and Repair**: Ideal for electrical installation, maintenance, and repair tasks in various environments.2. **Industrial Use**: - **Factory and Manufacturing**: Useful in industrial settings where electrical tools are frequently used, providing a safe and organized way to transport tools.3. **Commercial and Residential Electrical Work**: - **Service Technicians**: Perfect for electricians who require a mobile and well-organized toolkit for residential and commercial service calls.4. **Maintenance and Repair**: - **General Use**: Suitable for general maintenance and repair tasks where a comprehensive set of insulated tools is required.

Application : Agriculture

Country of Origin : Made in India

...more

VDE 1000V Insulated Socket Set

999 Per Piece

1 Piece (MOQ)

The term "VDE 1000V Insulated Socket Set" refers to a set of sockets that are designed and tested to meet the safety standards outlined by the Verband der Elektrotechnik (VDE), which is the Association for Electrical, Electronic, and Information Technologies in Germany. The "1000V" indicates that the tools in the set are insulated and rated for use in electrical systems with voltages up to 1000 volts. Here are some key points about VDE 1000V insulated tools: Insulation: The tools in the set, including sockets, are insulated to prevent electrical conductivity. This insulation is crucial when working with electrical systems to protect the user from electric shock. Testing Standards: VDE is known for its stringent testing standards. Tools that meet VDE standards undergo rigorous testing to ensure their safety and effectiveness in electrical work. Application: The VDE 1000V insulated socket set is specifically designed for use in electrical applications. Electricians and professionals working on or near live electrical components use these tools to reduce the risk of electrical accidents. Material: The sockets in the set are typically made from high-quality materials that offer good mechanical strength and durability. The insulation is often made of materials that provide protection against electrical conductivity. Color Coding: VDE tools often incorporate color-coding to help users quickly identify the insulation level. For example, yellow is a common color for 1000V insulation. When working on electrical systems, it's crucial to use tools that meet safety standards to minimize the risk of injury or damage. Always check that your tools are properly insulated and rated for the voltage levels you are working with. Additionally, following safety guidelines and procedures is essential for anyone working with electricity. Certainly, let's delve a bit deeper into the components and features of a VDE 1000V insulated socket set: Socket Types: The set may include a variety of socket types to accommodate different fasteners and applications. Common types include hex sockets, Torx sockets, and others. Having a diverse set ensures that the electrician or technician has the right tool for the job. Ratchets and Extensions: In addition to sockets, the set may include insulated ratchets and extensions. Ratchets are used to apply torque to fasteners, and extensions provide reach in confined spaces. Both are crucial for versatility in electrical work. Insulation Material: The insulation on VDE tools is often made from materials like high-quality polymers or rubber. These materials are not only good insulators but are also resistant to wear, tear, and common chemicals encountered in industrial environments. Testing and Certification: VDE 1000V insulated tools are subjected to thorough testing to ensure their compliance with safety standards. The tools may bear a certification mark from VDE or other relevant authorities, indicating that they meet or exceed safety requirements. Storage Case: Many sets come in a durable storage case to keep the tools organized and protected when not in use. This is especially important for maintaining the integrity of the insulation and ensuring that the tools are readily accessible. User Guidelines: Manufacturers often provide guidelines for the proper use and maintenance of VDE tools. Users should follow these guidelines to ensure the longevity and safety of the tools. Maintenance and Inspection: Regular inspection of the insulation is crucial. Any signs of wear, damage, or cracking should be addressed immediately, and the tool should be taken out of service if its insulation is compromised.

Feature : Best Quality, Fine Finished

Application : Industial

Material : Insulated

Grade : IEC 60900

Brand Name : Hi-Tech

...more

VDE 1000V Insulated Battery Toolkit

9,999 Per Set

1 Set (MOQ)

A VDE 1000V insulated battery toolkit is a specialized set of tools designed for working on electrical systems, including battery-related tasks, with a focus on safety and protection against electrical shock. The "VDE 1000V" designation means that these tools are tested and certified to withstand up to 1000 volts, making them suitable for use on live electrical circuits. Here’s a detailed overview of a typical VDE 1000V insulated battery toolkit: Components of a VDE 1000V Insulated Battery Toolkit Insulated Screwdrivers: Types: Includes various types of screwdrivers such as slotted (flat head), Phillips, Pozidriv, and sometimes Torx. Insulation: Each screwdriver is insulated to protect against electrical shocks up to 1000V. Handles are ergonomically designed for comfort and control. Insulated Pliers: Types: May include combination pliers, needle-nose pliers, and side-cutting pliers. Insulation: Pliers are insulated to provide protection when working near live wires or electrical components. Insulated Wrenches: Types: May include adjustable wrenches and specific-size wrenches (like open-end or box-end) with insulated handles. Insulation: Provides safety for tasks involving nuts and bolts in electrical systems. Insulated Socket Set: Components: Includes insulated sockets and ratchets for working with bolts and nuts. Insulation: Ensures safety while working on live electrical components. Battery Tools: Battery Spanners: Specially designed wrenches for handling battery terminals and related components. Battery Terminal Cleaners: Tools for cleaning battery terminals safely. Other Tools: Insulated Tweezers: For handling small electrical components safely. Insulated Wire Strippers/Cutters: For stripping or cutting insulated wires safely. Insulated Voltage Tester: To check for the presence of voltage. Features and Specifications Insulation Rating: VDE Certified: Tools are tested and certified according to VDE (Verband der Elektrotechnik, Elektronik und Informationstechnik) standards, ensuring they are safe for use up to 1000V. Material: Insulation is typically made from high-quality plastic or rubber designed to resist electrical current. Ergonomic Design: Handles: Tools have ergonomic handles for comfort, reducing hand fatigue during extended use. Handles are often non-slip for better grip. Tool Geometry: Designed for precision and ease of use in confined or complex spaces. Material Quality: Blades and Tips: Made from high-strength steel, such as chrome vanadium, for durability and resistance to deformation. Manufacturing Standards: Tools are manufactured to high standards to ensure reliability and safety. Applications Electrical Work: Battery Maintenance: Suitable for tasks such as replacing or maintaining batteries, including working on battery terminals and connections. Live Electrical Work: Can be used for working on live electrical systems where safety from electrical shock is crucial. Automotive: Car Batteries: Ideal for use in automotive repair and maintenance, particularly for working with car batteries and electrical systems.

