Horizontal Boring Machine

Get Price Quote

We present 'WMW-New Bharat' Horizontal Boring Machine to the customers. Our Horizontal Boring Machine can be availed in various models such as BFT-80, 110 & 110/ 3 and also available in CNC version BFP-100 & 125 Floor Type. Characteristic Features of these machines Low friction transmission makes maximum power available at the tool for high material removal Very wide range of speeds and feeds to take care of all the possible machining problems from the smallest to the largest working diameter High quality design of the bearing system for the sleeve and outer hollow spindle All operating elements are ergonomically arranged Close manufacturing tolerances due to precision scraped/ground slide ways and fine positioning by dial gauges, vernier or digital readout Geometric tests confirm to DIN-8620

Pipe Jacking Machine

Get Price Quote

With our excellence in this field, we share forefront for supplying world-class array of products from Mumbai(India). We make use of premium material for packaging the offered lot so as to ensure safe side deliveries.

Best Deals from Boring Machine

portable boring machine

Get Price Quote

Portable Boring Machine as per specifications in the catalogue and to list of parts comprising a standard machine F.O.R Bombay : Local taxes extra, as applicable.

Horizontal Boring Mill

Get Price Quote

We are offering Horizontal Boring Mill. Spindle Diameter - 200 MM Ram Size- 520 x 520 MM Vertical Head Travel, Y- 3300 MM Horizontal Column Travel, X - 4500 MM Ram Travel -1600 MM Spindle Travel - 2000 MM Spindle Speeds: 1.5 to 630 RPM Spindle Taper: #120 Metic W#50 Adapter Rapid Traverse: 3200 mmmin Feeds: Spindle- 0.5 - 3200 MM Ram - 05 - 3200 MM Vertical - 1 - 3200 MM Longitudinal - 1 - 3200 MM Equipped With: Rotary table model E20 , size : 2000x2000mm, 20Tons Loading capacity Floor Plates : 3750 x 1250 x 300 MM, 2 Nos.

Fine Boring Machine

Get Price Quote

Suitable for Automotive Engine Rebuilding, Boring head travels on Ground Guide Ways protected with bellows, Boring Head fitted with hardened alloy gears to give smooth feel and slide on columns, Mechanical Machine with 2 Speed Motor and Six Speed Gear Box.

boring mill

1,000,000 Per Piece

JUARISTI BORING MACHINE

Get Price Quote

Table Type Boring Mill – Juaristi Spain,Traves : Spindle dia : 110 / ISO 50X = 2000 mmY = 1850 mmZ = 2000 mmTabele size 1525 x 1250 mm With Facing Chuck3 axis DRO FAGORMachine weight approx.14 tons.

BORE WELDING CLADDING

Get Price Quote

The Bore Welding / Cladding Machine is a rugged weld head for high-production ID cladding applications using the MIG process. It is intended for small-diameter ID cladding and ID welding The latest in bore welder advancement. Our system surpasses current bore welder technology. The control panel guides the user step by step through the various modes available; Circular weld and Spiral weld. The Bore welder is a full function MIG system for ID or OD weld build up, it utilizes step technology, and it works with a wide array of wire. Its extensive bore range of 50mm and above gives this machine more range than any other. The machine is rated at 500 Amp, allowing to use standard 0.8 to 2.5mm wire for extended run times. It is capable of running many types of wire including solid, flux core, stainless, inconel and aluminum bronze. Control Panel – Simplified Control Panel Step Over – Automatic Step over system Program Stop – Program stop on number of bands Welding source – 450 Amp MIG / MAG (Lincoln Electric) Wire Feeder – Wire Feeder (Lincoln Electric). Runs solid, flux core, SS, inconel & aluminum wires Highly Equipped – Unit is equipped to weld 0.8mm to 2.5mm wires Torch – Up to 4000mm Torch Stroke. Torches available for cladding or groove welding applications. Water cooled torch. Torch Traveller – Horizontal stroke – 500 to 4000mm, Vertical stroke – 250 to 1000mm Minimum ID Welding – 50mm Idler / Roller support Water Chiller – Water chilling equipment for cooling the torch and improving the consumable life Clockwise & counter clockwise rotation Circular and Spiral Welding Wire feeder mounted over boom Aluminum rack-and-gear drive for consistent travel speeds in linear positions (no friction drives) Options available: TIG, PTA Process

Horizontal Boring Machine

Get Price Quote

The Horizontal Boring Machine, which we offer, is manufactured in compliance with the set industrial standards. We offer these Horizontal Boring Machines at the market leading rates. We are amongst the dependable Manufacturers, Suppliers and Exporters of Horizontal Boring Machine. Availability : Ranging from 50 mm to 150 mm such as W100- H100- H100A

Horizontal Boring Machine

Get Price Quote

Jig Boring Machine

2,400,000 Per Bag

We deal only imported machines. Azmi Machine Tools is among the leading used machinery dealers in India. We sell all types of CNC Lathe, Horizontal & Vertical Machining Center, and we also buy old and used machines. Machines are highly inspected and quality checked products, all we do quality inspections before we buy or resell to our customers, our motto Import imported products to serve in India and all over world with best quality good working condition products.

