AUTOMATIC ROTARY BOTTLE WASHING

Get Price Quote

This machine is designed to clean vials, bottles or other similar containers by subjecting each to a series of distinct processing operations. Independent line connection for various processing systems is provided .The machine is also equipped with one additional connection for washing or rinsing the outside of the container.The driving machine is arranged in the bottom part and is provided with a cone pulley and friction wheel for controlled drive.The rotting plate is fitted with 16 manifold each having five spraying tulips or bottle holders. These holders are fitted with spraying nozzles and adjustable neck ring for taking various sizes of bottles.The machine is provided with 5 stations including one spraying on top of the bottles for outside cleaning.

Powder Filling Machine

Get Price Quote

Robust Quality Collection of powder Filling Machines Exists At Unitech Engineering Company. These Powder Filling Machines Incorporates Advanced Features. Our Powder Filling Machines are Highly Durable as Well. We Proffer Very Affordable Rates for These Superior Quality Powder Filling Machines. Microprocessor Based Control. Auto / Foot Pedal Start. Counter Based Control / Loadcell Based also Available. Filling Capacity Available Up to 50 K.g. All Contact Parts in Stainless Steel 304/316 Quality. Filling Speed 20-22 Jars per Minute as per Quantity to Be Filled. Flame Proof Model Available. Power: 230 Volts/440 Volts, 50 Hz. Material Can Be Filled: Power, Granules, Semi-liquid, Grease, or Material of High Viscosity

Best Deals from Bottling Plant

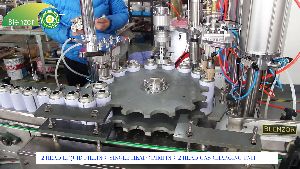

aerosol filling machine

Get Price Quote

Rotary machine consisted of- Container Feeding Turn Table Indeed Conveyor. Automatic 2 Head Rotary Liquid Filling Unit. Single Head Crimping. Automatic 2 Head Gas Charging Unit. Technical Parameters : Pump Loading-Manual LPG Columns & Storage tank for Aerosol Containers Consisted of 6” dia. Column MS seamless pipe with pressure gauge & filtering unit & then after pass the filter 500Lit capacity of MS Storage tank to pass the filtered Gas. All Contact Parts-SS316 FLP Arrangement Filling capacity-10ml to 200ml Consisted of NO Container NO Liquid Filling & NO Container - NO Pump Loading (Pump loading by manually) as well as No Container No Crimping & No Container No Gas Charging. Consisted of Simple System for UHMW/CAST NYLON TURRET with Height Adjustment Any Change over for Varies as per dia. of the Containers in Crimping & Gas Charging unit. Gassing Head for Charging the LPG Gas which is applying with Booster Pump (Individually operation) & it’s operated with Two Stations ie. Initially filled with 40% & then after remaining 60% filled. Indexing with Pneumatic operation MANIFOLD separately for Rotary Liquid Filling as well as Crimping & Gas Charging Stations. Crimping Device-Pneumatic Operated Gassing Device-Pneumatic Operated Turn table Motor & Conveyor Motor with FLP (from Rotary Liquid Filling M/C to Gas Charging M/C) 0.5HP & 1HP respectively with Make - HINDUSTAN & with Suitable Gear Box Ratio Make - Bonfigloli as per requirement of Drive arrangement. LPG gas columns (will be kept at outside of the m/c) for molecules filtration before gas passing to the Gas charging stations via providing the storage tank. Operational Description : The Empty Containers Feed Manually onto the Feeding Turn Table which moves forward slowly up to the Filling Heads. It’s detect with FLP Sensors & after getting the feedback through the panel. Filling Nozzles will come down & filled the Containers as per settled Volume. This all operation will be done with Pneumatically operated. This Filled Containers moves forward & comes on to the further Line of Crimping & Gas Charging M/C Conveyor. During that time Pump Loading will be manually into the Filled Containers. It’s Moves forward to the Turret Cavity as per size of the Containers. This containers Index & rotate Clock wise with proper guiding & after indexing completion; Crimp the Pump with Pneumatic operated Cylinders. Crimping Setting will be done as per trial & error method which will set once a time with using Crimping & Checking the Depth Gauge as per standardise. After Crimping the pump; again Index the Turret with Crimped Bottle & Comes at Gas Charging station. At that time sense the container & give the signal to the Gassing Head. Gas will be fill into the Container which is pass through the Booster Pump ie. For Pressurize Gas filled into the Containers. For these operation we will provided Two separate Booster Pump due to easily filled the container with High Volume & for better accuracy as well as increase the productivity. These filled container moves forward to the next station & comes out at the Exit side conveyor. This whole assly. will be provided with Height Adjustable type due to Various Container sizes. Gas Charging will be operate as per requirement of Gas has to be charge & filled into the Containers ie. Either 2Nos OR 3Nos (As applicable) Gas charging will be applied as per depends upon the Filled quantity. These Gas Filled containers are moves forward from Gassing Exit Conveyor. This finish container comes out at the exit side of the Conveyor. This whole entire cycle repeat again & again with all sequence one by one & with Pneumatically as well as Electrically Logic operation (wherever applicable).