Application : Agriculture

Material : Mild Steel

Country of Origin : Made in India

...more

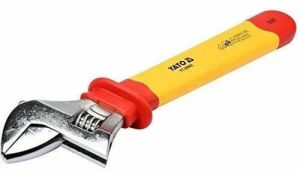

VDE 1000V Insulated Adjustable Wrench

1,999 Per piece

1 piece (MOQ)

An "1000V insulated adjustable wrench" is a type of adjustable wrench designed for electrical work in environments where there is a risk of exposure to high voltage. The term "1000V" indicates that the tool is rated for use in electrical systems with voltages up to 1000 volts. This type of wrench is also often referred to as an insulated adjustable spanner or insulated adjustable wrench. Here are some key features and considerations for a 1000V insulated adjustable wrench: Insulation: The wrench is designed with insulation to protect the user from electric shock. The insulation is typically made of materials that do not conduct electricity, such as high-quality plastics or rubber. Adjustability: Like a standard adjustable wrench, it should have a movable jaw that can be adjusted to fit different sizes of nuts and bolts. Material: The wrench should be made of durable and high-quality materials to ensure longevity and reliability. Safety Standards: It's important to ensure that the wrench complies with relevant safety standards for electrical work. This might include standards set by organizations like OSHA (Occupational Safety and Health Administration) or other regional safety authorities. Comfort: The ergonomic design of the handle is essential for comfortable use during extended periods of work. Markings: The wrench may have voltage rating markings, indicating the maximum voltage it can safely handle. When working with electricity, always prioritize safety. Make sure to use tools that are specifically designed and rated for electrical work to minimize the risk of electric shock or other hazards. Additionally, follow proper safety procedures and wear appropriate personal protective equipment as necessary. Certainly, here are a few more details and considerations: Usage in Electrical Work: A 1000V insulated adjustable wrench is primarily used in electrical work environments where there is a risk of exposure to high voltage. Electricians and other professionals working with live electrical systems use insulated tools to reduce the risk of electrical shock. Material of the Insulation: The insulation on the wrench is crucial for safety. It should be made from high-quality, non-conductive materials that can withstand the stresses of regular use. Common materials include rubber or specialized plastics. Testing and Certification: Tools designed for electrical work, including insulated adjustable wrenches, often undergo testing and certification to ensure they meet safety standards. Look for certification marks from relevant safety organizations when purchasing such tools. Durability: Given that these tools may be used in demanding environments, they should be durable and able to withstand rough handling. The durability of both the insulation and the metal parts of the wrench is essential. Size and Adjustability: The adjustable feature allows the wrench to accommodate various sizes of nuts and bolts. Ensure that the wrench's size and adjustment range match the requirements of your specific tasks. Maintenance: Regular inspection and maintenance of insulated tools are important to ensure that the insulation remains intact and effective. Any signs of wear or damage to the insulation should be addressed promptly. Storage: Proper storage is essential to maintain the integrity of the insulation. Avoid storing the wrench in a way that could cause damage to the insulation, such as exposure to sunlight, extreme temperatures, or contact with sharp objects. Manufacturer's Guidelines: Always follow the manufacturer's guidelines and instructions for the proper use and care of the tool. This includes information on cleaning, storage, and any limitations on use. Remember, using insulated tools is just one aspect of electrical safety. Adhering to established safety procedures,

Application : Electrical

Material : PU

Size : 8\"

Grade : IEC 60900

Brand Name : INSULA

Country of Origin : Made in India

...more

VDE 1000v 52 Pcs Insulated Toolkit

49,999 Per Piece

1 Piece (MOQ)

A VDE 1000V 52-piece insulated toolkit refers to a comprehensive set of tools that are specifically designed and certified for working on electrical systems up to 1000 volts. Here's what you can typically expect in such a toolkit: Insulated Tools: All tools in the kit are insulated to protect the user from electric shock when working on live circuits. The insulation is usually tested and certified according to standards like VDE (Verband der Elektrotechnik, Elektronik und Informationstechnik) in Germany. Variety of Tools: The toolkit includes a wide range of tools commonly used by electricians and technicians, such as: Screwdrivers (flathead and Phillips) Insulated pliers (combination pliers, long nose pliers, side cutting pliers) Insulated wrenches (adjustable wrenches, spanners) Insulated hex keys (Allen keys) Insulated sockets and ratchets Cable cutters Voltage tester (non-contact or contact type) Storage Case: The tools are typically organized in a durable and portable storage case or box, keeping them protected and easy to transport. Certifications and Standards: The toolkit meets international safety standards for insulated tools, ensuring they provide adequate protection against electrical hazards. Usage: Such toolkits are essential for electricians, maintenance technicians, and anyone working on or near electrical installations where there is a risk of exposure to live circuits. Maintenance: Insulated tools require regular inspection to ensure the integrity of the insulation. Any damage to the insulation can compromise safety and should be addressed immediately. When purchasing or using a VDE 1000V 52-piece insulated toolkit, ensure that it is certified and appropriate for the voltage levels you will be working with. Following safety procedures and using the right tools for the job is crucial to preventing accidents and ensuring personal safety when working with electricity.

