Membrane Bioreactor

Get Price Quote

Advantages : Reduced footprint, by eliminating secondary clarifiers and media tertiary filtration. The process produces exceptional effluent quality, capable of meeting the most stringent water quality requirements. Modular schematic that allows for ease of expansion and configuration flexibility. Robust and reliable operation and reduced downstream disinfection requirements.

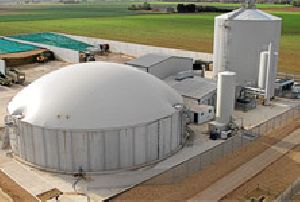

biogas holders

Get Price Quote

Biogas fabric holder storage systems are an active contribution to the generation of renewable energies and thus to environmental protection in general. At SATTLER concepts for the storage of biogas fabric, liquid manure, or brewery residues have a long tradition. Based on more than 30 years of experience we produce best quality of PVC-coated fabrics for biogas membrane systems in our own weaving and coating facilities. SATTLER Polyplan biogas holder membranes show low permeation values at optimal weight, highest flexibility and best processability due to a special bio gas fabric formulation. For further improvement our in-house laboratory continuously follows the increasing requirements of environmental conditions and gas technologies.

Best Deals from Biogas Plants

organic waste in Biogas plant

Get Price Quote

industrial fermenter

Get Price Quote

A fermentor or fermentation chamber is a type of bioreactor for containing and controlling fermenter microorganisms. Fermentation is an economical route to important raw materials (ethanol, lactic acid) and fermented foods. A fermentor must control temperature and keep the chamber anaerobic (free of oxygen) to optimize conditions for desired microbial fermentation. Fermentation is a basic and highly developed art, as well a pursuit of hobbyists. Necessary public information is available to create an economical and high performance OSE fermentor to complete certain product ecologies.

Biogas Storage Tank

Get Price Quote

Biogas covers

400 Per Square Feet

Biogas storage systems are an active contribution to the generation of renewable energies and thus to environmental protection in general. There are high quality PVC Coated Fabrics which are specially produced for the efficient production of the Biogas. Fabrics are treated with suitable chemicals to be resistant to Fire, UV, Weather, Rot and Abrasion. It is made from special PVC formula which provides high endurance and protection against sun rays and extreme weather conditions. These fabrics are available in ranges from 900 GSM (Grams per Square Meter) till 1300 GSM. Few MAJOR reasons listed below, one should be using PVC Coated Fabrics (over HDPE, Rubber, other plastic fabrics/ sheets) for their Biogas Structures. Salient Features: High mechanical strength Durability Excellent finish

Biogas Balloon

Get Price Quote

Biogas Balloons are manufactured with premium quality plastic materials and up- to-date technology. The Biogas Balloons.

Biomass Gasifier

Get Price Quote

We provide our clients with good quality Biomass Gasifier. It undertakes the process of converting solid biomass fuel into combustible gas through thermo-chemical reactions. It is efficient for biomass gasification process and is highly reliable for their working. Use The gas produced is low heating value fuel; possessing calorific value of 1000-1200 Kcal/Nm3. 1 kg of air-dried biomass produces 2.5-3 Nm3 of gas through gasification. Gas Composition Carbon monoxide -20-22%Hydrogen (H2O)-15-20%Methane(CH4)-2-3%Carbon dioxide (CO2)-9-11%Nitrogen(N2)-45-54%Water vapor (H2O)-10-15%Heavy hydrocarbon-0.2-0.4%Â Used In OvensBoilersKilnsHot air generatorThermic fluid heaters for thermal applications Features Appropriate designGood conversion efficiencyBetter control on burningProduction of clean flue gases in the exhaustLow investmentReduction in deforestationReduction in Diesel/Kerosene/Furnace Oil/ LDO costCapable of withstanding high temperatures up to 1860 degree centigradeNet zero CO2 emission

