vertical Double Head Decoiler

The Double Headed Decoiler Models minimizes the down time of coil changing. It is possible to load the next coil while decoiling the first without stopping the production. By simply unlocking and indexing the next coil comes in line with the press. for details Please mail us on biteral.corp@gmail.com

...more

Vertical Decoiler

We offer customized decoiler.

Servo Feeder Machine

This is a new Technology of Servo Driven press feeding system using Servo Motors to control the feeding pitch. It is time to replace your fast wearing Air Feeder with new Servo Roll Feeds. The Servo Roll Feeder have reduction in maintenance and minimum down time compared to Air Feeder.

...more

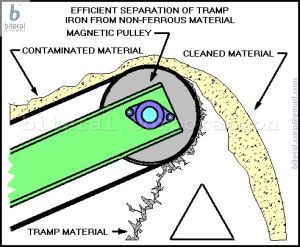

Permanent Magnetic Pulley

We are offering permanent magnetic pulley please write to us for your specific need on biteral.

...more

Magnetic Tube

We are offering magnetic tube.

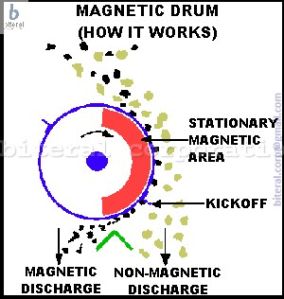

Magnetic Drums

We are offering magnetic drums.

Magnetic Conveyor

We are offering magnetic conveyor please write to us for your specific need on biteral.

...more

Magnet Cleaning Station

We are offering magnet cleaning station. Magnet cleaning station provides a safe place where magnets can be inspected and cleaned. Manufactured entirely from stainless steel to provide a non magnetic area, the cleaning station is a useful tool for customers who lack a safe secure area to clean magnets. The table is mobile with lockable stainless steel casters. It is supplied with a rubber mat to prevent abrasion. Contamination can be cleaned from the magnets, then swept into the discharge chute which can be bagged off. The contamination can then be sent for analysis. The discharge chute can also be fitted with an optional stainless steel sieve for separating larger particles. It is also fitted with drawers for easy access to tools and gloves.

...more

Gravity Roller Conveyor

We are offering gravity roller conveyor please write to us for your specific need on biteral.

...more

Dosing Pumps

Dosing pump the metering pump is a positive displacement chemical dosing device with the ability to vary capacity manually or automatically as process conditions require. It features a high level of repetitive accuracy and is capable of pumping a wide range of chemicals including acids, bases, corrosive or viscous liquids and slurries. The pumping action is developed by a reciprocating piston which is either in direct contact with the process fluid, or is shielded from the fluid by a diaphragm. Diaphragms are actuated by hydraulic fluid between the piston and the diaphragm. Metering pumps are generally used in applications where one or more of the following conditions exit: low flow rates in mlhr or gph are required high system pressure exists high accuracy feed rate is demanded dosing is controlled by computer, microprocessor, dcs, plc, or flow proportioning corrosive, hazardous, or high temperature fluids are handled viscous fluids or slurries need to be pumped

...more

Magnetic Separators

Automation System

engineering consulting solution

Manufacturing Unit

Be first to Rate

Rate ThisOpening Hours