Application : ELECTRICAL

...more

VDE 1000v 20 PC Insulated Ring Wrench Set

9,999 Per Piece

1 Piece (MOQ)

A **VDE 1000V 20-piece insulated ring wrench set** is a specialized tool kit designed for safe and effective use in electrical environments where there is a risk of electric shock. The set includes a variety of insulated ring wrenches, all rated for use with high voltages. Here’s an overview of its features, components, applications, and benefits:### **Key Features:**1. **VDE 1000V Insulation Rating**: - **High Voltage Protection**: Rated for use up to 1000V, ensuring protection against electrical shocks. The insulation on the tools provides a safety barrier when working with live circuits.2. **Insulated Construction**: - **Material**: Made from high-quality materials such as chrome vanadium steel or similar alloys, with an insulating coating that meets VDE (Verband der Elektrotechnik) standards. - **Insulation Compliance**: The insulation typically conforms to safety standards such as IEC 60900, ensuring reliable protection.3. **Ring Wrench Design**: - **Ring End**: Features a ring-shaped end designed to grip fasteners securely. The ring end is often equipped with a 12-point or 6-point design to fit various fasteners. - **Open End**: Some sets may also include open-end wrenches for additional versatility.4. **Variety of Sizes**: - **Comprehensive Set**: The set usually includes a range of sizes to cover various fastener sizes and applications, providing flexibility for different tasks. - **Size Markings**: Each wrench is marked with its size for easy identification.5. **Durability and Strength**: - **Robust Construction**: Designed to withstand heavy use and resist wear, impact, and corrosion. - **Wear Resistance**: The wrenches are engineered to maintain their performance and insulating properties over time.6. **Ergonomic Design**: - **Comfortable Grip**: The wrenches are often designed with ergonomic handles for a comfortable grip, reducing user fatigue during extended use.### **Components of the Set:**1. **Insulated Ring Wrenches**: - **Variety of Sizes**: Typically includes a range of sizes, from small to large, to accommodate various fasteners. - **Insulated Coating**: Each wrench is coated with insulation to ensure electrical safety.2. **Storage Case**: - **Organizer**: Often comes with a sturdy case or tool rack to keep the wrenches organized and easily accessible.### **Applications:**1. **Electrical Work**: - **High-Voltage Environments**: Essential for safely working with electrical components and live circuits. The insulation ensures user safety from electrical shocks. - **Electrical Maintenance**: Ideal for assembling or repairing electrical panels, devices, and installations.2. **Industrial and Mechanical Settings**: - **General Maintenance**: Suitable for various maintenance tasks where electrical safety is a concern. - **Assembly**: Useful for working on machinery and equipment with ring-type fasteners.3. **Safety Compliance**: - **Regulatory Requirements**: Helps meet safety regulations requiring the use of insulated tools in specific applications or environments.

Material : Mild Steel

Size : Medium

Grade : IEC 60900

Type : VDE TOOLS

...more

VDE 1000 V Insulated Combination Plier

999 Per Piece

1 Piece (MOQ)

A VDE 1000V Insulated Combination Plier is a specific type of combination plier designed for electrical work, meeting safety standards set by VDE (Verband der Elektrotechnik, Elektronik und Informationstechnik) or similar organizations. Here are some key features and considerations: Insulation Rating: The "VDE 1000V" designation indicates that the combination plier is designed to withstand voltages up to 1000 volts. This is essential when working on electrical systems to reduce the risk of electric shock. Insulation Material: The handles and other components that the user may touch are typically made from insulating materials with high dielectric strength. This prevents the conduction of electricity and enhances safety when working with live electrical components. Combination Plier Functionality: Combination pliers typically have multiple functions, such as cutting, gripping, and bending. The combination of functions in a single tool makes it versatile for various tasks. Material Quality: The tool is often made from high-quality materials to ensure durability and longevity, meeting safety standards for electrical work. The cutting edges are typically hardened for efficient cutting of wires and cables. Certification: Look for certification marks or labels indicating that the insulated combination plier has been tested and complies with relevant safety standards. Certification provides assurance that the tool meets specific quality and safety criteria. Application: Insulated combination pliers are commonly used by electricians and maintenance personnel when working on live electrical components. They are versatile tools suitable for tasks that require cutting, gripping, or bending wires in various electrical applications. Sizes and Varieties: Insulated combination pliers come in various sizes to accommodate different wire sizes and tasks. They may also come in sets with interchangeable heads or additional features for increased versatility. Color Coding: Similar to other VDE tools, the insulation of combination pliers may be color-coded to indicate the voltage rating. This helps users quickly identify the appropriate tool for the voltage level they are working with. Multi-Layer Insulation: The insulation may consist of multiple layers to enhance protection. The outer layer provides mechanical strength, while inner layers provide electrical insulation. Storage and Transport: Proper storage and transport are essential to maintain the insulation integrity of the tool. Some manufacturers provide protective cases or pouches to prevent damage to the insulation during transport or when not in use. Always adhere to the manufacturer's guidelines and recommended safety practices when using insulated tools. Regularly inspect tools for signs of wear, damage, or deterioration of the insulation, and replace them if needed to ensure ongoing safety. Joint Design: The joint of insulated combination pliers is often designed for durability and smooth operation. Some models may feature a box joint, lap joint, or other robust joint designs to withstand repetitive use and provide precise movement. Cutting Edge Design: The cutting edges of combination pliers are crucial for efficient wire cutting. Insulated combination pliers usually have sharp, precision-ground cutting edges that are induction-hardened to maintain sharpness and durability over time. Stripping Function: Many combination pliers designed for electrical work include a wire stripping function. This allows users to strip insulation from wires without the need for a separate stripping tool, adding to the tool's versatility. Gripping Mechanism: The gripping mechanism of combination pliers is designed to provide a secure grip on various materials. Some models may have serrated jaws or teeth to enhance grip, while others may have a smooth jaw surface for more delicate materials.

