YARN OIL POROUS PLASTIC LUBRICATOR

We have introduced first time in India the above product in year 1980 and it is performing excellent. This yarn oiling device is used in Apollo head container for high speed TFO (two for one twisting machine). By just putting one piece on each spindle which will give a tremendous advantage. Properties: Filter the finest suspended particle and will not allow water and oil to pass through the air. Available from 5 to 250 microns Withstand pressure up to 200 PSI. Temperature up to 800C. The new element includes lower unit cost, lower rejection from incoming inspections and simplified handling, chemical resistant, odorless, tasteless and non-toxic. Filter the finest suspended particles. Sterilization by any steam Advantages : Less hairiness of the yarn less fly and fluff liberations Fewer end breaks high twisting speed less lubricant consumption less co-efficient of friction increase in production efficiency easy to use and maintain

...more

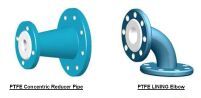

Tees and Valves

Our Fluoropolymer-lined speciality fittings are constructed from high-temperature corrosion resistant Fluoropolymer, including: PTFE, PFA, ETFE and PVDF PRODUCT RANGE Lined Pipe Spools 5mm - 150mm nominal bore up to 6000mm length 200mm - 300mm up to 3000mm length 350mm - 600mm up to 2000mm length Supplied with one fixed and one rotating flange to accommodate any bolt hole misalignment. Close fitting PTFE liners to increase surface life and performance. Spools will be supplied to the length specified by the customer If site fabrication is essential, pipes with loose liners together with portable flaring equipment can be supplied. Lined Fittings 5mm - 150mm nominal bore up to 6000mm length Alternatively they can be fabricated from carbon steel pipe, flanges and Boilerplate. One or more rotating flanges on carbon steel fittings if required. Fittings are lined with moulded PFA linings or PTFE. All fittings are interchangeable within the ANSI #150 or 300 or DIN 2848 specifications Special fittings can be designed and manufactured if required. The Fluorocarbon system is designed to handle, with safety, most highly corrosive and hazardous fluids over a wide temperature range. The system combines the strength of traditional metal pipework with the inertness of selected plastics materials to severe environmental conditions. Material SG Ultimate Tensile Strength Ultimate Elongation % Continuous temperature range Notes PTFE 2.13 to 2.19 24.5 250-350 -30° to +200° Almost universal chemical resistance PFA 2.12 to 2.17 28.5 300 -30° to +200° Almost universal chemical resistance PVDF 1.75 to 1.78 40 50 0° to +140° Excellent chemical resistance PP 0.92 26 17 (at yield) -20° to +95° Good chemical resistance Antistatic Liners HD - Heavy Duty: A thicker liner suitable for pressure and vacuum service throughout the temperature range. Also recommended for searching gaseous media. Heavy Duty Antistatic liners are available in PTFE/PFA to meet the requirements of process industries handling flammable materials. The electrical conductivity of the liner material is increased so that the volume resistivity is not greater than 106 ohm-cm. Antistatic liners are black.

...more

Studs Bolts and Nuts

Corrosion Protection and Resistant Products and Services for the Oil, Gas, Petrochemical, Power , Marine Industries and Offshore Industries We are proud to introduce ourselves as the Pioneers in Fluoropolymer / PTFE / Fluorocarbon Coated Fasteners, Studs, Bolts, Nuts, Washers, Screws. Supplying PTFE Coated Fasteners HIGH TENSILE , STAINLESS STEEL AS PER VARIOUS GRADES Stud & Bolts :ASTM A 193 : GR B7 , B7M , B 16 , L7 , B8 , B8M , SS 306 , SS 316 Nuts : ASTM A 194 : GR 2H , 2HM , GR 7 , GR 8 , GR 8M , GR 8.8 , 10.9 , 12.9. SS 306 , SS 316 PTFE coated Stud bolts and Nuts best suited for installations in offshore platforms, petrochemical and chemical plants, installations near the sea and in corrosive environments. The resin-like bonded coating provides a low coefficient of friction and excellent resistance to many chemicals and acids. PTFE dry film provides lubricity, thus preventing galling in breaking out. Apart from these TEFCOTTM coated B7 stud, bolts are installed under sea splash zones and chemical environments with great success Various Test's are undergone on PTFE/ FLUOROPOLYMER - TEFCOTTM coated Studs, Bolts & Nuts Acid Test Subjected to 720 Hours Caustic Test Subjected to 12.5 ph Caustic for 720 Hours Bromine Test exposed to Bromine Solution for 720 Hours Salt Fog Test Subjected to 720 Hours