Circle Boring Machine

Get Price Quote

The company is counted amongst the topmost Exporters and Suppliers of Circle Boring Machines in India and overseas. We only deal in Circle Boring Machines that are manufactured with conformance to the set industry standards. They efficiently carry on varying boring functions. Prices quoted by us are industry-best. Moreover, owing to our skilled production team, we meet bulk requirements within stipulated time.

VITAP Single Head Boring Machine

3 Per Piece

Horizontal Boring Machine

Get Price Quote

Fixed Column, built-in Rotary Indexing Table which also travels transversally Wide range of spindle speeds & gearbox feeds allow for high output with the use of high-speed steel and carbide tools Hardened & ground alloy steel spindle Facing Head coupled with main spindle facilitates large diameter boring and facing operations Auto Rapid Travel for Facing Slide for improved productivity Independent motors for Spindle & Motor with Centralized Pendant Control for easy operation Telescopic Steel Covers for Guide ways to prevent ingress from damaging the guide ways Turcite B-Lining on all guide ways for smooth operation Machine is provided with Boring Bar and Support, Five Limit Switches Bigger main motor available, if required Bigger Rotary Table available, if required Accuracy: As per Grade-I limits of Dr. G. Schlesinger’s Acceptance Test Quality of bore attainable H-7 Ovality in bore: 0.01mm Position accuracy of Rotary Table: 0.02mm Application: Horizontal boring, drilling and surface milling Reaming, turning and facing using facing head slide Machining bores in gearboxes & machine bodies 30º taper boring for 100-300 mm diameter using Taper Boring Attachment Inch threading (5-128) and Metric threading (0.28-7.5) using Threading Attachment 360º vertical milling up to 600mm depth using Vertical Milling Attachment Accessories:Digital Read Out, Threading Attachment, Vertical Milling Attachment, Taper Boring Attachment

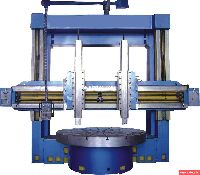

Vertical Boring Machine

Get Price Quote

Table Dia. from 1000-5000 mm, Turning hgt. upto 2000 mm, Fixed Moving cross rail, With Without live tool, Turret Ram, Single Double column construction, Grinding attachment (option).

Horizontal Floor Borer

Get Price Quote

Cone Rod Boring Machine

Get Price Quote

Minimum and Maximum Bore centre distance of the connecting rod - 80mm - 450mm Boring spindle speeds 240, 320,470, 500, 630,1000 RPM Boring range - 15mm to 140mm. Feed both directions infinitely variable. Bottom part traverse crosswise - 50mm Table movement Longitudinal - 300mm Motor spindle speed (Dual speed) HP/KW/0.95/1.7-0.7/1.25 720/1420RPM Motor spindle feed - 0.25HP (D.C.) Length of the Machine - 1450mm Width of the Machine - 850mm Height of the Machine - 1850mm Net weight (approx.) - 725kgs. Gross Weight (approx) - 925Kg. Shipping Volume - 3 M3.

Horizontal Boring Machine

Get Price Quote

We are offering horizontal boring machine. Backed by a team of highly experienced professionals, we are involved in providing a wide range of horizontal boring machine.

Motorized Piling winch Machine

90,000 - 150,000 Per Piece

Cone Rod Boring Machine

Get Price Quote

SPECIFICATIONS Minimum and Maximum Bore centre distance of the connecting rod - 80mm - 450mm Boring spindle speeds 240, 320,470, 500, 630,1000 RPM Boring range - 15mm to 140mm. Feed both directions infinitely variable. Bottom part traverse crosswise - 50mm Table movement Longitudinal - 300mm Motor spindle speed (Dual speed) HP/KW/0.95/1.7-0.7/1.25 720/1420RPM Motor spindle feed - 0.25HP (D.C.) Length of the Machine - 1450mm Width of the Machine - 850mm Height of the Machine - 1850mm Net weight (approx.) - 725kgs. Gross Weight (approx) - 925Kg. Shipping Volume - 3 M3.