Feature : High Durability, High Performance

Size : 8 Inch

Application : Industrial

Warranty : 1 Year

Country of Origin : Made in India

...more

Torque Multiplier X4 TD1500

4,999 Per Piece

1 Piece (MOQ)

The X-4 Tool TD-1500 and TD-2000 Torque Multipliers provide MORE THAN FOUR TIMES the power of an ordinary wrench delivering up to 4000 ft-lbs and 8000 ft-lbs of output torque The X-4 Tool TD-1200 two-stage Torque Multiplier provides MORE THAN FOURTEEN TIMES the power of an ordinary wrench delivering up to 3000 ft-lbs of output torque Offers a much safer and effective alternative to using drive tool extensions All components of the X-4 Tool TD-1200, TD-1500 and TD-2000 Torque Multipliers are made from high grade materials for maximum strength and durability Requires no air or electricity to operate and is invaluable in an unlimited range of maintenance, production, and equipment service applications Use with a calibrated torque wrench when higher levels of precision are required Multipliers may be used in combination to provide even more power All X-4 Tool Torque Multipliers are 100% MADE IN THE USA

Weight : 2.5 kg

Application : Industrial

Material : Carbon Steel

Color : Golden And Black

...more

TCT Annular Cutter

999 Per Piece

1 Piece (MOQ)

The annular cutter is suitable for making clearance holes on metal, for bolt connection, as well as for cables & pipes. Its Effortless drilling, with comparable durability makes it the best choice Standard 19mm Universal Shank that fits Magnetic drills with 19mm Universal interface or weldon interface. Works on Magnetic drills. Using with a lubricant increases the life of the annular cutter Fine grade carbide ensures high hardness and thus gives extended long life. It further ensures cutting rate, as well as strong resistance to wear. The Silver brazing of the carbide tips ensures a high brazing strength compared to Copper brazing. For Diameters above 18mm, the Optimized tip geometry which is an Inner-middle-outer combination* maximize cutting action and reduce friction. Used in Railway Maintainance, Building Constructions, Infrastructure construction, Steel structure building, Shipyard, Manufacturing of machineries

Shape : Round

Color : Silver

Type : Annular Cutters

Application : Industrial

Brand Name : Innocut

...more

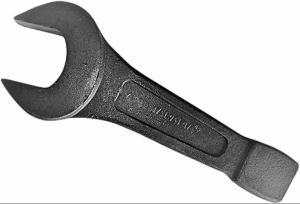

Taparia Slogging Open Spanner

199 Per Piece

10 Piece (MOQ)

A "slogging spanner" is a heavy-duty tool used for applying significant force to loosen or tighten bolts, typically in industrial or mechanical applications. It's designed to withstand heavy impacts from a hammer or mallet, hence the term "slogging," which implies using forceful blows to achieve the desired effect. The term "slogging" suggests a certain level of brute force being applied to the task at hand. These spanners are often used in situations where bolts or nuts are heavily corroded or tightly stuck, requiring more force than a standard wrench can provide. Slogging spanners usually have a robust construction to endure the impacts without deformation or damage. They come in various sizes to fit different bolt heads and are an essential tool in many maintenance and repair tasks, especially in industries like construction, automotive, and manufacturing.

Brand Name : Taparia

Type Of Spanner : Hammering Open

Packaging Type : Box

Material : Chrome Vanadium Steel

Color : Black

Country of Origin : Made in India

...more

Taparia Single Ended Open Jaw Spanner

100 Per Piece

100 Piece (MOQ)

Made from high grade chrome vanadium steel Scientifically heat treated to give maximum strength and wear resistance Hardness: 40 – 50 HRC Slightly rounded handles-sand blasted –fit snugly in the hand and gives comfortable grip Good accessibility in confined spaces due to slim and practical design DIN 894 – ISO 3318 Metric sizes from 6mm to 135mm forged from special tool steel and hardened to 120kg/mm² for high torque applications i.e. Construction, Heavy Industry, Railways, Shipyards, Mines, Farming, Oil rigs etc. Jaws ground precisely to exact size Extra long shaft for deep applications High Bending Strength: Spanner does not fracture or splinter when overloaded. Ergonomy: Profile designed for more efficiency, open end angled at 15°. Manganese-Phosphate finish with hanging hole.

Type Of Spanner : Single Ended Spanner

Size : 32 mm

Brand Name : Taparia

Packaging Type : Box

Material : Cast Iron

Color : Silver

Usage : Automobile Industry

...more

Taparia Heavy Duty Pipe Wrench

999 Per Piece

100 Piece (MOQ)

Taparia is a renowned brand in the hand tool industry, known for producing high-quality tools, including heavy-duty pipe wrenches. While specific information about a Taparia heavy-duty pipe wrench may vary depending on the model and specifications, here are some general features and characteristics you can expect from a Taparia heavy-duty pipe wrench: Design and Construction: Taparia heavy-duty pipe wrenches are typically designed to provide maximum strength, durability, and reliability. They are made from high-grade materials, such as alloy steel, which ensures their ability to withstand heavy loads and tough working conditions. Jaw Design: The jaw of a Taparia heavy-duty pipe wrench is usually equipped with hardened teeth or serrations that offer a firm and secure grip on pipes and cylindrical objects. The jaws are designed to prevent slipping or damaging the workpiece while applying torque. Size Range: Taparia heavy-duty pipe wrenches are available in different sizes to accommodate a variety of pipe diameters. The size range typically varies from small to large sizes, enabling you to choose the appropriate wrench for the specific pipe or object you're working with. Adjustable Jaw Opening: Taparia heavy-duty pipe wrenches often feature an adjustable jaw opening. This allows you to modify the width of the jaws to match the diameter of the pipe or object you need to grip. The adjustable feature adds versatility and adaptability to different tasks. Handle Design: The handles of Taparia heavy-duty pipe wrenches are designed with ergonomics and user comfort in mind. They are often coated or covered with materials like rubber or PVC to provide a secure grip and reduce hand fatigue during prolonged use. Leverage and Torque: Heavy-duty pipe wrenches are designed to provide high leverage and torque, allowing you to exert significant force to turn or loosen stubborn pipes or fittings. This feature is particularly useful for heavy-duty applications and tasks that require substantial grip strength. Applications: Taparia heavy-duty pipe wrenches are suitable for various applications, including plumbing, mechanical installations, construction, and maintenance tasks that involve working with pipes, fittings, and other cylindrical objects. It's important to refer to the specific model and user manual provided by Taparia for detailed information about a particular heavy-duty pipe wrench. This will ensure that you have accurate and up-to-date information regarding its features, specifications, and recommended usage guidelines. Taparia is a renowned brand in the hand tool industry, known for producing high-quality tools, including heavy-duty pipe wrenches. While specific information about a Taparia heavy-duty pipe wrench may vary depending on the model and specifications, here are some general features and characteristics you can expect from a Taparia heavy-duty pipe wrench: Design and Construction: Taparia heavy-duty pipe wrenches are typically designed to provide maximum strength, durability, and reliability. They are made from high-grade materials, such as alloy steel, which ensures their ability to withstand heavy loads and tough working conditions. Jaw Design: The jaw of a Taparia heavy-duty pipe wrench is usually equipped with hardened teeth or serrations that offer a firm and secure grip on pipes and cylindrical objects. The jaws are designed to prevent slipping or damaging the workpiece while applying torque. It's important to refer to the specific model and user manual provided by Taparia for detailed information about a particular heavy-duty pipe wrench. This will ensure that you have accurate and up-to-date information regarding its features, specifications, and recommended usage guidelines.