...more

Stainless Steel Fasteners

Our specialty is in manufacturing foundation bolts, anchor bolts, eye bolts, tie rods, U-bolts/clamps and castle nuts etc. as per required drawings / specs. Material: Mild carbon steel, middle carbon steel, stainless steel, alloy steel A full range of specifications available. Produce according to customers' drawings or samples Industrial fasteners are common. You have any number of suppliers for this product, but we present a unique combination. Decades of experience, quality, and above all dependability. We have served various industries and are one of the leading manufacturer and supplier of graded fasteners, confirming to Indian, American, British, and German Specifications.

...more

SINTERED POROUS PLASTIC MOULDED COMPONENTS

Blinex produces Porous POLYPOR™ by using several polymer groups of plastics and proprietary manufacturing technologies. Expertise and specialties in chemical, mechanical, industrial, biological and research engineering which has led to the development and refinement of production techniques enabling us to economically supply simple or complex custom made shapes in a range of sizes, porosities, with colours impregnated Activated Charcoal of Iodized and silver as well have the expertise to work with you to ensure the right match between our capabilities and your requirements. Porous POLYPOR™ also offers the features like dimensionally stable, uniform pore size, smooth surface, light weight, resistance to shocks, free from rot, corrosion, odourless, tasteless and non-toxic, conform to use with food products, easy to machine, can be welded and glued, high dielectric constant, hydrophilic, custom moulding availability, Tortuous filtration path as a "depth filter". Applications: Porous POLYPOR™ plastics are used throughout industry, medicine and the home; for applications ranging from noise reduction to air, water and chemical filtration; from marker pen tips to automotive battery safety vents; from surgical implants to clinical laboratory filters.

...more

SINTERED POROUS PLASTIC

Plastic materials are formed by sintering for applications that require materials of specific porosity. Sintered plastic porous components are used in filtration and to control fluid and gas flows. Material used Polyethylene (PE), ultra high molecular weight polyethylene (PE‐UHMW) Industries served automotive, aerospace, home appliance, power & hand tools, pumps & valves , filtration and separation, medical, food, chemical, oil, refinery, sports vehicles, etc. We offer top quality diffuser, aeration, and filtration tubes. These tubes are made from UHMW Polyethylene PE co-polymers Polypropylene SAN, Polycarbonate Polystyrene Cross linked polyethylene We can offer hydrophobic and hydrophilic tubes to accommodate your needs. Our porous tube is strong at various wall thicknesses with the ability to withstand high pressure. Also the plastic material is resistant to many chemicals and a wide range of temperatures. Our tight process controls allow us to maintain a homogeneous pore structure throughout the tube for greater consistency. If our standard sizes do not meet your needs your custom size prototype samples will be available quickly. Production quantities can be supplied swiftly after prototype approval.

...more

Single and Multiple Filter Housing Systems

It was developed by BLINEX FILTER-COAT PVT LTD in 1978 for the first time in India remarkable Single And Multiple Candle Plastic Filter Housing . The cartridge is of Polypropylene and available form 0.5 to 250 microns. The range of Industrial Non-metallic Housing/System offers an economical answer to low flow requirements. Non-metallic housings are available in a number of materials of construction to suit a range of chemical applications. These strong industrial designed housings are ideally suited for use for flows of potable water. The unit is polycarbonate bowl with ABS cap. Properties: Filter the finest suspended particles. The cartridges have uniform pore size, smooth surface, lightweight, odorless, tasteless, non-toxic, resistant to shocks and impacts. The unit withstands the pressure upto 150 PSI. The flow rate form 4 to 15 LPM in different microns cartridge. Typical Application: Air regulators filters Aquarium Aerators Breather vents Marker tip Controlled metering devices Foaming devices Water conditioning filters Pneumatic mufflers Filtration support media Battery flame arrestors ETO vents Chromatography frits Production of defined foams Introduction of oxygen into water Drying Cooling Stripping of solvents Silencing the insulation Diaphragms for electrochemical processes. Application On Various End Uses: Filtration of domestic and industrial water, air, gas, oil, syrups, electroplating and photography solution