Boiler Water Treatment Plant

Get Price Quote

When feedwater containing an inorganic oxygen scavenger is used for attemperation, harmful deposits on superheater tubes andor turbines may result. Because CorTrol OS5601 contributes no inorganic dissolved solid, it is preferable to other inorganic scavengers when feedwater is used for attemperation.

Demineralised Water Plant

Get Price Quote

Water is one of the most abundant natural compounds. It is also one of the most contaminated one. A number of minerals readily dissolve in to water. They have to be removed from the raw water before it can be used for any industries application. Komal's water demineraliser employ the modern ion-exchange technology to give to chemically pure water. A demineraliser removes these minerals from the raw water by an ion- exchange process. This process first exchanges the cations of the salt for the hydrogen ions and, then, exchanges the anions of the salt for the hydroxylions.

Automatic Superglue Bottle Filling Machine

Get Price Quote

Suitable for cyano filling in bottles. Filling: 0.5ml-20ml 8 Station Rotary type model Compact in design Digital Special Grade Filler-FLOWTECH MAKE Screw Capper Drip free filling 1HP Main Motor Drive Stainless Steel Construction Reputed make electrical Control Panel Geneva Mechanical Indexing Unit Machine Size: 3 Feet L x 3 Feet W x 4 Feet H (300Kg) Speed: 1000-1200 Bottles Per Hour Industrial Catagories: Cyano Filling Machine, Cyano Filler,Cyanoacrylate Bottle Filling Machine, Superglue Filling Machine, Glue Filling Machine, Fevikwick Bottle Filling Machine, Cyano Bottle Filling Machine, Cyano Bottle Filler.

AUTOMATIC ROTARY BOTTLE WASHING

Get Price Quote

AUTOMATIC ROTARY BOTTLE WASHING MACHINE:FEATURES: This machine is designed to clean vials, bottles or other similar containers by subjecting each to a series of distinct processing operations. Independent line connection for various processing systems is provided .The machine is also equipped with one additional connection for washing or rinsing the outside of the container. The driving machine is arranged in the bottom part and is provided with a cone pulley and friction wheel for controlled drive. The rotation speed is one round per minute with capacity to wash 2000 to 4000 bottles an hour. The rotting plate is fitted with 16 manifold each having five spraying tulips or bottle holders. These holders are fitted with spraying nozzles and adjustable neck ring for taking various sizes of bottles. The machine is provided with 5 stations including one spraying on top of the bottles for outside cleaning. Depending on requirement of the client the remaining 4 stations can be connected to jets of detergent, Steam /Hot water and Air. The machine works on A.C. OTHER WASHING EQUIPMENTS: Automatic linear bottle/vial washing machine. Automatic rotary vials washing machine.

Powder Filling Machine

160,000 Per Piece

Liquid Filling Machine

Get Price Quote

Liquid Filling Machine these machines are capable of filling different and packaging of bottles, thereby saving time and money. These machines provide accurate and precise filling of the liquid. Few of the salient features of the machine are mentioned below.The speed of the machines and the conveyor can be varied through a vary frequency AC drive.

Linear Bottle Filling Machine

Get Price Quote

Features Quality checked Best working Less power consumption

Automatic Liquid Filling Machine

Get Price Quote

Semi Automatic Jar Washing Machine

90,000 Per Piece

Bottle brush

Get Price Quote

This Bottles Cleaning Brush works effortlessly to clean, scrub and leave your cookware and utensils shining like new. Italian designed and engineered, these items are beautiful and easy to use.

Filling Machine

250,000 - 300,000 Per Piece

Water Treatment Plants

Get Price Quote

Water Treatment Plants, etp plant services, Water Treatment Plant Overhauling

Water Softening Plant

Get Price Quote

Water Purified Generation Systems, Ultrapure Water Systems

Water Treatment Plant

Get Price Quote

Water Treatment Plants For Waste Water

Water Treatment Plants

Get Price Quote

Water Treatment Plants

Water Treatment Plant

Get Price Quote

Wastewater Treatment Plant, Water Recycling System

Water Softening Plant

Get Price Quote

Drinking Water, Water Purification, Reverse Osmosis, disinfectant liquid

Sewage Water Treatment Plant

Get Price Quote

wastewater treatment services, Water Treatment System

Mineral Water Plants

Get Price Quote

Pharmaceutical Bulk Drugs, Pharmaceutical Machinery

Compact Water Treatment Plants

Get Price Quote

Compact Water Treatment Plants, Ozonation System

Filling Machine

Get Price Quote

paint machinery, Pharmaceutical Machinery, Resin Plant, soap machinery

Water Treatment Plants

Get Price Quote

Water Treatment Plants

Grey Water Treatment Plant

Get Price Quote

Grey Water Treatment Plant, Organic Solid Waste Odour Control Misting System

Water Treatment Plants

Get Price Quote

Water Treatment Plants, Pumps

Water AND Waste water Treatment Plants

Get Price Quote

Water AND Waste water Treatment Plants, Luminaries, rainwater harvesting