Size : 10 Inch

Application : Pipe Fittings

Material : Cast Iron

Finishing : Coated

Color : Blue

Country of Origin : Made in India

...more

Standard Torque Wrench

999 Per Piece

1 Piece (MOQ)

A standard torque wrench is a tool used to apply a specific amount of torque to a fastener, such as a bolt or nut. It typically consists of a handle, a mechanism for setting the desired torque level, and a head for attaching sockets or other tools. The handle is usually elongated and may have a grip for comfortable use. The mechanism for setting torque often involves a calibrated scale or a digital display, allowing users to adjust the wrench to the desired torque value. Torque wrenches are essential in various industries, including automotive, aerospace, construction, and manufacturing, where precise torque application is critical for safety and performance. They help ensure that bolts are tightened to the correct specifications, preventing issues like overtightening, which can damage components, or undertightening, which can lead to loosening and failure. There are different types of torque wrenches available, including beam type, click type, and digital torque wrenches, each with its own advantages and ideal applications. The choice of torque wrench depends on factors such as the required torque range, accuracy, and the specific needs of the task at hand.

Weight : 2.8 Kg

Application : Industrial

Country of Origin : Made in India

...more

Spud Handle Box Wrench

999 Per Piece

1 Piece (MOQ)

Spud Handle Box Wrench A spud handle box wrench is a versatile hand tool designed for efficiently gripping and turning fasteners in tight spaces. Its unique design features an elongated shape and a handle (the spud handle) that enhances leverage, making it particularly effective for heavy-duty applications in various industries. Key Features Box End Design: The box end provides a secure fit around nuts and bolts, minimizing the risk of stripping or rounding the edges. This feature is particularly important when dealing with rusted or corroded fasteners. Spud Handle: The long, straight handle allows for increased torque application, making it easier to loosen stubborn fasteners without requiring excessive force from the user. Versatile Sizes: Spud handle box wrenches come in a range of sizes to accommodate different fastener dimensions, ensuring versatility across various tasks. Material Construction: Typically made from high-strength steel or chrome vanadium, these wrenches are designed to withstand heavy use and resist deformation. Applications Industrial Maintenance: Commonly used in maintenance and repair tasks on machinery and equipment in factories, power plants, and manufacturing facilities. Automotive Repair: Essential for mechanics working on vehicle engines, transmissions, and undercarriages where space constraints make traditional wrenches impractical. Construction: Frequently utilized for assembling and disassembling structural components, such as steel beams and heavy fixtures, where robust torque is required. HVAC and Plumbing: Useful in installing or repairing pipes and fittings that require a strong grip and leverage. Advantages Enhanced Leverage: The spud handle design allows users to apply greater torque, making it easier to turn fasteners that may be difficult to move. Durability: Constructed from high-quality materials, spud handle box wrenches are designed for longevity, providing reliable performance over time. Compact and Accessible: The elongated shape enables access to confined spaces that standard wrenches cannot reach, increasing the tool's utility in various settings. Ease of Use: The ergonomic design reduces strain on the hands and wrists, making it more comfortable to use during extended periods. Safety Considerations Proper Fit: Always ensure the wrench fits snugly over the fastener to prevent slippage and potential injury. Use Appropriate Force: Apply steady, controlled force when turning fasteners; avoid sudden jerks that could lead to tool breakage or personal injury. Regular Inspection: Periodically check the wrench for signs of wear, damage, or deformation, and replace it if necessary to maintain safety and effectiveness. Personal Protective Equipment (PPE): Wear safety gloves and goggles when using the tool, especially in environments where debris or sharp edges may pose risks.