...more

Self Sealing Porous Medical Filter

PORSELF TM Self Sealing Porous Medical Filters act like a valve, when liquid touches it; it closes and stops the flow immediately. It is widely installed in suction liner bags, suction liner bottles which are used in hospital to collect waste liquid from patient who is performing surgical operations. The overflow-stop cartridge can make the operation more smoothly and safe. Technical Data : BLINEX TM - PORSELF TM Self - Sealing Porous Filter Elements Material: PE ,PP with Special Self Sealing Additives Manufacturing Type: Sintered Elements Application: Hospital suction liner bags , ESR Pipette , self-sealing hospital vacuum canister filter valves, and filtration of bodily fluids. pipette tip filters, to catheter vents, to hospital suction canister valves. Working Temp 80 deg C Filtration Rating 2 to 50 (Micron) PORSELF TM Porous Plastic Pipette Tip BLINEX FILTER COAT PVT LTD pipette tip filters act as vents to prevent aerosol contamination of the pipettor when using air displacement pipettors. Our filters offer protection against cross-contamination by isolating the pipette body from the chemicals being drawn into the tips. Our pipet filters are used for a wide variety of applications including , DNA amplification and sequencing, forensics, tissue culture etc. Porous Plastic Liquid Chromatography & (SPE) Column Frits p> As a leader in porous plastics, BLINEX FILTER COAT PVT LTD has developed a unique technology to manufacture liquid chromatography and solid phase extraction (SPE) frits. These frits are made from UHMW Polyethylene or PE copolymers with an average pore size from 5-50 microns. Standard hydrophobic and hydrophilic formulations are available to suit your needs.

...more

SELF SEALING ESR PIPETTE FILTER

PORSELF TM Self - Sealing Filter Tip is breathable in dry state but when wet by water , the pores are closed and become less breathable and waterproof. “ Self-sealing ” Porous Plastic Filter - PORSELF ™ media in this invention are defined as porous media that allow air and gas to pass through when the media are dry and do not allow air, gas or solutions to pass through when the media contacts aqueous based or organic solvent-based liquid solutions, for example under suction forces or pressure. The suction forces are vacuum or negative pressures. In the dry condition, polymeric elastomer will not swell and the gas can be uniformly through.In the water condition, polymeric elastomer swell and block BLINEX ™ PORSELF ™ Porous “ Self – Sealing ” Filters Tips are used in Disposable ESR pipettes with the graduated tubes up to 180 mark where the “ Self – Sealing ” filter Tip which is a unique fibrous plug located at the zero mark is fixed as a fitted stopper above avoiding the blood overflowing. The Polypropylene stopper is specifically designed to be a self sealing barrier that avoids the accidental contact of blood with mouth while sucking. For direct testing in 12/13mm blood collection tubes No additional vials, tubes or transfer pipettes necessary. No need to transfer blood. Risk free, accurate and reproducible results.

...more

Scissors

Low voltage electrical current-distribution on the medical apparatus, while operating by the doctor causes considerable risk in damaging the other parts of the body, to overcome this remedy insulated medical apparatus are specifically coated with PTFE thick powder. The temperature resistance is upto –50 Degree C to +150 Degree C and it can be sterilized or Autoclaved Non-Stick Coating – All our Bipolar Forceps are coated with a non-stick technology, preventing tissue build-up Properties: Metals can be insulated, decorated, self-lubricated and protected from chemicals. Withstands impact force and elongation upto 30%. Wide color range Thickness from 250 to 500 microns. Any articles of intricate configurations can be processed. Non-stick, Non-toxic, Electrical insulation, Anti-static and Release-surface. Resistant to almost all chemicals and solvents. Application Its applicable on Unipolar and Bipolar Current (Electricity) for medical parts. Application Various End Uses: Medical surgical parts like forceps, seizers, Door Handle, Wheel of valves, grills, Reaction Vessels, Agitators, Flanges, Absorbers, Stirrers, Valves, Reducers, Thermo wells, Pumps, Bends, Tees, Heat Exchangers, Boiler Dish End, Autoclaves, Charging Covers, Nuclear parts, Large diameter pipes, impellers, Heating Coils, Spindles, Dip-tubes, Manway Covers, Sight Glasses, Pressure Filters, Steam Ejectors, Process Control Equipment, Centrifuge Housings, Floats, Springs, Mushrooms etc. Important Notes: For cost working furnish drawing / dimension along with temperature and chemical specification. All metals, which have previously undergone chemical exposure, must be decontaminated and cleaned prior to shipment.

