BIG CLEM BULK BLAST MACHINES

Get Price Quote

120 Cuft Big Clem Bulk Blast MachinesUnbeatable for production, strength and safetyClemco makes Bulk Blast Machines that outperform every competitive unit on the market. Clemco’s extensive inventory of manual, automatic and remote controls allow flexible configurations to match large scale production needs exactly. A built in Pop-Up valve for quickly loading abrasive and an optional operator controlled Abrasive Cut-off Switch operated at the blast nozzle are a boost to production rates, drastically cutting back on down time.Big Clems are offered in three sizes: 60, 120 and 160 cubic feet (pressure vessel abrasive volume). Each size is available as stationary, yard towable or highway towable. Nine models give you a wide choice to meet your specific bulk blast requirements.Superb quality features make the Clemco Big Clem unbeatable! Strong steel frame trailer, axles and wheels not duplicated by any of our competitors. Additional safety is provided through four wheel brakes and emergency break-away switch on highway models and multi-ply tires based on weight loads.Top and bottom of the blast pressure vessels are fitted with semi elliptical chamber ends. The shape of the bottom of the blast chambers allows freer flow of abrasive by eliminating dead space. All Big Clems are built to strict ASME codes for pressure vessels. Unique to the Big Clem is a 12” X 16” manway located in the side of the pressure vessel to permit access to the chamber interior for cleaning and maintenance.Clemco’s Big Clems incorporate the latest operator safety technology. The operator has complete control over air and abrasive flow with a fail-to-safe system initiated in an emergency by a “dead man” switch located at the nozzle. The operator can also cut off abrasive flow while maintaining air flow to permit blow off of blasted parts or work pieces.

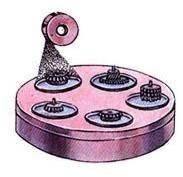

Multi Table Shot Blasting Machine

Get Price Quote

Best Deals from Blasting Machine

Auto Centrifugal Pipe Airless Shot Blasting Machine

Get Price Quote

1 Piece(s) (MOQ)

Airless / Centrifugal Blast Cleaning uses motor driven Blast Wheel rotating at high speed. The abrasive is propelled by this blast wheel, which uses radial and tangential forces to impart the necessary velocity to the abrasive. The position of the wheel from which the shot is projected is controlled to concentrate the blast in the desired direction. Among the advantages of the wheel method of propulsion are easy control of shot velocity, high production capacity, and freedom from the moisture problem encountered with compressed air. Airless / Centrifugal blast systems are popular, economical and high production machines for various industries.

Sandblasting Equipment

Get Price Quote

Conveys sand from sandblast equipment to clean steel or concrete before painting or sealing. Conveys sand or shot basting work and wherever abrasive materials are carried at a high velocity.TUBE: Uniform thickness seamless (6.3mm mm. thick), smooth bore rubber inner tube blended with abrasion, age and weather resistant rubber.

Mini Dry Sand Blaster

45,000 Per piece

Compact Dry Ice Blasting Machine

500,000 Per Piece

Automatic Sand Blaster

35,000 Per Piece

Universal Blaster

650,000 - 2,300,000 Per piece

sand blaster

Get Price Quote

Water Blasting Machine

60,000 Per Piece

Sand Blasting Machine

15,500 Per Piece

Semi Automatic Sand Blaster Machine

8,500 Per Piece

1 Piece(s) (MOQ)

Manual Mini Dry Sand Blaster

4,000 Per Piece

Wet Sand Blast Machine

32,000 Per Piece

SAND BLASTER MACHINE

Get Price Quote

A fully stainless steel sand blasting machine for imparting Matt finish as per desired design on any surface which unmasked for better effects and appearance. Quartz crystals sucked by in built solenoid valve are combarded through the nozzle at 80psi. On the unmasked surface by using compressor, provided with a large viewing glass for clear visibility. High quality rubber gloves prevent abrasion of the hands while Matt finishing process.

Sand Blasting Machine

Get Price Quote

SAND BLASTING MACHINE IS USED FOR GETTING SATIN FINISHED ON VARIOUS JEWELLERY ITEM SUCH AS BANGLE,RING,NICKELS,BALL,PENDANTETC.WITH THE HELP OF VARIOUS GRID SAND.THE SAND IS FORCED THROUGH PEN HAVING CARBIDE TIP ON THE REQUIRED SURFACE TO OBTAIN BRIGHT AND SHINING ,FINISHING. DESCRIPTION 1. FULLY M S PODER COATED BODY 2. ELECTRONIC FOOT PADEL 3. USE WITH AN AIR COMPRESSOR 4. OVER ALL DIMESION L15XW14XH23

pressure blasting cabinet

65,000 Per Piece

automatic shot blasting machine

Get Price Quote

Sand Blasting Machine

Get Price Quote

Yash Blast Abrasive blasting machine can be fitted in variety of versions, with various kits and accessories, in order to meet exact requirement of the customer. Sand Blasting Machines are used for various applications like cleaning of moulds, putting Grains on the moulds, preparing surface for painting, PTFE Coatings etc.

Sand Blasting Machine

Get Price Quote

Designed with utmost precision, our Sand Blasting Machine has high demands in the market. This offered is prepared under strict supervision of expert professionals while also following organizational guidelines. Also, keeping in mind satisfaction of the valued clients our range is offered at the competitive prices.Specifications: Brand model: Prakash Carbide tip on the required Surface Pneumatically operated foot switch Easy controlling on the blasting of sand Used for obtaining satin finished on:: Bangle Ring Nickles Ball Pandent