Type Of Spanner : Spud Handle

Material : Steel

Size : 1-11/16 Inch

Brand Name : PROTO USA

Color : Black

Packaging Type : Box

...more

Sparkless Non Sparking Hammering Ring Spanner

999 Per Piece

1 Piece (MOQ)

A sparkless slogging ring spanner, also known as a spark-resistant slogging wrench, is a specialized tool designed for heavy-duty applications in environments where avoiding sparks is essential, such as in hazardous or explosive atmospheres. The term "slogging" refers to the use of a tool with a striking force, typically used with a hammer or mallet. Here’s a detailed overview of this tool: Features and Design Spark-Resistant Material: Material Composition: Made from non-ferrous materials such as beryllium copper or aluminum bronze, which are selected for their spark-resistant properties. These materials prevent the generation of sparks during use. Properties: Designed to minimize the risk of igniting flammable gases, vapors, or dust in hazardous environments. Slogging Ring Design: Ring Head: The slogging ring spanner features a ring-shaped head designed to fit over nuts and bolts. The ring is typically a six-point or twelve-point design to provide a secure grip and reduce the risk of rounding off the fastener. Slogging Use: The tool is built to withstand the impact of being struck with a hammer or mallet, making it suitable for heavy-duty applications where high torque is required. Construction: Strength and Durability: Constructed from robust, high-strength alloys to handle the stresses involved in heavy-duty applications. The tool is designed to be durable and long-lasting. Finish: Often treated to resist corrosion and wear, maintaining performance over time in demanding conditions. Comfort and Ergonomics: Handle: The handle is designed for durability and may include features to enhance grip and control during use. Although ergonomics are less emphasized in slogging tools compared to precision tools, ensuring a comfortable grip can still be beneficial. Applications Hazardous Environments: Flammable or Explosive Atmospheres: Ideal for use in industries such as oil and gas, mining, and chemical processing, where avoiding sparks is crucial to prevent explosions or fires. Safety: Ensures that tools used in potentially dangerous environments do not generate sparks, enhancing overall safety. Heavy-Duty Maintenance and Repair: Equipment and Machinery: Used for tasks that require high torque and where traditional wrenches may not be sufficient. The slogging spanner can handle tough, stubborn fasteners. Industrial and Construction Work: Worksites: Suitable for construction and industrial applications where heavy-duty tools are needed and where spark prevention is important. Usage Tips Inspect Before Use: Regularly check the slogging spanner for any signs of damage, such as cracks or wear. Damaged tools should be replaced to ensure safety and effectiveness. Proper Handling: Use the tool according to manufacturer instructions. The spanner is designed to be struck with a hammer or mallet, so use it with appropriate striking tools and techniques. Storage: Store the spanner in a clean, dry environment to prevent corrosion and damage. Avoid exposure to harsh chemicals or extreme temperatures. Cleaning: Clean the spanner with non-abrasive methods. Ensure that the tool is free from debris and contaminants that could affect its performance.

Specialities : Non Breakable, High Quality

Type : Ring Spanner

Material : Cast Iron

Type Of Spanner : Ring Spanner

Packaging Type : Packet

Color : Golden

...more

slogging hammering striking ring spanner

999 Per Piece

1 Piece (MOQ)

Material : Carbon Steel

Color : Black

Type Of Spanner : Ring Spanner

Size : 22mm-135mm

Packaging Type : Box

Usage : Industrial

...more

Slogging Ring Spanners

999 Per Piece

1 piece (MOQ)

Sledge Hammer Ring Spanner (7444SG) Short profiled handle with heavy duty striking end. For heavy industrial applications and ideal for work in areas such as shipyards and the rail industry. Ring endedForged Steel constructionSteel grey finish

Type Of Spanner : Ring Spanner

Size : 32 mm

Packaging Type : Packet

Material : Carbon Steel

Color : Black

Usage : Industrial

...more

Slogging Open End Spanner

100 Per Piece

100 Piece (MOQ)

Slogging Open End SpannerIntroduction A slogging open end spanner is a specialized hand tool designed for heavy-duty applications where significant torque is required. Unlike standard open-end wrenches, slogging spanners are built to withstand high-impact forces, making them ideal for use in industrial settings, construction, and automotive repair. 1. Definition and Purpose1.1 What is a Slogging Open End Spanner? A slogging open end spanner features an open-ended jaw that grips the flat sides of a nut or bolt. The "slogging" aspect refers to its ability to be struck with a hammer or mallet, allowing the user to apply additional force and torque when loosening or tightening fasteners. 1.2 Key Uses Heavy Machinery: Used in industries such as mining, construction, and manufacturing to work with large bolts and nuts. Automotive: Ideal for loosening rusted or over-tightened bolts. General Maintenance: Effective in various maintenance tasks that require significant torque. 2. Design Features2.1 Material Construction Slogging open end spanners are typically made from high-strength steel alloys. Common materials include: Chrome Vanadium Steel: Known for its strength and durability, this material offers excellent resistance to wear and tear. Chrome Molybdenum Steel: Offers superior strength and toughness, making it suitable for high-impact applications. 2.2 Jaw Design The open end of the spanner is designed to fit snugly over nuts and bolts, usually with a specific angle to provide better access in tight spaces. The jaw's width and shape are critical for ensuring a secure grip. 2.3 Size Variability Slogging spanners come in various sizes to accommodate different fastener dimensions. It's essential to select the correct size for optimal performance and to avoid damaging the fastener. 3. Advantages of Slogging Open End Spanners3.1 Enhanced Torque Application The ability to be struck with a hammer allows for greater torque application compared to standard wrenches, making it easier to deal with stubborn fasteners. 3.2 Durability Constructed from robust materials, slogging spanners are designed to endure heavy use without bending or breaking. 3.3 Versatility These spanners can be used in a wide range of applications, from automotive repairs to industrial machinery maintenance. 4. How to Use a Slogging Open End Spanner4.1 Proper Technique Select the Correct Size: Ensure the spanner fits the fastener snugly to avoid rounding off the corners. Position the Spanner: Place the open end over the nut or bolt. Apply Torque: Strike the end of the spanner with a hammer to apply force. Use controlled blows to prevent damage. Loosen or Tighten: Continue to strike until the fastener loosens or tightens as needed. 4.2 Safety Considerations Wear Protective Gear: Always wear safety glasses and gloves when using slogging spanners. Secure Workpiece: Ensure that the workpiece is stable to prevent accidents during use. Use Appropriate Tools: Avoid using the slogging spanner for tasks it's not designed for, as this could lead to tool failure or injury. 5. Limitations and Considerations5.1 Weight and Bulkiness Slogging spanners can be heavier and bulkier than standard wrenches, which may limit their use in tight spaces. 5.2 Cost Due to their specialized nature and materials, slogging open end spanners can be more expensive than standard wrenches. 5.3 Potential for Damage Improper use or excessive force can lead to damage to the spanner or the fastener, so it's crucial to use them correctly.