...more

PVDF Coating for Acid Resistance

Coatings made from Halar® provide excellent chemical resistance and good electrical properties to equipment operating in temperatures from -50°C to +175°C. Suitable for full vacuum applications, Halar® coatings combine outstanding abrasion resistance with excellent impact strength. Coatings made from Halar® are also available to comply with FDA regulations. Thickness of coating from 800 microns to 1000 microns. Temperature Resistance - 50 Degree C to + 175 Degree C Features: High dielectric strength Excellent resistance to weathering Ability to self extinguish Abrasion resistance

...more

PTFE SOFT FOAM GASKET

In Developing PTFE / TEFOMTM our objective was to provide the chemical Industry in particular, with a universally applicable Gasket material offering substantially better characteristics than coventional gasket material. In order to cover the range of possible applications PTFE / TEFOMTMsheets and rings dark grey in colour was developed. Product performance and technical data have been determined and checked in numerous test series. Our tests were carried out under diffcult conditions of pressure and temperature variation over peorods of several weeks. The extremely low leakage figures should be assessed against this background. PTFE / TEFOMTM is a modified PTFE which is supplied in flat from which seals can be punched or cut in ring form or In addition to the standard applications - PTFE / TEFOMTM is particulary suitable where sensitive flange materials, such as glass or ceramic, and could be damaged by other excessively hard seal materials. PTFE / TEFOMTM is extermely resistant to various media and is insensitive to frequent load alternation. It is adaptable over the whole temperature range between - 1000C and +2600C. It can deal reliably with pressure upto 40 bar. PTFE / TEFOMTM has been use with gaseous oxygen at pressure upto 40 bar and at temperatures upto 2250C. Properties: Flexible and soft Very adaptable for uneven surfaces Good sealing effect Good recovery capability Gas permeability No reactions with the media tobe sealed Anti-adhesive

...more

PTFE Non Stick Coating On Biscuits Die Roll

PTFE coatings provides excellent Non-Stick properties, these materials have the highest operating temperature of any Fluoropolymer and have extremely low coefficient of friction coupled with good abrasion and chemical resistance. These coatings are either single or two-coat systems, comprising of a primer and topcoat and for premium systems three coat systems are available. PTFE coatings are available in aqueous based forms. PTFE coatings can provide the solution to many engineering questions particularly those relating to non-stick (release), low friction, chemical resistance and wear resistance, there are many other solutions that can be resolved by the application of PTFE coatings PTFE Coating surfaces are both oleo phobic and hydrophobic, they are not readily wet, cleanup is easier, more through and in many cases self cleaning. Self-lubricating, Heat Resistant properties. Temperature resistance upto 250 Degree C which requires no special precaution. The coefficient of friction is generally in the ranger of 0.05 to 0.20, depending on the load sliding speed.

...more

PTFE NON-STICK COATING

We introduce ourselves as a prominent manufacturer and supplier of PTFE Roller Coatings, which are available in aqueous based forms. These products are able to work at 260°C and also have higher operating temperature. Our products are having low friction coefficient and are used in different engineering applications. These applications are related to the non-stick (release), chemical resistance, low friction, wear resistance and other solutions. These different industrial coating grades are basically used in the plastic industries and textile drying rollers. Features: Excellent Non-stick Properties Low friction Low maintenance Technical specifications: Thickness: 25 to 100 Microns Working temperature: -50 0C to +250 0C