BIOREACTOR and FERMENTER

Get Price Quote

The Pro-pack is one of the pioneers manufacturer, supplier and exporter of Bioreactor/Fermenter, Pharma Plant Exporter. The offered Fermenter is manufactured by using fine quality stainless steel pilot scale and cutting-edge techniques. With a backing support of professional expert and strong infrastructure we can cater to the specific requirement of the clients. We offer this of bioreactor/ Fermenter 5L – 25000L capacity. The offered Bioreactor and fermenter our valuable experience has enabled us to deliver the most innovative, reliable and cost effective solutions. Our Bioreactor is manufactured under strict International standards and undergoes accurate test before dispatching to our valuable clients. The offered Bioreactor/ Fermenter are utilized in pharmaceutical, Health care, sterile process, CIP/SIP system, Laboratory etc. and other industries. Additionally, we offer this Bioreactor/fermenter at very nominal cost. Unique Features of Bioreactor/ Fermenter :- Minimum space requirement Easy to use Range of 5L – 25000L customized requirement Flexibility Less maintenance required Optimized design Cost effective

Membrane Bioreactor

Get Price Quote

Membrane Bioreactor (MBR) Units Required: Raw sewage collection sump Equalization tank Aeration tank Membrane bioreactor MBR (Membrane bioreactor): Results in high efficiency in removal of bod, cod, suspended and dissolved solids. Meets all effluent standards. Tertiary treatment doesn’t required as membrane system is used. Membrane filtration process produces an effluent which have low suspended solids concentration and turbidity units. Specifications: Treatment capacity (m³/d): 10 to 300 Size (m): 1.8x1.5x1.8 to 8.5x3x3

Biomass Gasifier

Get Price Quote

We are offering Biomass Gasifier. Biomass Gasifier is an excellen Solution for Community Cooking. It Works on firewood and Briquettes with thermal Efficiency in the range of 40-50 %. Smoke only at start, just for 5-10 minutes. Once clean flame is achieved, it can be run for any number of hours without constant attention, so more time for other activities. It can be used for Roti making, Boiling, Frying etc. Minimum Maintenance i.e cleaning of tar from gas pipe once in 2-3 months. Available in two burners design also. Payback period is approx.500 hours(2-6 months). Life is approximately 10 years. As Briquettes are made from waste biomass; hence it helps for waste management too. Thermal Efficiency in the range of 40-50 % Smoke only at start, just for 5-10 minutes Used for Roti making, Boiling, Frying etc. Minimum Maintenance Payback period is approx.500 hours(2-6 months) Life is approximately 10 years

Jain Biogas Power Plant

Get Price Quote

We are offering jain biogas power plant. In case you dont have biological waste, you can grow energy crops for biogas production like corn, rosinweed, sweet sorghum, sugarbeat or algae. Also biogas plant can be used as separate business on waste recycling and energy production.

Membrane Bioreactor

Get Price Quote

A membrane bioreactor is an activated sludge process where the clarifiers are replaced with membranes for solid separation. A membrane bioreactor is a technology integrating membrane separation and biological process.Biological waste water treatment with submerged membrane modules in the form of membrane bioreactors (MBR) is the process of the future.This advanced membrane technology offers operational safety, high efficiency and cost effectiveness.Types of membrane Hollow Fiber MBR Plate and Frame MBR BIOCEL ® MBR’s produce a high effluent quality which can not be achieved with typical conventional systems. For the first time the new BIO-CEL ® - module combines the advantages of submerged hollow fiber and flat modules.This application of self-supporting membrane sheets allows the construction of modules with high packing density. Advantages of the new BIO-CEL ® - Module: Absolute separation of bacteria and suspended solids Separation of adsorbed viruses Resistant to clogging e.g. with hairs and fibers or sludge High packing density due to self-supporting membrane sheets Efficient use of surface area by a hydro - dynamically optimized design Effective membrane cleaning with permeate