Type Of Spanner : Single Ended Spanner

Size : 70MM

Color : Black

Usage : Bolt Tightening

Country of Origin : Made in India

...more

Single Open End Spanner

99 Per Piece

10 Piece (MOQ)

A single open-end spanner, also known as an open-end wrench, is a type of hand tool used to turn nuts and bolts. Here’s a quick rundown on its features and uses: Design: It has two open-ended jaws, each with a fixed width that fits around the flat sides of a nut or bolt. The two jaws are usually angled relative to the handle, allowing the spanner to fit into tight spaces. Sizes: Open-end spanners come in various sizes to fit different sizes of nuts and bolts. The size is usually marked on the tool itself. Material: They’re typically made from steel or other durable metals, often treated to resist corrosion and wear. Use: To use an open-end spanner, you place the jaws around the nut or bolt and turn it. Because the spanner only grips two opposite sides, it may slip if the fit isn’t perfect, so it’s important to choose the right size. Advantages: They’re simple and provide good access to nuts and bolts in tight spaces. They also tend to be lightweight and easy to use. Limitations: Unlike box-end or combination wrenches, open-end spanners have less contact with the nut or bolt, which can sometimes lead to slipping or rounding off the corners if not used carefully. Detailed Features Jaws: The jaws are typically parallel and are designed to fit snugly around the nut or bolt. The size of the jaws is determined by the distance between them, which corresponds to the size of the nut or bolt they are intended to turn. Material and Construction: Steel: Most open-end spanners are made from high-carbon steel or chrome vanadium steel, which offer durability and strength. Some are coated with chrome plating to resist rust and corrosion. Forged Construction: Quality spanners are forged, meaning they are made by heating and shaping the steel to ensure strength and durability. Handle: The handle of an open-end spanner is usually designed for comfort and grip. Some models have ergonomic designs or cushioned grips. Angle: The jaws are often set at an angle (commonly 15°) from the handle, which helps to access nuts and bolts in confined spaces and allows for a better grip. Applications Automotive Work: Open-end spanners are frequently used in automotive repair for loosening or tightening bolts and nuts in engine compartments, where space can be limited. Construction: They are used in construction for assembling and disassembling equipment and structures, as they are effective for bolts and nuts in various sizes. Home Improvement: In home improvement projects, open-end spanners come in handy for tasks such as assembling furniture or repairing household fixtures.

Size : 24 mm

Type Of Spanner : Single Ended Spanner

Packaging Type : Packet

Material : Carbon Steel

Color : Black

Usage : Bolt Tightening And Loosening

Country of Origin : Made in India

...more

Single Ended Ring Spanner

500 Per Piece

10 Piece (MOQ)

Type Of Spanner : Metric Deep Ring Spanner

Size : 55mm

Material : Stainless Steel

Packaging Type : Box

Brand Name : Gedore

Usage : Automobile Industry

Color : Grey

...more

Single Acting Threaded RAM Jack

999 Per Piece

1 Piece (MOQ)

Best Hardware is your premier destination for top-of-the-line hydraulic jacks, catering to a diverse range of industrial and automotive needs. With a steadfast commitment to quality, reliability, and customer satisfaction, we have established ourselves as a trusted authority in the hardware industry.At Best Hardware, we understand the critical role that hydraulic jacks play in various applications, from heavy-duty lifting in industrial settings to precise automotive repairs. That's why we meticulously curate our product selection to offer only the finest hydraulic jacks crafted by renowned manufacturers known for their superior engineering and durability.Our extensive inventory boasts a wide array of hydraulic jacks, including bottle jacks, floor jacks, toe jacks, and more, designed to meet the unique demands of every project. Whether you're lifting heavy machinery in a manufacturing facility or performing routine maintenance on vehicles in an auto shop, our comprehensive range ensures that you'll find the perfect hydraulic jack for the job.At the heart of Best Hardware's ethos is a relentless pursuit of excellence. We prioritize product quality above all else, sourcing hydraulic jacks constructed from premium materials and subjected to rigorous quality assurance measures. This unwavering commitment to excellence guarantees that every hydraulic jack you purchase from us delivers exceptional performance, durability, and safety.In addition to our unparalleled product quality, Best Hardware prides itself on providing exemplary customer service. Our knowledgeable and friendly staff are always on hand to offer expert guidance, helping you select the ideal hydraulic jack for your specific requirements. Whether you have questions about product specifications, compatibility, or usage instructions, we're here to ensure that you make informed decisions and achieve optimal results.Furthermore, we understand the importance of convenience and efficiency in today's fast-paced world. That's why Best Hardware offers seamless online ordering options, allowing you to browse our extensive catalog, place orders, and track shipments with ease. With swift shipping and hassle-free returns, we strive to make your purchasing experience as smooth and convenient as possible.Beyond merely selling hydraulic jacks, Best Hardware is committed to fostering long-term partnerships with our customers. We view every transaction as an opportunity to build trust and exceed expectations, cultivating relationships built on integrity, reliability, and mutual respect. Whether you're a seasoned professional or a DIY enthusiast, you can rely on Best Hardware to be your trusted ally in all your hydraulic jack needs.In conclusion, Best Hardware stands as a beacon of excellence in the hardware industry, providing premium hydraulic jacks, unparalleled customer service, and a commitment to customer satisfaction that is second to none. Experience the difference that quality, reliability, and expertise can make—choose Best Hardware for all your hydraulic jack needs.