...more

ptfe non stick coating

PTFE Coating materials have the highest operating temperature of any Fluoropolymer and have extremely low coefficient of friction coupled with good abrasion and chemical resistance. PTFE Coatings are either single or two-coat systems, comprising of a primer and topcoat and for premium systems three coat systems are available. PTFE coatings are available in aqueous based forms. PTFE coatings can provide the solution to many engineering questions particularly those relating to non-stick (release), low friction, chemical resistance and wear resistance, there are many other solutions that can be resolved by the application of PTFE coatings Properties: Non-stick, Non-wetting, Anti-static, self-lubricating, heat-resistant properties Thickness from 25 microns to 50 microns Very low adhesion to most materials, excellent water repellent, Low-coefficient of friction, chemical inertness, and unusual thermal stability. Temperature resistance -100oC to +260oC. Not attacked by corrosive chemical or strong solvent NON-STICK Very few solid substances will permanently adhere to TEFCOTTM coating and while tacky materials may show some adhesion, almost all substances release easily. NON-WETTING TEFCOTTM surface are both oleo phobic and hydrophobic, they are not readily wet, clean-up is easier, more through and in many cases self-cleaning. HEAT-RESISTANCE There is no decomposition of TEFCOTTM below 250o C, insignificant decomposition between 250o and 300o which requires no special precautions LOW COEFFICIENT OF FRICTION The coefficient of friction of TEFCOTTM is generally in the range of 0.05 to 0.20, depending on the load sliding speed. CRYOGENIC STABILITY TEFCOTTM will withstand severe temperature extremes without loss of physical properties UNIQUE ELECTRICAL PROPERTIES Over a wide range of frequencies, TEFCOTTM has high dielectric strength, a low dissipation factor, and very high surface receptivity. CHEMICAL RESISTANCE TEFCOTTM is normally unaffected by chemical environments. The only chemicals known to affect all are the alkali metals and highly reactive fluorinating agents.

Usage : Appliance Paint

...more

Ptfe Moulded Products

Chemical Resistance PTFE is resistant to virtually all chemicals, even at very high temperature and pressures. It is only affected under certain conditions by elementary fluorine, strong fluorinating agents (such as chlorine trifluoride) and molten alkali metals (such as metals sodium). It contains no additives such as lubricants, stabilizers, plasticizers or antioxidants that can contaminate process fluids. Temperature Resistance PTFE components can be used at temperatures ranging from approximately -100oC to +260oC Electric Insulator PTFE has excellent electric properties which remain constant independent of frequency and temperature. Coefficient of Friction PTFE has the lowest coefficient of friction of all solid materials; its abrasions resistance is adaptable to demanding environments by using inorganic fillers such as glass fiber, carbon or graphite. Anti stick Effect PTFE is an anti-adhesive, i.e. other materials do not adhere to PTFE Service Life PTFE exhibits excellent retention of properties after a long period of time, even at elevated temperatures and in the presence of oils, solvents, UV light, oxidizing agents and other environmental agents. PTFE Rods Standard Sizes: Diameter: 3 mm to 300 mm; Length: 300 mm and 1000 mm We can provide customized (special) sizes on request; PTFE Bush Standard Sizes: Outer Diameter O.D.: 12.5 mm to 250 mm; Inner Diameter I.D.: 12.5 mm to 250 mm; Length: 100 mm to 300 mm We can provide customized (special) sizes on request; PTFE Tubing Flexible Standard Sizes: Outer Diameter O.D.: 3.2 mm to 28.0 mm; Inner Diameter I.D.: 1.6 mm to 25.1 mm; Wall thickness: 0.8 mm to 1.6 mm Length: 3 mtrs to 120 mtrs We can provide customized (special) sizes on request; PTFE Pipes Rigid Standard Sizes: Outer Diameter O.D.: 25 mm to 100 mm; Inner Diameter O.D.: 19 mm to 89 mm; Wall thickness: 3 mm to 25 mm Length: upto 50 mtrs We can provide customized (special) sizes on request; Please note Fillers such as Glass/ Carbon/ Graphite/ Bronze + MOS2; are available for PTFE Rods and Bushes PTFE Sheets - Thin Sheets (Skiving Sheets) Standard Sizes: Thickness: 1.5 mm to 3 mm Width: 300 mm to 600 mm Length: Available in roll form or length cut to order PTFE Etched Sheets: When you need to glue PTFE to the surface of another material such as stainless steel, a process called \"etching\" is required. Typical applications would include the lining of chemical process tanks or other equipment used in caustic environments. We can provide customized (special) sizes on request; PTFE Sheets - Thick (Rigid) Sheets Standard Sizes: Thickness: 1.5 mm to 30 mm Sizes: 300 mm width x 300 mm length 1000 mm width x 1000 mm length We provide customized (special) sizes on request; PTFE Special Items (Moulded and Machined Finished Products) It is often more efficient to use moulded semi - finished products to avoid excessive machining of relatively expensive materials and also to reduce machining labor and time. The tooling costs are generally very low. We provide customized (special) items on request;