SEQUENCING BATCH BIOREACTOR

Get Price Quote

One advantage of this orientation is flexibility of operation. The total time in the SBR is used to establish the size of system and can be related to the total volume of a conventional continuous-flow facility. As a result, the fraction of time devoted to a specific function in SBR is equivalent to some corresponding tank in a space oriented system. Therefore the relative tank volumes dedicated to , say aeration and sedimentation in the SBR can redistributed easily by adjusting the mechanism which controls the time ( and , therefore share the total volume) planned for either function. In conventional ASP, the relative tank volume is fixed and cannot be shared or redistributed as easily as in SBR. Advantages Single tank for reaction and settling. True batch mode of operation & can be operated as a time-based control system allowing continuous inflow of wastewater during all phases of the cycle. Ability to achieve biological oxidation, nitrification, de-nitrification, phosphorus removal and solid/liquid separation. Computer interface technologies, and advanced monitoring instrumentation capability, and ability to be operated remotely. Less labour required when operated automatically and computer controlled.

Bioreactor

Get Price Quote

Bioreactor, Fluid Bed Dryer

Industrial Fermentation

Get Price Quote

industrial fermentation is the intentional use of fermentation by microorganisms such as bacteria and fungi to make products useful to humans. Fermented products have applications as food as well as in general industry. Some commodity chemicals, such as acetic acid, citric acid, and ethanol are made by fermentation. Industrial fermentations are typically carried out in large tanks, called fermenters or bioreactor. Depending on the nature of the fermentation, gas may be sparged into the fermentation medium. For aerobic fermentations, air is typically used because it is inexpensive to provides enough oxygen for cellular respiration. Anaerobic fermentations, such as the production of ethanol, typically do not require the addition of any air, and only require agitation from a mixer to keep the organisms suspended. Aerobic fermentations may be conducted in a variety of fermenters, such as a bubble column or a packed bed over which fermentation medium drips (as in the production of vinegar). Cooling is typically required, since organisms produce waste heat as part of their metabolism.

biogas power generation plant

Get Price Quote

biogas power generation plant, thermal power generation services

NATURAL GAS PLANTS

Get Price Quote

NATURAL GAS PLANTS, natural gas nitriding plants, gas plants

bio reactors

Get Price Quote

We are counted amongst the foremost traders and suppliers of Bio Reactors

Biogas Storage Balloon

Get Price Quote

The energy released when Biogas is combusted or oxidized with oxygen allows biogas to be used as a fuel. Organic waste is segregated, thoroughly mixed, shredded and converted into a slurry form and fed to the Digester. The Biogas generated by the Anaerobic Digestion is collected in the Biogas Holder Digester Dome. Biogas can be used for Cooking, Lighting, in boilers for water heating and steam generation, fuel for vehicles. Besides it can be scrubbed and subsequently fed to a gas engine to convert the energy into electricity and heat.The outflow of the Digester is dried and is high quality manure which can be used as a rich nutrient for soil in the field garden and as a soil conditioner.

Bioreactor

Get Price Quote

Bioreactor, liquid handling equipment, Ovens, Incubators, Heating Equipment

Membrane Bio Reactors

Get Price Quote

Membrane Bio Reactors, Water treatment systems, Waste Water Treatment System

Membrane Bio Reactors

Get Price Quote

Membrane Bio Reactors

80 Biodigester

Get Price Quote

80 Biodigester

Biogas Storage Tank

Get Price Quote

Biogas Storage Tank, Garden Planter Pots, Fiberglass Garden Planter Pot

biogas

Get Price Quote

biogas, Pharmaceutical Product

Biogas Purification Plant

Get Price Quote

Biogas Purification Plant

bio reactors

Get Price Quote

bio reactors, Orbital Shaking Incubator, Bacteriological Incubator

Membrane Bio Reactor

Get Price Quote

Membrane Bio Reactor, drinking water filters, Demineralizers

Membrane Bioreactor

Get Price Quote

Membrane Bioreactor, Organic Solid Waste Odour Control Misting System