Capacity : 100 Ton

Application : Construction

Material : EN47

...more

Single Acting Hollow Plunger Hydraulic Cylinder

5,000 Per Piece

1 Piece (MOQ)

A single-acting hollow plunger hydraulic cylinder is a type of hydraulic actuator that uses fluid pressure to extend the plunger while relying on an external force, like gravity or a spring, to retract it. Here are some key features and characteristics: Design Hollow Plunger: The plunger is hollow, allowing for other components, such as rods or tools, to be inserted or operated through it. Single-Acting: It operates in one direction; hydraulic fluid is applied to one side of the piston to extend it, and the retraction happens due to an external force. Operation Extension: When hydraulic fluid is pumped into the cylinder, it creates pressure that pushes the plunger outwards. Retraction: Once the pressure is released, the plunger returns to its original position through external forces. Applications Lifting and Positioning: Commonly used in applications where lifting or positioning is required, such as in construction, manufacturing, and material handling. Mold Opening/Closing: Often used in die-casting or molding processes. Advantages Simplicity: Fewer components compared to double-acting cylinders, which can mean easier maintenance. Cost-Effective: Generally more affordable due to their simpler design. Disadvantages Limited Force in One Direction: Only provides power in one direction, requiring additional mechanisms for retraction. Dependency on External Forces: The efficiency of operation can depend on gravity or springs. Hollow Design: The hollow center allows for easy access to the interior, which can be beneficial for certain applications, like threading tools or rods through the cylinder. Piston Mechanism: The piston within the cylinder is designed to handle high pressures while minimizing friction. This ensures smooth operation during extension. Seals: Effective sealing is crucial to prevent hydraulic fluid leakage. Seals are typically designed to withstand high pressures and environmental conditions. Mounting Options: Many cylinders come with various mounting configurations, allowing for flexible installation in different setups. Advantages Space Efficiency: The hollow design can save space and allow for more compact machinery setups. Less Complexity: With fewer moving parts, single-acting cylinders can be easier to troubleshoot and repair. Weight Reduction: They are generally lighter than double-acting cylinders, which can be a significant factor in mobile applications. Cost-Effective: Lower initial investment and maintenance costs compared to more complex hydraulic systems. Limitations Retracting Mechanism: Since retraction relies on external forces, systems must be designed to ensure these forces are sufficient, which can complicate design. Power Limitations: They may not be suitable for applications requiring high retraction forces, as the hydraulic system can only provide power for extension. Fluid Dependency: Performance can be affected by fluid viscosity and temperature; proper fluid selection and maintenance are necessary. Typical Applications Construction Equipment: Used in jacks and lifts for raising heavy loads, where gravity assists in retraction. Manufacturing: Common in automation processes where items need to be pushed or pulled with precision. Automotive Repair: Hydraulic jacks utilize single-acting cylinders to lift vehicles safely.

Material : EN-19

Type : Single Acting Plain Ram

Country of Origin : Made in India

...more

Scaffolding Construction Ratchet Spanner Wrench

500 Per piece

10 piece (MOQ)

Scaffolding Construction RatchetDescription: The Scaffolding Construction Ratchet Spanner Wrench is a high-performance tool designed specifically for use in scaffolding assembly, disassembly, and maintenance. Combining the versatility of a ratchet mechanism with the durability of a heavy-duty wrench, this tool is essential for professionals working in construction environments. Its ability to quickly tighten and loosen nuts and bolts makes it a time-saving, efficient solution for scaffolding work, particularly in tight spaces or areas that require repetitive motion. Key Features: Ratchet Mechanism for Fast, Efficient OperationThe integrated ratchet mechanism allows for continuous tightening or loosening without having to reposition the tool after each turn. This feature significantly reduces the time and effort required for scaffolding assembly and disassembly. High-Quality ConstructionMade from chromium vanadium steel, the tool is designed to withstand the demanding conditions of scaffolding work. It is durable, corrosion-resistant, and capable of withstanding high torque without bending or breaking. Ergonomic HandleThe tool is equipped with an ergonomically designed handle, ensuring a comfortable and secure grip. Whether you're working for hours or in difficult conditions, this feature reduces hand fatigue and provides a better user experience. Versatile Socket CompatibilityWith interchangeable sockets (or an adjustable jaw), the ratchet spanner is compatible with a wide range of bolt sizes, making it an ideal tool for scaffolding structures where various fastener sizes are used. Compact and Lightweight DesignThis spanner is lightweight yet robust, designed to easily fit into confined spaces between scaffolding components. Its compact size allows for easy transportation and maneuverability on-site. Safety FeaturesThe anti-slip handle provides a secure grip, even in wet or oily conditions, while some models include a locking mechanism to prevent the socket from detaching during use, enhancing safety. Built for Heavy-Duty UseWhether you're tightening large bolts on scaffolding frames, platforms, or support structures, this wrench is built to handle high-torque applications without failure, ensuring the stability and security of scaffolding systems. Benefits: Time Efficiency: The ratchet feature allows for faster assembly or disassembly of scaffolding components, reducing the amount of time spent on each task. Reduced User Fatigue: The ergonomic handle and ratchet system make repetitive tasks easier, reducing the physical strain of working on scaffolding for extended periods. Enhanced Precision: The fine-toothed ratchet mechanism provides greater control and precision when applying torque to fasteners, reducing the likelihood of over-tightening or damaging scaffolding components. Safety: The tool’s design minimizes the risk of slippage, ensuring safe use even in challenging construction environments. Applications: Scaffolding Assembly and Dismantling: Ideal for tightening and loosening bolts used in scaffolding frames, platforms, and other scaffolding equipment. Construction and Industrial Projects: Essential for work in construction zones, factories, or any setting where scaffolding is needed for elevated work. Maintenance and Repair: Useful for maintaining and repairing scaffolding systems by loosening and tightening structural bolts.

Size : 24 mm

Packaging Type : Box

Material : Chrome Vanadium Steel

Color : Black

Country of Origin : Made in India

...moreBe first to Rate

Rate ThisOpening Hours