...more

PTFE Lined Sparger Nozzle and Dip Pipe

Our PTFE Lined dip tubes combine the strength and rigidity of steel with the Corrosion resistance of isostatically molded PTFE or Porous PTFE. This combination offers universal chemical resistance and can also add the ability to withstand the forces of agitation. Ideal for adding or withdrawing fluids in corrosive environments. Unique Capibility of Providing Improved Gas, Steam or Liquid Dispersion Properties: Resistance to almost all Chemicals Temperature Resistance upto 200 Degree C Fit to all Dimension Dip Pipes Operates Silently with no Vibrations Generates Fine & Uniform Bubbles Excellent agitation & high mixing Designed for specific Flow Rates Available for 25 NB to 100 NB Dip Pipes.

...more

PTFE Coatings FOR OffShore and Marine

With the demands placed upon precision engineered parts by the marine environment, there needs to be an equal response to the problems of environmental corrosion and chemical corrosion. That is why there is a range of PTFE coatings to provide answers to these demanding situations. Fasteners, valves and mechanical connectors benefit from the High performance PTFE / Fluoropolymer coatings that are now available to match this demanding business sector. PTFE coatings offer the benefits of corrosion protection, precise torque loading, anti-galling and with the added benefits of some systems offering colours as identifiers and to improve visibility. Where ever the marine industry faces such severe conditions that demand's the best performance, the range of protective coatings within the fluoropolymer performance coatings can meet the challenges. Dry film lubricants on wear surfaces can provide low coefficient of friction (0.04-1.00). With the addition of bonding resins, excellent abrasion resistance is achieved. Low friction coatings are designed to reduce make-up and break-out torque levels, even after prolonged exposure to corrosive conditions. Dry film lubricants are also formulated with PTFE and MoS2 for high-pressure and low speed applications. The formulations of dry film lubricants also make the provision for extreme pressures of up to 10,500 kg/cm². Some formulations have the ability to operate in excess of 200°C. Renewable energy is high on the agenda to meet the growing demands for electricity, whether such equipment is onshore or offshore, PTFE coatings can play their part in bringing solutions to this growing industry. The systems formulated within the range of PTFE performance coatings, assist designers and engineers make the provision for the difficult and demanding applications within the off-shore business.

...more

PTFE Coating on Valves and Machine Parts

PTFE COATINGS has got good non-stick, self-lubricating, heat resistant and chemical fume resistance. The coefficient of friction is extremely low (the lowest of all the fluoropolymers).} PTFE coatings are FDA compliant for direct food contact uses. Operating temperatures are generally - 100°C To + 260°C. Other Characteristics include good abrasion resistance and Non-wetting. PTFE coating application thicknesses can range from 25 microns to 50 microns.

...more

PTFE COATING ON VALVES AND MACHINE PART

PTFE COATINGS has got good non-stick, self-lubricating, heat resistant and chemical fume resistance. The coefficient of friction is extremely low (the lowest of all the fluoropolymers).}PTFE coatings are FDA compliant for direct food contact uses.Operating temperatures are generally - 100°C To + 260°C. Other Characteristics include good abrasion resistance and Non-wetting.PTFE coating application thicknesses can range from 25 microns to 50 microns.

...more

PTFE Coating on Valves

PTFE COATINGS has got good non-stick, self-lubricating, heat resistant and chemical fume resistance. The coefficient of friction is extremely low (the lowest of all the fluoropolymers). PTFE coatings are FDA compliant for direct food contact uses. Operating temperatures are generally - 100°C To + 260°C. Other Characteristics include good abrasion resistance and Non-wetting. PTFE coating application thicknesses can range from 25 microns to 50 microns.

...more

PTFE COATING ON VALVE

PTFE COATINGS has got good non-stick, self-lubricating, heat resistant and chemical fume resistance. The coefficient of friction is extremely low (the lowest of all the fluoropolymers). PTFE coatings are FDA compliant for direct food contact uses.Operating temperatures are generally - 100°C To + 260°C. Other Characteristics include good abrasion resistance and Non-wetting.PTFE coating application thicknesses can range from 25 microns to 50 microns.

...more

PTFE COATING ON SS FLEXIBLE BELLOWS AND HOSE PIPE

We offer a wide range of PTFE (Poly tetra fluoro ethylene)Coating on Flexible SS Below / Hose Pipes which are mainly used for pipe fittings. Our organization has gained vast expertise in offering a superior range of PTFE (Poly tetra fluoro ethylene) Coating on SS (Stainless Steel) Bellows that are manufactured with superior quality stainless steel materials that are procured from reputed vendors across the globe with zero defects. They are widely used in various industries like textile, pharmaceutical , Chemical , Offshore and agriculture. They are available in different sizes, lengths. They have excellent tolerance capacity and are highly durable.

...more

PTFE COATING FOR PHARMACEUTICAL APPLICATION

For many years Blinex Filter-Coat Pvt Ltd have provided a PTFE coating service to companies involved within the pharmaceutical industry, such product areas range from sampling probes, soft gel equipment, powder mills and tablet & capsule packaging equipment. These areas of technology have benefited from one of the PTFE coatings that are available.Working with pharmaceutical companies has provided Fluoro Coatings with the opportunity to develop techniques and with the support of raw material suppliers, to offer a level of service compliant to industry standards.Many coatings used in this business sector are compliant to FDA (Food and Drug Administration) which is the worlds leading consumer protection agency and the most respected.There are many processes that require particular answers to some very interesting problems, whether the requirement is for release properties or for chemical protection, most of these questions can be answered with a single PTFE coating system or by a high deposition (PFA) coating system, affording the benefits of chemical resistance. The nature of the pharmaceutical business sector demands a higher profile and that is why many companies look to BLINEX FILTER-COAT PVT LTD Coatings and our services to meet their expectations.PTFE coatings provide a barrier coating to ensure that product does not come into contact with the base substrate, particularly when formulating powders for pharmaceutical applications, materials such as high molecular weight PFA is an ideal candidate for this purpose, but there are others that have a FDA compliance statement.For many years Blinex Filter-Coat Pvt Ltd have provided a PTFE coating service to companies involved within the pharmaceutical industry, such product areas range from sampling probes, soft gel equipment, powder mills and tablet & capsule packaging equipment. These areas of technology have benefited from one of the PTFE coatings that are available.Working with pharmaceutical companies has provided Fluoro Coatings with the opportunity to develop techniques and with the support of raw material suppliers, to offer a level of service compliant to industry standards.Many coatings used in this business sector are compliant to FDA (Food and Drug Administration) which is the worlds leading consumer protection agency and the most respected.There are many processes that require particular answers to some very interesting problems, whether the requirement is for release properties or for chemical protection, most of these questions can be answered with a single PTFE coating system or by a high deposition (PFA) coating system, affording the benefits of chemical resistance. The nature of the pharmaceutical business sector demands a higher profile and that is why many companies look to BLINEX FILTER-COAT PVT LTD Coatings and our services to meet their expectations.PTFE coatings provide a barrier coating to ensure that product does not come into contact with the base substrate, particularly when formulating powders for pharmaceutical applications, materials such as high molecular weight PFA is an ideal candidate for this purpose, but there are others that have a FDA compliance statement.

...more

PTFE NON-STICK COATING ON TEXTILE CYLINDER

We introduce ourselves as a prominent manufacturer and supplier ofPTFE Roller Coatings, which are available in aqueous based forms. These products are able to work at 260°C and also have higher operating temperature. Our products are having low friction coefficient and are used in different engineering applications.These applications are related to the non-stick (release), chemical resistance, low friction, wear resistance and other solutions. These different industrial coating grades are basically used in the plastic industries and textile drying rollers. Features: Excellent Non-stick Properties Low friction Low maintenance Technical specifications:Thickness: 25 to 100 MicronsWorking temperature: -50 0C to +250 0C

...more

Fluoropolymer Coatings On Fasteners

Be first to Rate

Rate ThisOpening Hours